optical mechanism

An optical mechanism and bushing technology, applied in optics, optical components, installation, etc., can solve the problems of mutual influence of strokes and strokes, and achieve the effect of stable operation, maintaining stability, and excellent coaxial accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

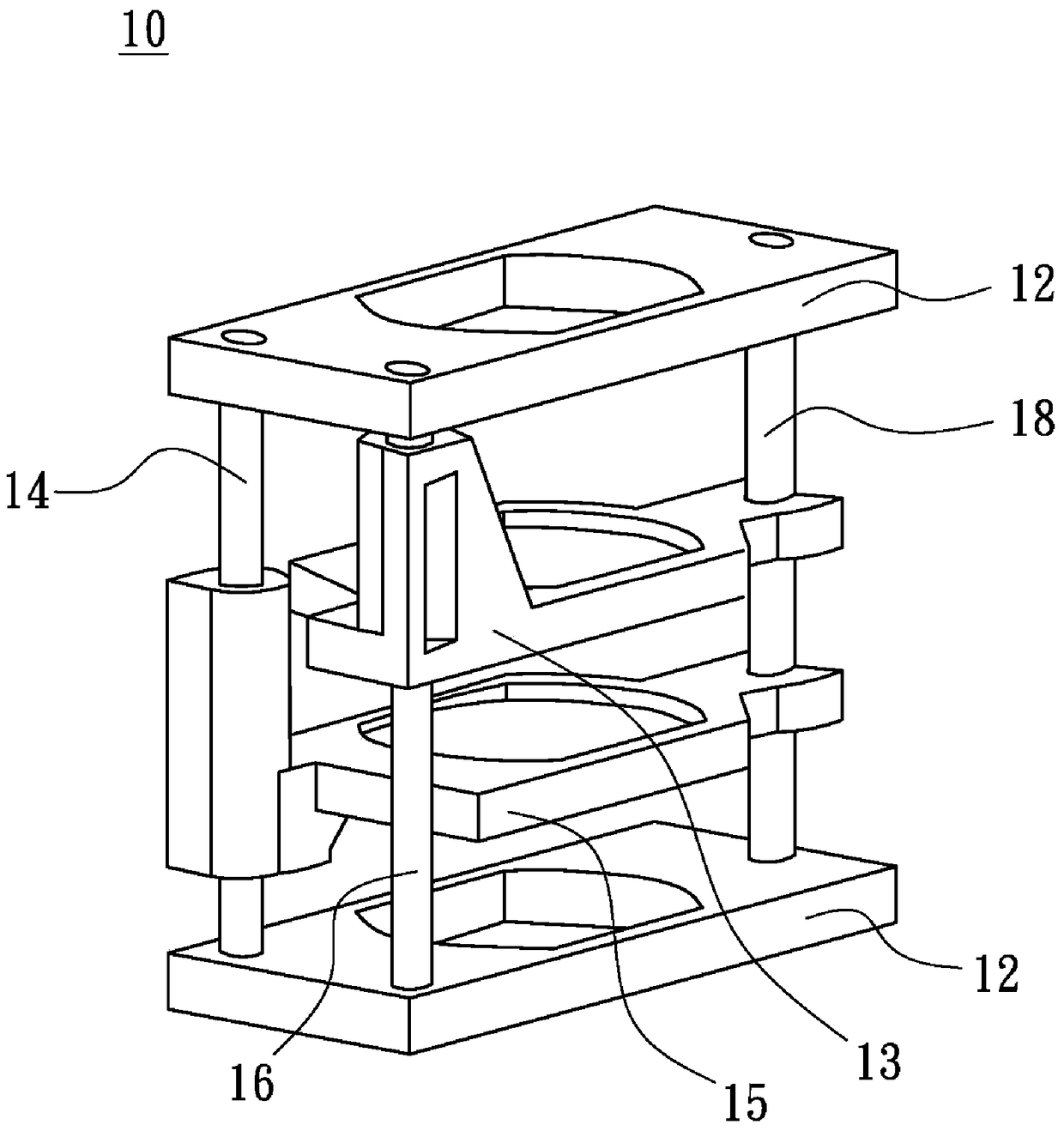

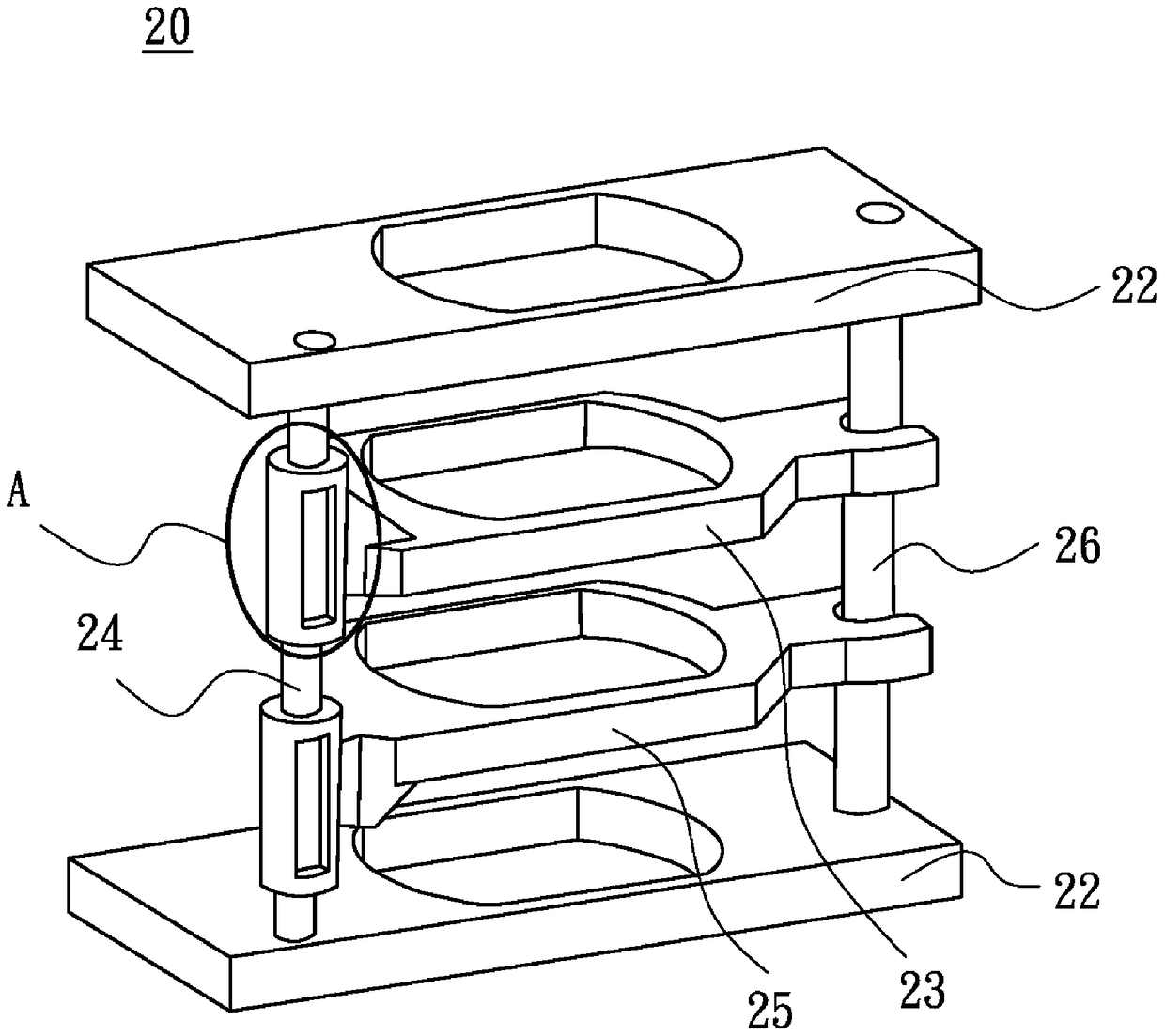

[0025] see Figure 4 , 5 , which represents the optical mechanism of the present invention. The optical mechanism 100 of the present invention includes a base 120 , a main shaft 140 , a secondary shaft 160 , a first group frame 130 and a second group frame 150 . The base 120 is divided into an upper base 122 and a lower base 124. The upper base 122 and the lower base 124 are plate-shaped and arranged parallel to each other. The main shaft 140 and the auxiliary shaft 160 are arranged between the upper base 122 and the lower base 124. , and the primary axis 140 is parallel to the secondary axis 160 .

