Nozzle

A nozzle and body technology, applied in the field of nozzles, can solve problems such as air pollution, increased cost of electricity, increased purchase costs of electroplating liquid and other industrial chemical liquids, and the cost of waste liquid treatment, etc., to achieve high liquid ejection volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The embodiments of the present invention will be described in more detail below with reference to the drawings and reference numerals, so that those skilled in the art can implement them after studying this specification.

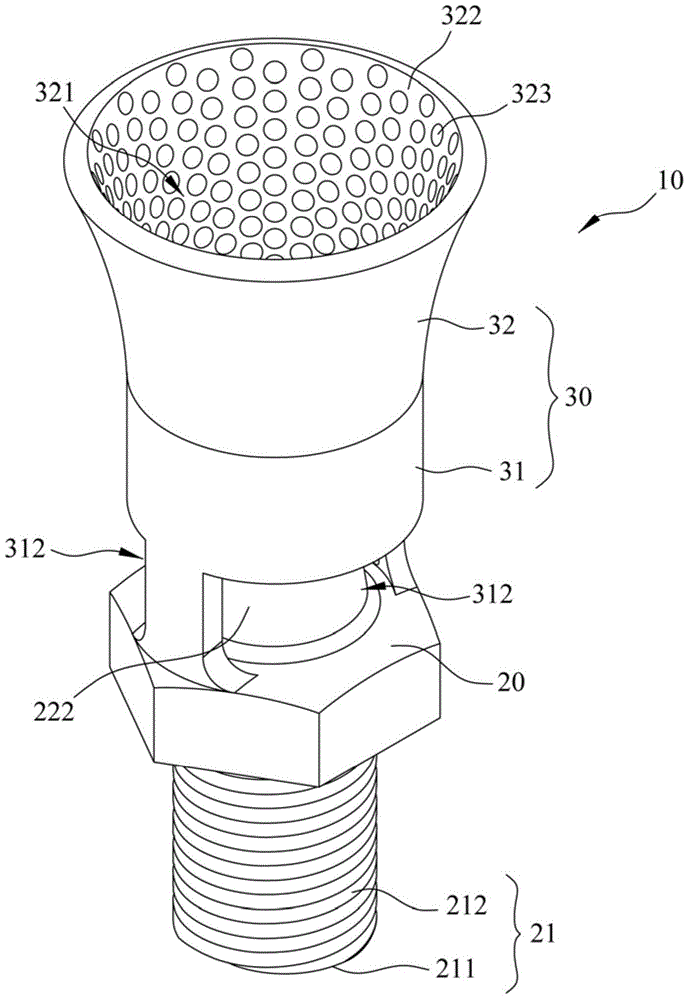

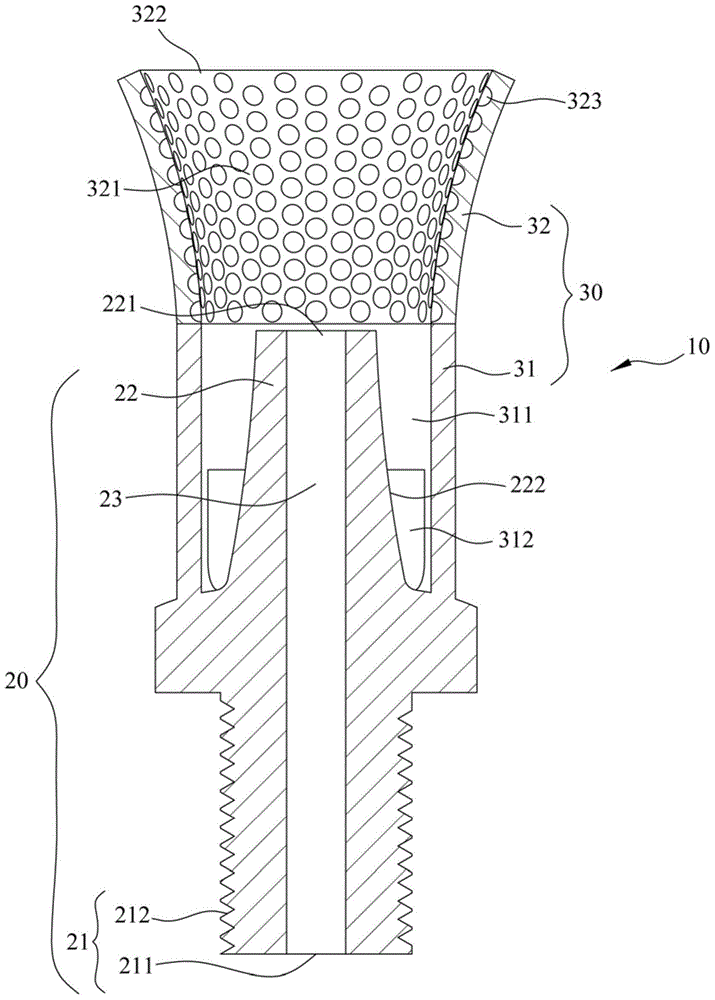

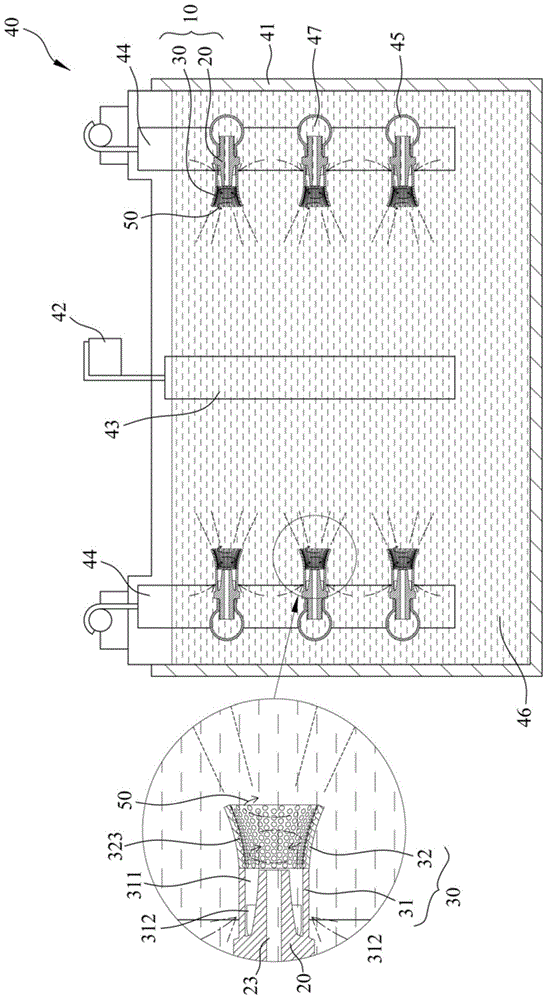

[0059] Please refer to figure 1 , figure 2 , the present invention provides a nozzle 10 including a body 20 and a cover 30 .

[0060] The body 20 includes a water inlet 21 and a water outlet 22 . The water inlet 21 forms a water inlet 211 and is installed on a liquid source. Preferably, the water inlet 21 includes an outer peripheral surface 212, and the outer peripheral surface 212 of the water inlet 21 is screwed to the liquid source, so that the water inlet 211 communicates with the inner space of the liquid source. The water outlet 22 forms a water outlet 221 and has an outer peripheral surface 222 . The main body 20 encloses a waterway 23 inside, and the waterway 23 runs through the water inlet 21 and the water outlet 22 and communicates be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com