Structure and manufacturing method of light load gear

A manufacturing method and gear technology, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems of waste of metal raw materials, unfavorable environmental protection, high noise, etc., and achieve low cost, small vibration, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

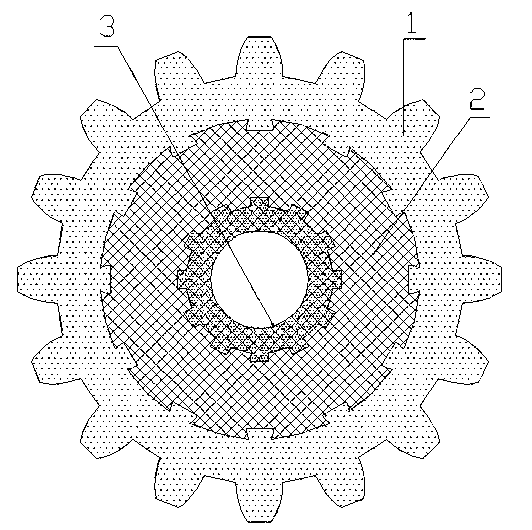

[0008] In the figure, the invention includes a ring gear 1 , a spoke 2 and a hub 3 . The invention adopts a cold stamping process to form an independent ring gear 1 and a hub 3 made of metal. The inner circular surface of the ring gear 1 and the outer circular surface of the hub 3 are provided with matching convex and concave platforms. The spokes 2 is polyamide PC, polyamide PA, polyoxymethylene POM and other engineering plastic materials. The hub 3 is fixed on the central part of the ring gear 1 through a mold, and the high-temperature melted spoke 2 is pressed and filled in the space between the hub 3 and the ring gear 1 through the mold. After cooling, the spoke 2 and the hub 3 and the ring gear 1 Form a unified overall gear.

[0009] The ring gear 1 and the hub 3 of the present invention are manufactured by sheet metal stamping and forming, and the spokes 2 are formed by engineering plastic molding, so that the requirements of the transmission technology can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com