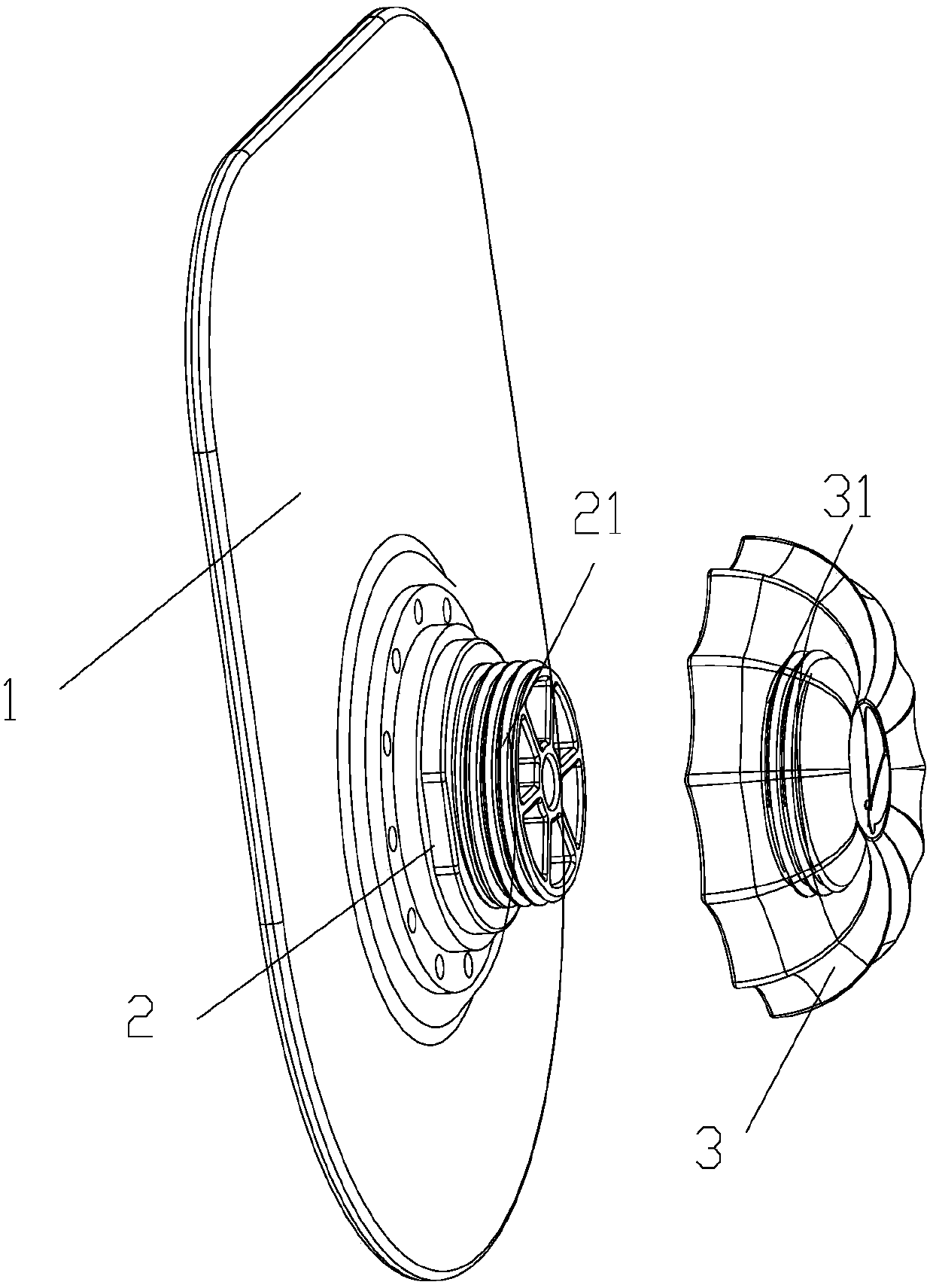

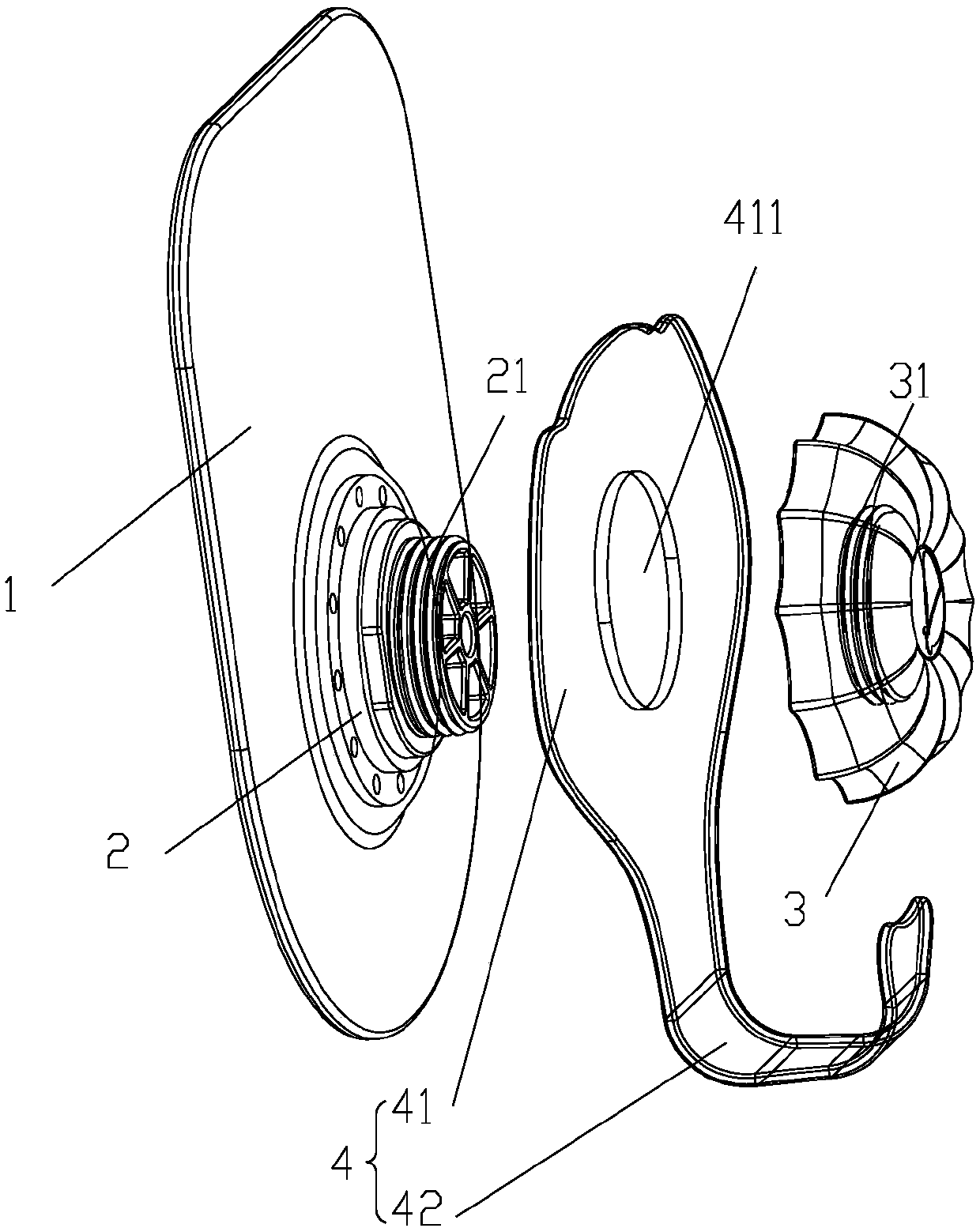

A silica gel suction cup, its preparation method and a pendant comprising a silica gel suction cup

A technology of silica gel and suction cup, applied in the field of silica gel, can solve the problems of affecting the use effect, large temperature change, loss of negative pressure of the suction cup, etc., and achieve the effect of not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method of a silica gel suction cup, comprising the following steps:

[0045] 1) Prepare raw materials by the following parts by weight:

[0046]

[0047]

[0048] Wherein, the methyl vinyl silicone rubber is divided into two parts, methyl vinyl silicone rubber a and methyl vinyl silicone rubber b, the weight ratio of methyl vinyl silicone rubber a and methyl vinyl silicone rubber b It is 3:1; Described white carbon black is divided into two parts, white carbon black a and white carbon black b, the weight ratio of white carbon black a and white carbon black b is 2:3; Described zinc stearate part It is two parts, zinc stearate a and zinc stearate b, and the weight ratio of zinc stearate a and zinc stearate b is 2:3;

[0049] Wherein, the molecular weight of the methyl vinyl silicone rubber is 550,000-700,000, the molar percentage of vinyl content is 0.05-0.20%, and the volatile matter is 0.4-1.0%;

[0050] Wherein, the content of zinc in zinc stearat...

Embodiment 1

[0069] A preparation method of a silica gel suction cup, comprising the following steps:

[0070] 1) Prepare raw materials by the following parts by weight:

[0071]

[0072]

[0073] 2) Kneading and kneading: mix the methyl vinyl silicone rubber a and zinc stearate a in step 1) into a kneader, and perform closed-cover kneading and kneading at a temperature of 45° C.;

[0074] 3) Adding powder: After completing step 2), under the condition of a temperature of 60°C, fill with nitrogen and divide the silica a into four parts and add them to the kneader. When adding the silica a for the first time, add the hydroxyl group at the same time Silicone oil, when adding silica a for the fourth time, add dimethyl silicone oil at the same time;

[0075] The first part of white carbon black a accounts for 40% of the mass fraction of white carbon black a, the second part of white carbon black a accounts for 30% of the mass fraction of white carbon black a, and the third part of white...

Embodiment 2

[0084] A preparation method of a silica gel suction cup, comprising the following steps:

[0085] 1) Prepare raw materials by the following parts by weight:

[0086]

[0087]

[0088] 2) Kneading and kneading: mix the methyl vinyl silicone rubber a and zinc stearate a in step 1) into a kneader, and perform closed-cover kneading and kneading at a temperature of 40° C.;

[0089] 3) Adding powder: After completing step 2), under the condition of a temperature of 60°C, fill with nitrogen and divide the silica a into four parts and add them to the kneader. When adding the silica a for the first time, add the hydroxyl group at the same time Silicone oil, when adding silica a for the fourth time, add dimethyl silicone oil at the same time;

[0090] The first part of white carbon black a accounts for 45% of the mass fraction of white carbon black a, the second part of white carbon black a accounts for 30% of the mass fraction of white carbon black a, and the third part of white c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com