A plastic waste shredding device

A technology for crushing devices and waste products, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of troublesome replacement, short residence time, limited effect, etc., to achieve convenient installation, disassembly and replacement, ensure the crushing effect, and connect firmly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

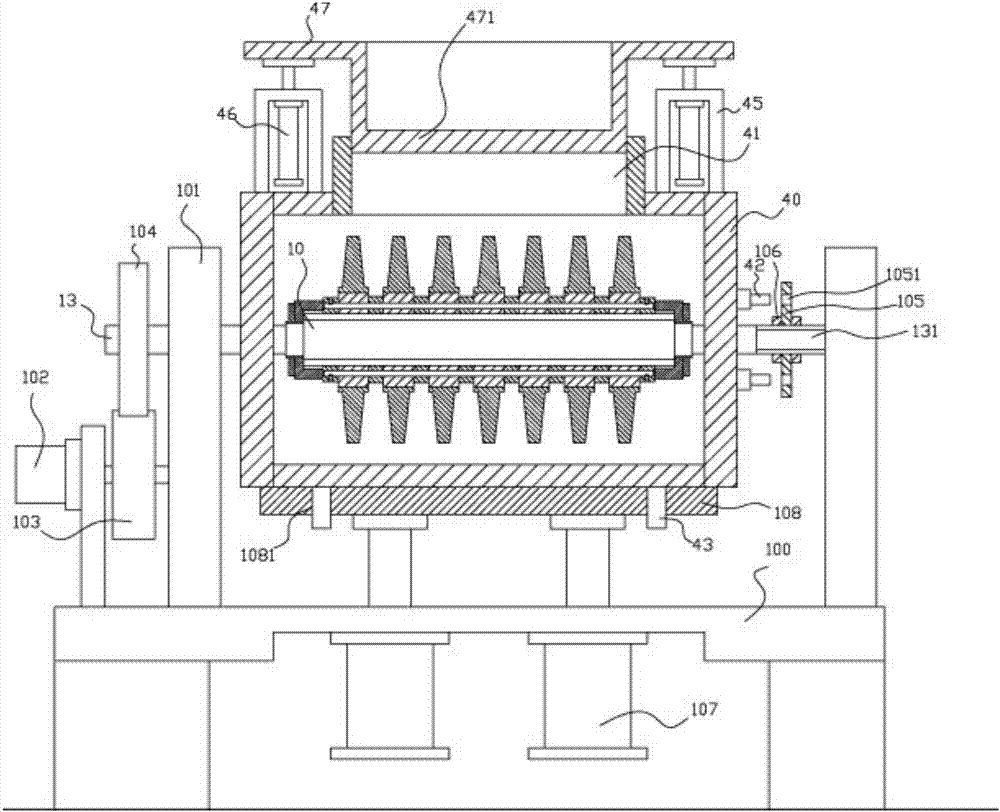

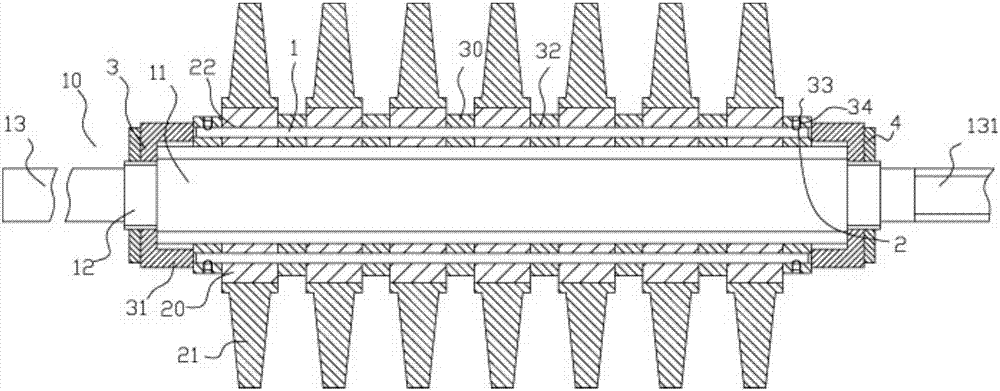

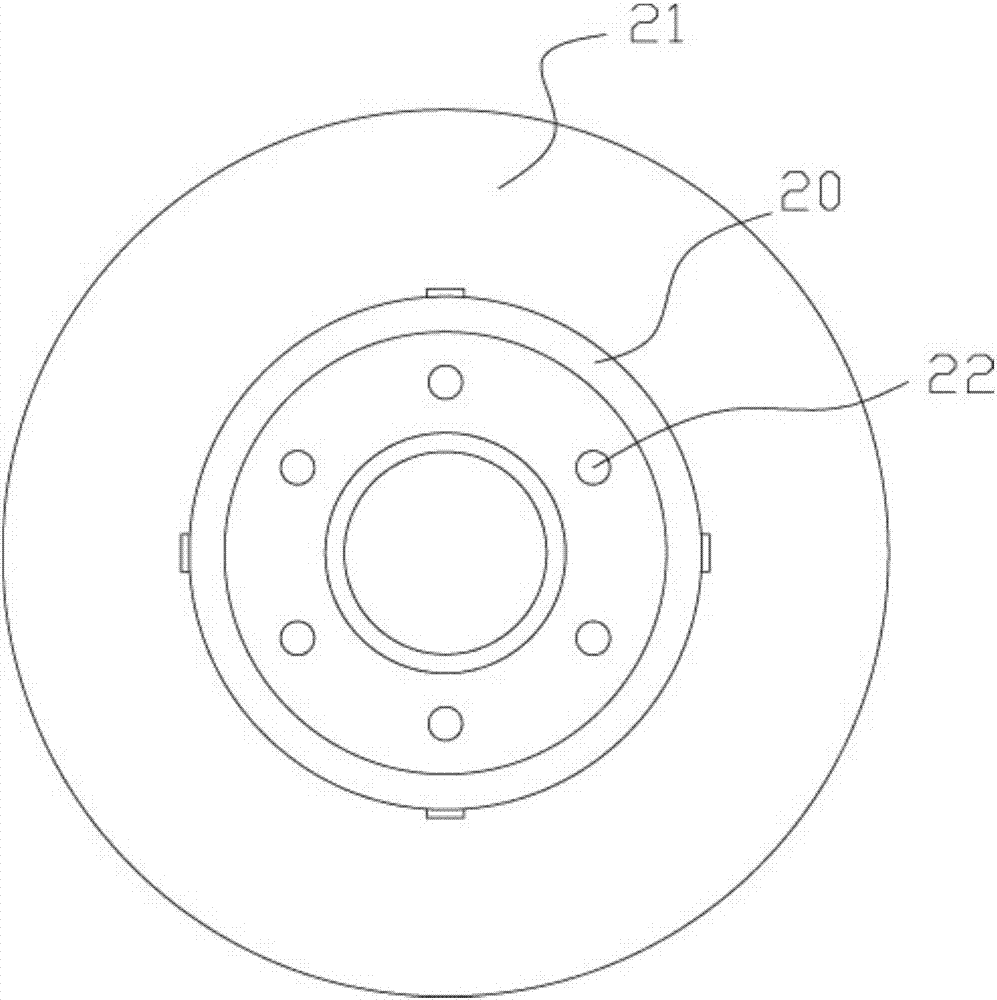

[0022] Example: see Figure 1 to Figure 5 As shown, a plastic waste crushing device includes a crushing circular barrel body 40 and a tool rotating shaft 10. The top of the crushing circular barrel body 40 is connected with a feed pipe 41, and the crushing circular barrel body 40 is provided with Cutter rotating shaft 10, two hinged shaft parts 13 of cutter rotating shaft 10 are hinged on two end plates of crushing circular barrel body 40, and the ends of hinged shaft parts 13 stretch out the two ends of crushing circular barrel body 40 The plate is hinged on the support plate 101, the support plate 101 is welded and fixed on the frame 100, the frame 100 is fixed with a rotary drive motor 102, and the output shaft of the rotary drive motor 102 is fixed with a drive gear 103, one of which is hinged The end of 13 protrudes from the support plate 101 and is fixed with a driven gear 104, and the driving gear 103 is meshed with the driven gear 104;

[0023] There is a threaded sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com