Winding type extruding and twisting device for silks

A technology of winding type and wire guide device, which is applied in the direction of silk reeling, can solve the problems of non-uniform silk sheath quality, low labor productivity, and the influence of raw silk quality, and meet the requirements of silk reeling process, improve production efficiency, and improve cohesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

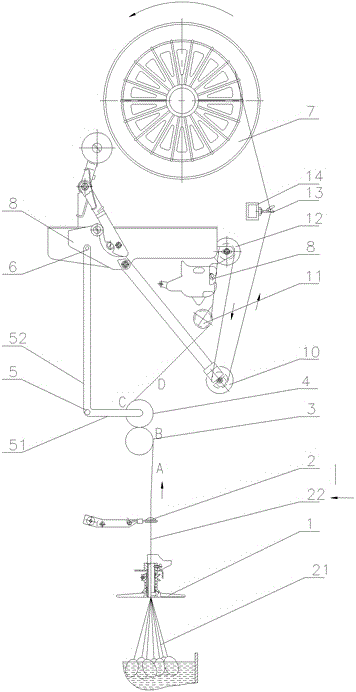

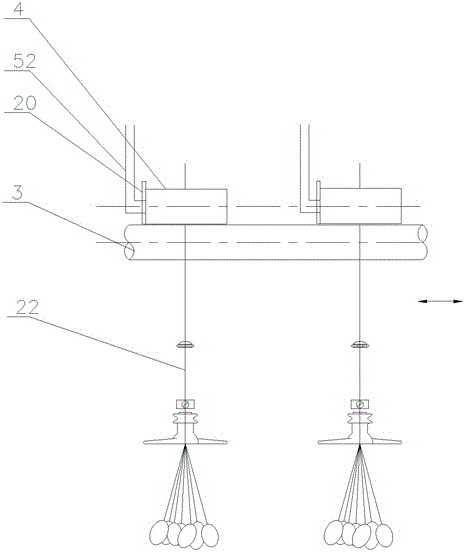

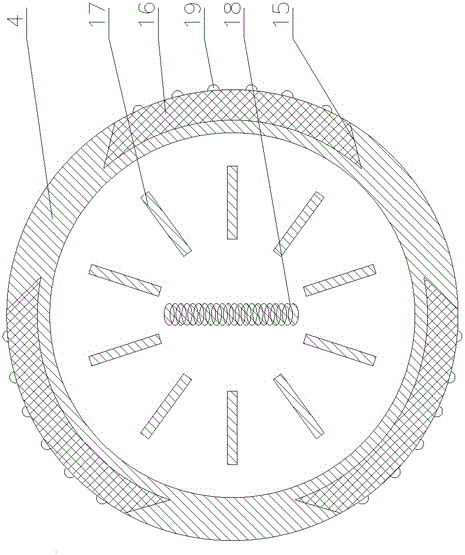

[0027] Embodiment: a kind of extruding and twisting device that is used for thread winding type of this example, as figure 1 , figure 2 , including threading wing 1, thread collecting device 2 is arranged on the top of threading wing, lower friction roller 3 and upper friction roller 4 are arranged successively above the thread collecting device, and upper friction roller is connected with swing connecting rod 5, and the swing connecting rod Be connected with vertical connecting rod 52 by connecting shaft 51, and vertical connecting rod is connected on the cut-off prevention bar 8 by fixed pin 6, and the top of upper friction roller is provided with guide wire device, and the top of guide wire device is provided with small ring 7. The wire guide device includes an upper wire guide wheel 9 and a loose wire guide wheel 10 . A detection displacement wheel 11 and a fineness detector 12 are arranged between the upper friction roller and the upper godet wheel. Between the pine wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com