A filling liquid level double wheel control system

A technology of control system and filling liquid, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of poor versatility and high cost of production line transformation, and achieve the effect of more adjustment, convenient horizontal position adjustment, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

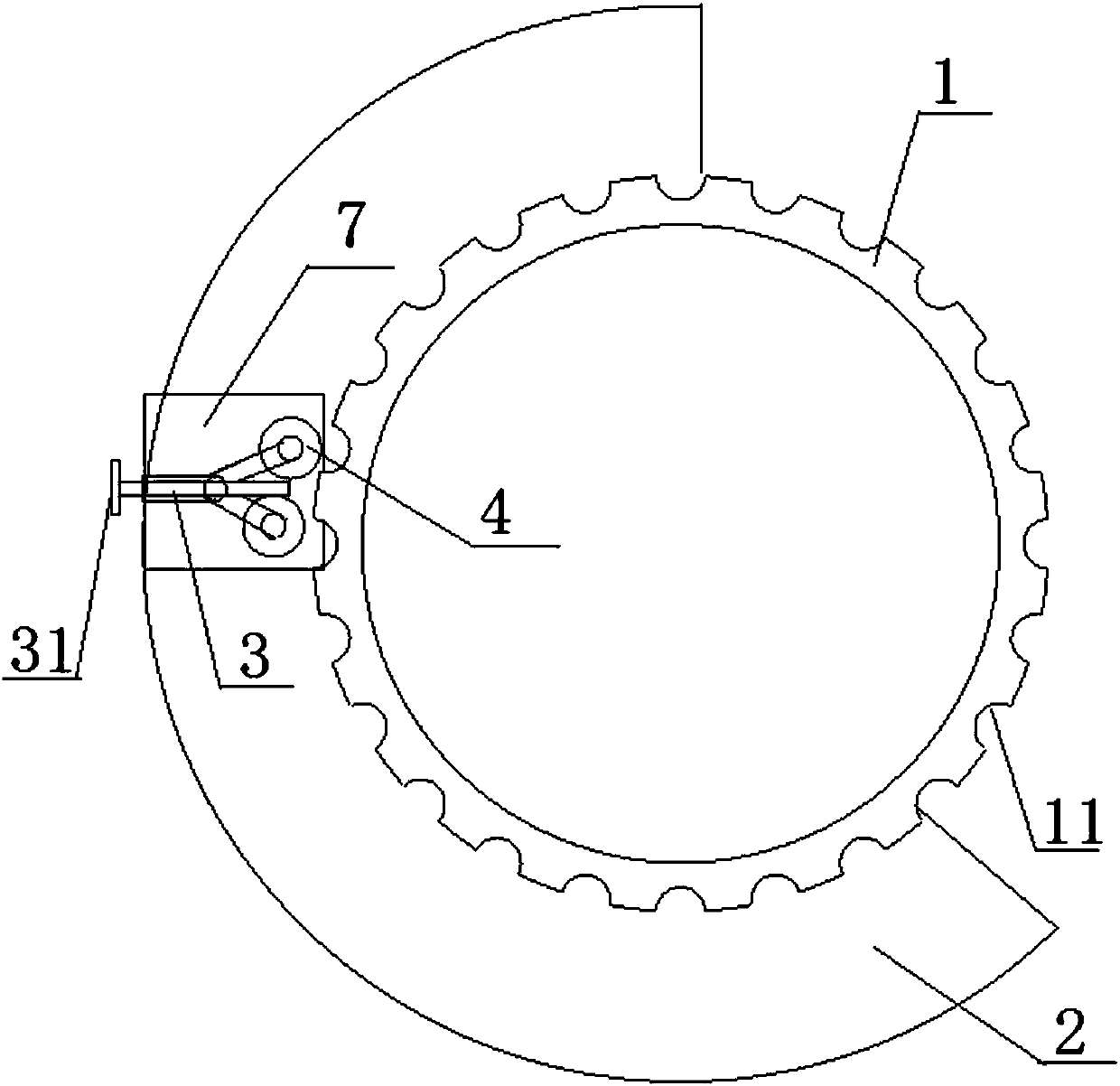

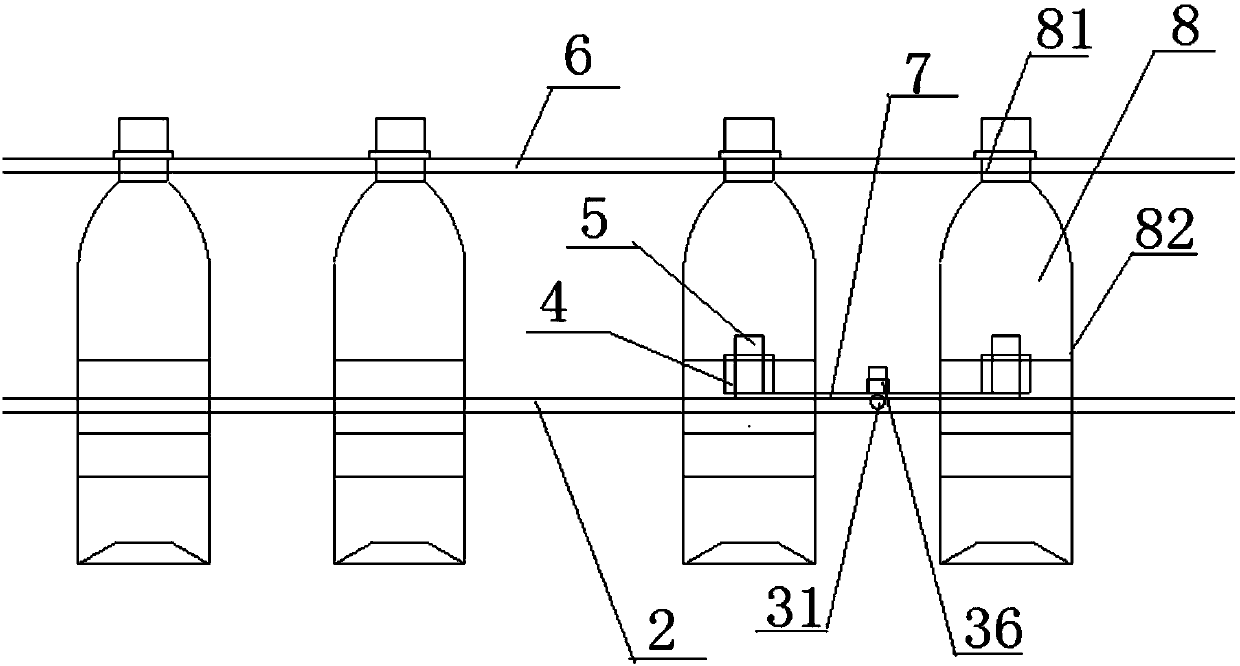

[0057] A two-wheel control system for filling liquid level in this embodiment includes a lower star wheel guard plate 2, a fixed plate 7 and two extrusion rollers 4, and the two extrusion rollers 4 are close to two adjacent filling bottles 8 bottle body 82, and is detachably fixed on the upper surface of the fixed plate 7, and the fixed plate 7 is fixed on the upper surface of the lower star wheel guard plate 2.

[0058] During the use of the two-wheel control system for filling liquid level in this embodiment, the two extrusion rollers 4 are fixed on the fixed plate 7 after they are tangent to the bottle body 82. The degree of tangency can squeeze the rollers A deep , Squeeze roller B is shallower, use squeeze rollers A and B to squeeze the bottle that has been filled before capping after filling the bottle, which can force the excess water level in part of the bottle to be squeezed Squeeze out; in order to achieve the most ideal extrusion effect, the squeeze roller A is adju...

