Preparation method and application of active ingredient of Artemisia annua

An active ingredient and drying technology, which is applied in the preparation and application of the active ingredient of Artemisia annua, can solve the problems of less access, difficult synthesis, complex structure of monomer components, etc., and achieve the effect of simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

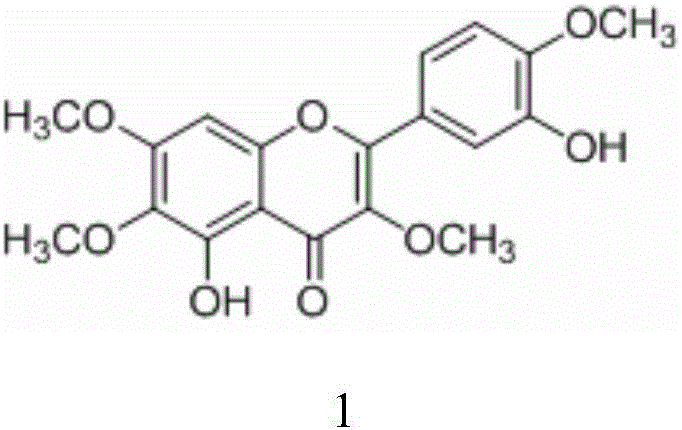

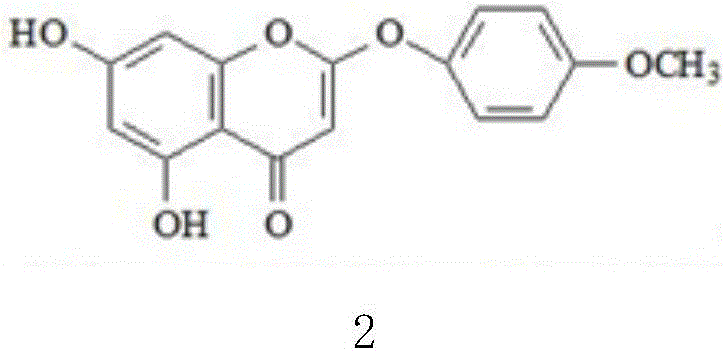

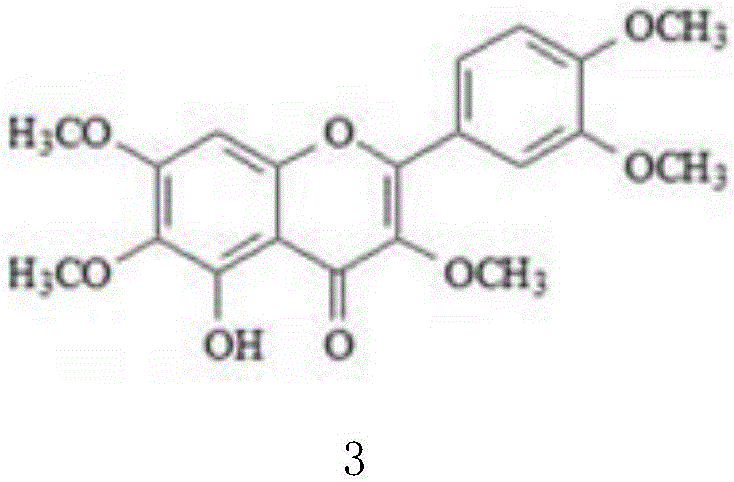

Image

Examples

Embodiment 1

[0025] a. Take 1kg of dried Artemisia angustifolia medicinal material, smash it, pass a 10 mesh sieve, put it in a round-bottomed flask, add 8 times the weight of 30% ethanol aqueous solution for extraction, heat the water bath at 50℃, reflux for 5 times, time 1 hour / time, the extracted filtrate is concentrated under reduced pressure to a relative density of 1.2 to obtain an extract for use;

[0026] b. The extract obtained in step a is dried in a vacuum drying oven with a vacuum degree of -0.08MPa and a temperature of 45° C. to obtain an extract of Artemisia annua, for use;

[0027] c. The extract obtained in step b and the polyamide resin are nylon-6 resin at a weight ratio of 1:6 for adsorption, the resin column diameter to height ratio is 1:3, the sample liquid extract concentration is 4%, and the sample flow rate It is 0.5BV / h. After adsorption, the polyamide resin 10BV is first eluted with water, and the elution flow rate is 0.5BV / h. After the water eluent is discarded, 5BV i...

Embodiment 2

[0031] a. Take 1kg of dried Artemisia angustifolia medicinal material, smash it, pass a 10 mesh sieve, put it in a round bottom flask, add 10 times the weight of 50% ethanol aqueous solution to extract, heat the water bath at 60℃, reflux and extract 3 times, time 2 hours / time, the extracted filtrate is concentrated under reduced pressure to a relative density of 1.3 to obtain an extract for use;

[0032] b. The extract obtained in step a is dried in a vacuum drying oven with a vacuum degree of -0.08MPa and a temperature of 50°C to obtain an extract of Artemisia angustifolia for use;

[0033] c. The extract obtained in step b and the polyamide resin are nylon-66 resin at a weight ratio of 1:8 for adsorption, the column diameter to height ratio of the resin is 1:5, the concentration of the sample liquid extract is 6%, and the sample flow rate It is 1.0BV / h. After adsorption, the polyamide resin 8BV is first eluted with water, and the elution flow rate is 1.0BV / h. After the water elua...

Embodiment 3

[0037] a. Take 1kg of dried Artemisia annua medicinal material, smash it, pass a 10 mesh sieve, put it in a round-bottomed flask, add 15 times the weight of 75% ethanol aqueous solution for extraction, heat in a water bath at 80°C, reflux and extract twice, time 1 hour / time, the extracted filtrate is concentrated under reduced pressure to a relative density of 1.3 to obtain an extract for use;

[0038] b. The extract obtained in step a is dried in a vacuum drying oven with a vacuum degree of -0.08MPa and a temperature of 65°C to obtain an extract of Artemisia annua, for use;

[0039] c. The extract obtained in step b and the polyamide resin are nylon-610 resin for adsorption at a weight ratio of 1:10, the resin column diameter to height ratio is 1:7, the sample solution extract concentration is 10%, and the sample flow rate It is 3BV / h. After adsorption, the polyamide resin 5BV is first eluted with water at a flow rate of 3BV / h. After the water eluate is discarded, 10BV is eluted w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com