Glass Screen Screen Printing Fixture

A glass screen and screen printing technology, applied in screen printing machines, printing, printing machines, etc., can solve the problems of large equipment investment, low screen printing efficiency, and high labor intensity, so as to reduce maintenance costs, improve production efficiency, Profit maximization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

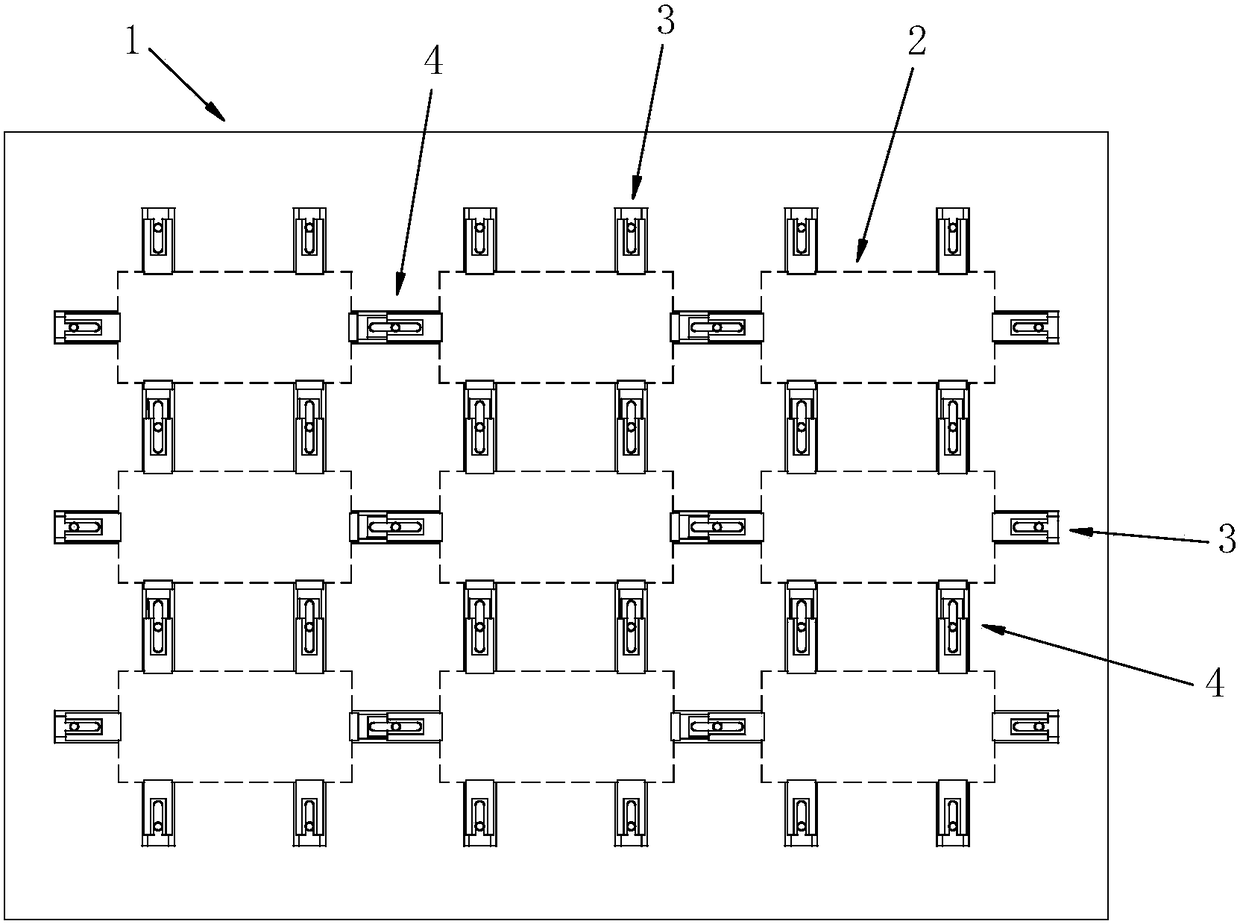

[0044] Such as figure 1 , 6 As shown in and 7, a screen printing fixture for glass screens includes a screen printing base 1, and several glass screen placement areas 2 are arranged on the screen printing base 1, and are located on the edge of each glass screen placement area 2 on the screen printing base 1 A number of stoppers are provided, and the stoppers are slidably connected with the silk screen base 1 . Specifically, the glass screen placement area 2 is used to fix the screen of the mobile phone. The limiter is detachably connected to the silk screen base 1. Compared with the traditional silk screen base 1 that only has a placement slot, since only the worn limiter needs to be replaced, the silk screen base 1 does not need to be scrapped as a whole. The maintenance cost of the detachable limiting member structure of the present invention is lower, which is conducive to saving production costs.

