Rail type gate micro valve device

An orbital and orbital technology, applied in valve devices, sliding valves, engine components, etc., can solve problems such as hindering gate impact, increasing process difficulty and actuation power consumption, avoiding necessity and enriching gate micro-valve structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

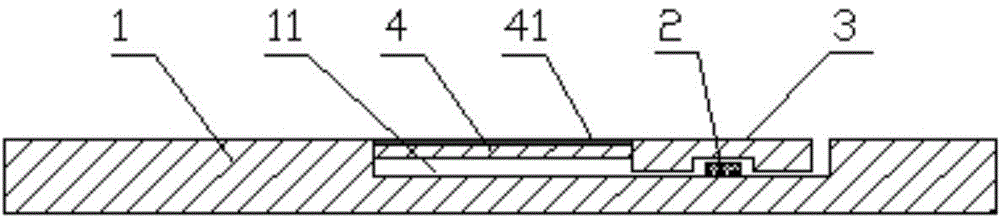

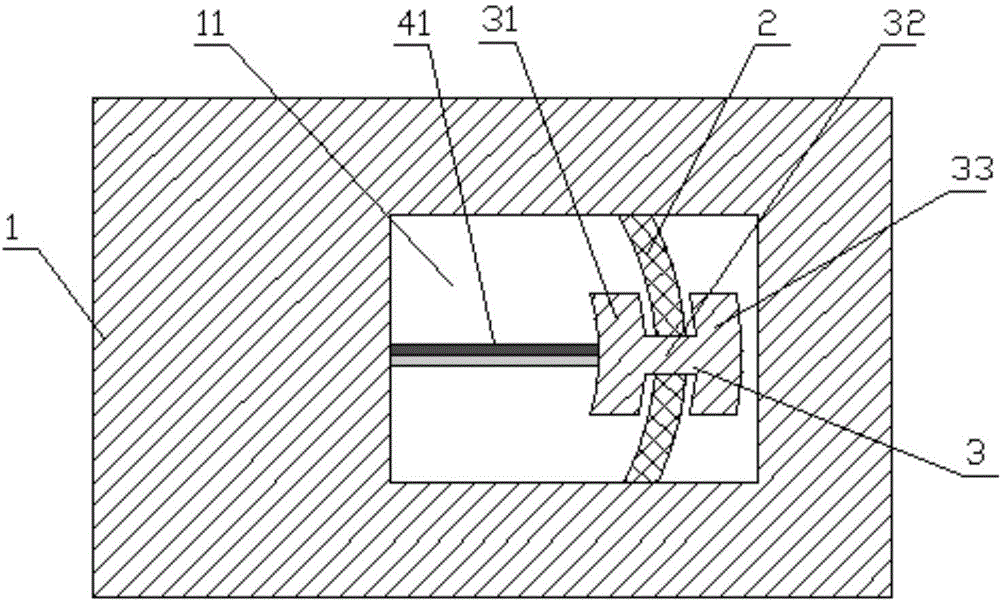

[0021] Embodiment 1 of the present invention is described below. The orbital gate microvalve of the present invention is formed by bonding double-layer silicon wafers, including a first silicon wafer on the upper layer and a second silicon wafer on the lower layer. Such as figure 1 with figure 2 As shown, a groove 11 is provided at the bottom of the first layer of silicon wafer 1 , and a microvalve track 2 , a moving member 3 and an actuating beam 4 are arranged in the bottom groove of the first layer of silicon wafer 1 . Among them, such as image 3 As shown, the microvalve track 2 is a convex track protruding from the bottom surface of the bottom groove. The microvalve track 2 can be formed of a material with sufficiently smooth surface, which can reduce the movement resistance to the moving member during the contact process. In order to further reduce the movement resistance, the microvalve track extends in an arc shape. The moving member 3 and the actuating beam 4 form...

Embodiment 2

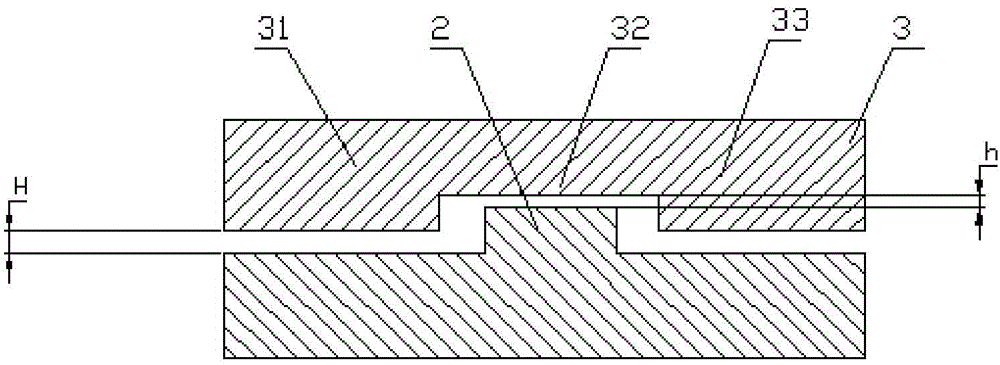

[0029] In this implementation example, the cooperation structure between the microvalve track and the moving member is as follows: Figure 4 As shown, the convex track is provided with a track groove away from the side of the actuating beam. The moving member is composed of a gate, a limiting beam and a compensating beam. The beam connected to the actuating beam is a gate, and the vertical beam connected to the end of the gate is Compensation beam, and one end of the limit beam is connected to the compensation beam, and the other end extends into the track groove. The distance between the limiting beam and the upper and lower tracks inside the track groove is h, and the distance between the gate and the upper surface outside the track groove is H. This structural design is mainly to limit the vertical direction under the impact of fluid. The displacement is between the upper and lower orbits.

Embodiment 3

[0031] This implementation example is Figure 5 As shown, the basic structure is similar to that of Example 2, except that the compensation beam and the limiting beam are on the side of the microvalve track close to the actuating beam. Between the upper track and the lower track on one side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com