Improved pile foundation vertical bearing capacity test reverse self-balanced method and testing device

An improved bearing capacity technology, applied in the engineering field, can solve problems such as failure of test piles, inability to be used in engineering piles, failure to recycle and reuse, etc., and achieve the effect of strong practicality and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, the present invention will be further described in detail in conjunction with the accompanying drawings and specific implementation, so as to facilitate a clear understanding of the present invention, but they do not constitute a limitation to the present invention.

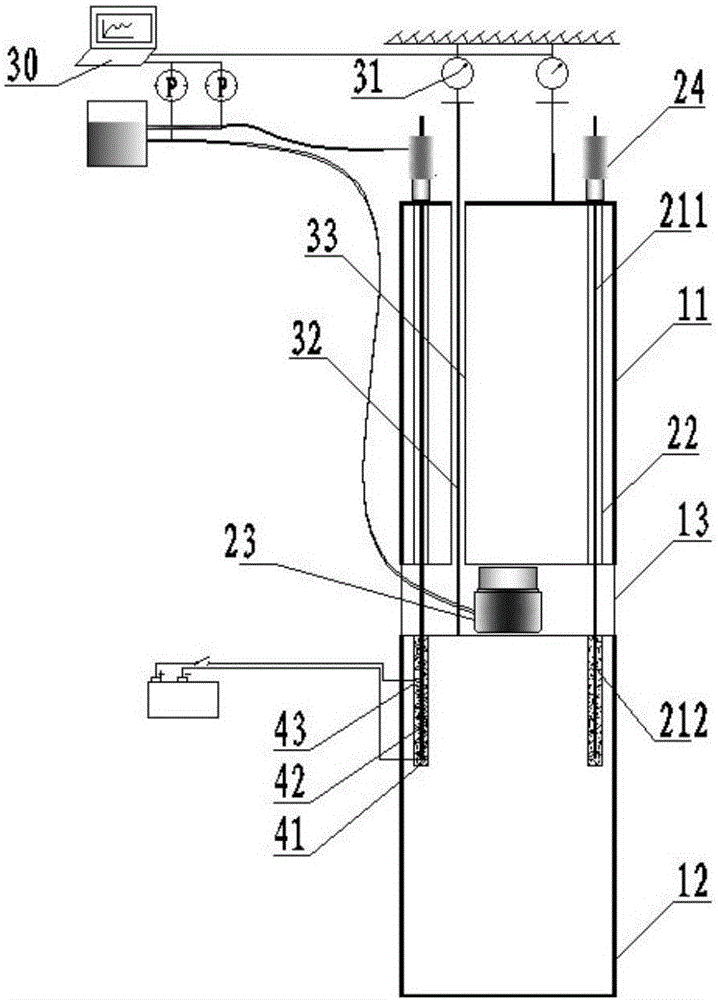

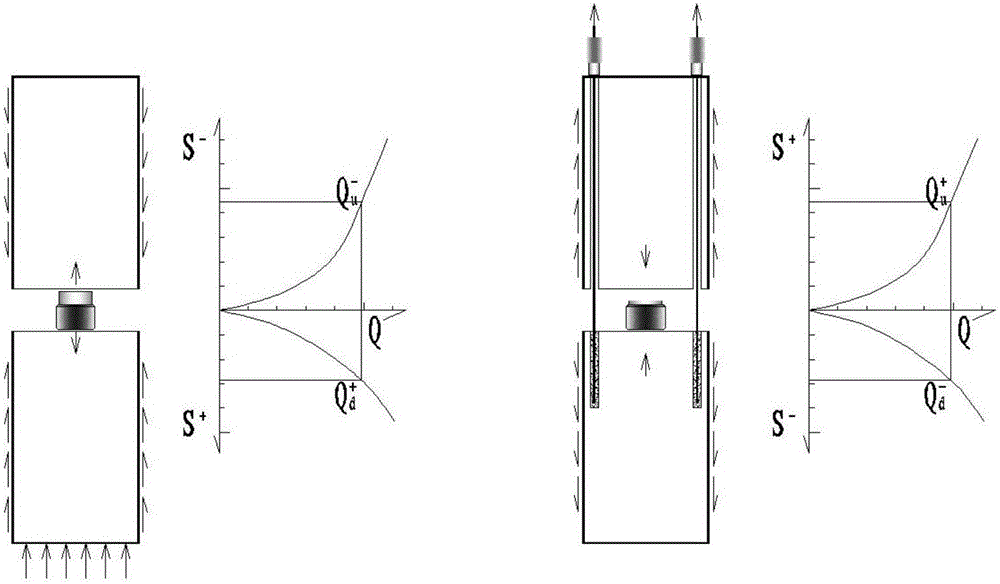

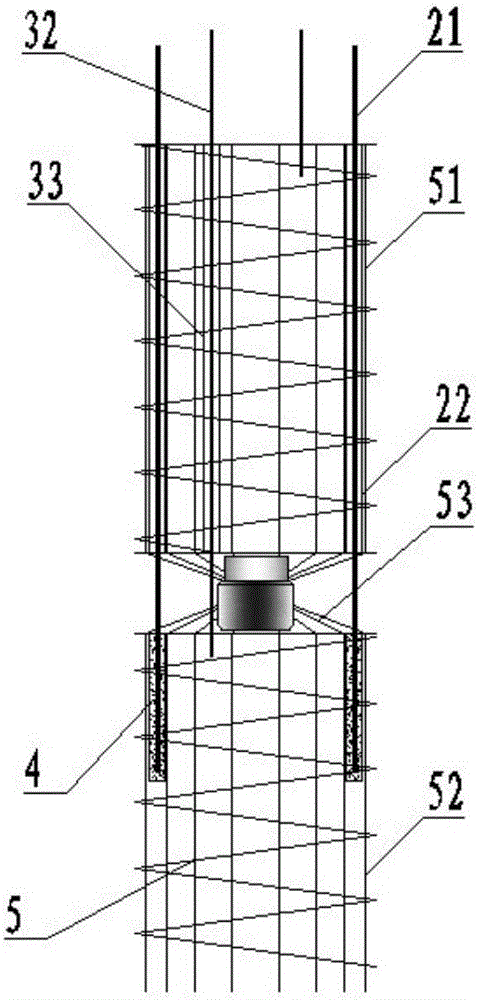

[0037] The invention provides an improved pile foundation vertical bearing capacity test reverse self-balancing device, the test device mainly consists of a pile foundation, a test loading device and a deformation monitoring device. Described pile foundation is a reinforced concrete structure, is divided into upper section pile 11, lower section pile 12 and middle section pile 13, and middle section pile 13 displacement load balance points, is equipped with the necessary load box 23 of self-balancing method, and upper section pile 11, lower section The pile 12 is poured first, and after the load test of the pile foundation is completed, the isolation pipe 22 is used for grouting, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com