Crow plate type hydraulic support loading device

A hydraulic support and plate type technology, applied in the field of frame transport vehicles, can solve the problems of long pulling and loading stroke, large swing of the support, difficult front-end hooking, etc., to achieve the effect of easy pulling, safe and stable loading process, and preventing chain decoupling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

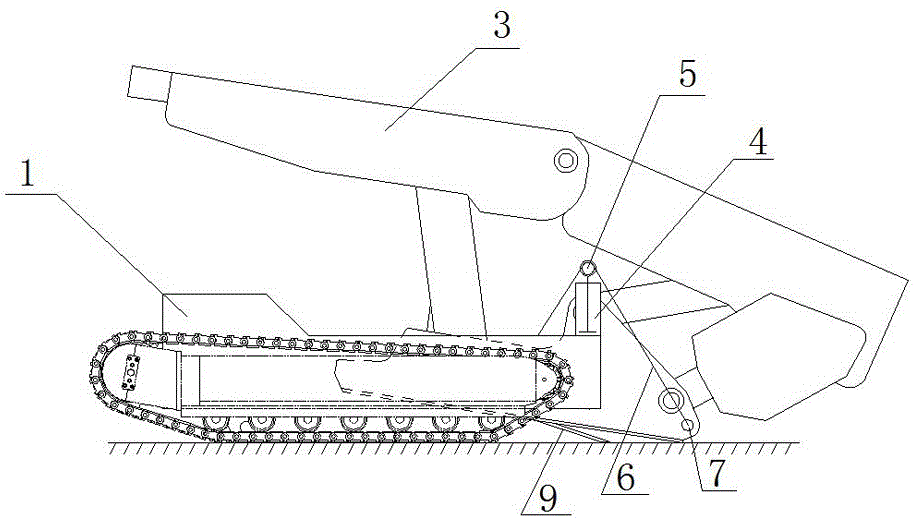

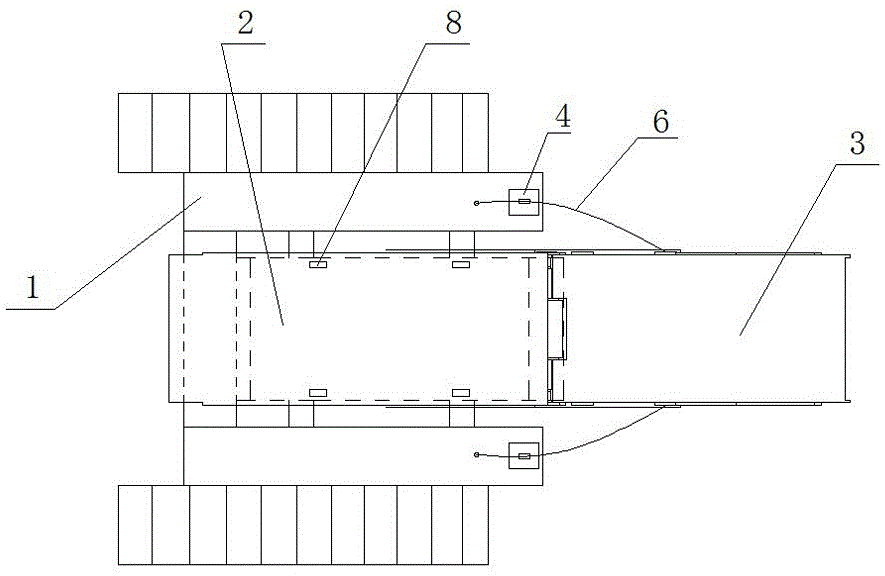

[0017] Such as figure 1 and figure 2 As shown, the skid plate type hydraulic support loading device of the present invention includes a U-shaped frame 1 and a support supporting plate 2, and the support supporting plate 2 is located between the two side walls of the U-shaped frame 1, and on the support supporting plate 2 The support 3 to be mounted on the car is set, and the upper surfaces of the two side walls of the U-shaped frame 1 are respectively provided with a traction cylinder 4, and the traction cylinder 4 is vertically arranged on the open end of the side wall of the U-shaped frame 1, and the traction cylinder 4 is vertically arranged on the open end of the side wall of the U-shaped frame 1. The movable end of the oil cylinder 4 is set upward, and the movable ends of the two traction cylinders 4 are respectively provided with a pulley 5, and the two pulleys 5 are respectively wound with a steel wire rope 6 for pulling the support 3, and one end of the steel wire rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com