Patents

Literature

33results about How to "Effective thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

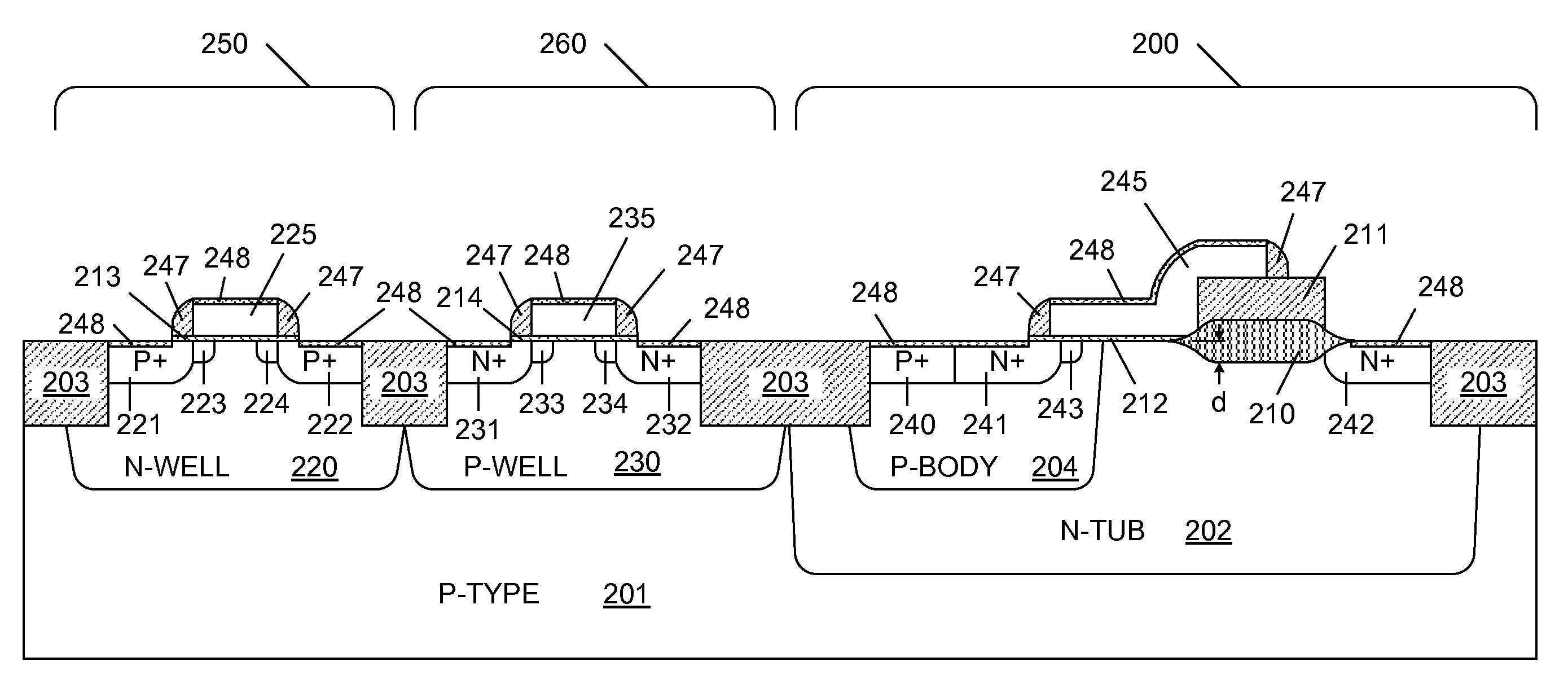

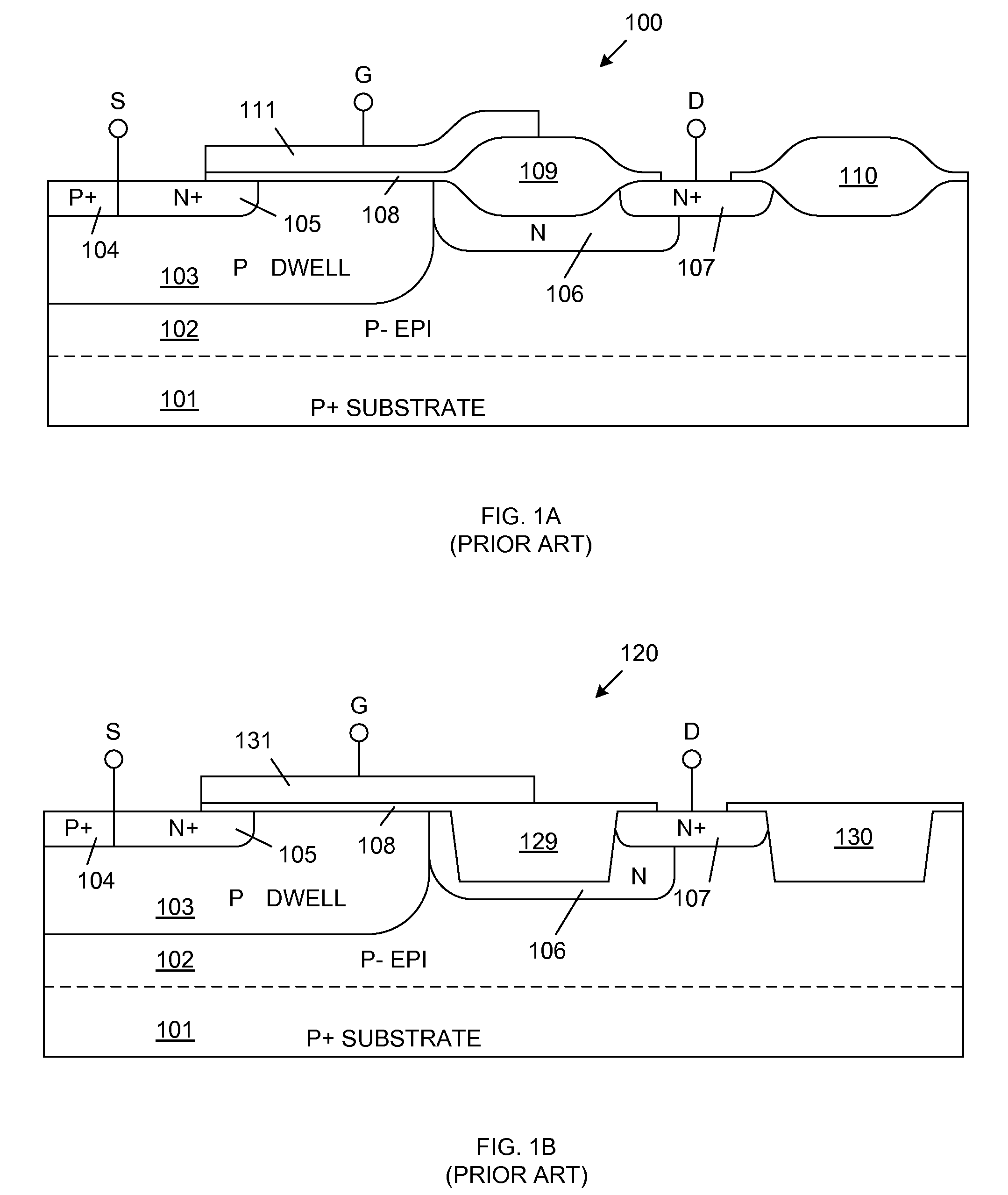

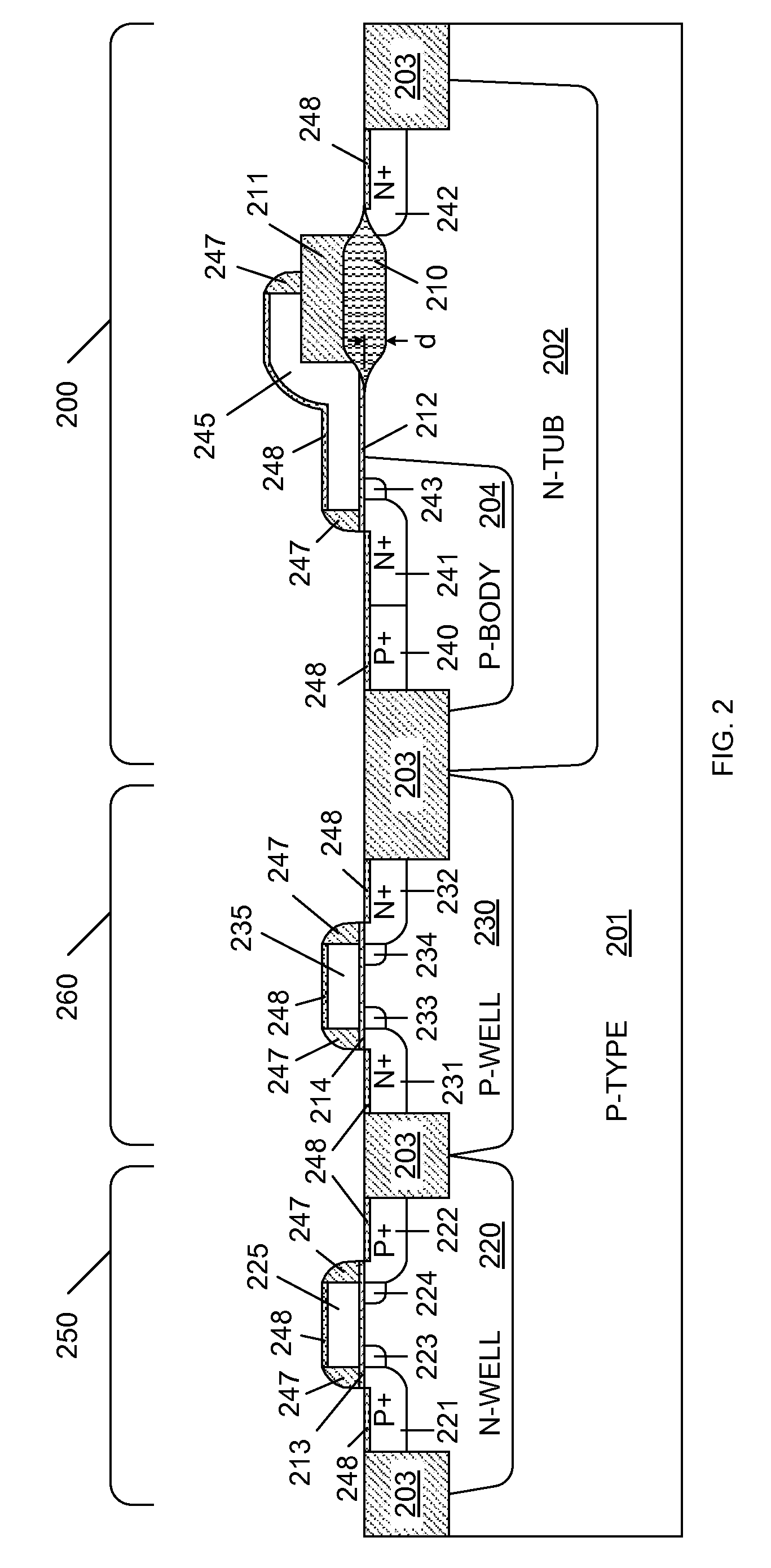

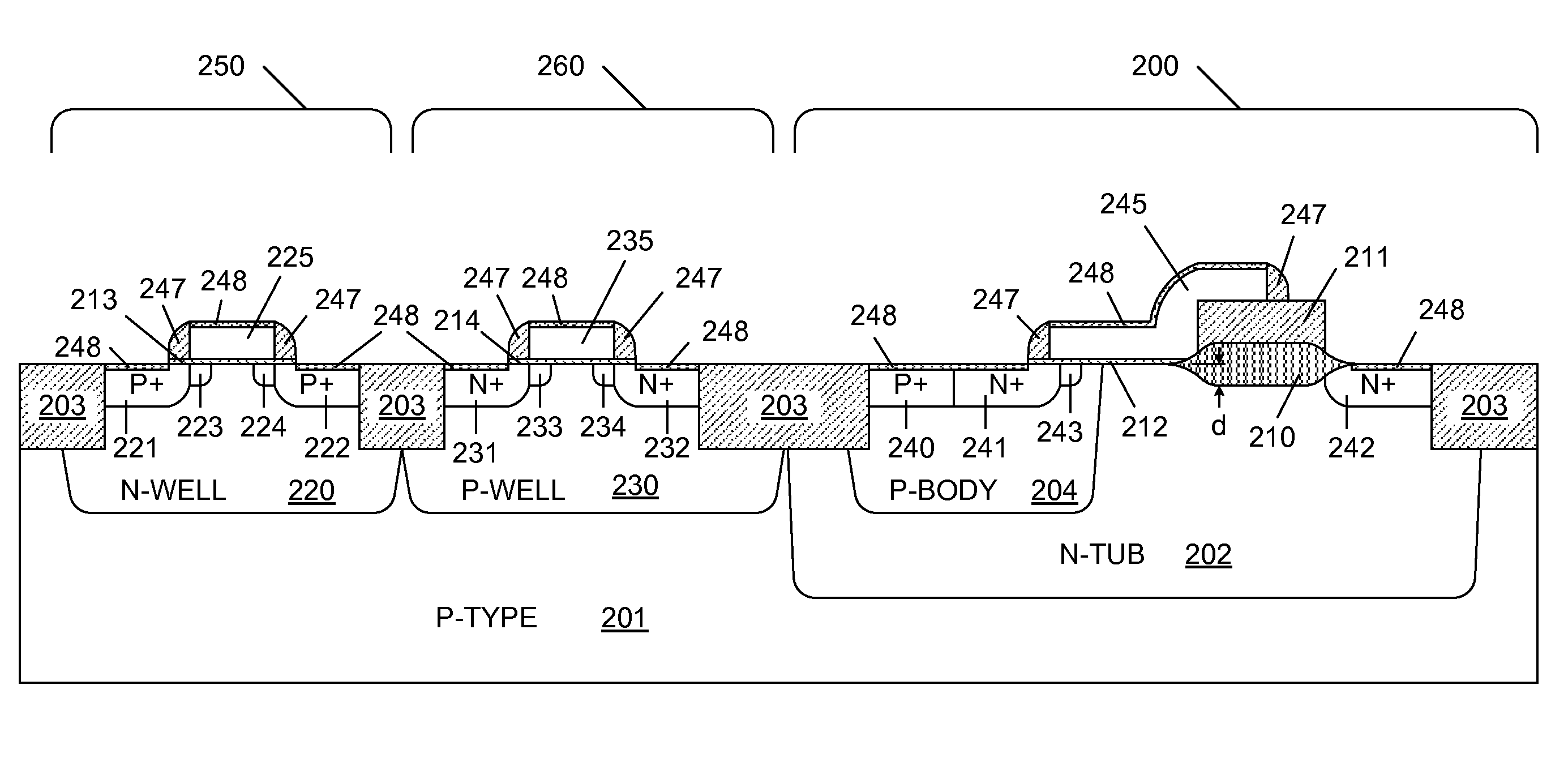

