Roller support reciprocated driving device for high-speed cold pilger mill

A reciprocating driving device, cold rolling mill technology, applied in the direction of the driving device for metal rolling mills, metal rolling, metal rolling, etc., can solve the problem that the speed of rolling tubes is difficult to achieve, the production capacity of steel tubes cannot be obtained, and the reciprocation of partial waste roll stands Movement speed and other issues to achieve the effect of improving rolling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate a clearer understanding of the technical essence and beneficial effects of the present invention, the applicant will describe in detail below by way of examples, but the description of the examples is not intended to limit the solution of the present invention, and any Equivalent transformations that are only formal but not substantial should be regarded as the scope of the technical solutions of the present invention.

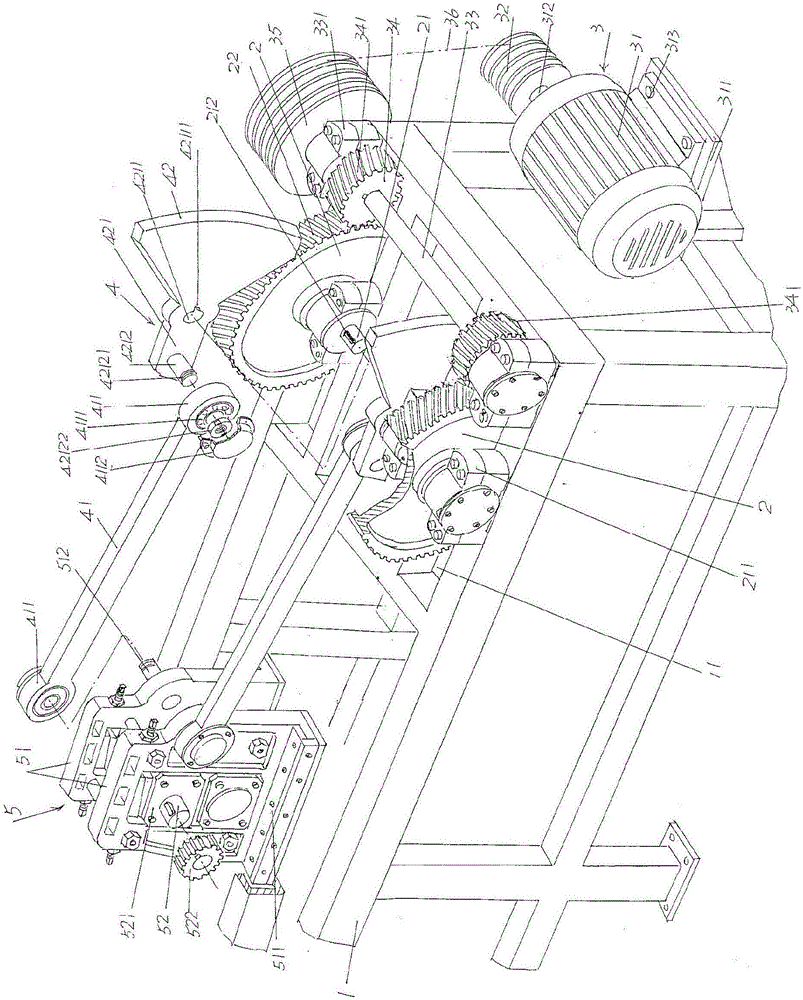

[0021] See figure 1 , shows a frame 1 with a frame-like structure; a pair of large gears 2 are rotatably supported on the right end of the frame 1 through a large gear half shaft 21 in a state corresponding to each other; a large gear drive mechanism 3 is shown , the large gear drive mechanism 3 is arranged on the frame 1 at a position corresponding to the right side of the aforementioned pair of large gears 2 and is in driving cooperation with the pair of large gears 2; a pair of connected A lever mechanism 4, the pair of link m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com