Metal zipper double tooth selection mold

A metal zipper, bilateral technology, applied in sliding fastener components, clothing, applications, etc., can solve the problems of deviation in the number of teeth, affect product quality, low work efficiency, etc., achieve accurate tooth selection, save labor costs, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure and working principle of the metal zipper bilateral tooth selection mold involved in the present invention will be further elaborated below with specific examples:

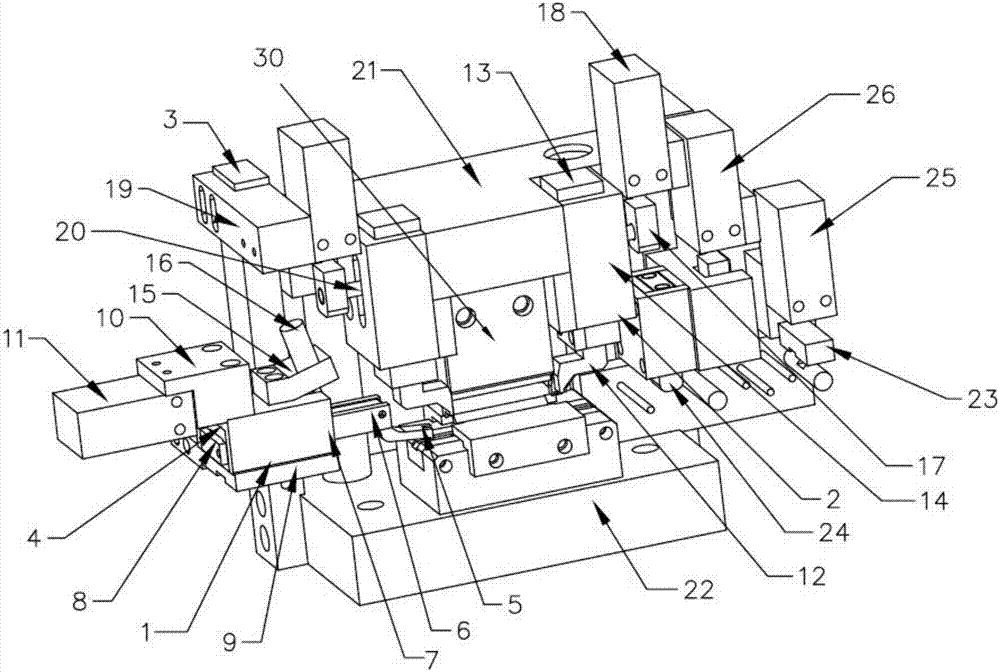

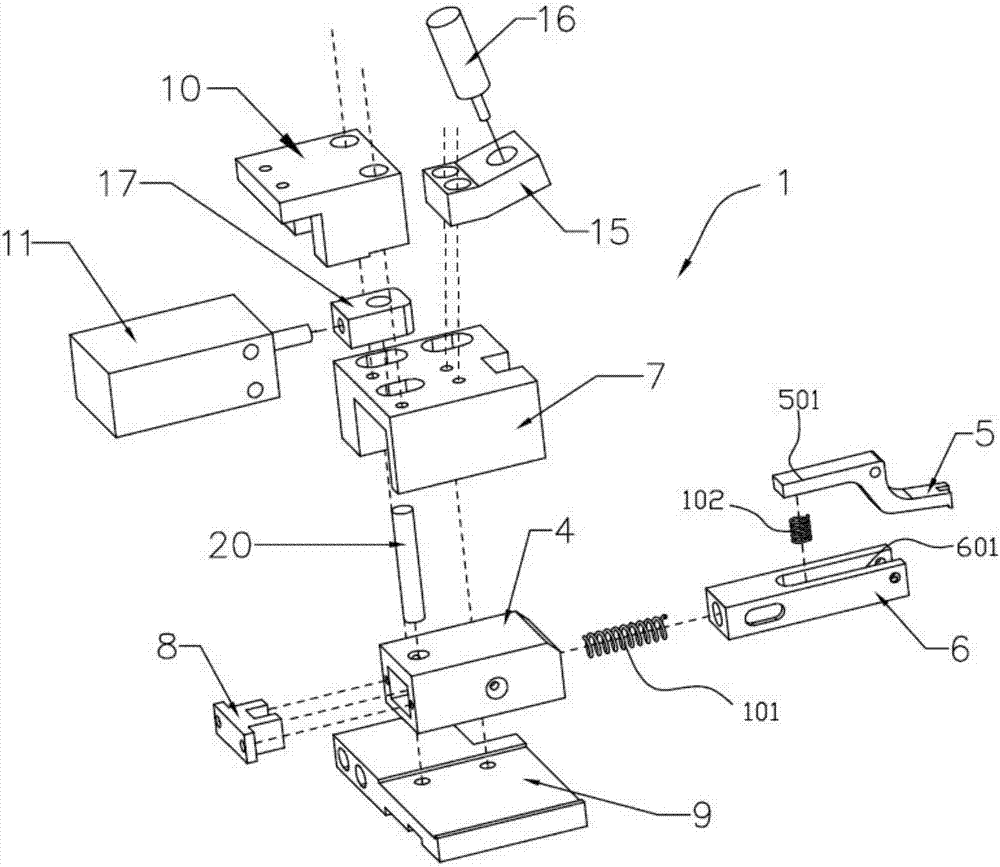

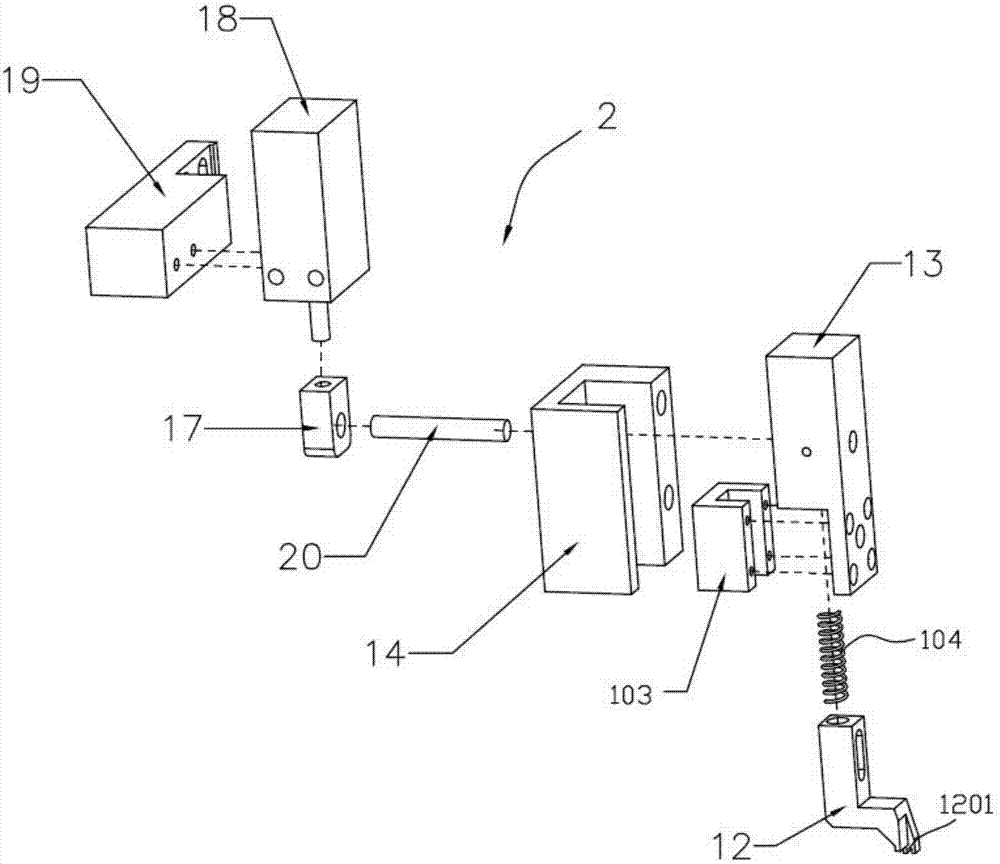

[0025] see figure 1 As shown, the present embodiment provides a metal zipper bilateral tooth selection mold, which is used for tooth selection and positioning of the chain elements on the left and right sides of the metal zipper. It includes an upper mold frame 21, a lower mold frame 22 and a 21 and the tooth punching device 30 between the lower mold frame 22, the metal zipper bilateral tooth selection mold also includes a belt pressing device 23, a tooth pressing device 24, a tooth pushing device 1 and a tooth selection device 2 symmetrically arranged on the left and right sides , the tooth selection device 2 includes a tooth selection device 12 for positioning the teeth at a selected distance from the chain elements on one side, and the tooth selection device 12 has a card that is adapted to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com