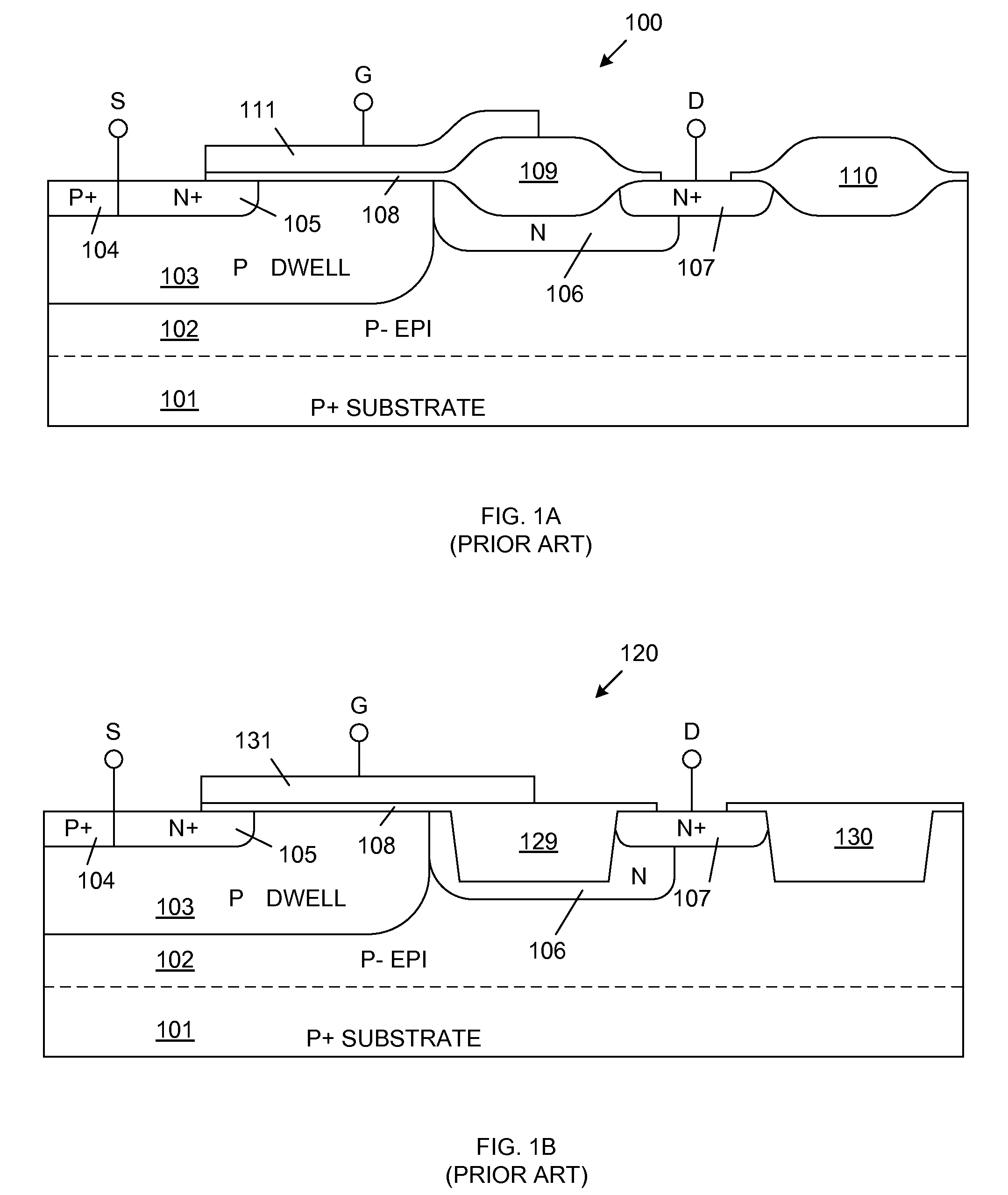

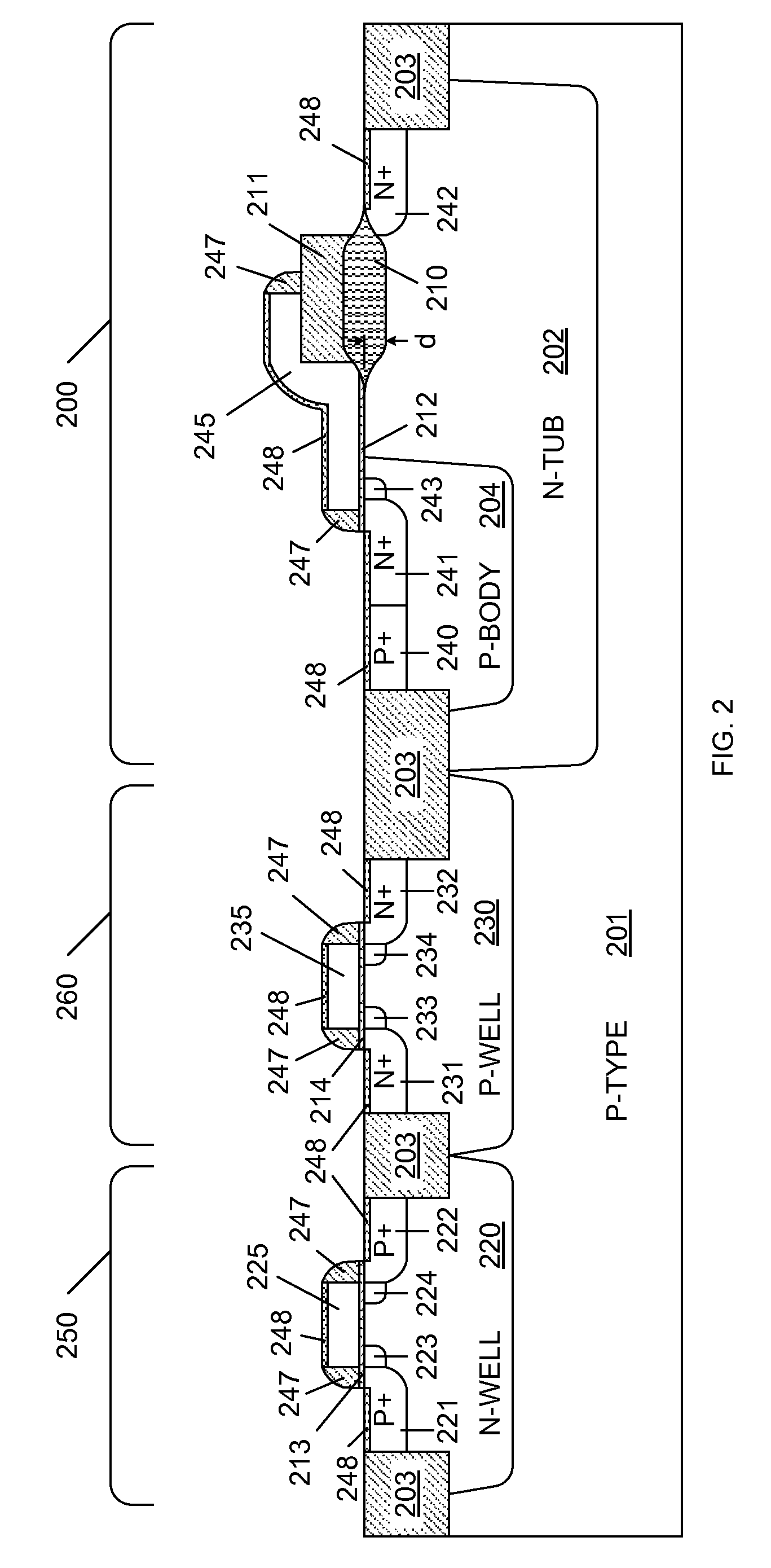

LDMOS Transistor Having Elevated Field Oxide Bumps And Method Of Making Same

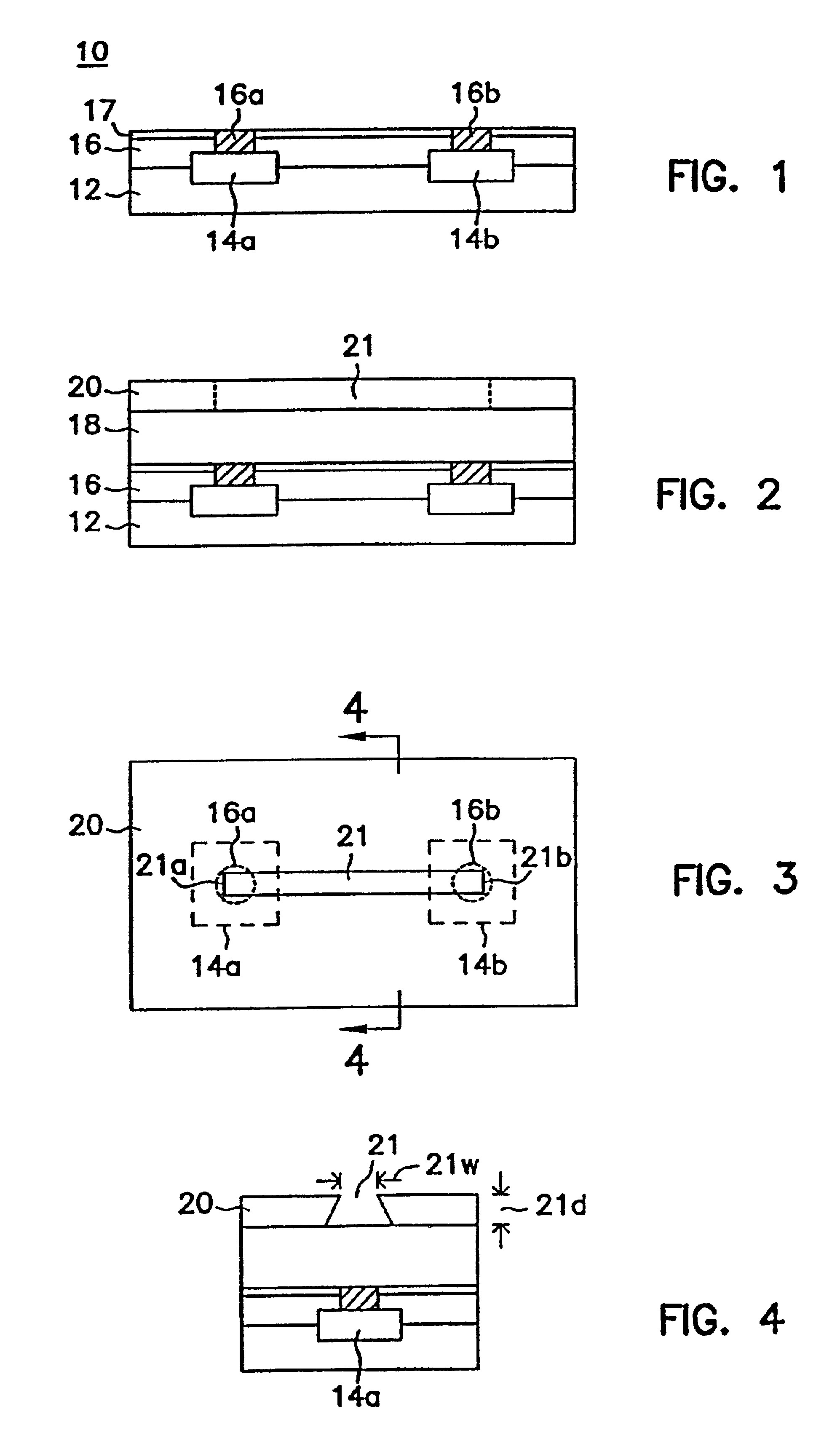

ActiveUS20100102388A1Effective thicknessTransistorSemiconductor/solid-state device manufacturingOxideDepth of field

A low Rdson LDMOS transistor having a shallow field oxide region that separates a gate electrode of the transistor from a drain diffusion region of the transistor. The shallow field oxide region is formed separate from the field isolation regions (e.g., STI regions) used to isolate circuit elements on the substrate. Fabrication of the shallow field oxide region is controlled such that this region extends below the upper surface of the semiconductor substrate to a depth that is much shallower than the depth of field isolation regions. For example, the shallow field oxide region may extend below the upper surface of the substrate by only Angstroms or less. As a result, the current path through the resulting LDMOS transistor is substantially unimpeded by the shallow field oxide region, resulting in a low on-resistance.

