Strand false twisting device and strand false twisting method in silk reeling process

A technology of thread and false twisting, which is applied in the field of silk reeling devices, can solve the problem of different lengths of silk sheaths, and achieve the effects of simple structure of the device, improvement of harmony, and reduction of yarn breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

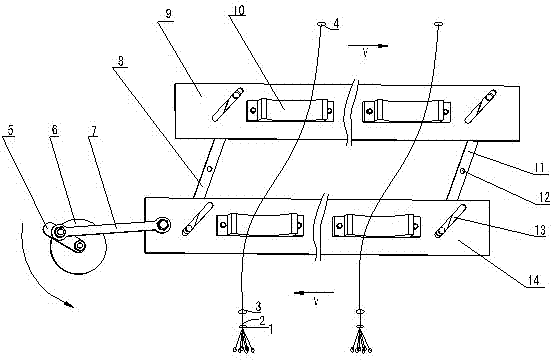

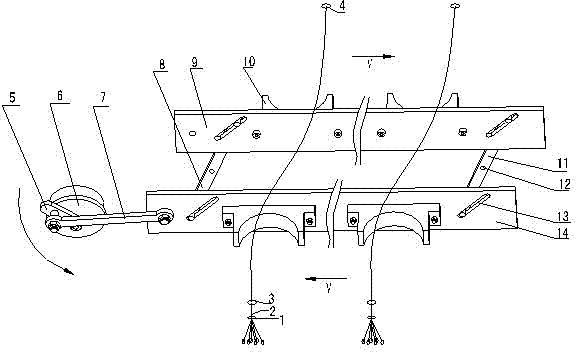

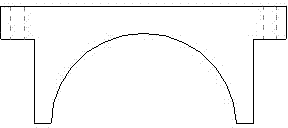

[0030] Reeling 20 / 22D spring cocoon raw silk, the thread 2 passes through the thread collector 1 and the lower guide wire hook 3 in sequence, and then clings to the lower arched twisting disc (the depth is 15mm, the opening width is 75mm) and the upper arched twisting disc (depth 15mm, opening width 75mm) on the inner wall and through the upper guide wire hook. The opening direction of the upper and lower arched twist discs is consistent. The motor drives the driving wheel 6 to rotate through the output shaft. The rotation of the driving wheel drives the crank 5 to make a circular motion, and the crank 5 drives the rocker 7 to reciprocate. The reciprocating linear motion of the plate 14, and the swing of the two rockers 8 and 11 make the upper reciprocating plate 9 do linear motion in the opposite direction, the moving speed is 50 times / min, and the moving distance is 30 mm. The reciprocating linear motion of the arched twisting disc makes the thread on it rotate around its...

Embodiment 2

[0032]Reeling 20 / 22D spring cocoon raw silk, the thread 2 passes through the thread collector 1 and the lower guide wire hook 3 in sequence, and then clings to the lower arched twisting disc (the depth is 27mm, the opening width is 60mm) and the upper arched twisting disc (depth 27mm, opening width 60mm) on the inner wall and through the upper guide wire hook. The opening direction of the upper and lower arched twist discs is consistent. The motor drives the driving wheel 6 to rotate through the output shaft. The rotation of the driving wheel drives the crank 5 to make a circular motion, and the crank 5 drives the rocker 7 to reciprocate. The reciprocating linear motion of the plate 14, and the swing of the two rockers 8 and 11 make the upper reciprocating plate 9 do linear motion in the opposite direction, the moving speed is 100 times / min, the moving distance is 20 mm, and the arched twist disc The reciprocating linear motion makes the thread on it rotate around its own axis...

Embodiment 3

[0034] Reeling 20 / 22D autumn cocoon raw silk, the thread 2 passes through the thread collector 1 and the lower guide wire hook 3 in sequence, and then clings to the lower arched twisting disc (depth: 30mm, opening width: 50mm) and upper arched twisting disc (depth 30mm, opening width 50mm) on the inner wall and through the upper guide wire hook. The opening directions of the upper and lower arched twist discs are opposite. The motor drives the driving wheel 6 to rotate through the output shaft. The rotation of the driving wheel drives the crank 5 to make a circular motion. The reciprocating linear motion of the plate 14, and the swing of the two rockers 8 and 11 make the upper reciprocating plate 9 do linear motion in the opposite direction, the moving speed is 150 times / min, the moving distance is 10 mm, and the arch twist disc The reciprocating linear motion makes the thread on it rotate around its own axis, and the reeled small For silk flakes, the moisture regain of doff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com