Static Scheduling Optimization System for Discrete Manufacturing Workshop Based on Teaching and Learning Algorithm

A discrete manufacturing workshop, static scheduling technology, applied in control/regulation systems, general control systems, program control, etc., can solve problems such as unreasonable parts production arrangements, long machine tool standby time, etc., to achieve fast convergence speed and optimization. Strong ability and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

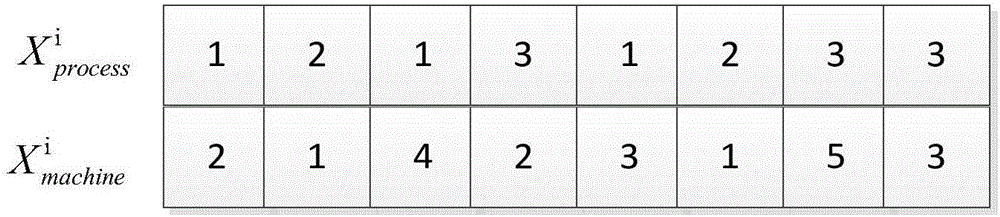

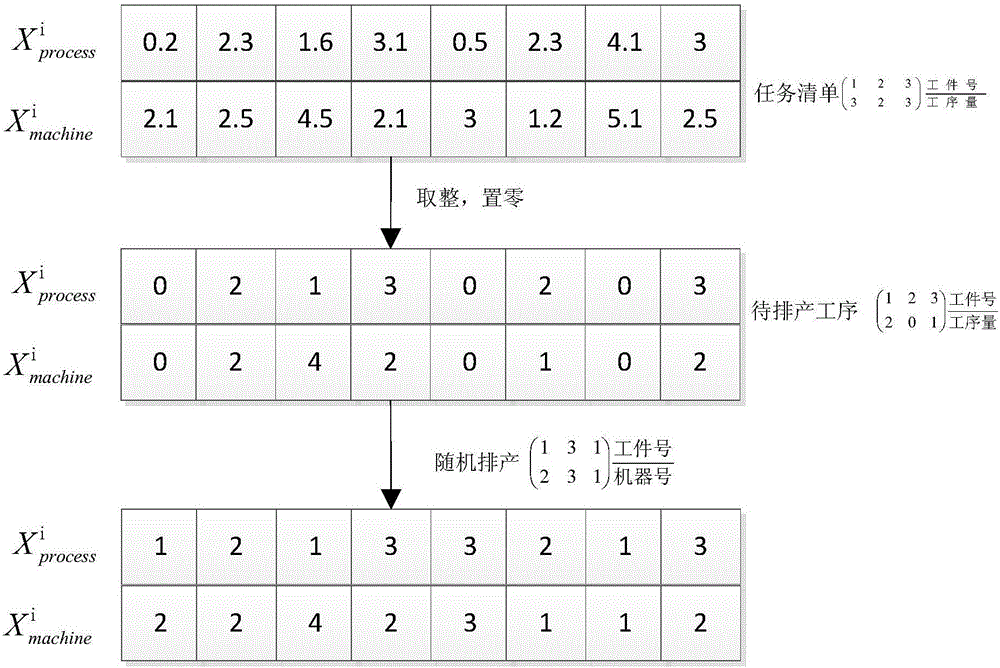

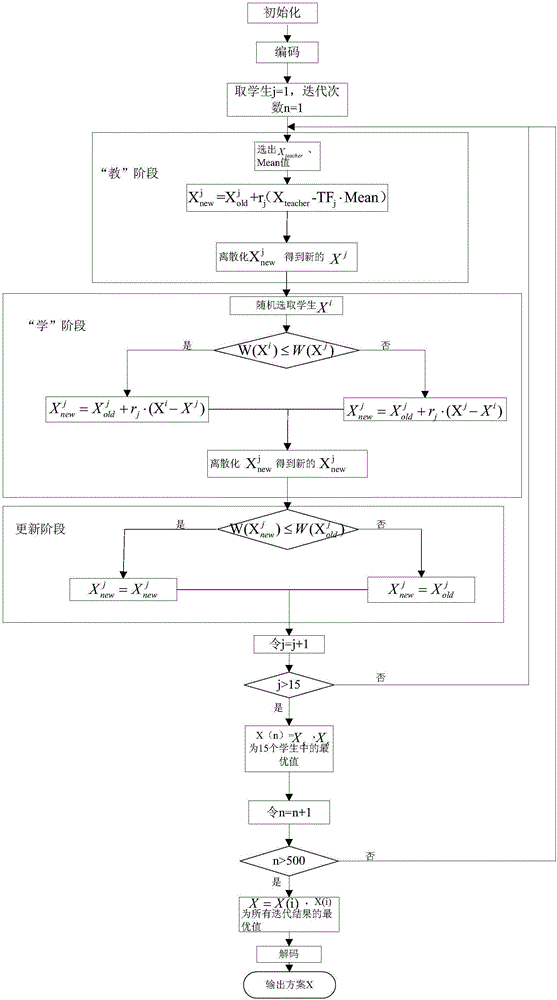

Method used

Image

Examples

Embodiment example

[0104] Step 1: Build a data server and communicate with the workshop machine tool system to obtain the processing time (including standby time) of a single process of a single workpiece processed by the machine tool dead time cutting time ) and processing energy consumption details (including standby energy consumption No-load energy consumption Cutting energy consumption ), where i represents the machine tool, j represents the workpiece, k represents the specific process, d represents standby, o represents no-load, and q represents cutting, so the time taken by machine tool i to process the kth process of workpiece j and energy consumption In the data server, the acquired data is analyzed and processed, and the energy consumption information is integrated:

[0105] The time for the machine tool to process workpiece j:

[0106] The energy consumption of the machine tool to process workpiece j:

[0107] Among them, t xy Indicates the time taken by the yth pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com