Croisure-replacing parallel block filament false twisting device

A technology of parallel block and wire guide device, applied in the direction of silk reeling, textile and paper making, etc., can solve the problems of non-uniform silk sheath quality, different silk sheath functions, influence of raw silk quality, etc. Moisture, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

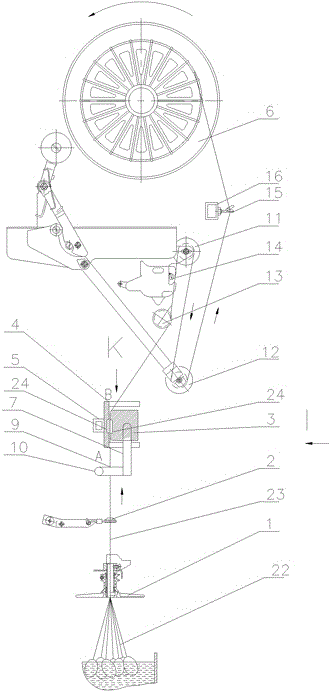

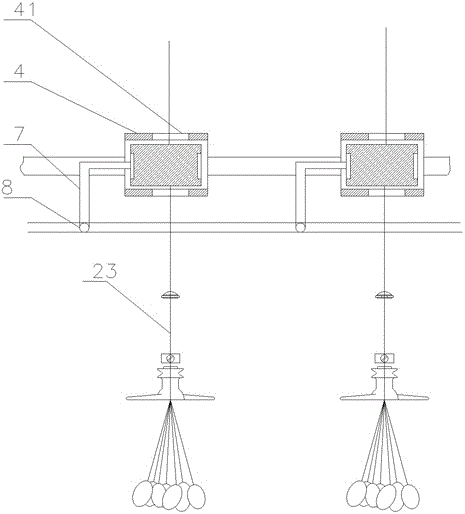

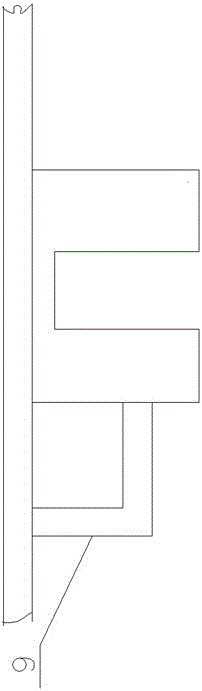

[0027] Example: In this example, a parallel block wire thread false twisting device instead of the wire sheath, such as figure 1 , figure 2 , image 3 , Including the thread connecting wing 1, the thread collecting device 2 is arranged above the thread connecting wing, the parallel block 3 and the concave groove 4 are sequentially arranged above the thread collecting device, and the parallel block is arranged in the concave groove. A gap 41 is provided for the thread to pass through. A gap for the thread to pass is provided between the parallel block and the concave groove. The concave groove is connected to the first support rod 5, and the parallel block is connected with a swing mechanism. A guide wire device is provided above the guide wire device, and a small Yu 6 is provided above the guide wire device. The swing mechanism includes a 90-degree bent connecting rod 7 connected with the parallel block 3, the connecting rod is connected with a fixed rod 9 through a bayonet 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com