Spare tire installation aid

A technology of installation assistance and vertical arrangement, applied in the direction of the lifting device, etc., can solve the problems of smashing the driver, reversing the spare tire, falling, and the weight of the spare tire, saving time and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

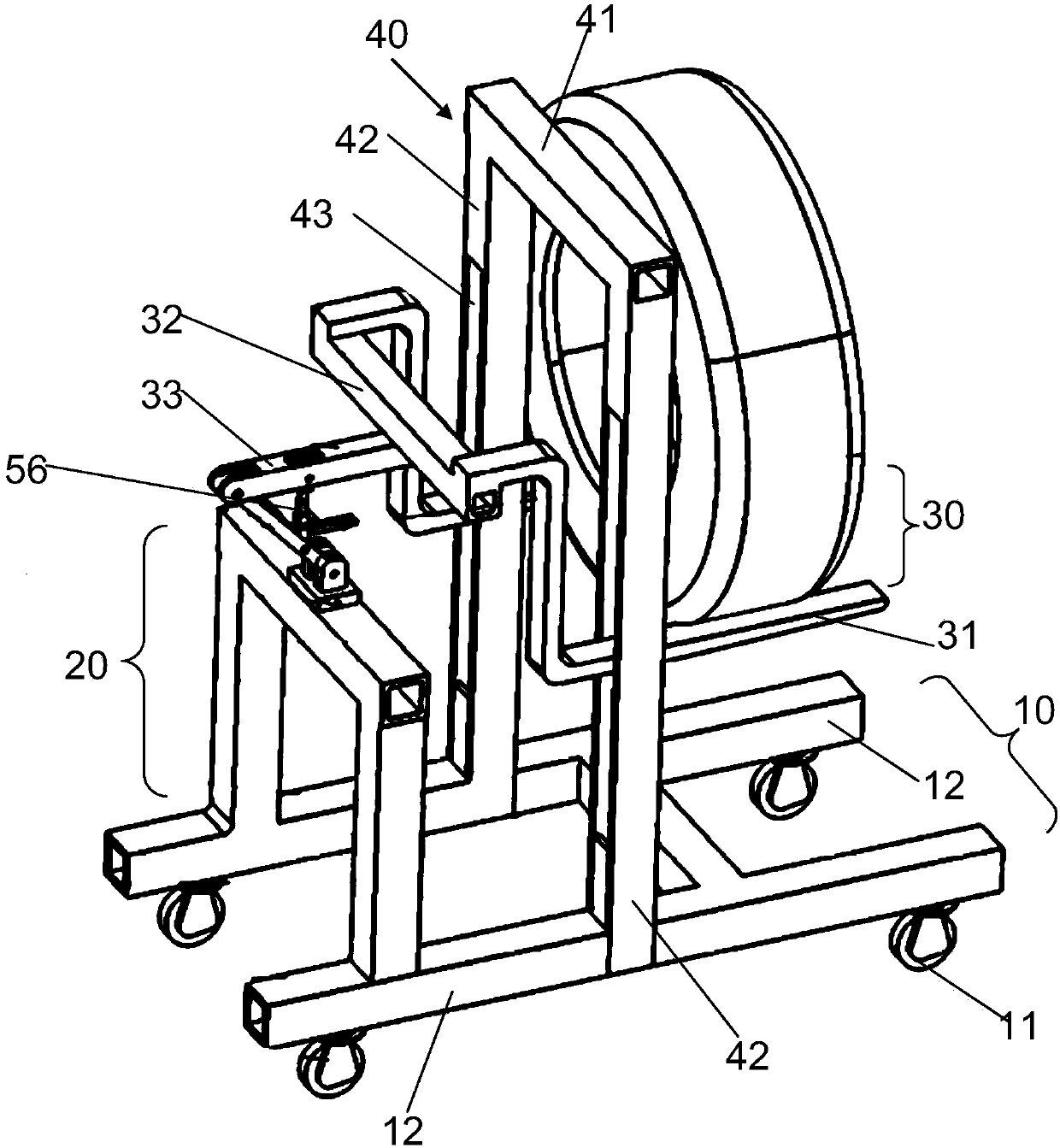

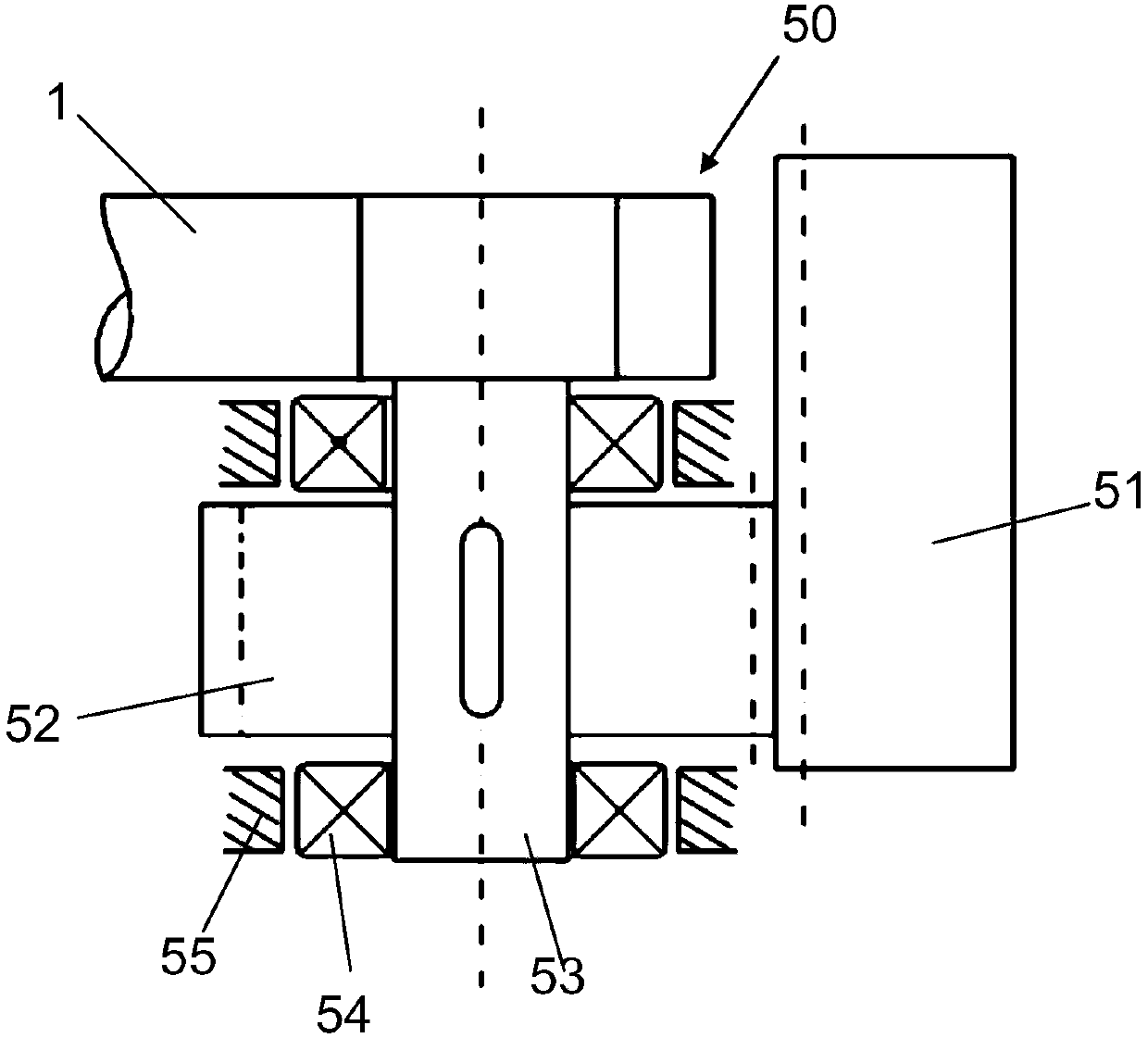

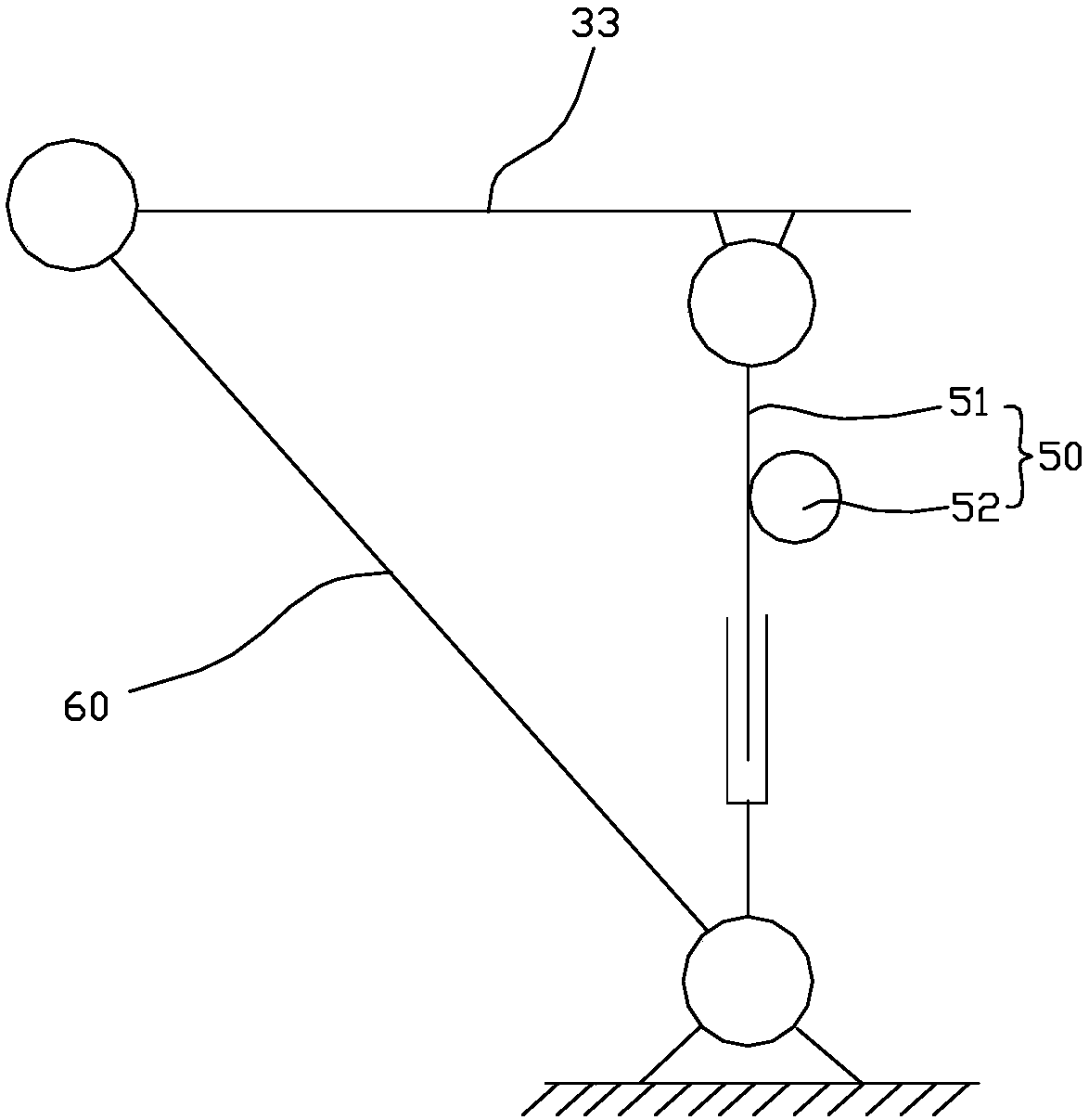

[0009] Such as figure 1 As shown, the spare tire installation auxiliary device includes a frame bottom frame 10, the corners of the frame bottom frame 10 are provided with universal wheels 11, and a vertical frame 20 is arranged vertically upward on the frame bottom frame 10, and on the vertical frame 20 A lifting mechanism is provided, and the supporting shovel 30 for supporting the tire is connected with the lifting mechanism 50 .

[0010] The present invention drives the supporting shovel 30 to move up and down through the action of the above-mentioned lifting mechanism 50, and then lifts the tire to a suitable height position. At the same time, since the lower part of the frame bottom frame 10 is provided with universal wheels 11, the frame bottom frame 10 can be easily moved. Make the tires in the proper front and rear position, so that the spare wheel can be installed. Adopting the present invention can reduce the work intensity and save a lot of time, meanwhile, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com