[0045] In this embodiment, the screen printing base 1 is provided with n...

Embodiment 2

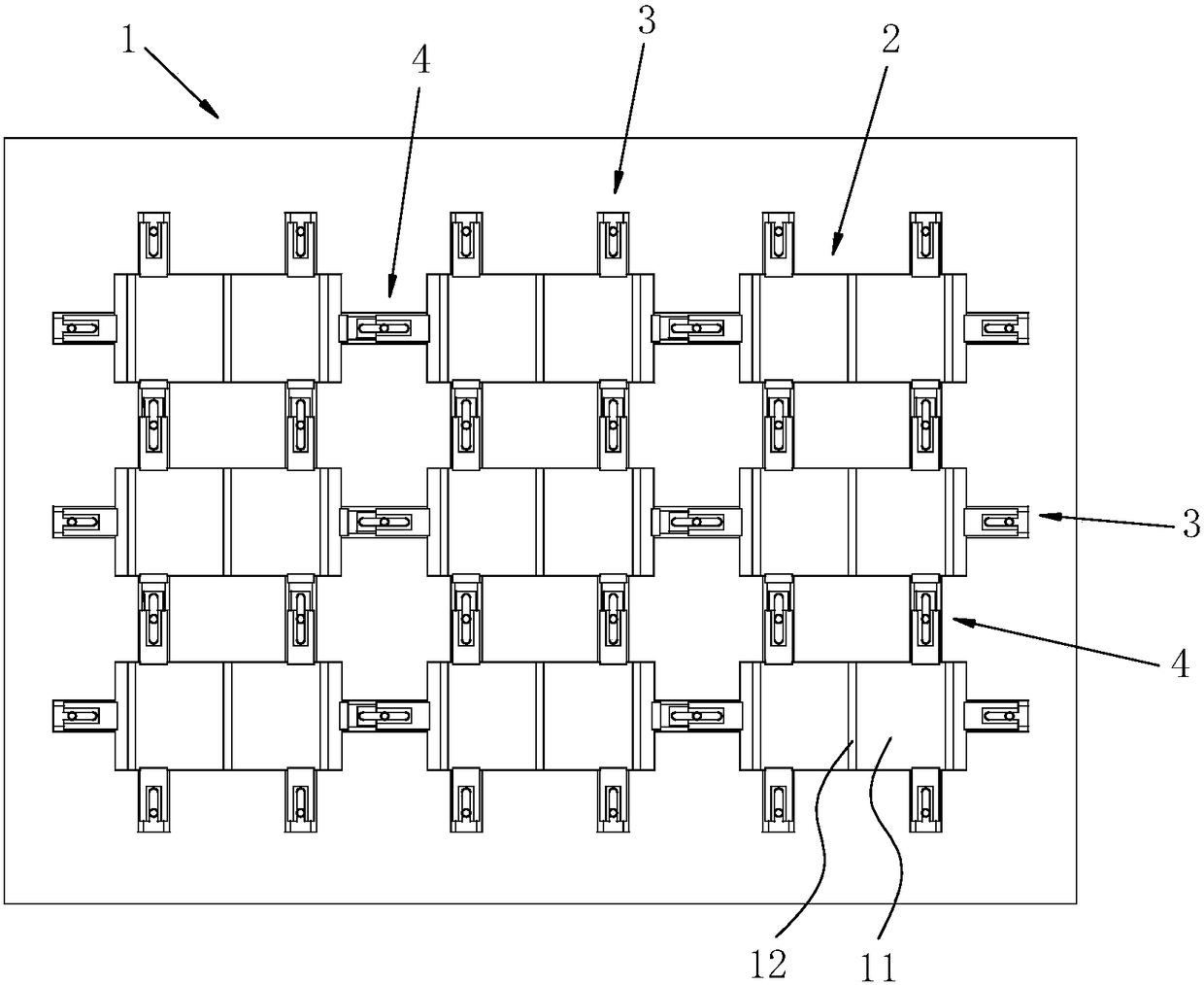

[0051] Such as figure 2 , 6 As shown in and 7, a screen printing fixture for glass screens includes a screen printing base 1, and several glass screen placement areas 2 are arranged on the screen printing base 1, and are located on the edge of each glass screen placement area 2 on the screen printing base 1 A number of stoppers are provided, and the stoppers are slidably connected with the silk screen base 1 . Specifically, the glass screen placement area 2 is used to fix the screen of the mobile phone. The limiter is detachably connected to the silk screen base 1. Compared with the traditional silk screen base 1 that only has a placement slot, since only the worn limiter needs to be replaced, the silk screen base 1 does not need to be scrapped as a whole. The maintenance cost of the detachable limiting member structure of the present invention is lower, which is conducive to saving production costs.

[0052] In this embodiment, the screen printing base 1 is provided with ...

Embodiment 3

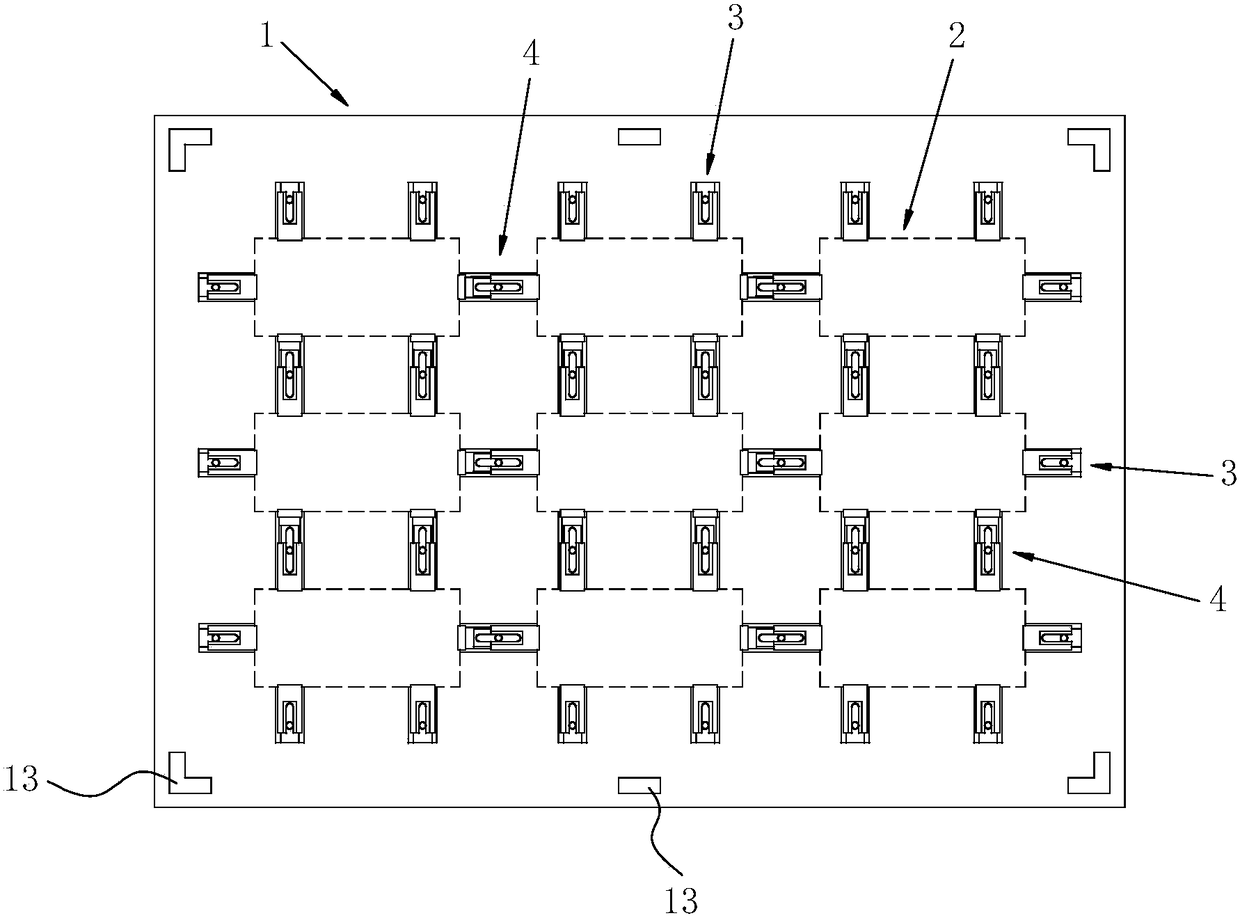

[0059] Such as image 3 , 6 As shown in and 7, a screen printing fixture for glass screens includes a screen printing base 1, and several glass screen placement areas 2 are arranged on the screen printing base 1, and are located on the edge of each glass screen placement area 2 on the screen printing base 1 A number of stoppers are provided, and the stoppers are slidably connected with the silk screen base 1 . Specifically, the glass screen placement area 2 is used to fix the screen of the mobile phone. The limiter is detachably connected to the silk screen base 1. Compared with the traditional silk screen base 1 that only has a placement slot, since only the worn limiter needs to be replaced, the silk screen base 1 does not need to be scrapped as a whole. The maintenance cost of the detachable limiting member structure of the present invention is lower, which is conducive to saving production costs.

[0060] In this embodiment, the screen printing base 1 is provided with n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com