Production method of ultra-low shrinkage glossy fdy

A production method, ultra-low shrinkage technology, used in textile and papermaking, filament/thread forming, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

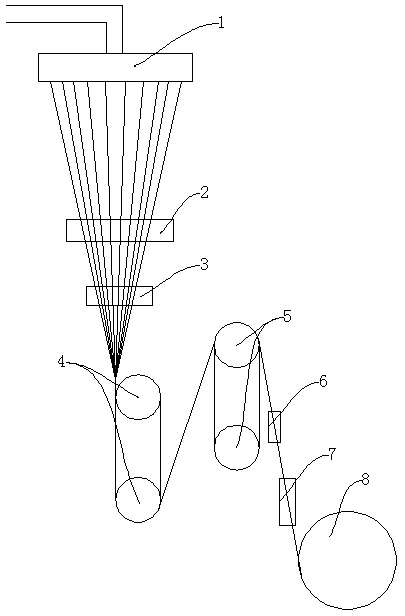

[0015] Such as figure 1 As shown, the production method of the ultra-low shrinkage glossy FDY described in this embodiment uses the glossy polyester melt as raw material, transports the glossy polyester melt into the melt cooler, and utilizes the melt cooler to After the melt is cooled, it is sent to the spinning box 1, and after being metered by the metering pump, it is filtered by the spinning assembly in the spinning box 1 and then extruded. Triangular, after the spinning is cooled by the side blowing process, the tow enters the winding tanker for oiling 2, pre-network 3, double-roll heating 4, double-roll shaping 5, main network 6, post-heating plate 7 heating, and finally package forming 8 . The bright polyester melt conveying temperature is 279°C, and the temperature of the spinning box 1 is 290°C.

[0016] The temperature of the two heat rollers in the process of the double roller heating 4 is between 80°C.

[0017] The temperature of the two hot rollers in the proce...

Embodiment 2

[0020] The production method of the ultra-low shrinkage glossy FDY described in this embodiment uses the glossy polyester melt as a raw material, transports the glossy polyester melt into the melt cooler, and uses the melt cooler to cool the melt Finally, it is sent into the spinning box 1, and after being metered by the metering pump, it is filtered by the spinning assembly in the spinning box 1 and then extruded. After the silk is cooled by the side blowing process, the tow enters the winding tanker for oiling 2, pre-internetting 3, double-roll heating 4, double-roller shaping 5, main network 6, post-heating plate 7 heating, and finally package forming 8. The bright polyester melt conveying temperature is 279°C, and the temperature of the spinning box 1 is 290°C.

[0021] The temperature of the two heat rollers in the process of the double roller heating 4 is between 100°C.

[0022] The temperature of the two hot rollers during the double-roll shaping process 5 is between 1...

Embodiment 3

[0025] The production method of the ultra-low shrinkage glossy FDY described in this embodiment uses the glossy polyester melt as a raw material, transports the glossy polyester melt into the melt cooler, and uses the melt cooler to cool the melt Finally, it is sent into the spinning box 1, and after being metered by the metering pump, it is filtered by the spinning assembly in the spinning box 1 and then extruded. After the silk is cooled by the side blowing process, the tow enters the winding tanker for oiling 2, pre-internetting 3, double-roll heating 4, double-roller shaping 5, main network 6, post-heating plate 7 heating, and finally package forming 8. The bright polyester melt conveying temperature is 279°C, and the temperature of the spinning box 1 is 290°C.

[0026] The temperature of the two heat rollers in the process of the double roller heating 4 is between 90°C.

[0027] The temperature of the two hot rollers in the process of the double roller setting 5 is betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com