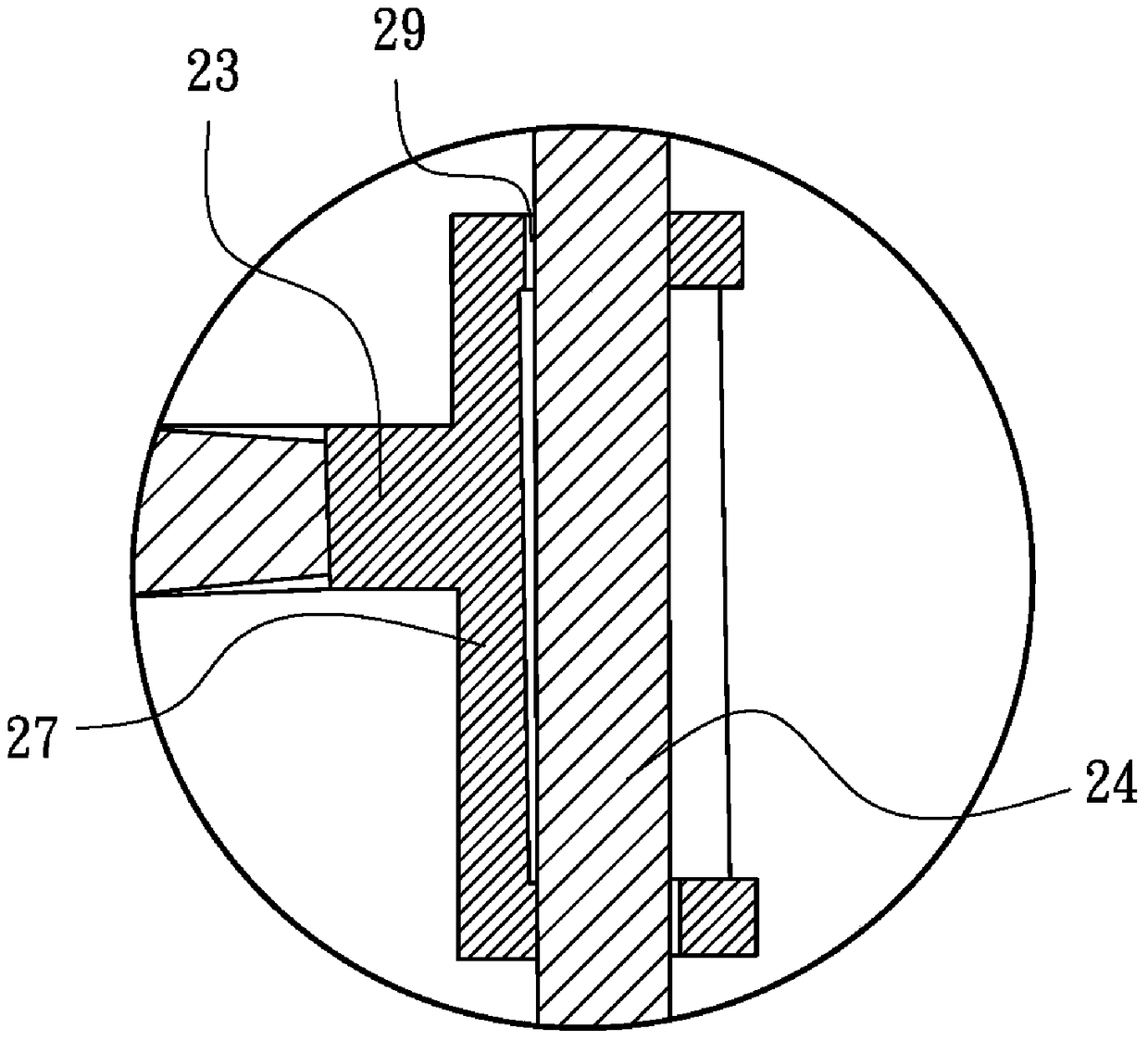

[0026] The first group frame 130 can carry a first lens group (not shown) and has a first bushing 131 and a third bushing 133, the first bushing 131 and the third bushing 133 are respectively arranged on the first group frame 130. On opposite sides, the first bushing 131 is movably disposed on the main shaft 140 , and the third bushing 133 is movably disposed on the auxiliary s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap