A glass screen screen printing jig, screen printing equipment and screen printing method

A glass screen and silk screen printing technology, which is applied to screen printing machines, printing machines, printing machines, etc., can solve the problems of large investment in equipment, high labor intensity, and low efficiency of silk screen printing, so as to reduce maintenance costs and labor intensity of employees , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

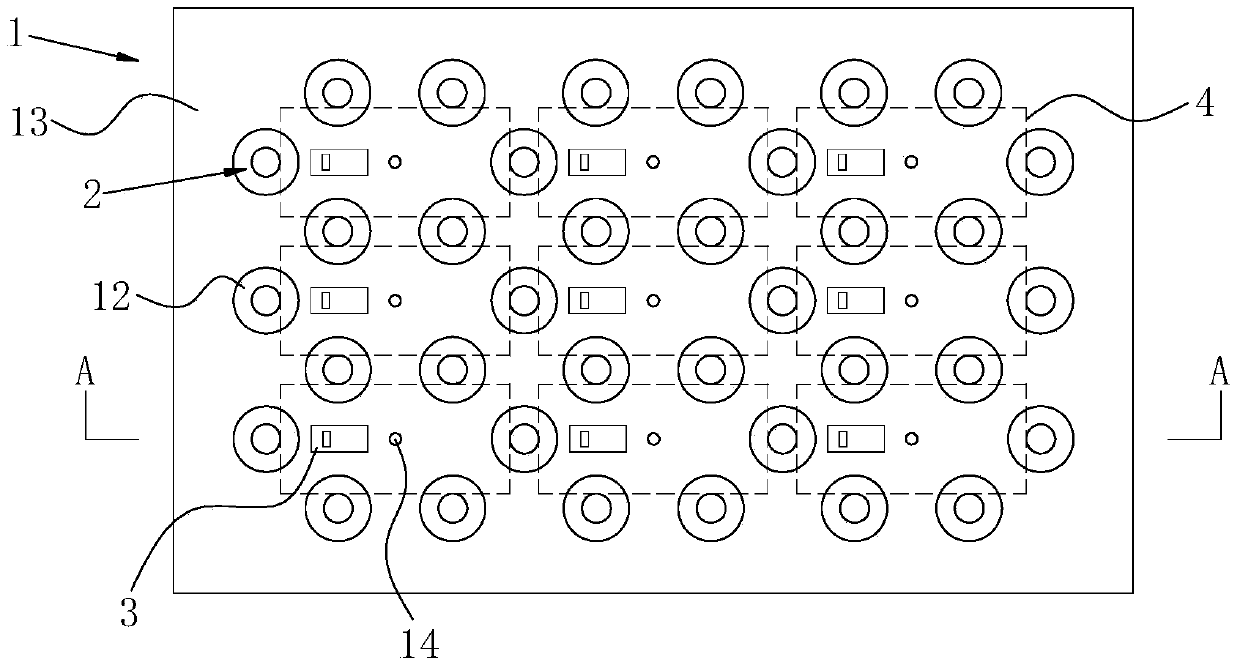

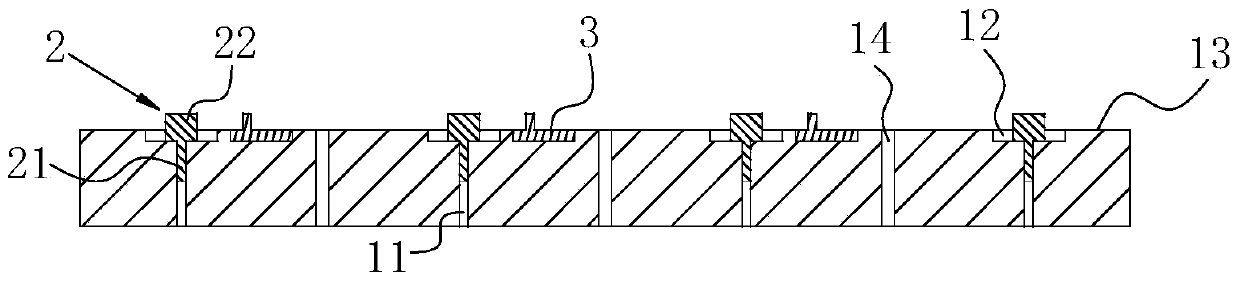

[0065] On the one hand, if figure 1 with 2 As shown, a screen printing fixture for glass screens includes a screen printing base 1, and several glass screen placement areas 4 are arranged on the screen printing base 1, and the screen printing base 1 is inserted on the edge of each glass screen placement area 4 There are several limit posts 2, and the limit posts 2 are detachably connected with the silk screen base 1. By arranging the silk screen base 1 on which multiple glass screens can be placed, silk screen processing can be performed on multiple glass screens at one time, effectively improving production efficiency. In this embodiment, the screen printing base 1 is provided with nine glass screen placement areas 4 , and the nine glass screen placement areas 4 are arranged in three rows, with three glass screen placement areas 4 in each row. On the silk screen base 1 and at the edge of each glass screen placement area 4, six limit posts 2 are inserted, and two short sides...

Embodiment 2

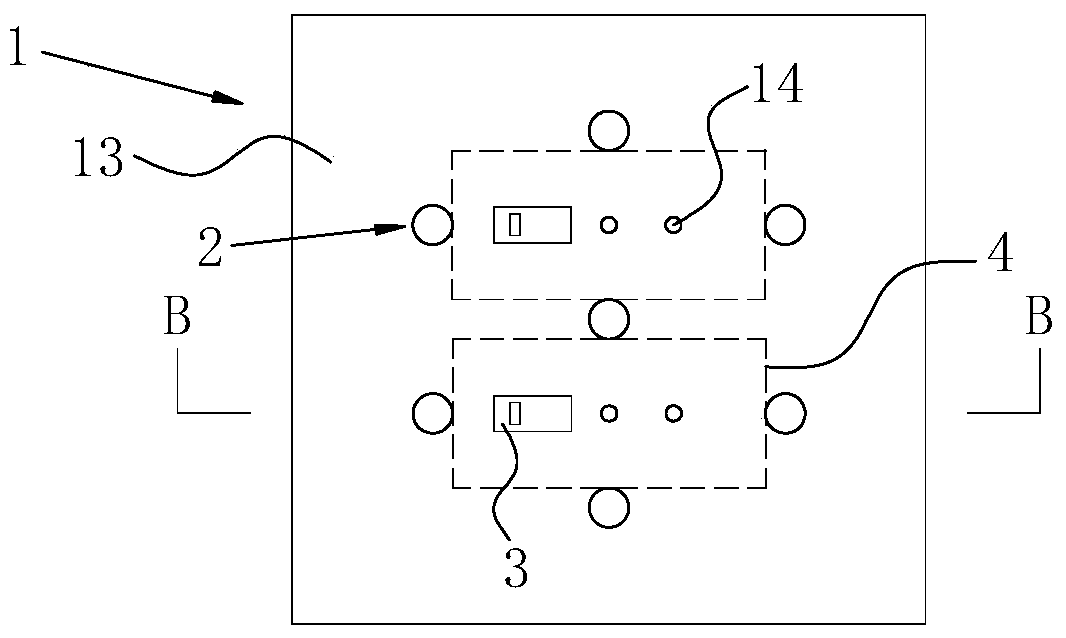

[0082] On the one hand, if image 3 with 4 As shown, a screen printing fixture for glass screens includes a screen printing base 1, and several glass screen placement areas 4 are arranged on the screen printing base 1, and the screen printing base 1 is inserted on the edge of each glass screen placement area 4 There are several limit posts 2, and the limit posts 2 are detachably connected with the silk screen base 1. By arranging the silk screen base 1 on which multiple glass screens can be placed, silk screen processing can be performed on multiple glass screens at one time, effectively improving production efficiency. In this embodiment, the screen printing base 1 is provided with two glass screen placement areas 4 , and the two glass screen placement areas 4 are arranged side by side. On the silk screen base 1 and at the edge of each glass screen placement area 4 are inserted four limiting columns 2, and one of the limiting columns 2 is respectively arranged on the two sh...

Embodiment 3

[0098] On the one hand, if Figure 5 with 6 As shown, a screen printing fixture for glass screens includes a screen printing base 1, and several glass screen placement areas 4 are arranged on the screen printing base 1, and the screen printing base 1 is inserted on the edge of each glass screen placement area 4 There are several limit posts 2, and the limit posts 2 are detachably connected with the silk screen base 1. By arranging the silk screen base 1 on which multiple glass screens can be placed, silk screen processing can be performed on multiple glass screens at one time, effectively improving production efficiency. In this embodiment, the screen printing base 1 is provided with six glass screen placement areas 4 , and the six glass screen placement areas 4 are arranged in three rows, with two glass screen placement areas 4 in each row. On the silk screen base 1 and at the edge of each glass screen placement area 4, six limit posts 2 are inserted, and two short sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com