A control method for a superimposed logistics delivery system

A conveying system and control method technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of low conveying control efficiency, etc., so as to improve the utilization rate of equipment, speed up the conveying speed, and reduce the power and energy. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

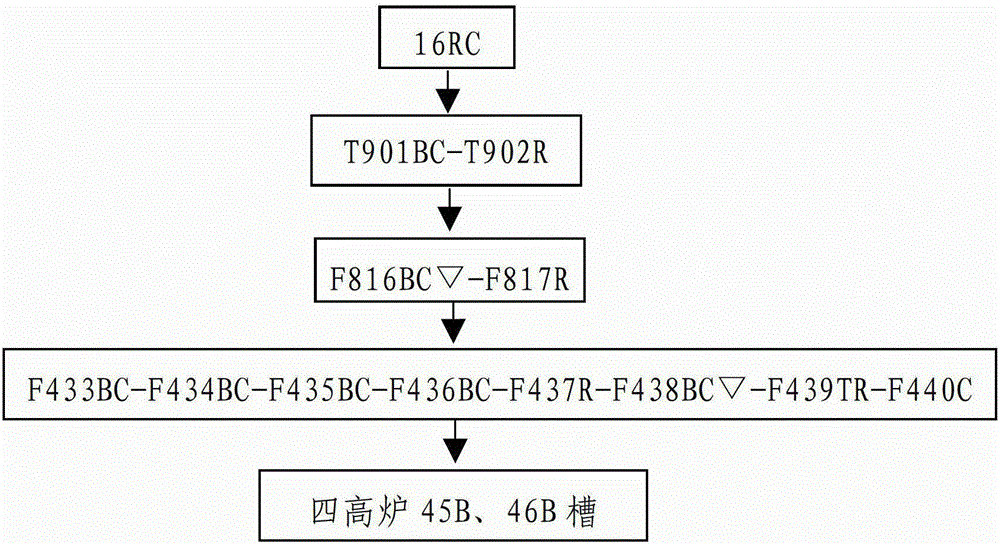

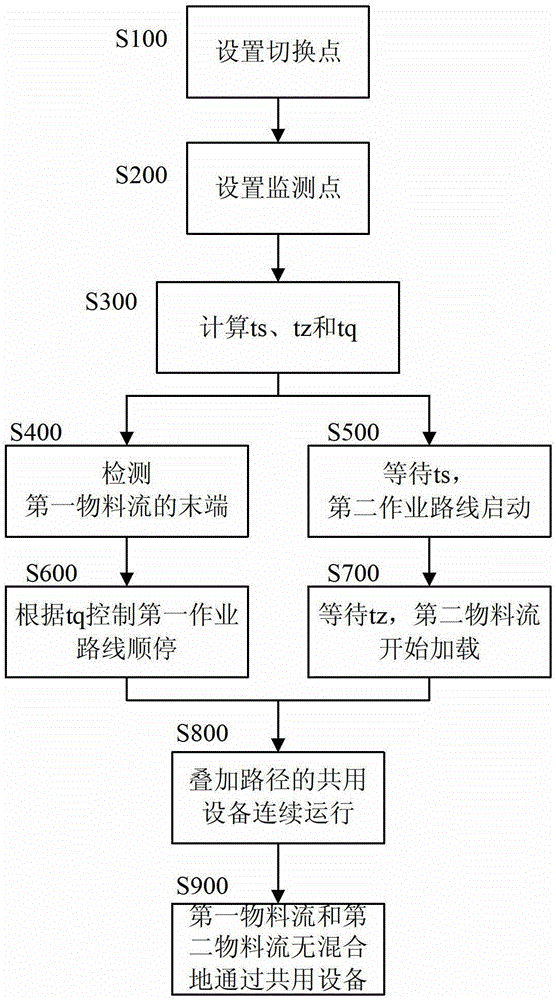

[0092] The first embodiment is two operating routes with the same starting point and the same end point. These two operating routes transport different materials from the same starting point to the same end point, and unload them into different material tanks through unloading trucks: the first operating route is as follows: figure 1 As shown, from the No. 16 reclaimer 16RC to the B-side chute 45B and 46B of the fourth blast furnace, the OHP concentrate ore is transported; the second operation route is as Figure 4 As shown, the ONE concentrate ore is transported from the No. 16 reclaimer 16RC to the B-side hopper 50B of the No. 4 blast furnace. from figure 1 and Figure 4 From the two operation routes shown, it can be seen that the starting point and end point of the two are the same, and the only difference is that the types of materials to be transported and the ore tanks into which they are fed are different. According to the existing operation method, after the OHP conc...

