Mobile Tail Feed Chain Bulk Cargo Stacker

A material chain and flow technology, applied in the field of construction machinery, can solve the problems of poor flexibility and mobility of equipment, limited bulk material stacking height, and high useless energy consumption. The effect of low useless energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

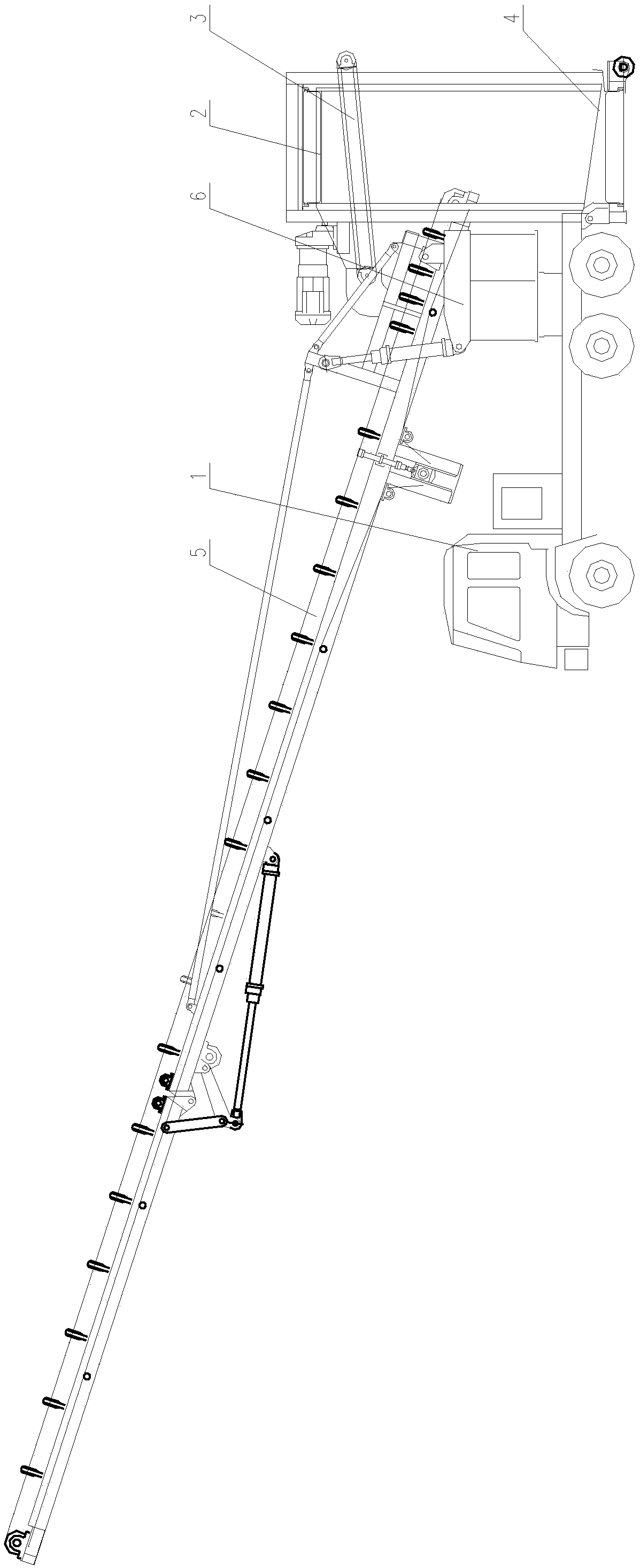

[0035] like figure 1 As shown, the flow type tail feeding chain type bulk cargo stacker 56 includes a car body assembly 1, a lifting transfer device 2, a horizontal transfer device 3, a receiving device 4, a folding belt conveyor 5, and a turning mechanism 6. The car body assembly 1 is used as the carrier of the whole machine equipment, and is used to install the lifting transfer device 2, the horizontal transfer device 3, the material receiving device 4, the folding belt conveyor 5, the slewing mechanism 6, and the walking and Transitions. The lifting transfer device 2 is connected to the tail of the vehicle body assembly 1 through the frame connecting hinge seat 12, and is used for lifting and transporting the material to the horizontal transfer device 3. The dump truck hopper 29 of the material receiving device 4 is fixedly connected to the bottom of the conveying device support frame 39 of the lifting transfer device 2, and forms a top open material receiving bin with the...

Embodiment 2

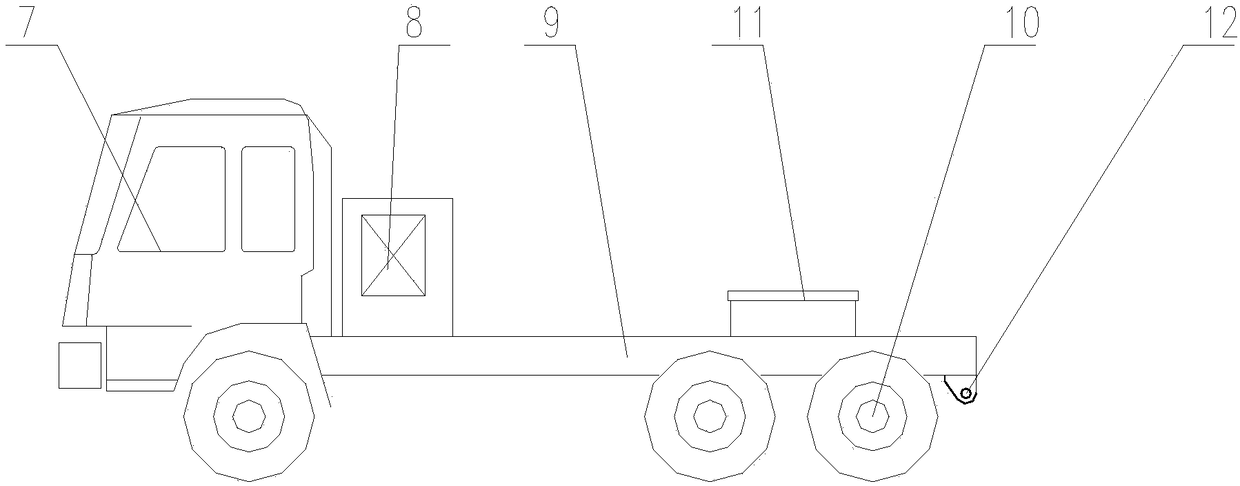

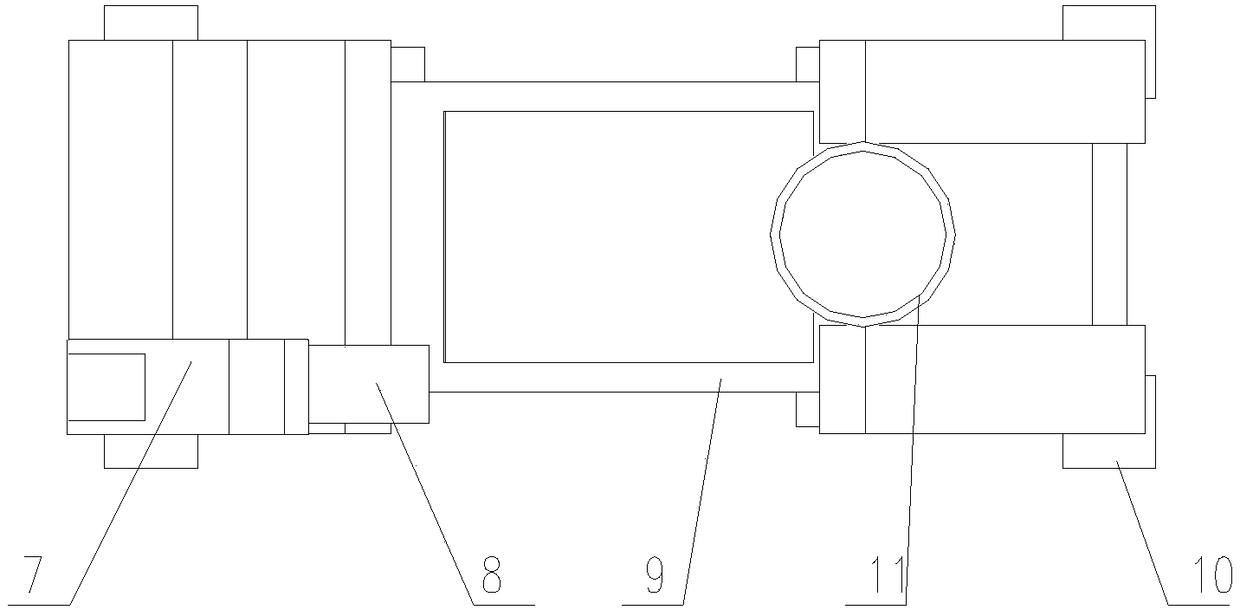

[0046] like Figure 13 In the figure shown, the mobile tail feeding chain type bulk cargo stacker 56 includes a car body assembly 1, a lifting transfer device 2, a horizontal transfer device 3, a receiving device 4, a folding belt conveyor 5, and a turning mechanism 6 . The car body assembly 1 is used as the carrier of the whole machine equipment, and is used to install the lifting transfer device 2, the horizontal transfer device 3, the material receiving device 4, the folding belt conveyor 5, the slewing mechanism 6, and the walking and Transitions. The lifting transfer device 2 is connected to the tail of the vehicle body assembly 1 through the frame connection hinge seat 12, and the material is lifted and transported to the horizontal transfer device 3 through the lifting transfer device 2. The dump truck hopper of the material receiving device is fixedly connected to the bottom of the conveying device supporting frame of the lifting transfer device, and forms a receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com