Project quality supervision personnel supervision capability evaluation method and device

A technology for supervising personnel and engineering quality, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of multiple manpower, time, space cost, lack of comprehensiveness, systematization, and easy to be restricted by time and space, etc. To achieve the effect of improving ability evaluation and improvement, stimulating learning interest, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

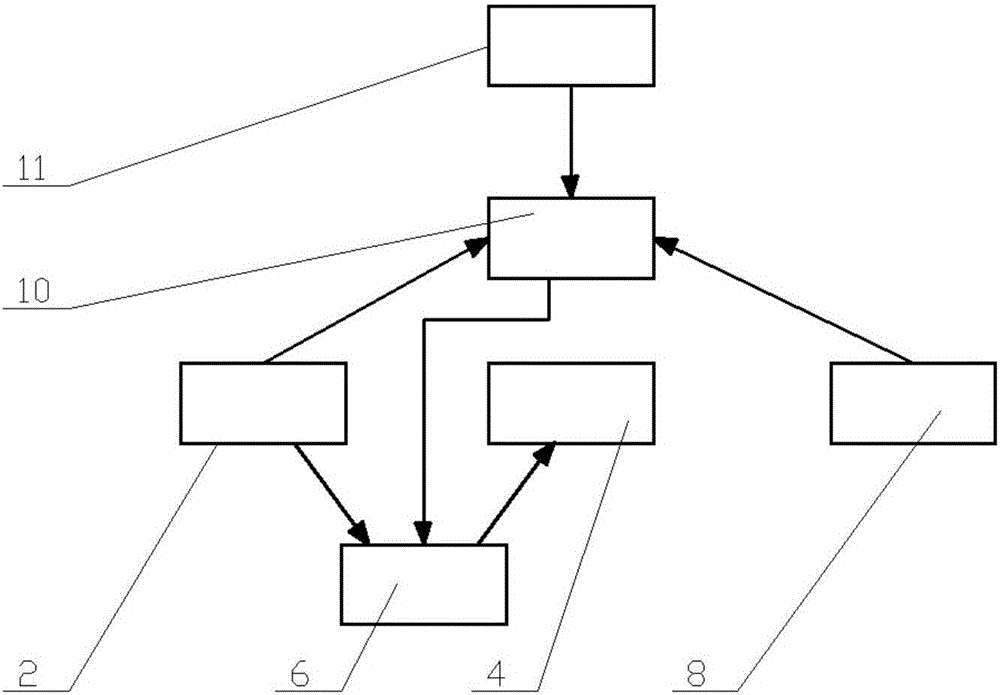

[0050] Such as figure 1 As shown, taking a beam-column quality supervision and management capability evaluation process as an example, the specific steps are as follows:

[0051]S1. According to the common quality problem database, the possible problems are made into the first type of BIM model, and the first database is formed in the form of data and stored in the storage unit 2 of the computer, and the real-time modification and adjustment of the BIM model can be completed by means of the computer In addition, the storage unit of the computer also stores a second-type BIM model that is opposite to each of the first-type BIM models and has no quality problems.

[0052] S2. The sending unit 6 of the computer retrieves a first-type BIM model from the first database in the storage unit of the computer, and performs data conversion, and converts the first-type BIM model from data information to an output unit that can be used by the computer 4 Recognized image information:

[0...

