An ultrasonic automatic inspection device for blade root

An automatic inspection, blade root technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of low inspection efficiency, poor positioning, and high labor intensity, and achieve the effect of small available space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

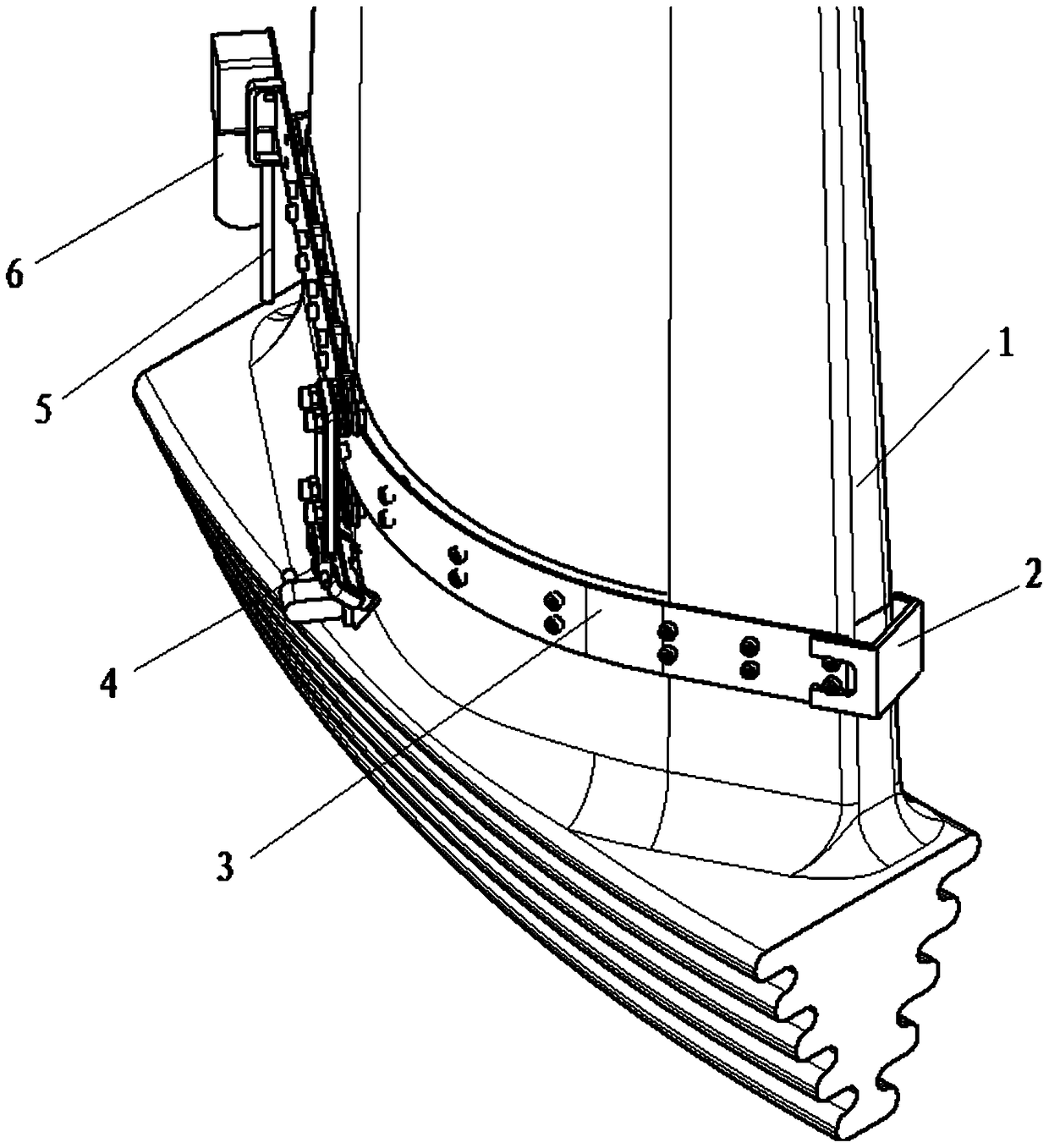

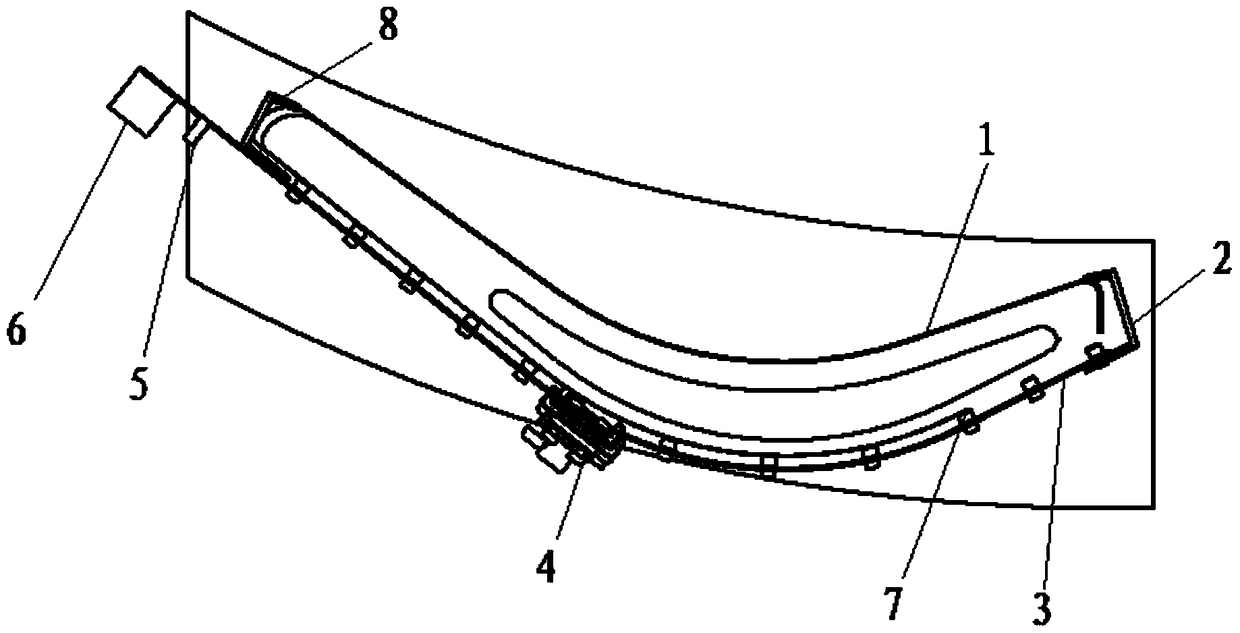

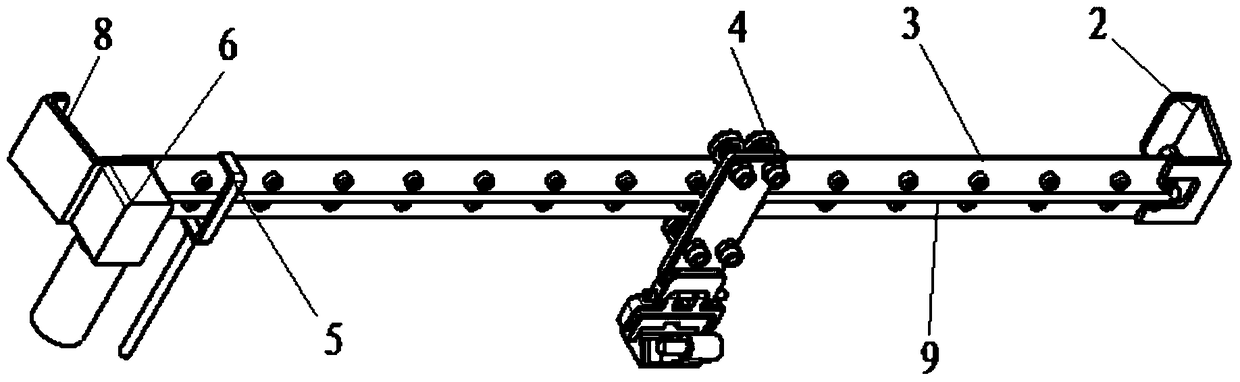

[0019] Such as figure 1 — Figure 5 As shown, according to the fact that the available space for the inspection of the steam turbine blade 1 is small, and the shape and structure of the steam turbine blade 1 are irregular curved surfaces and many types of shape specifications, the ultrasonic automatic inspection device for the blade root of the present invention includes a motor driver 6, a scanning Arm 4, flexible guide rail 3, steel wire rope guide block 7, steel wire rope 9, positioning frame 5, locking fork 8 and fixed fork 2; the two ends of flexible guide rail 3 respectively use fixed fork 2, locking fork 8 to install the inspection device on steam turbine blade 1 Both ends are fixed, and the flexible guide rail 3 can be adaptively attached to the outer surface of the steam turbine blade 1 according to the shape of the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com