GIS shell flange butt joint tool

A technology for cylinder flanges and tooling, which is applied to workpiece clamping devices, manufacturing tools, etc., and can solve problems such as damage to internal parts of the cylinder and uneven force on the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

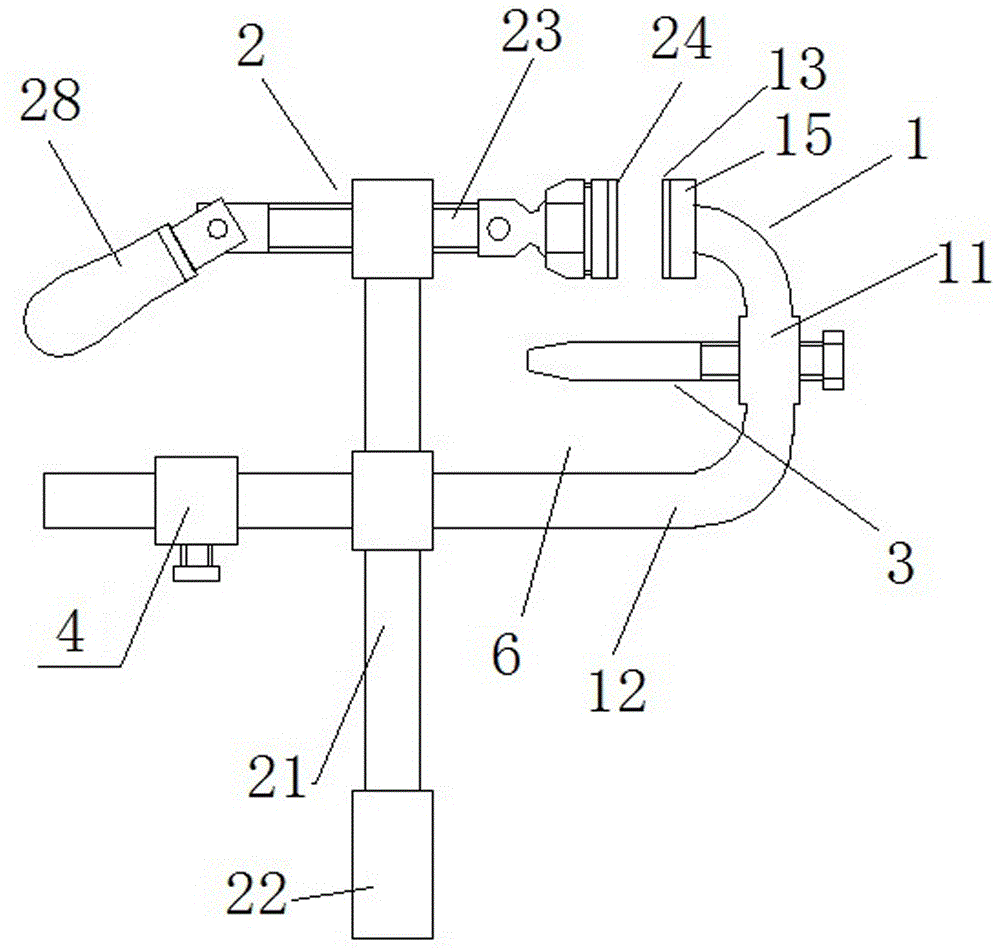

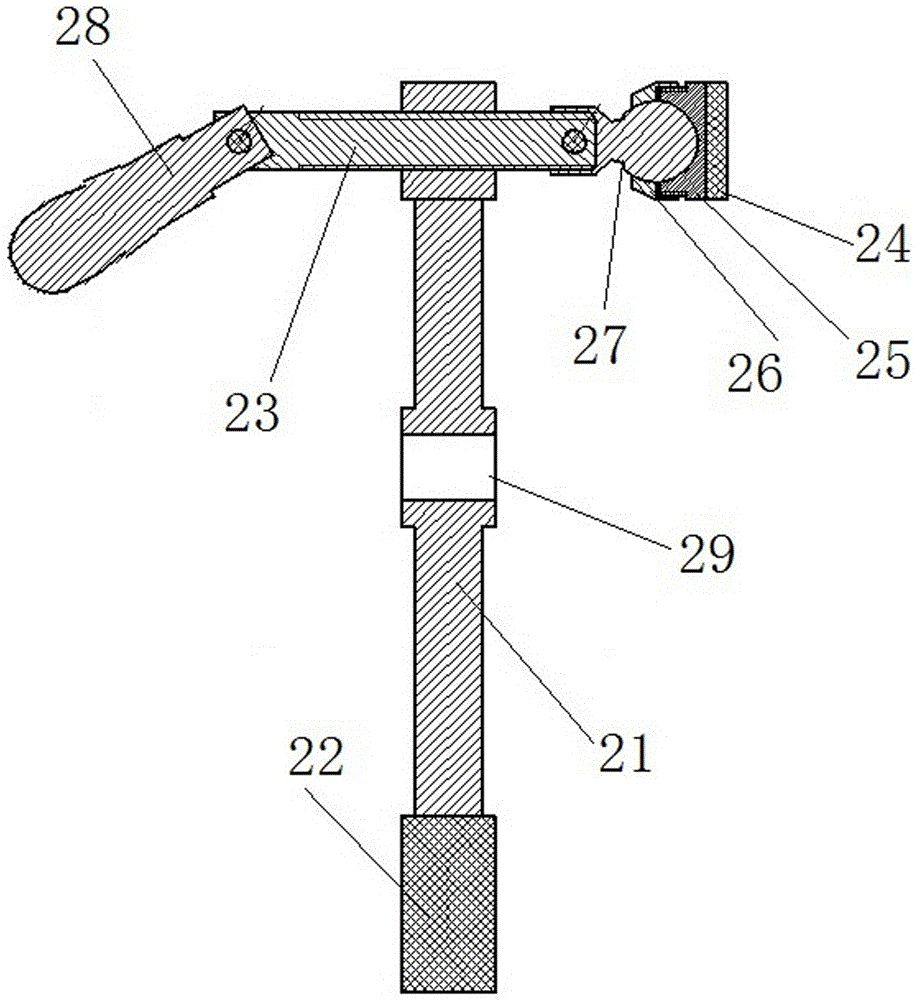

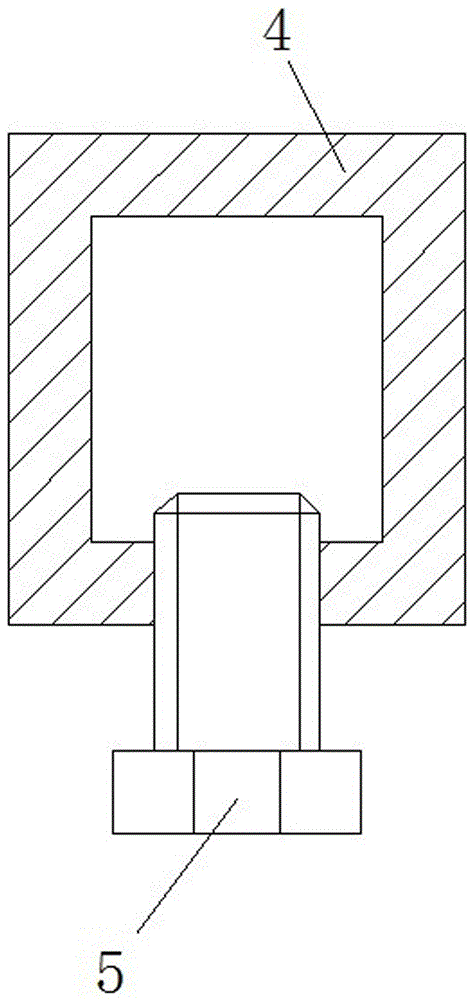

[0020] The embodiment of the GIS cylinder flange butting tooling of the present invention: Figure 1-5 As shown, the GIS cylinder flange docking tool includes a fixed clamp 1 and a movable clamp 2. The fixed clamp 1 and the movable clamp 2 can move relatively before clamping the cylinder flange. The fixed clamping member 1 is provided with a clamping part for clamping the flange of the first cylinder, the fixed clamping part includes a vertical section 11, and a clamping block is provided on the vertical section, and the clamping part is formed by the clamping block , The clamping block is provided with a clamping surface for buckling with the flange surface of the first cylinder flange. The vertical section and the clamping block are transitionally connected by a circular arc section. The clamping block is composed of an installation base block 15 and a fixed spacer block 13. The fixed spacer block 13 is made of plastic material to prevent bumps and scratches between metal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com