Guide membrane tension regulating device for polaroid cutting machine

A tension adjustment and polarizer technology, which is applied in transportation and packaging, winding strips, thin material processing, etc., can solve problems such as deflection, impact, damage, and loose PP guiding film, so as to save wasted time, Reduce the effect of impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

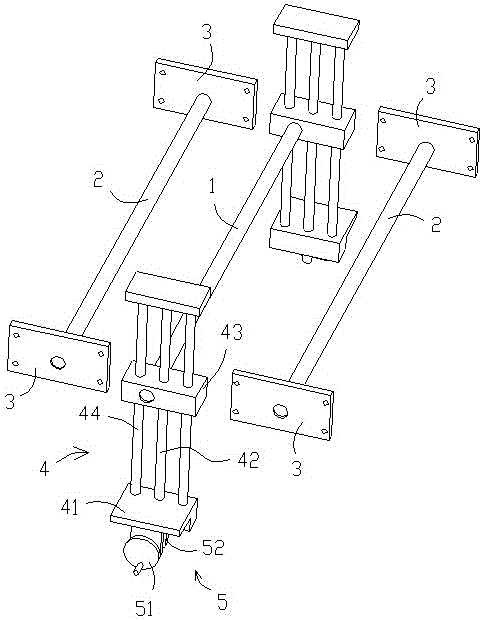

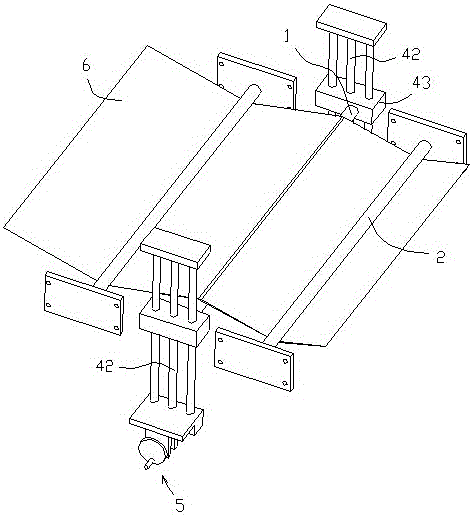

[0015] Such as figure 1 As shown, the guiding film tension adjustment device includes a tension roller 1 , two limit rollers 2 and two lifting mechanisms 4 . The tensioning roller 1 is located between two limit rollers 2, and the three rollers are arranged in parallel, wherein the tensioning roller 1 is driven by the lifting mechanism 4 on both sides to move up and down, and is used to guide the film. For tension adjustment, the two limit rollers 2 are fixedly connected to the cutting machine table through the mounting plates 3 on both sides.

[0016] The lifting mechanism 4 includes a base 41, a screw rod 42 vertically arranged on the base, and a slider 43 sleeved on the screw rod. A pair of guide rods 44 are arranged in parallel on both sides of the screw rod. Two guide rods pass through the slider and are fixedly connected with the base. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com