Method and system for identifying varieties of piled and taken raw materials in stockyard

An identification method and identification system technology, which is applied in the field of industrial automation and can solve problems such as mixed-quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in conjunction with the accompanying drawings.

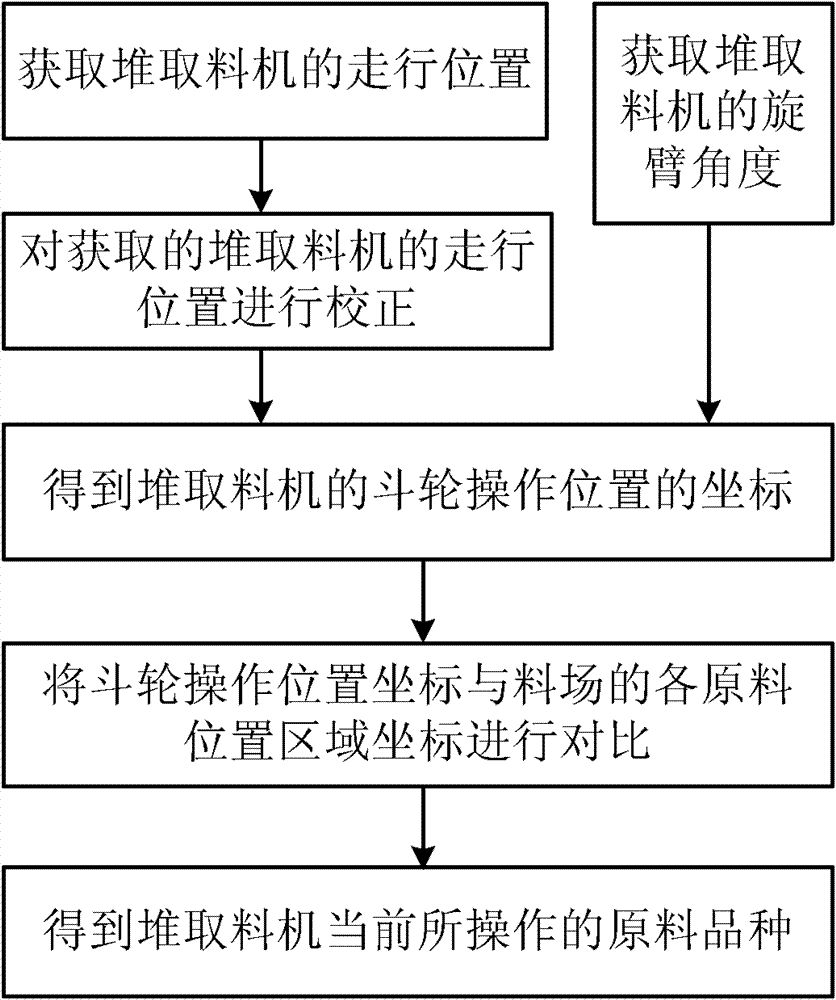

[0032] figure 1 It is a preferred structural flow chart of the identification method for stockyard stacking and reclaiming raw material varieties of the present invention. The method first obtains the running position of the stacker-reclaimer and the angle of the arm of the stacker-reclaimer, and performs an operation on the obtained running position of the stacker-reclaimer. Correction; then according to the obtained stacker-reclaimer walking position and arm angle, as well as the stacker-reclaimer arm length and stockyard length, the stacker-reclaimer is located at the arm end of the bucket wheel operating position coordinates; then The operating position coordinates of the bucket wheel are compared with the coordinates of each raw material position area in the stockyard to obtain the type of raw material currently operated by the stacker-reclaimer.

[0033] Specific steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com