Ultrasonic monitoring device and method for nanoparticle agglomeration of non-Newtonian base fluid fluid

A nanoparticle and ultrasonic monitoring technology, which is applied in the fields of nanoparticle analysis, measuring devices, particle and sedimentation analysis, etc., can solve problems such as not suitable for online measurement, limited penetration ability, measurement error, etc., and achieve rapid and accurate measurement of particle size distribution , good penetration, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

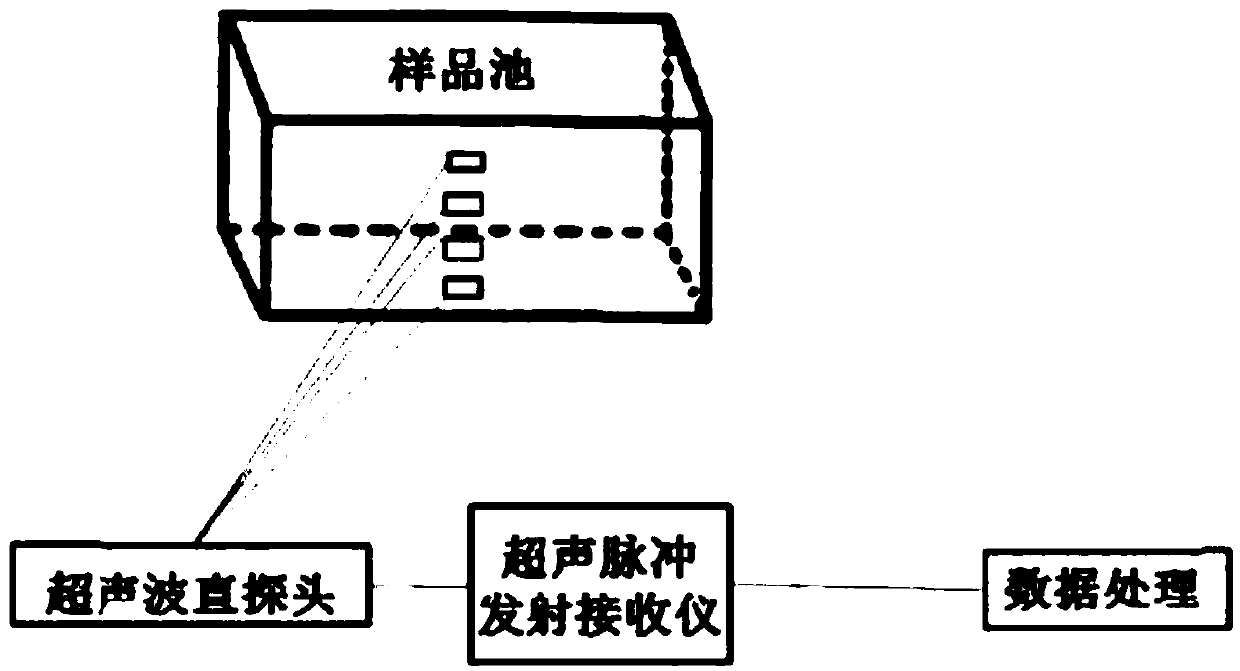

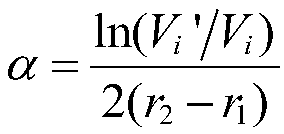

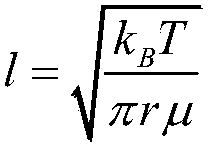

[0033] The invention provides a non-Newtonian base liquid fluid nanoparticle agglomeration ultrasonic monitoring method, which mainly uses the sound attenuation spectrum when the ultrasonic wave propagates in the nanoparticle two-phase medium, and can be obtained by comparing the sound attenuation spectrum with the mathematical model and inversion calculation The particle size distribution and concentration distribution of the particle phase can monitor the influence of the agglomeration and precipitation of nanoparticles in the production and life practice on the mass transfer phenomenon of non-Newtonian fluids in the flowing state. When the nanoparticles are suspended, their suspension stability is determined. The decisive factor for the quantity and quantity is the comprehensive effect of the interaction force between the nanoparticles and between the nanoparticles and the base fluid. At this point, the nano-solution is injected into the fluid delivery tank, and the nano-par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com