Paper tray

A paper plate and paper corner technology, which is applied in the field of utensil production, can solve the problems of unsatisfactory inner curing, easy deformation of inner folded parts, and weak locking function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

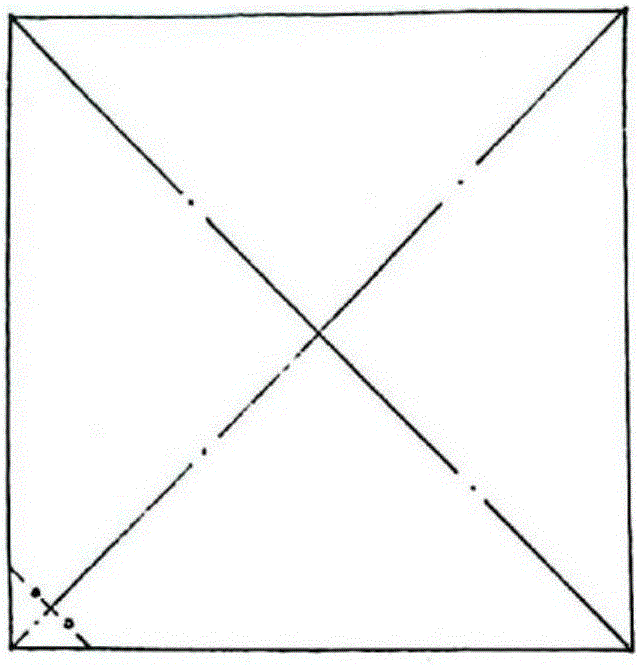

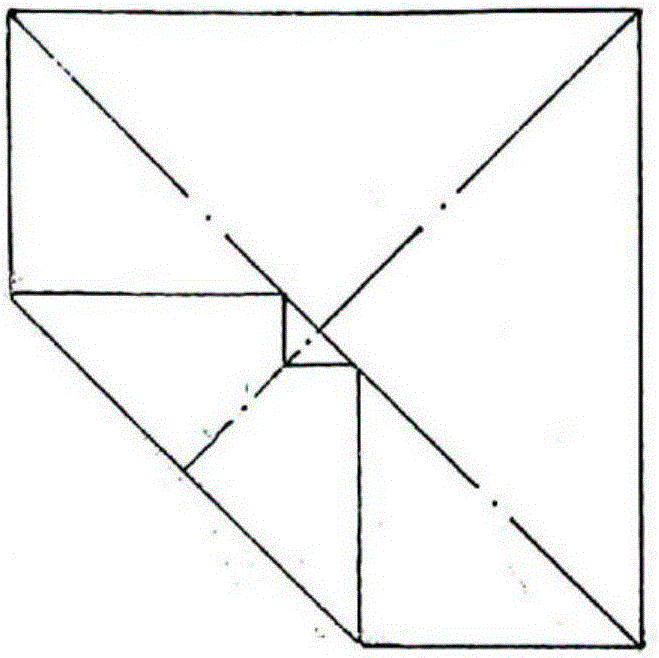

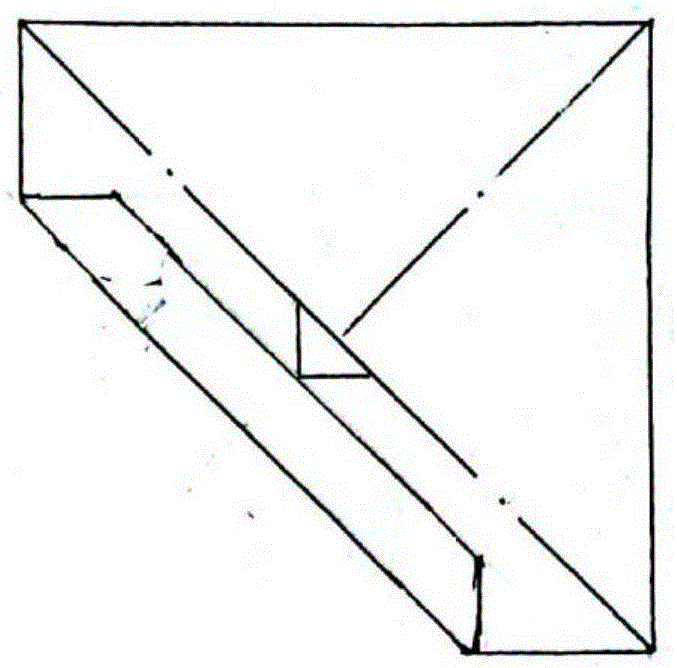

[0028] A dotted line is used to indicate the positive fold line of the front half fold, that is, when folding, the front and the front of the paper are folded relative to each other; a solid line plus a circle indicates the reverse fold line of the reverse face fold, that is, when the paper is folded, the back and the back of the paper are folded opposite each other; the solid line plus a dot indicates the indicator line ;

[0029] Take a square paper and make a diagonal indicator line, the two diagonal indicator lines intersect at the center point of the square paper; make four equal-length paper corner inversion lines perpendicular to the diagonal indicator line at the four corners of the square paper, It intersects with the diagonal indicator line at the intersection point of the paper corner inversion line, and forms a right-angled isosceles triangle with the paper corner inversion line as the base; The length from the polyline intersection to the nearest endpoint of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com