Owner:TOWER SEMICONDUCTOR

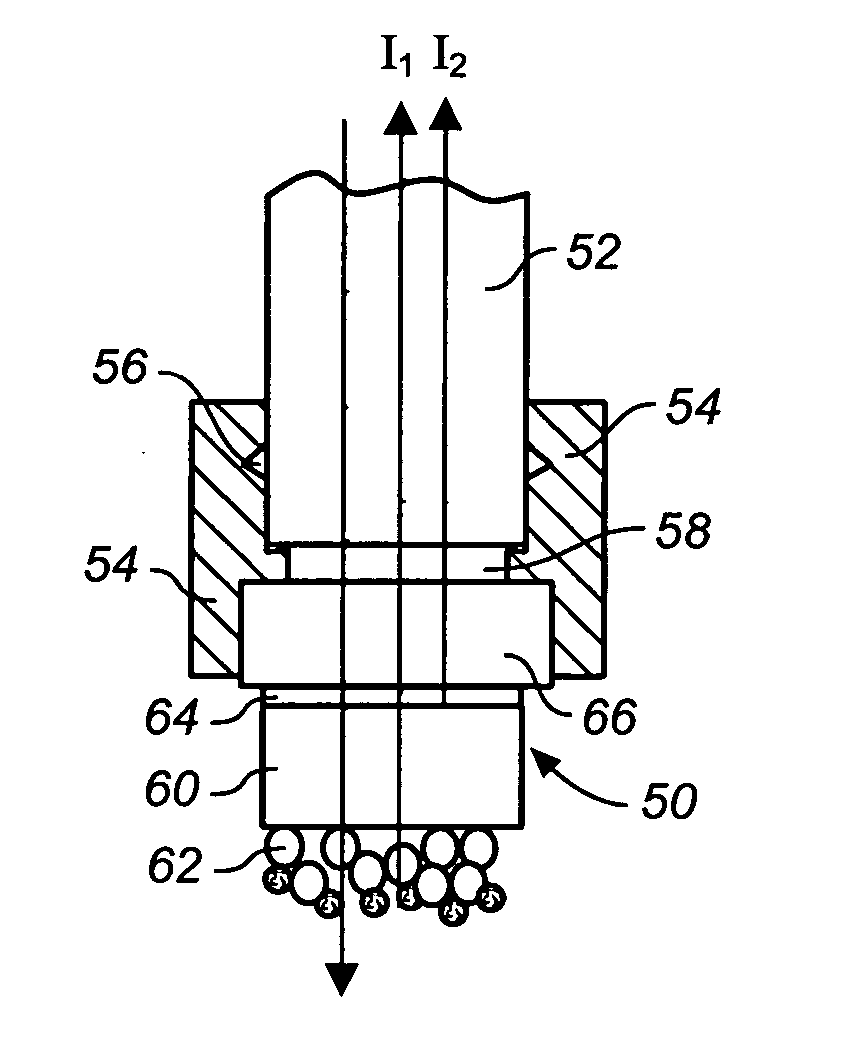

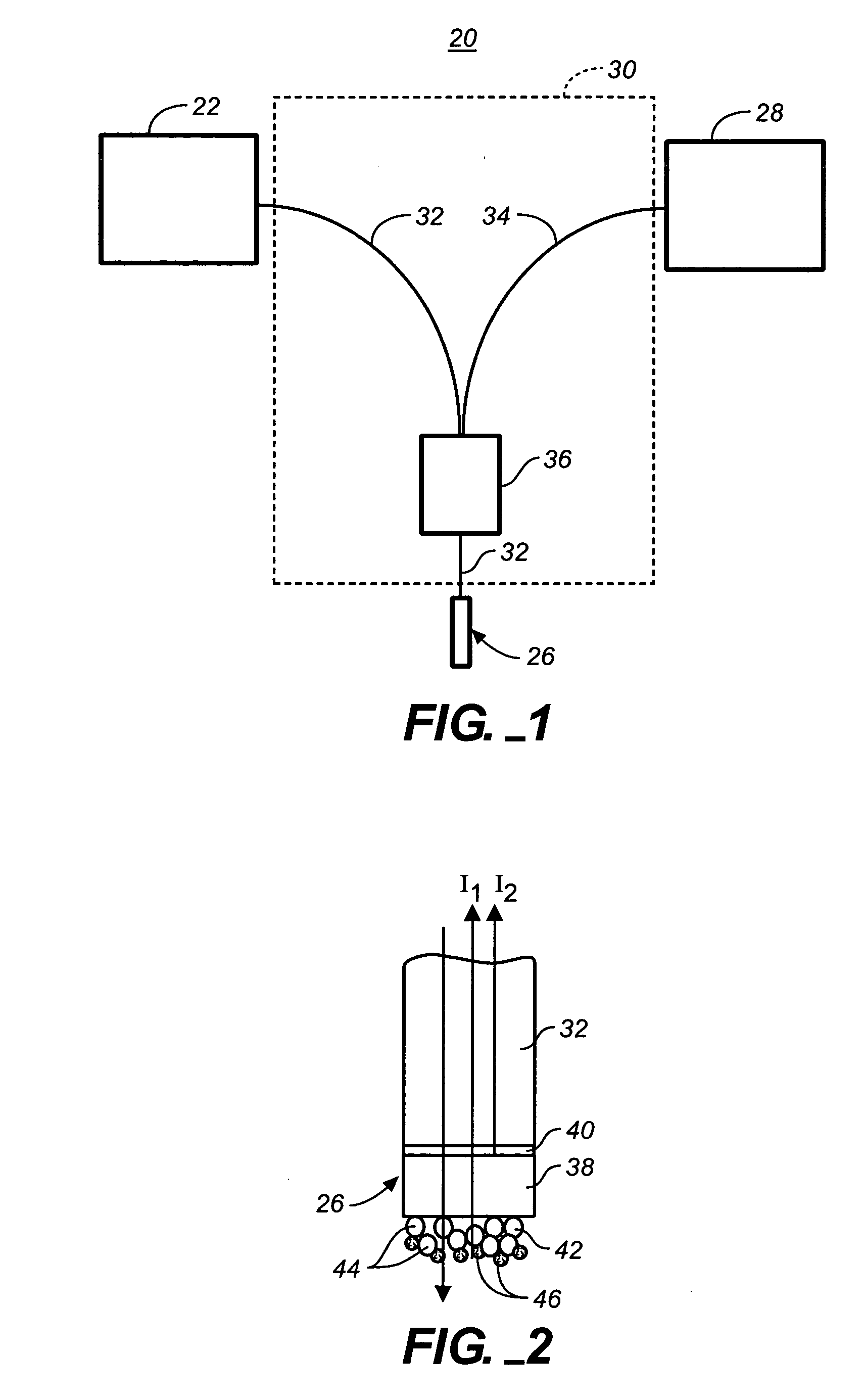

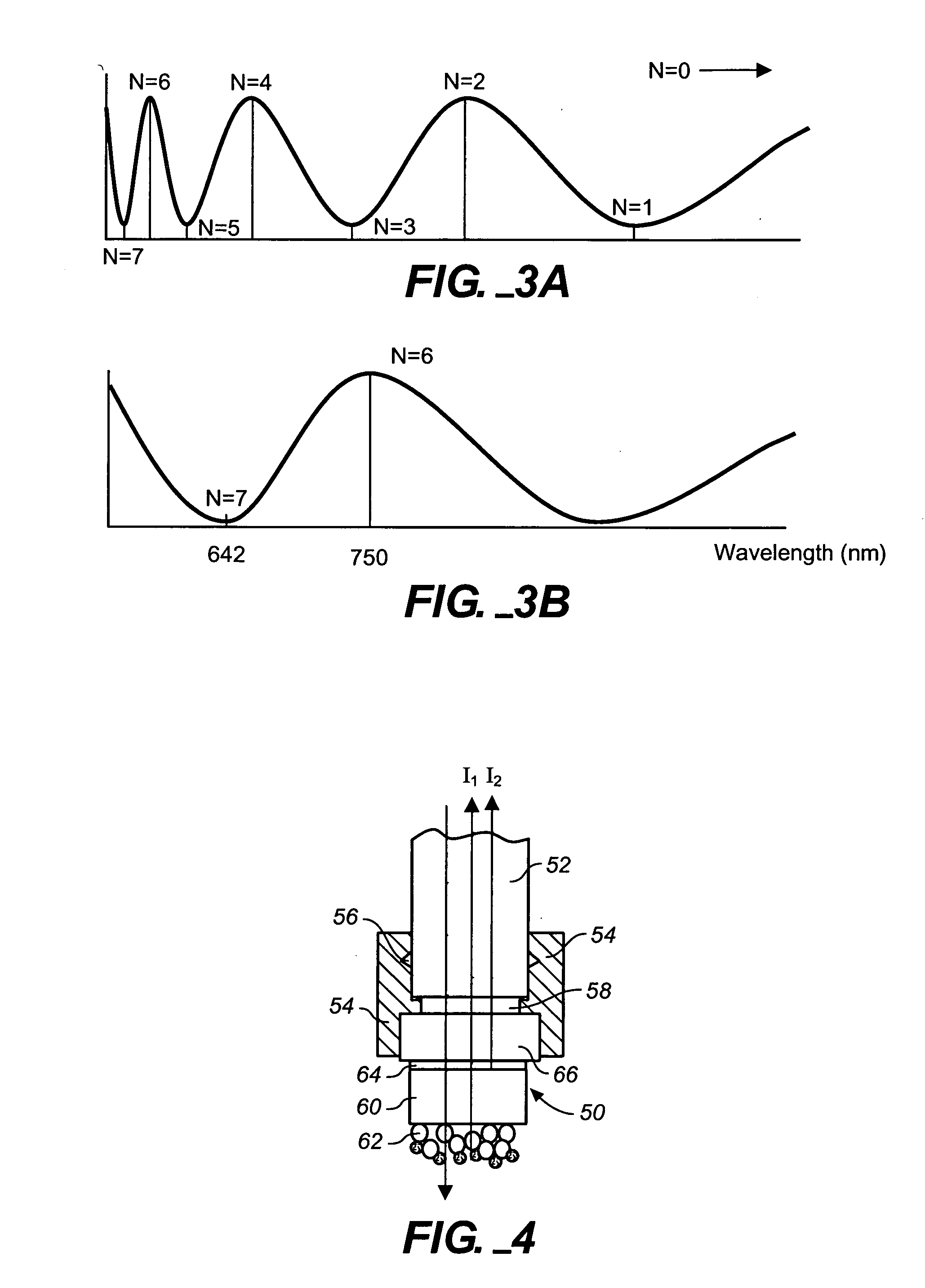

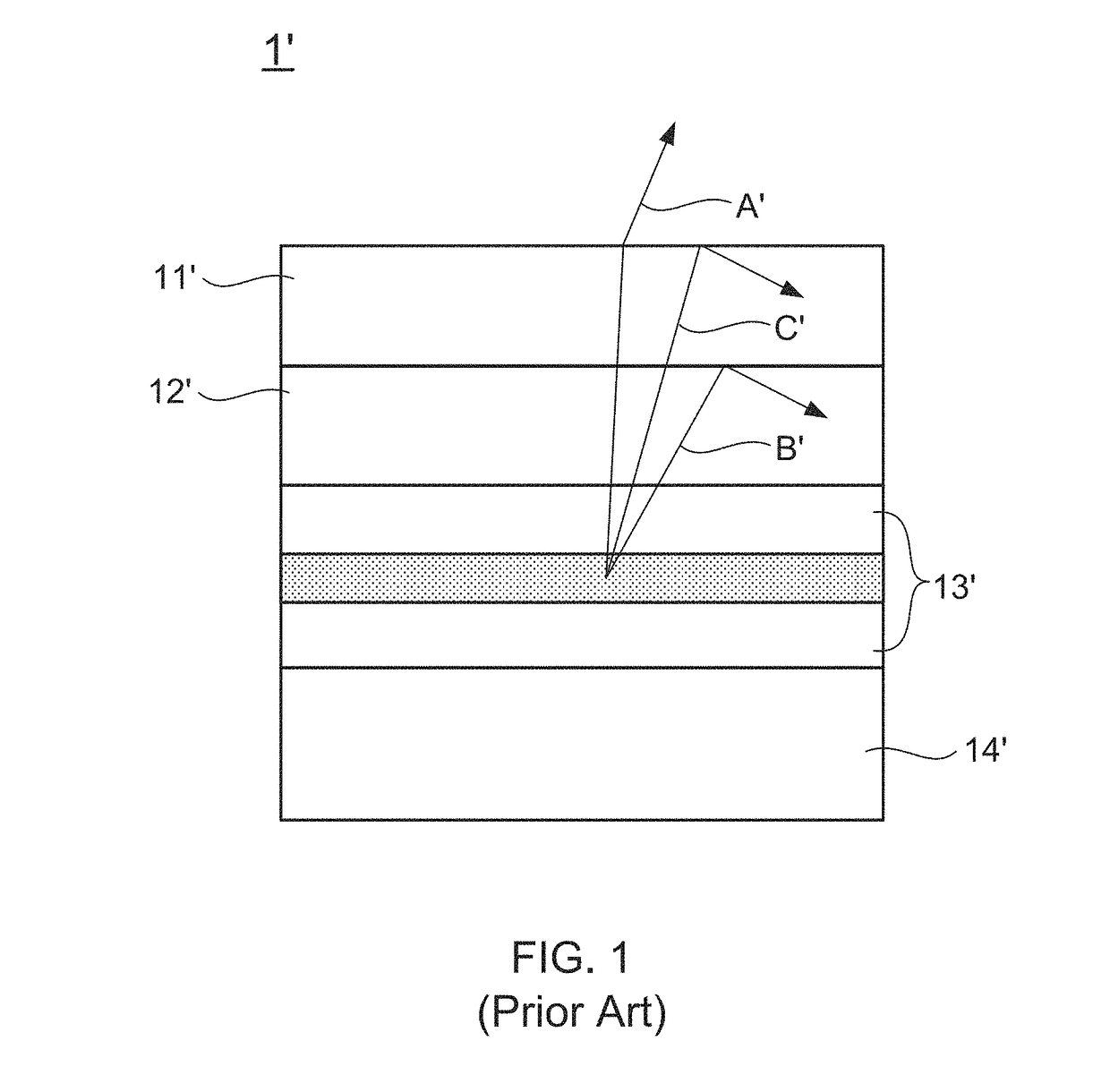

Fiber-optic assay apparatus based on phase-shift interferometry

ActiveUS20050254062A1Increase thicknessEffective thicknessMaterial analysis by observing effect on chemical indicatorUsing optical meansPhysicsPhase variance

