Seat power test device for high-speed ships and test method thereof

A dynamic test and seat technology, applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problems of small displacement capacity, uncontrollability and influence of the table surface, and achieve stable and refined actuation process High, precise output load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

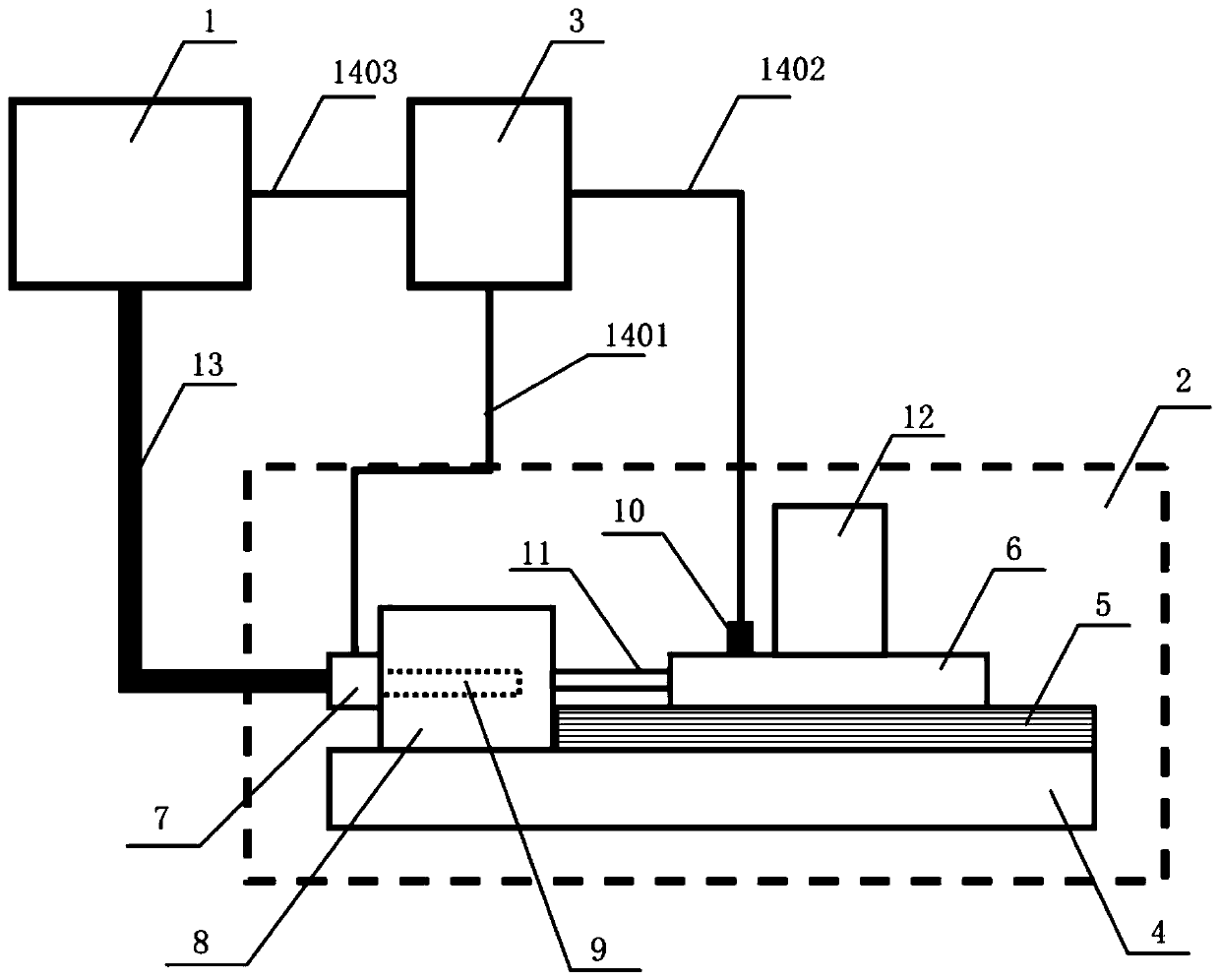

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0033] Such as figure 2 , image 3 and Figure 4 As shown, the high-speed ship seat dynamic test device of the present embodiment includes a mechanical platform body 2, on which the sample 12 to be tested is installed and actuated according to the instruction of the control signal, and one end of the mechanical platform body 2 passes through The oil pipe 13 is connected with a hydraulic oil source 1, the hydraulic oil source 1 provides the power required for the actuation of the device, and also includes a measurement and control system 3 respectively connected with the hydraulic oil source 1 and the mechanical platform body 2, and the measurement and control system 3 is used to output control signals, Acquisition and analysis of measurement signals.

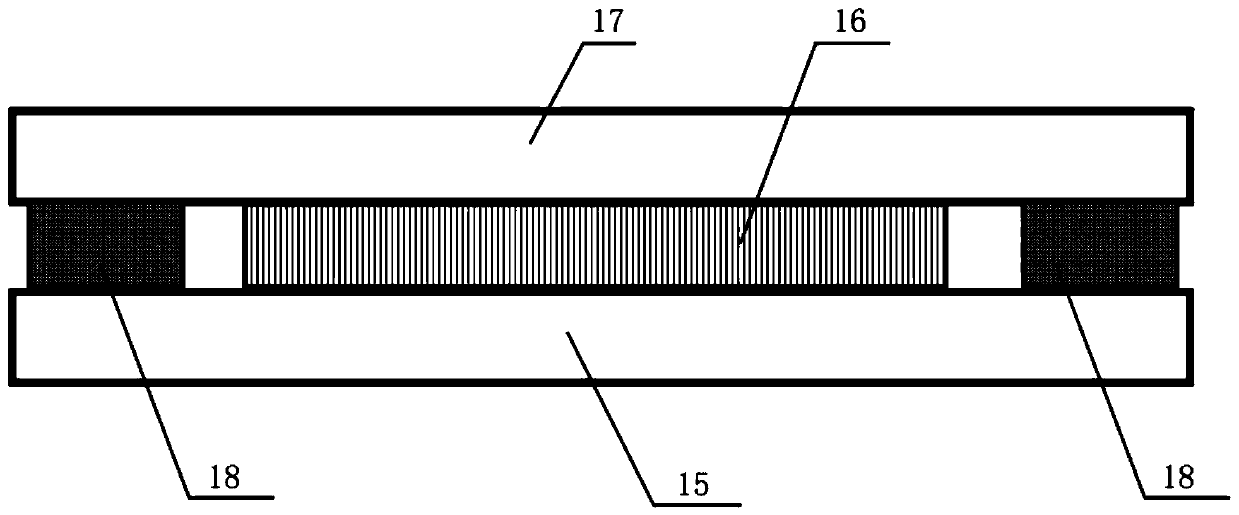

[0034]The installation structure of the mechanical table body 2 is: including a base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com