Embodiment 2

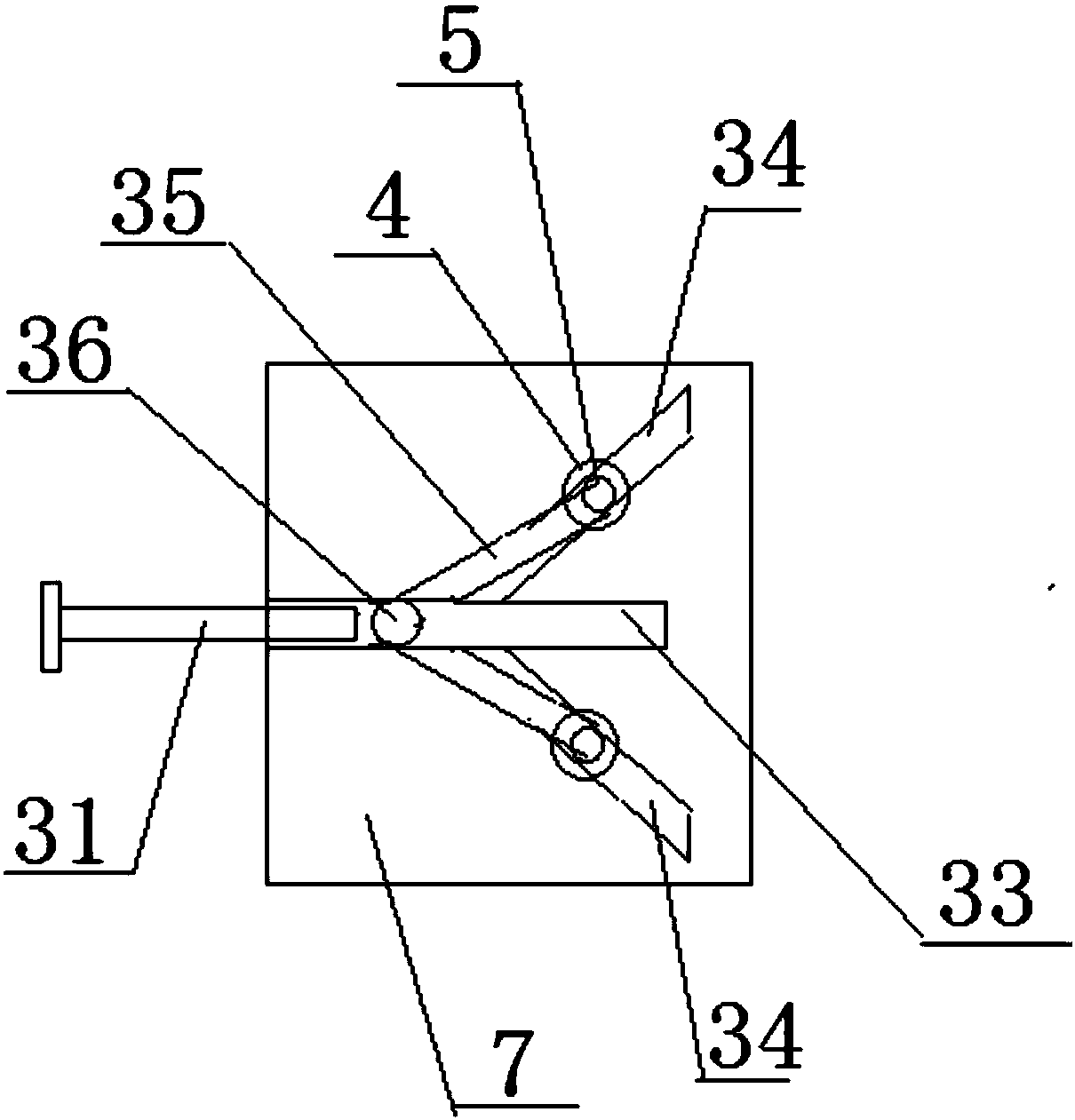

[0060] The basic structure of the two-wheel control system for filling liquid level in this embodiment is the same as in Embodiment 1, and the improvements are as follows: figure 1 As shown in and 2, it also includes an adjustment mechanism 3. The adjustment mechanism 3 includes a horizontal adjustment groove 33, an angle adjustment groove 34 and an adjustment bolt 31. The horizontal adjustment groove 33 is a horizontal slot hole provided on the fixed plate 7, and one of them squeezes The pressing roller 4 , that is, the pressing roller A41 is inserted into the horizontal adjustment groove 33 through the fastening bolt 5 . The outer surface of the fixed plate 7 is provided with a through hole communicating with the horizontal adjustment groove 33, and a thread is arranged in the through hole, and the adjusting bolt 31 is inserted into the through hole and resists the fastening bolt 5 of the extrusion roller A41. The angle adjustment groove 34 is also a slotted hole provided o...

Embodiment 3

[0069] The two-wheel control system for filling liquid level of this embodiment has the same basic structure as that of Embodiment 2. The improvement and difference are that it is applied to the filling of pure water, and there are two angle adjustment tanks 34 and one horizontal adjustment tank 33. A three-slot structure in the shape of a "broom" is formed. The two extrusion rollers 4 are detachably fixed in the two angle adjustment grooves 34 respectively, and after being connected by the "V" shaped adjustment connecting rod 35, they move left and right in the horizontal adjustment groove 33 through the adjustment screw rod 36, and the adjustment bolt 31 The end is against the adjusting screw 36. The liquid level standard requirement is 2~4mm from the lower edge of the bottle cap.

[0070] The control method of the filling liquid level two-wheel control system of this embodiment, the steps are:

[0071] A: Installation: put the extrusion roller A41 and the extrusion roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com