Cycloid rotor pump with unsmooth surfaces

A non-smooth surface, cycloid rotor pump technology, used in rotary piston pumps, rotary piston/oscillating piston pump components, pumps, etc., can solve the problem of reducing fast swimming resistance, reducing wall friction resistance, Affect the life of the pump and other problems, and achieve the effect of prolonging the time of filling oil, reducing vibration and noise, and preventing oil trapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

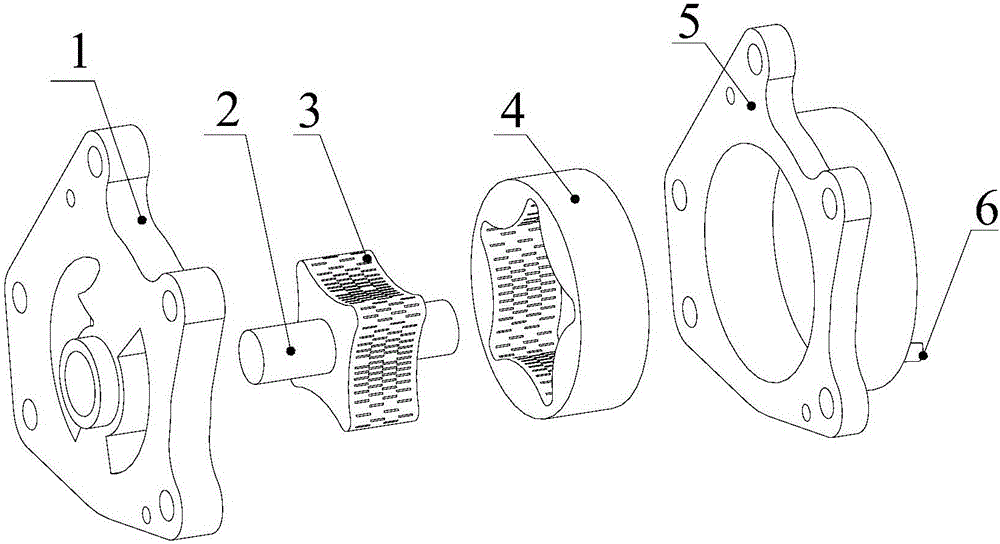

[0029] Embodiment 1 The cycloidal rotor pump with a non-smooth surface of the present invention includes an inner rotor 3, an outer rotor 4, a connecting shaft 2, a pump body 5, and a pump cover 1 fixed to the pump body. The inner rotor 3 is engaged with the outer rotor 4 installed in the cavity of the pump body 5, and the closed volume formed by the tooth gap between the inner rotor 3 and the outer rotor 4 is used as a working chamber; the inner rotor 3 is heated to 250°C, Use a press to press into the shaft 2, so that the connection shaft 2 and the inner rotor 3 are tightly connected. The end of the shaft 2 passing through the shaft hole of the pump body 5 is the input end, and the end of the connecting shaft 2 passing through the shaft hole of the pump cover 1 is the output end. The pump cover 1 is provided with an asymmetrical oil inlet groove 11 and The oil outlet groove 12, the oil inlet groove 11 and the oil outlet groove 12 are respectively communicated with the closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com