High-voltage wire remote monitoring system

A remote monitoring system, high-voltage wire technology, applied in the direction of electrical components, circuit devices, overhead lines/cable equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

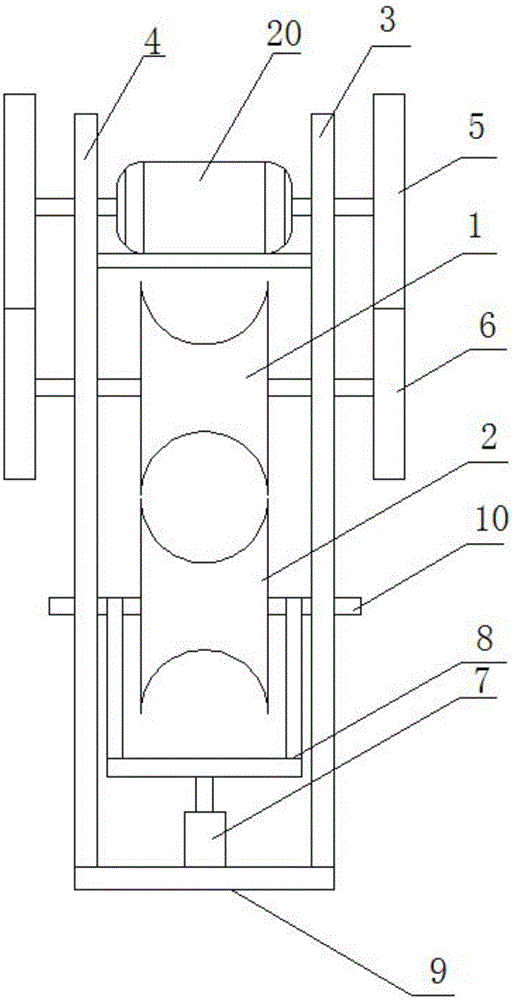

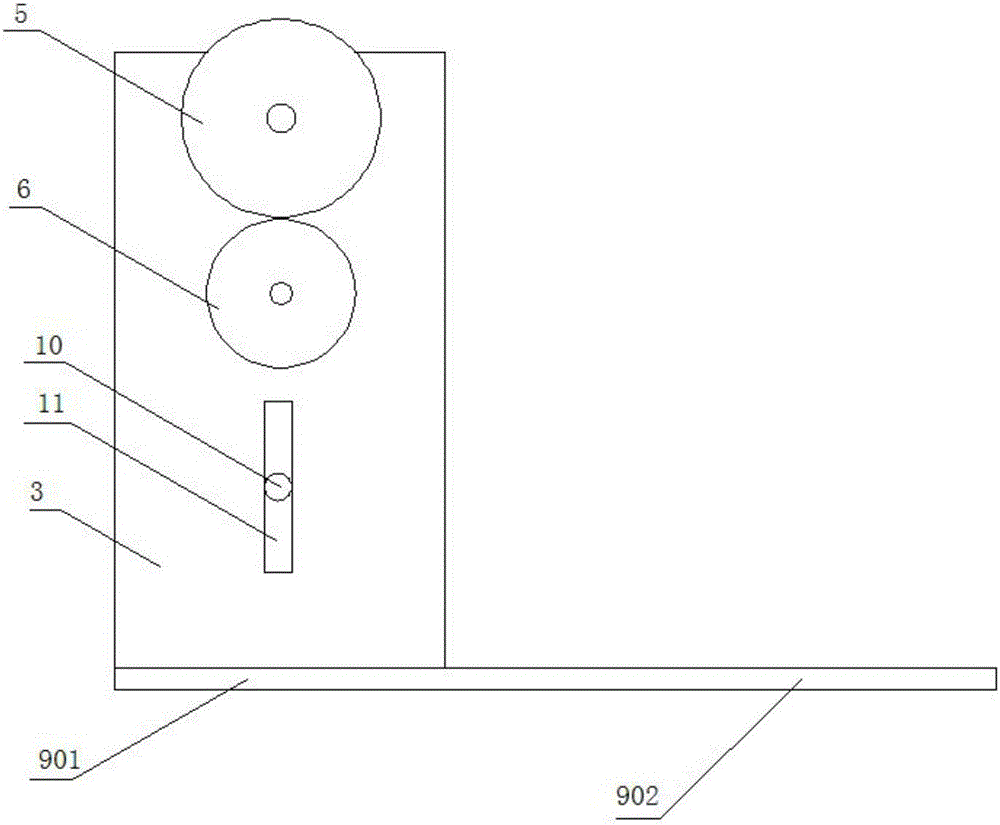

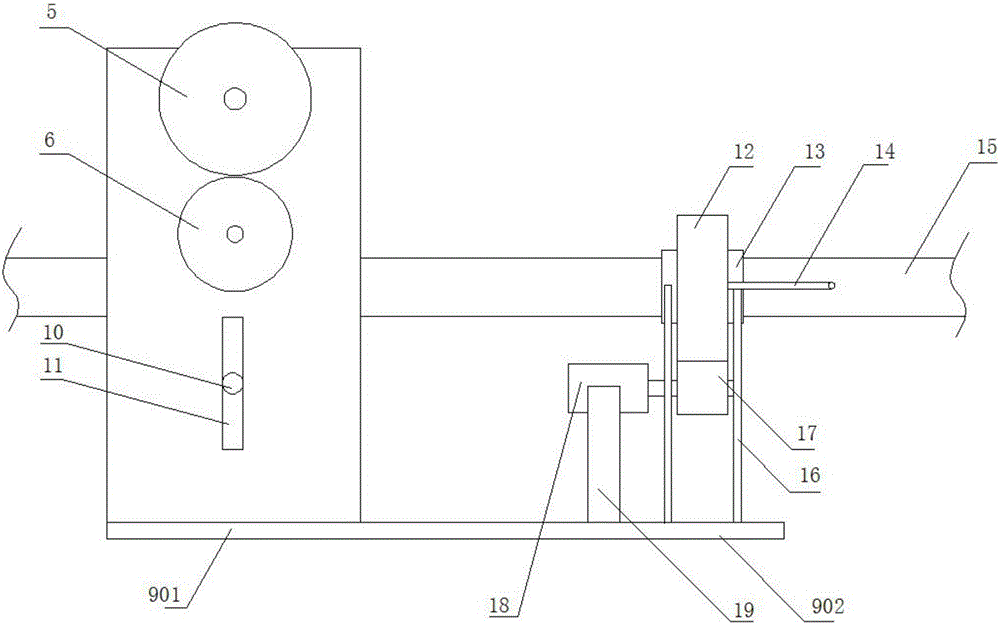

[0042] In this embodiment 1, if figure 1 , the running mechanism of the present invention is symmetrically arranged left and right, and the right side is used as an example for illustration. The traveling mechanism includes a roller set, which is composed of a first roller 1 and a second roller 2, and a gap is formed between them, and the gap is used to pass through high-voltage electric wires. The purpose is to use the first roller 1 and the second roller 2 to Squeeze the high-voltage wires, hang and fix the traveling mechanism as a whole on the high-voltage wires.

[0043] In this embodiment, in order to further optimize the extrusion and fixing effects of the first roller 1 and the second roller 2 on the high-voltage wires, see figure 1 , arc-shaped grooves are set on the extrusion peripheral surfaces of the first roller 1 and the second roller 2, so that the high-voltage wires can be partially embedded in the arc-shaped grooves, and the first roller 1 and the second rolle...

Embodiment 2

[0053] Compared with Embodiment 1, this embodiment differs in that: in this embodiment, the central control device and the remote monitoring center adopt CDMA mode to realize data interaction. In addition, the transmission between the two main transmission wheels of the biaxial motor and the two corresponding secondary transmission wheels of the first roller is through the track structure; the transmission between the runner 17 of the second power unit and the outer sleeve 12 is also through the track structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com