Navvy cover

A technology for an excavator and a main body is applied in the field of covers for excavators, and can solve the problems of not considering weight and formability, increasing the weight, and being difficult to form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] One embodiment of the present invention will be described with reference to the drawings.

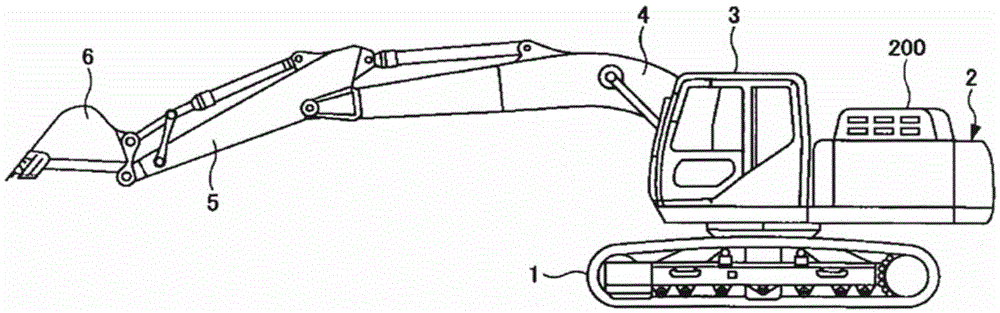

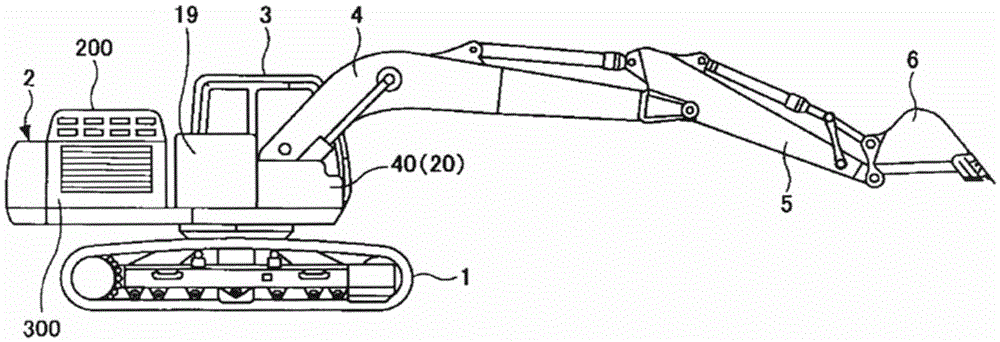

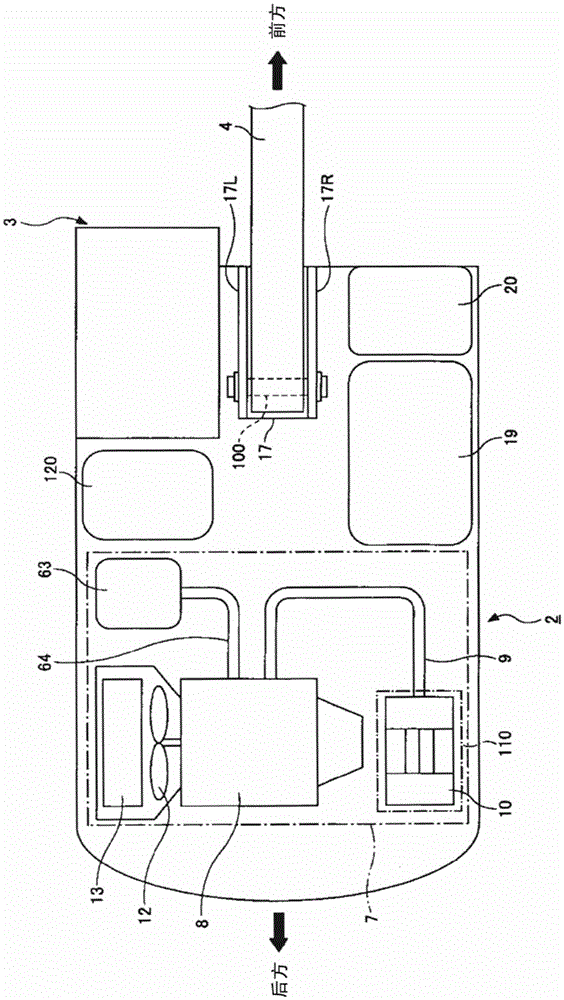

[0022] figure 1 It is a left side view of the shovel provided with the shovel cover of one embodiment. figure 2 yes figure 1 Right side view of the excavator shown.

[0023] Such as figure 1 and figure 2 As shown, the excavator has a lower traveling body 1 , an upper revolving body 2 , a control room 3 , a boom 4 , an arm 5 , and a bucket 6 . The upper revolving body 2 is mounted on the lower traveling body 1 via a revolving mechanism (not shown). The left front part of the upper revolving body 2 is provided with a manipulation room 3 . One end of the boom 4 is rotatably attached to the front center of the upper revolving structure 2 . The arm 5 is rotatably attached to the front end portion of the boom 4 . A bucket 6 as a terminal attachment is rotatably attached to the front end portion of the arm 5 . A terminal attachment such as a crusher or a crusher may be attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com