Motor and dissipation fan with the motor

A technology for cooling fans and motors, applied in the field of motors, cooling fans, and motors with metal bases, can solve the problems of uneconomical efficiency, increase the overall weight of the motor 9, and increase additional costs, so as to save metal materials and reduce the overall Weight, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0048] In order to make the above and other objectives, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

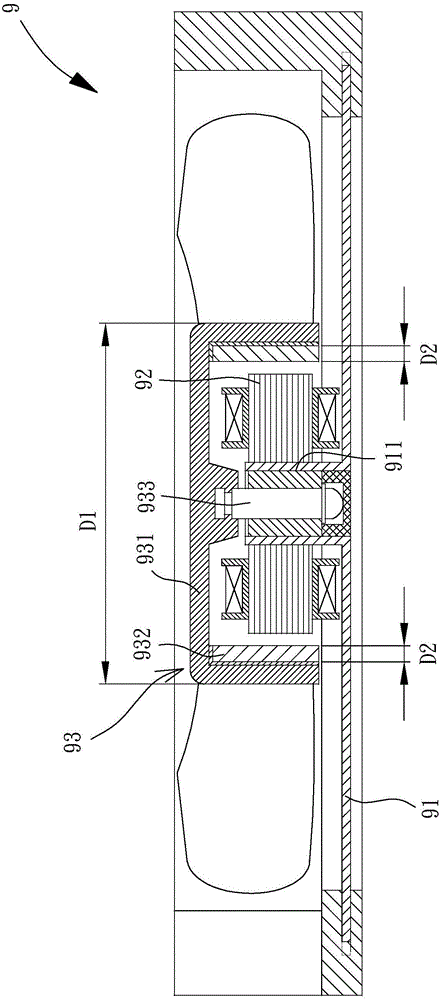

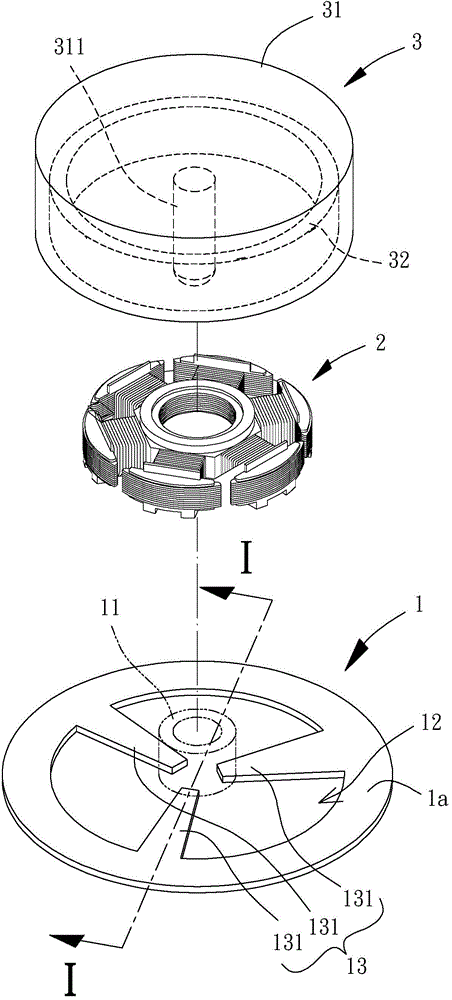

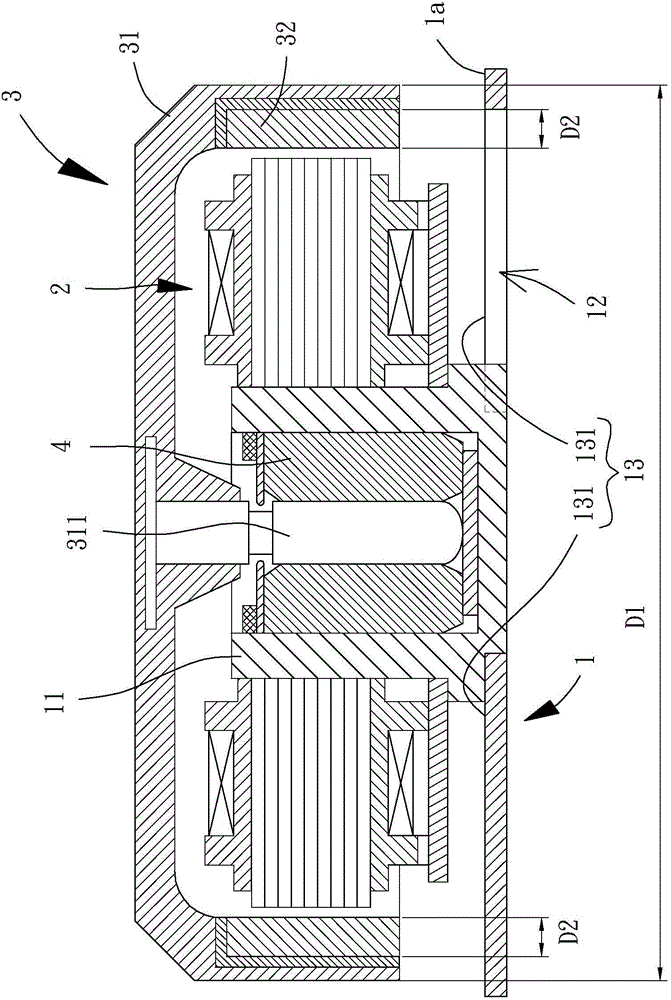

[0049] Please refer to figure 2 and image 3 As shown, the motor of the present invention includes a metal base 1, a stator 2 and a rotor 3. The metal base 1 can be used for combining the stator 2 and the rotor 3, and the stator 2 is used for driving the rotor 3 to rotate.

[0050] The metal base 1 is provided with a shaft connecting portion 11; wherein the metal base 1 is a metal member of various shapes capable of combining the stator 2 and the rotor 3, and the shaft connecting portion 11 of the metal base 1 can be It is a metal shaft tube or a plastic shaft tube, which is not limited by the present invention. It is preferably a plastic shaft tube for the arrangement of the plastic shaft tube, thereby improving the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap