Machining process for bent sleeve

A processing technology and a technology of bending sleeves, which are applied in the field of parts processing, can solve problems such as unfavorable production, complicated processing steps, and high defective rate, and achieve the effects of improving precision, reducing production costs, and reducing defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

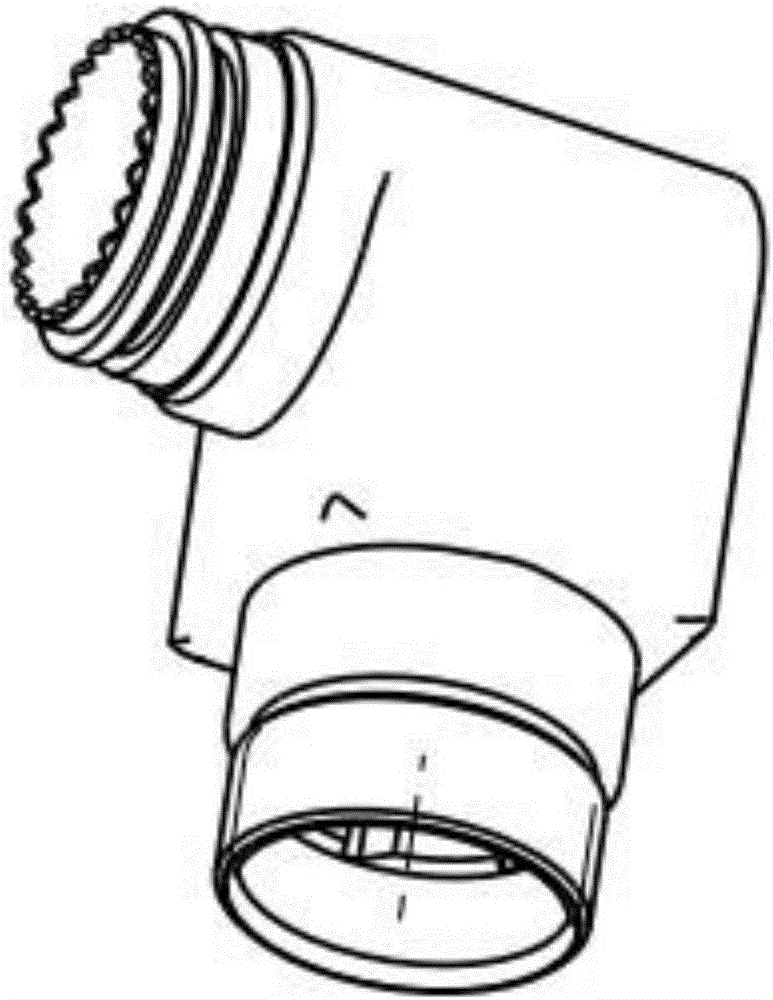

[0012] as attached figure 1 Shown is a processing technology of a connecting rod according to the present invention, embodiment 1: a processing technology of a curved sleeve, the first step: select a φ60mm bar, and use a turning-milling compound machining center to process the shape of the material; Step 2: Machining with a turning-milling compound machining center, processing the cylinder at one end of the bar and processing the other end of the bar into a cube; Step 3: Boring a round hole at the end of the cylinder, and boring to the bottom of the cylinder end; Step 1: Turn the outer circle of the cylinder end and turn the two-stage outer circle; Step 5: Use a tool to grind the tooth-shaped groove inside the two-stage outer circle; Step 6: Use the fixture to reverse the workpiece and process the square end ;The seventh step: process the outer circle of the body end, and turn the multi-layer stepped outer circle; the eighth step: bore the body end, and the boring depth reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com