A coating method for accessories

A coating method and a technology for fittings, applied in the field of spare parts processing, can solve the problems of low coating efficiency, reducing the service life of pipe fittings, pipe fitting corrosion, etc. The effect of coating speed and reducing the amount of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below by specific embodiments:

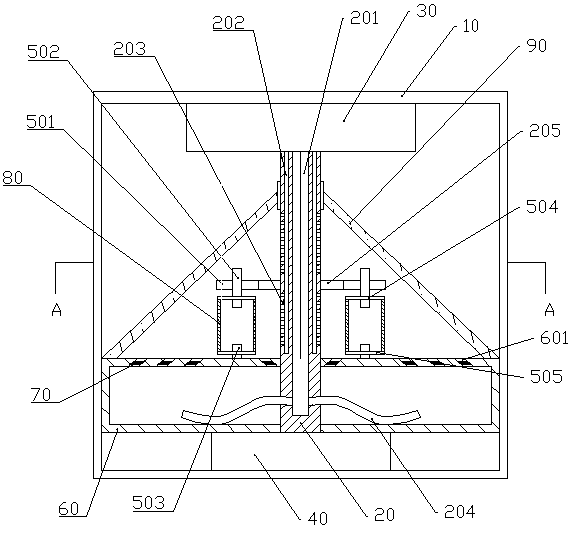

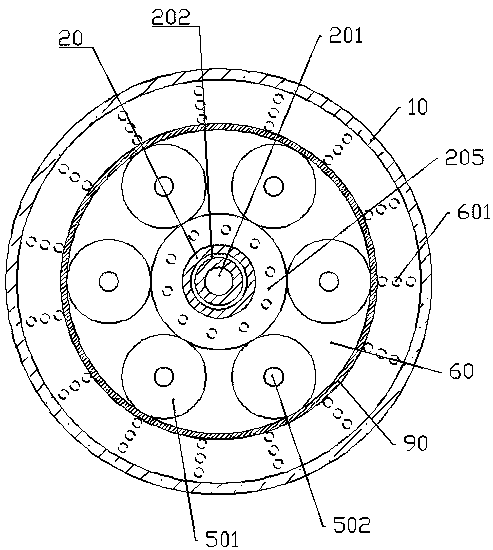

[0019] Reference numerals in the accompanying drawings include: housing 10, spray shaft 20, air outlet cavity 201, air inlet cavity 202, air suction hole 203, air outlet pipe 204, first gear 205, negative pressure suction machine 30, Motor 40 , second gear 501 , first rotating rod 502 , second rotating rod 503 , first clamping plate 504 , second clamping plate 505 , accommodating box 60 , paint spray port 601 , paint atomizer 70 , pipe fitting 80 , cover plate 90.

[0020] The coating equipment in the embodiment is basically as attached figure 1 and attached figure 2 Shown: it includes a casing 10 , a coating mechanism and a transmission mechanism. The coating mechanism includes a paint accommodating box 60 and a paint atomizer 70 , and the accommodating box 60 is horizontally installed in the casing 10 .

[0021] The transmission mechanism includes a spray shaft 20, a negative pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com