Screwdriver capable of clamping screws made of any material

A screwdriver and material technology, applied in screwdrivers, wrenches, wrenches, etc., can solve problems such as troublesome screwdriver operation, and achieve the effects of simple structure, guaranteed symmetry, and labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

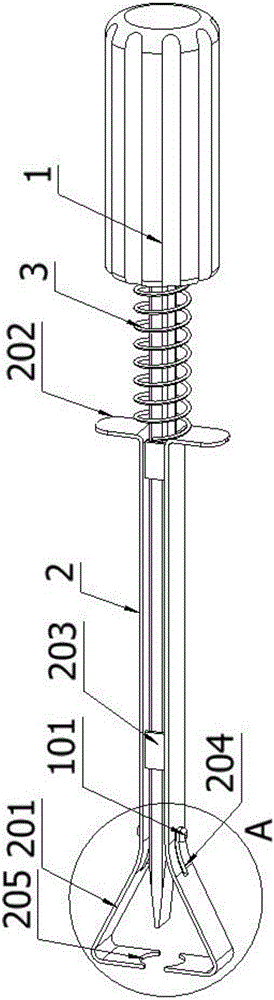

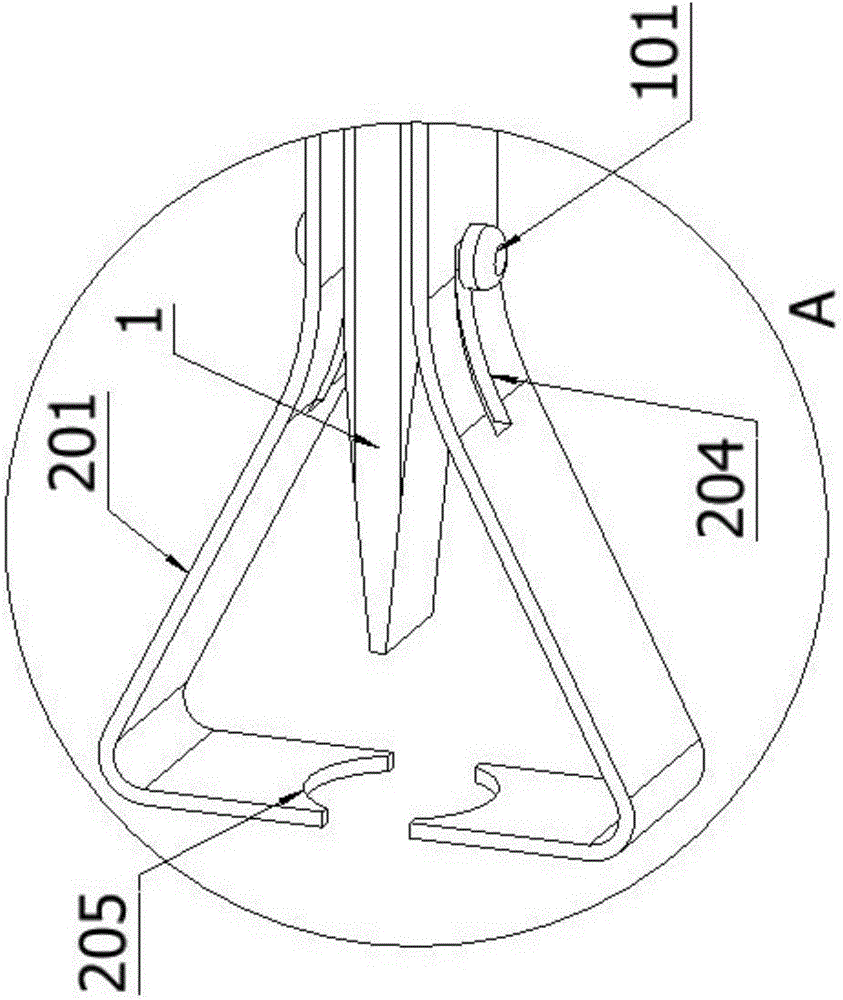

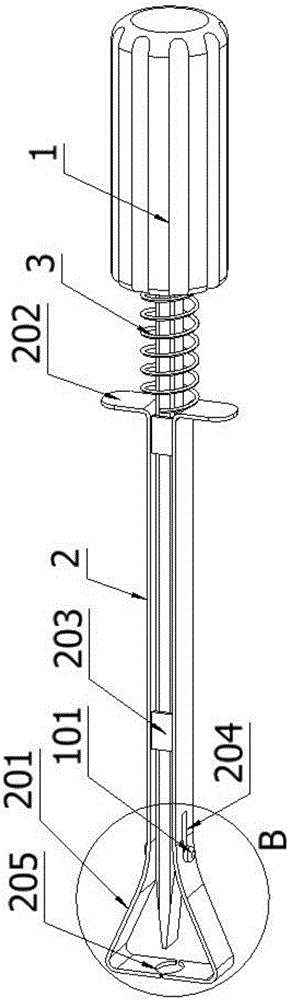

[0027] Figure 1 to Figure 4 It is an embodiment of the present invention. As shown in the figure, a screwdriver capable of clamping screws of any material includes a screwdriver 1 and a sleeve clip 2. The sleeve clip 2 includes two symmetrical clips 201, and the front ends of the clips 201 are openings. shape, the front end of clip 201 is provided with bending chuck 205, and bending chuck 205 is provided with arc opening; A handle 202 is provided at the end of the corresponding nail 101 and clip 201 , and the two clips 201 are connected by at least one pair of connecting plates 203 . The pressure nail 101 acts on the opening-shaped bend of the clip 201, and the forward and backward movement of the collet 2 is controlled by the handle 202. When the collet 2 is pushed forward, the bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com