Embodiment 2

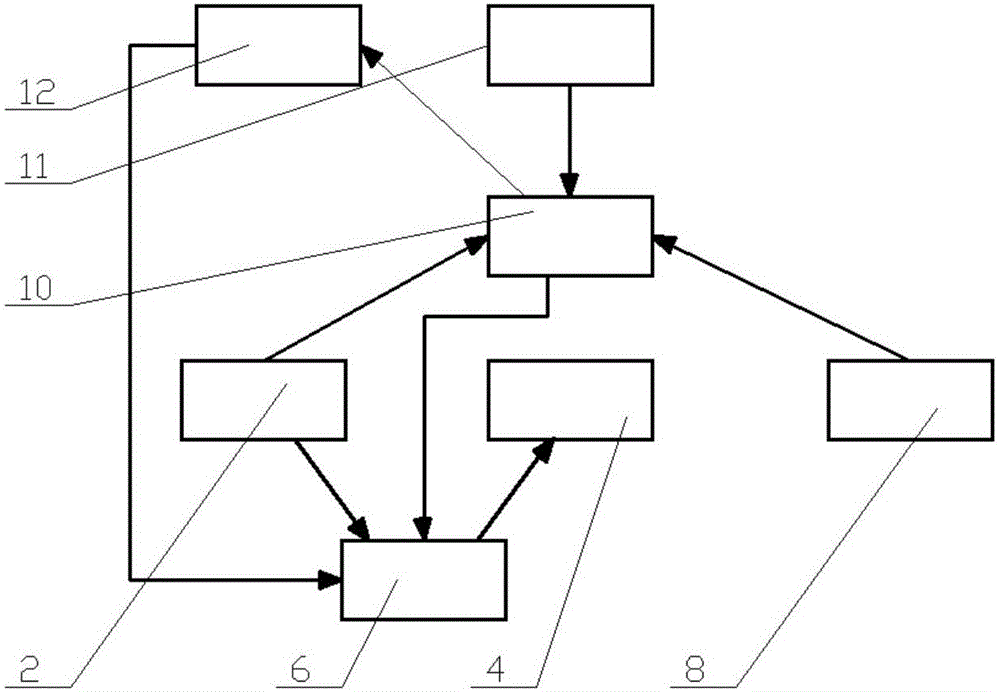

[0062] Such as figure 2 As shown, taking the quality supervision and management ability evaluation process of a cast-in-place slab as an example, the specific steps are as follows:

[0063] S1. According to the common quality problem database, the possible problems are made into the first type of BIM model, and the first database is formed in the form of data and stored in the storage unit 2 of the computer, and the real-time modification and adjustment of the BIM model can be completed by means of the computer In addition, the storage unit of the computer also stores a second-type BIM model that is opposite to each of the first-type BIM models and has no quality problems.

[0064] S2. The sending unit 6 of the computer retrieves a first-type BIM model from the first database in the storage unit of the computer, and performs data conversion, and converts the first-type BIM model from data information to an output unit that can be used by the computer 4 Recognized image infor...

Embodiment 3

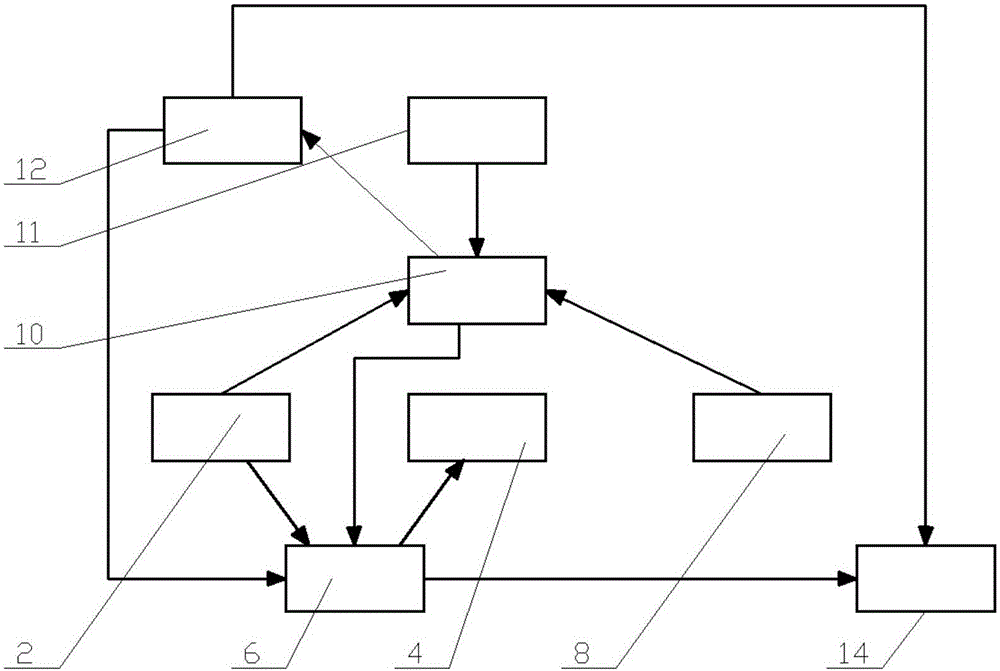

[0075] Such as image 3 As shown, taking the evaluation process of a hydropower installation quality supervision and management capability as an example, the specific steps are as follows:

[0076] S1. According to the common quality problem database, the possible problems are made into the first type of BIM model, and the first database is formed in the form of data and stored in the storage unit 2 of the computer, and the real-time modification and adjustment of the BIM model can be completed by means of the computer , in addition, the storage unit of the computer also stores a second-type BIM model that is opposite to each of the first-type BIM models and has no quality problems;

[0077] S1.5. Obtain the biological information of a single supervisor through the biometric identification device 14, and schedule a second database that is stored in the computer storage unit 2 and is composed of a number of identity information and biological information in a one-to-one corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com