Floating workbench device with steady structure

A worktable, floating technology, applied in the direction of manufacturing tools, large fixed members, metal processing equipment, etc., can solve the problems of affecting the transmission and adjustment accuracy, increasing the overall weight of the workbench, and difficult to form position adjustment, so as to improve the overall movement The effect of adjustment accuracy, reliable device structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

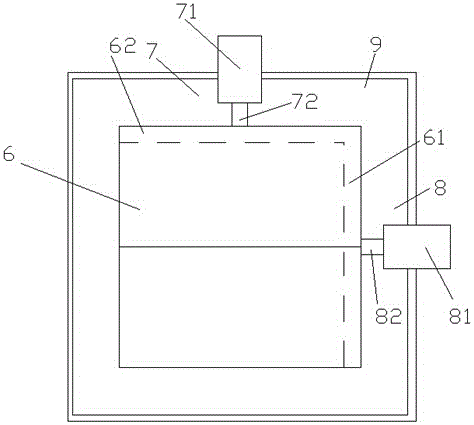

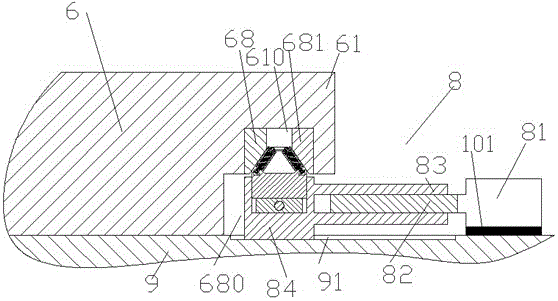

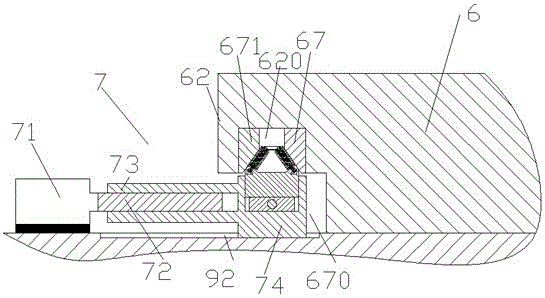

[0014] Combine below Figure 1-4 The present invention will be described in detail.

[0015] According to an embodiment of the present invention, a structurally stable floating workbench device includes a base 9 and a workbench 6 capable of floating and moving on the plane of the base 9, and the workbench 6 is provided with a horizontal axis drive device 8 and the vertical axis driving device 7, the horizontal axis driving device 8 includes a horizontal axis motor 81 coupled with the horizontal axis screw 82, and the vertical axis driving device 7 includes a vertical axis motor 71 coupled with the vertical axis screw 72, wherein , the right side of the workbench 6 is provided with a longitudinally extending protruding portion 61 so as to form a horizontal driving suspension portion 680 between the longitudinally extending protruding portion 61 and the base 9, for placing and threading on the The horizontal push-pull assembly 84 fixedly connected to the horizontal shaft screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com