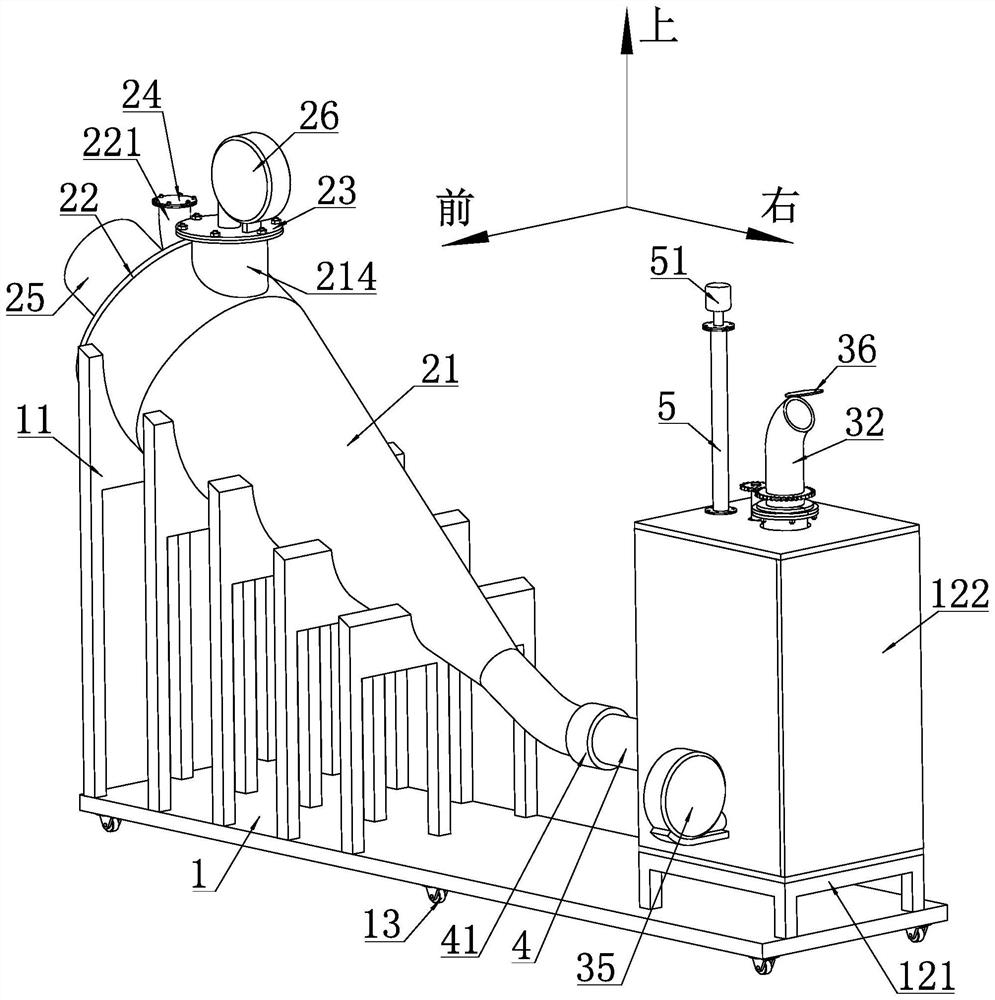

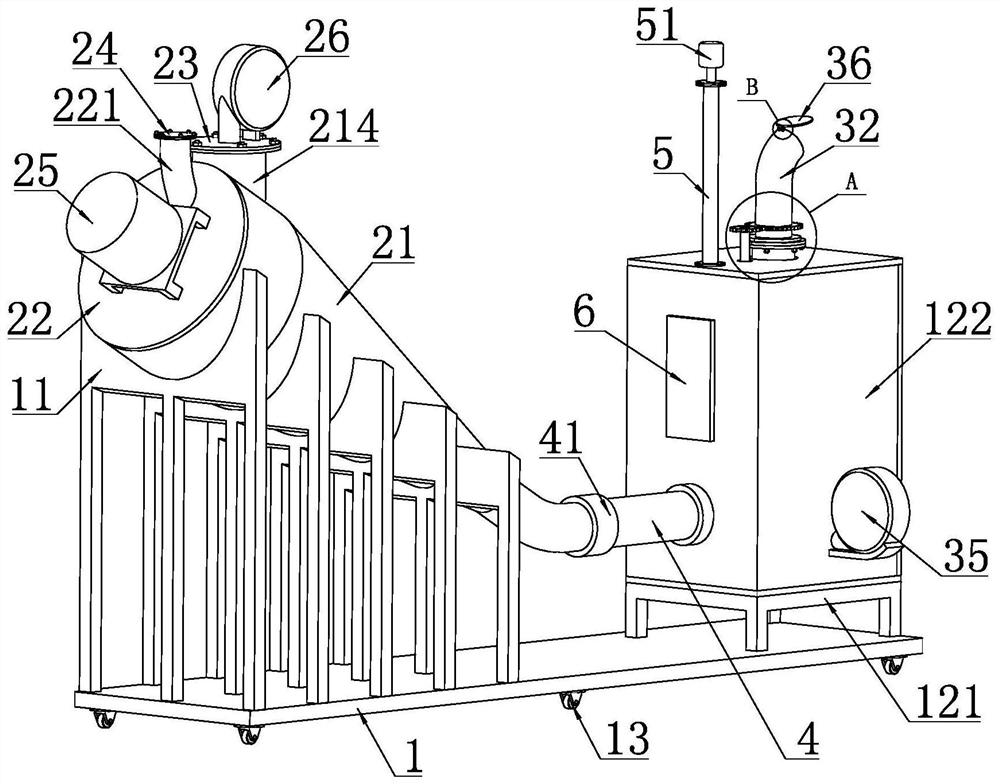

A gas automatic fire extinguishing device for a substation

An automatic fire extinguishing and substation technology, which is applied in fire rescue and other directions, can solve the problems of inability to arrange fire extinguishing points, high cost, and inability to change the layout structure, and achieve the effects of reducing losses, light structure, and improving fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

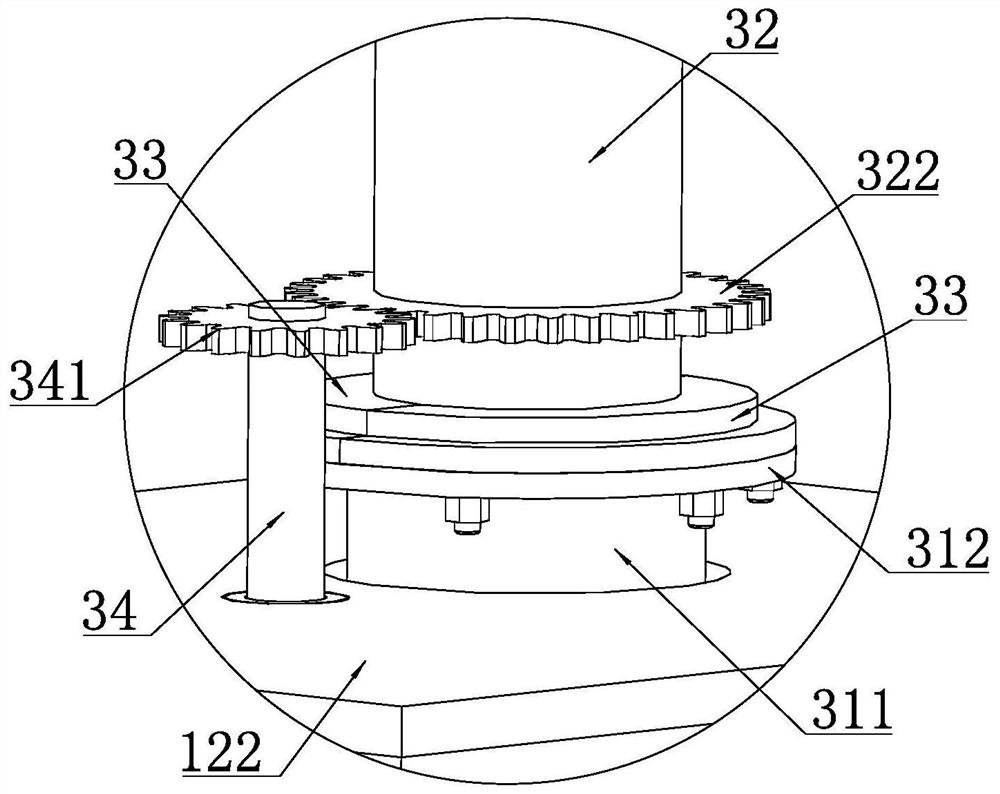

[0065] The second supporting frame includes an underframe 121 fixedly arranged on the bottom plate 1, and the underframe 121 includes a square frame formed by four side beams connected sequentially. The four sides of the square frame Outriggers extending downwards in the vertical direction are arranged on the corners, and the lower ends of the outriggers are fixedly provided with anchor plates by welding, and the anchor plates are fixedly connected with the bottom plate 1 by screws. The lower part of the pressurized tank 31 is fixedly provided with a square connecting plate by welding, and the connecting plate is fixedly connected with the side beam of the chassis 121 by screws, and the lower end of the pressurized tank 31 is inserted into into the square frame as described. A motor mounting plate is fixedly arranged on the discharge pipe 311 by welding, the rotating motor 34 is fixedly arranged on the motor mounting plate, and the power output shaft of the rotating motor 34 p...

Embodiment 3

[0067] The transmission mechanism includes a driving pulley fixedly arranged on the power output shaft of the rotary motor 34, a driven pulley is fixedly arranged on the powder spray pipe, and the driven pulley is connected with the timing belt through a synchronous belt. The driving pulley is connected, and all the other structures are the same as in Embodiment 1.

Embodiment 4

[0069] A plurality of stirring rods 2221 are arranged in a helical shape along the rotating shaft 222, and the rest of the structure is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com