Heading face fore support capable of achieving synchronous anchoring and protecting

A technology of advanced support and driving surface, which is applied in the direction of mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of insufficient support effect, low work efficiency, and low safety, and achieve stable support effect and save energy. Good effect of space and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

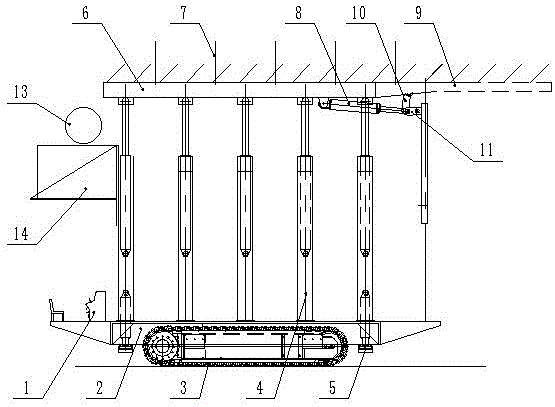

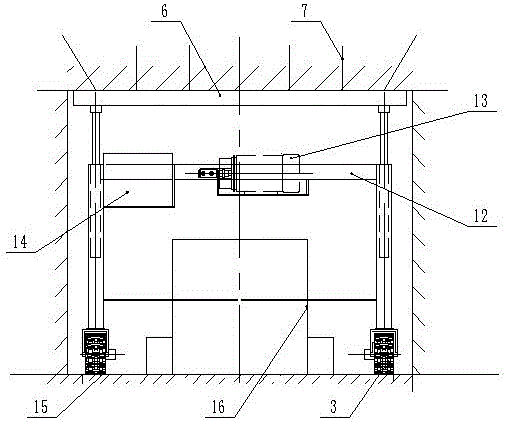

[0019] like figure 1 , figure 2 As shown, the advance support of the excavation surface that can be anchored and protected synchronously includes an operation console 1, a frame 2, a first running part 3, a second running part 15, a top beam 6, a plurality of telescopic top beam columns 4, a plurality of lower Support oil cylinder 5, top beam 6, front probe beam 9, motor 13, hydraulic oil tank 14 and foldable anchor protection platform 16. A plurality of top beam columns 4 supporting the top beam 6 are provided, and connecting beams 12 are provided between every two top beam columns 4 opposite to each other on both sides of the frame 2, and a connection beam 12 is provided near the top of the console 1. The beam 12 is provided with a hydraulic oil tank 14 and a motor 13. The foldable anchor protection platform 16 is arranged on the top of the frame 2 and between the top beam columns 4 on both sides. The first running part 3 and the second running part 15 are symmetrical It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com