Roller

A technology of rollers and cylinders, which is applied in the field of paint painting tools, can solve the problems of leakage of paint slurry, insufficient uniformity of paint slurry, low reliability, etc., and achieve reasonable structure, prevent leakage of paint slurry, and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

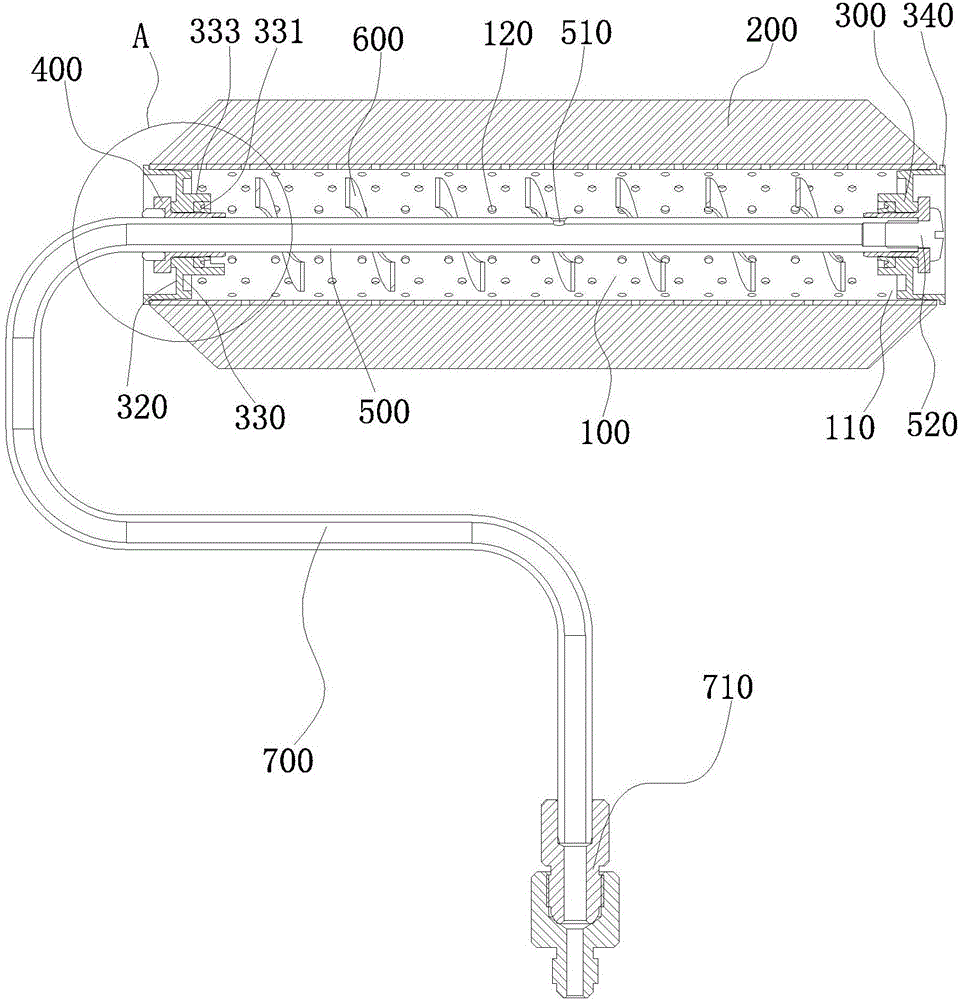

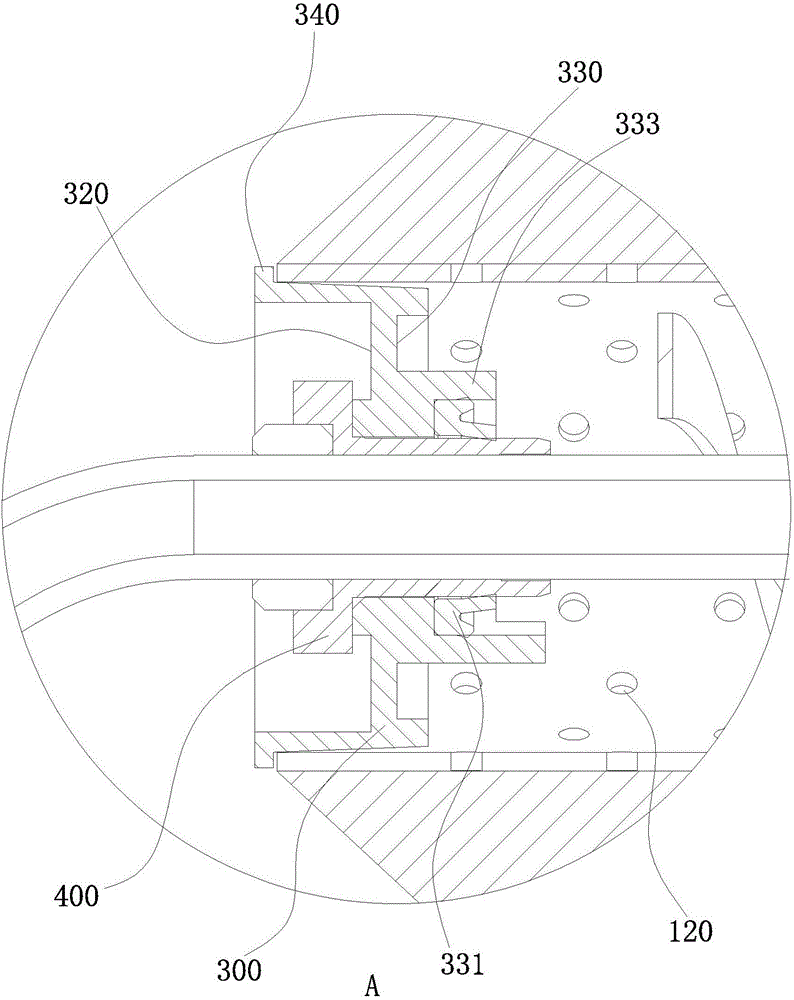

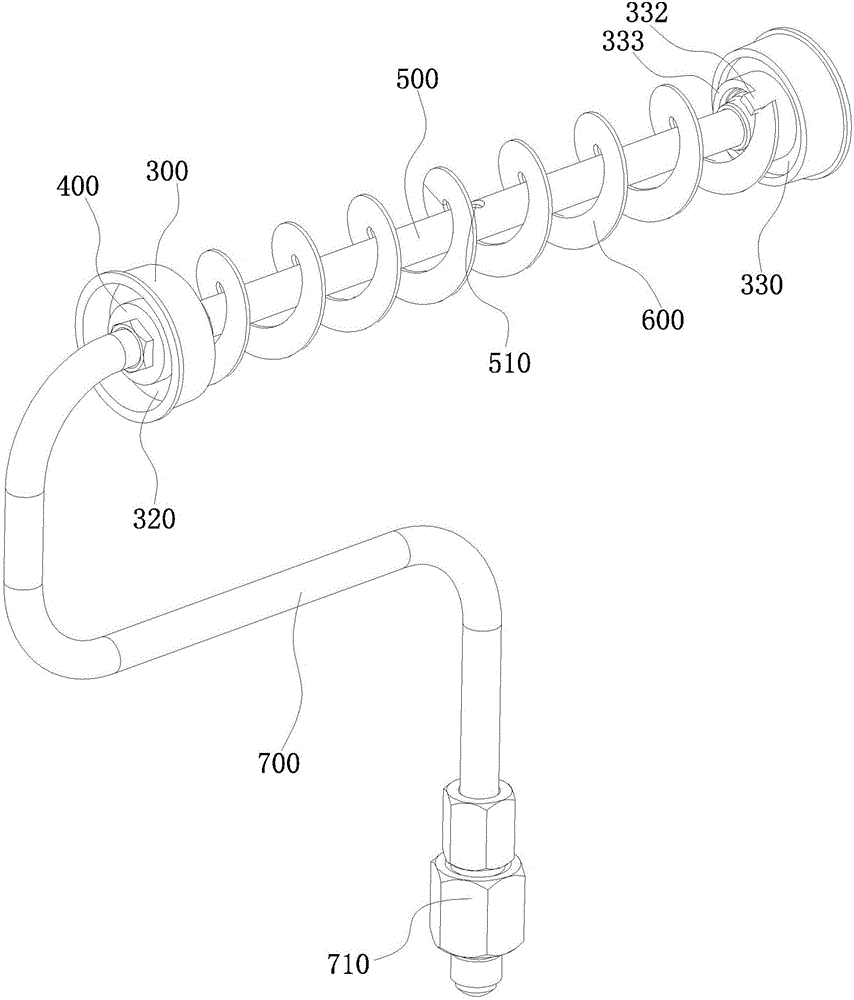

[0037] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a roller includes: a cylinder body 100, a brush cover 200, a roller support seat 300, a pipe cover 400, a first feeding pipe 500, a spiral blade 600 and a second feeding pipe 700. The above-mentioned roller is different from the traditional The difference between the roller brush or the roller is that it does not need to keep dipping the paint, and then brush the wall, and the paint can be injected into the cylinder body 100, and then infiltrated from the cylinder body 100 to the brush cover 200, so as to prevent dipping. and when it is brushed on the wall, the inner wall of the barrel 100 and the helical blade 600 produce relative motion, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com