Embodiment 2

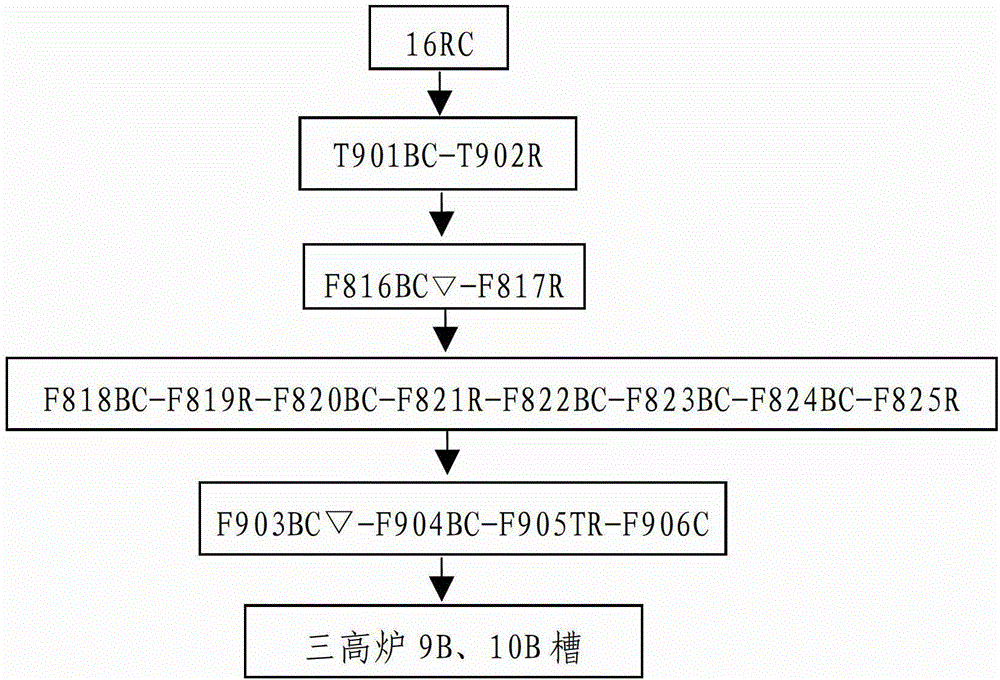

[0099] The second embodiment of the control method of the superimposed logistics conveying system of the present invention is two operating routes with the same starting point and different end points, and the first operating route is still figure 1 As shown in the operation route, the OHP concentrate ore is transported from the No. 16 reclaimer 16RC to the B-side chute 45B and 46B of the fourth blast furnace; the second operation route is as follows: figure 2 As shown, the No. 16 reclaimer 16RC transports ONE concentrate lump ore to the B-side chute 9B and 10B of the No. 3 blast furnace. The No. 3 blast furnace ore slot is distributed as follows Image 6 shown. According to the existing operation method, after the OHP concentrate ore collection is completed, the whole system starts to stop smoothly. The conveying distance (sum of horizontal machine length) ΣLi of each equipment from T901BC to F440C is 1660.8 meters, and the operating speed V is 125 meters / minute, all equi...

Embodiment 3

[0106] The third embodiment of the control method of the superimposed logistics conveying system of the present invention is two operating routes with different starting points and the same end point, and the first operating route is still figure 1 As shown in the operation route, the OHP concentrate ore is transported from the No. 16 reclaimer 16RC to the B-side chute 45B and 46B of the fourth blast furnace; the second operation route is as follows: Figure 10 As shown, the ONE concentrated lump ore is transported from the No. 15 reclaimer 15RC to the B-side chute 50B of the No. 4 blast furnace. These two operating routes transport different materials from different starting points to the same end point, and unload them into different material tanks by unloading trucks. According to the existing operation method, after the OHP concentrate ore collection is completed, the whole system starts to stop smoothly. The conveying distance (sum of horizontal machine length) ΣLi of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com