Side plate structure

A side plate and plate body technology, applied in the field of side plate structure, can solve the problems of radial displacement between the side plate and the pump body, affecting the sealing performance of the side plate and the pump body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

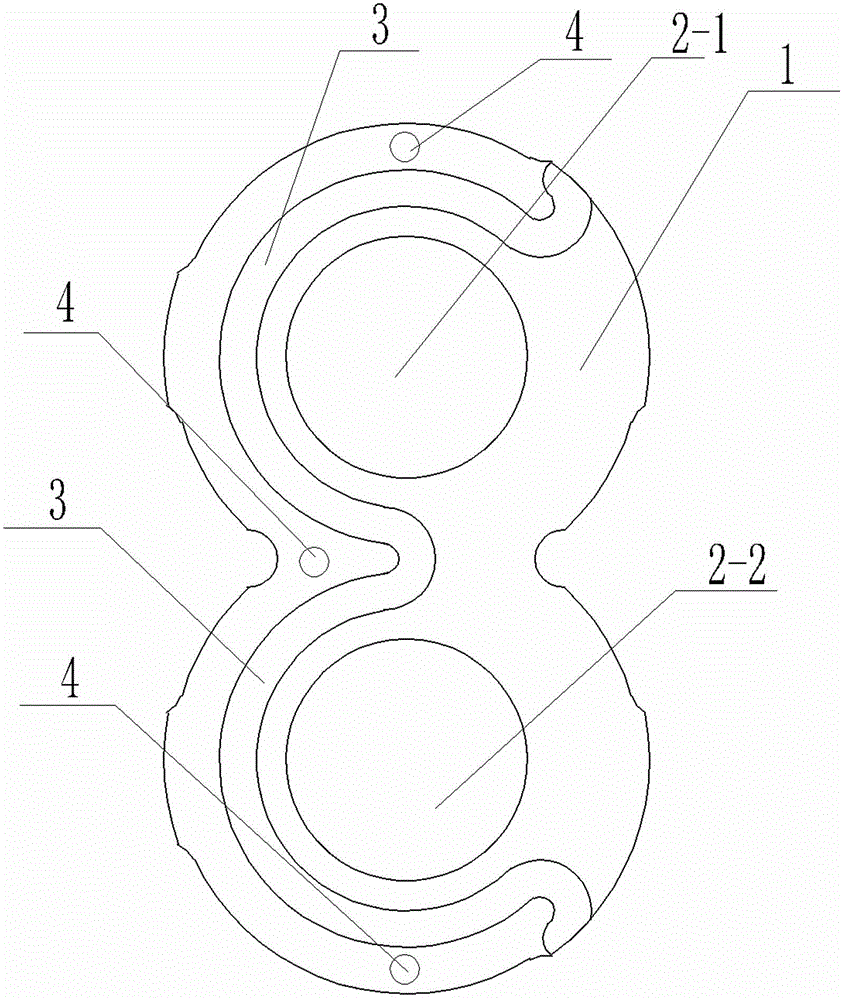

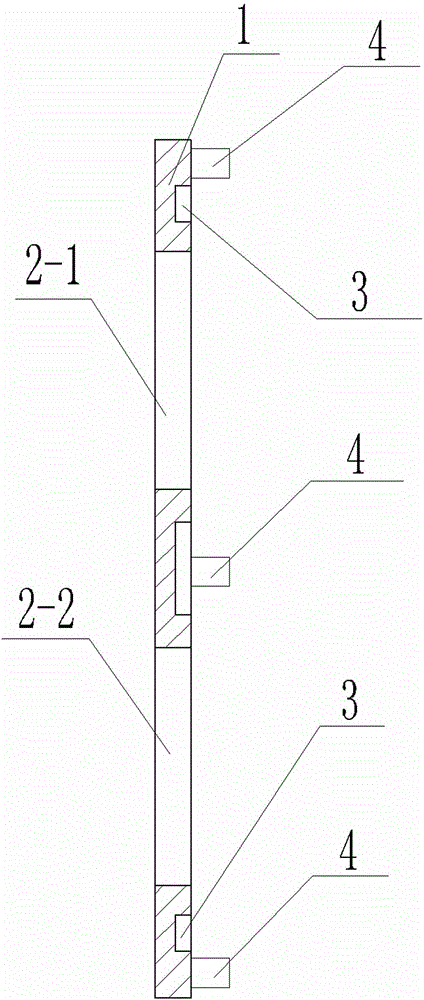

[0009] See figure 1 , figure 2 , a side plate structure, which includes a side plate body 1, gear shaft holes 2-1, 2-2 are arranged on the side plate body 1, and a seal is arranged on the side corresponding to the gear shaft holes 2-1, 2-2 Groove 3, three positioning protrusions 4 are arranged on the side plate body 1, and positioning protrusions 4 are respectively arranged between the outer ends of the gear shaft holes 2-1, 2-2 and the gear shaft holes 2-1, 2-2. When installing, when the positioning protrusion is connected with the pump body, the positioning is realized through the positioning protrusion, which effectively prevents the radial displacement of the side plate and the pump body, and ensures the sealing performance of the side plate and the pump body.

[0010] In this embodiment, the positioning protrusions 3 are respectively arranged on the side between the outer ends of the gear shaft holes 2-1, 2-2 and the gear shaft holes 2-1, 2-2. Of course, the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com