Apparatus and method for detecting the presence or amount or rate of binding of an analyte in a sample solution is disclosed. The apparatus includes an optical assembly having first and second reflecting surfaces separated by a distance “d” greater than 50 nm, where the first surface is formed by a layer of analyte-binding molecules, and a light source for directing a beam of light onto said first and second reflecting surface. A detector in the apparatus operates to detect a change in the thickness of the first reflecting layer resulting from binding of analyte to the analyte-binding molecules, when the assembly is placed in the solution of analyte, by detecting a shift in phase of light waves reflected from the first and second surfaces.

Owner:SARTORIUS BIOANALYTICAL INSTR INC

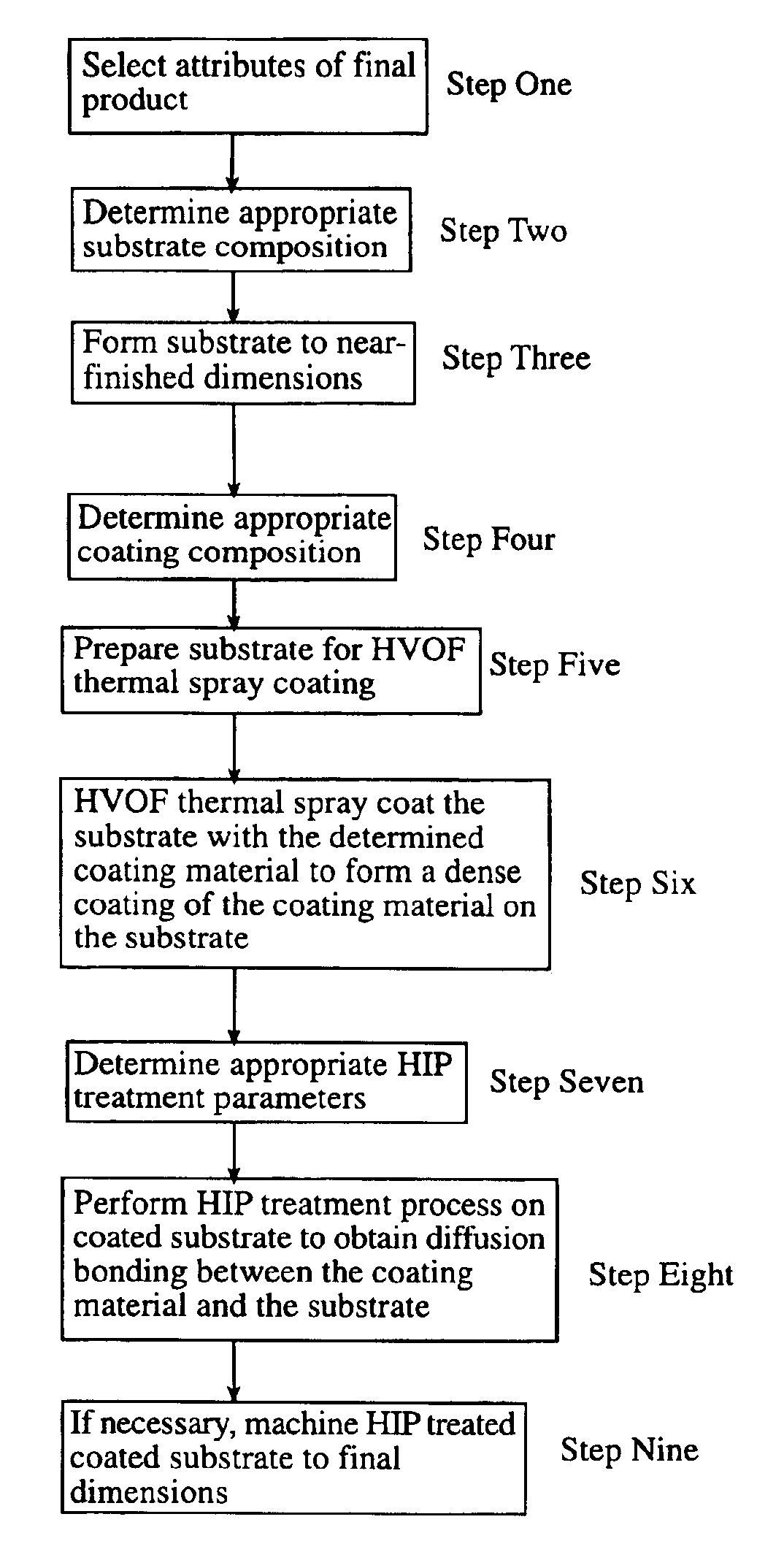

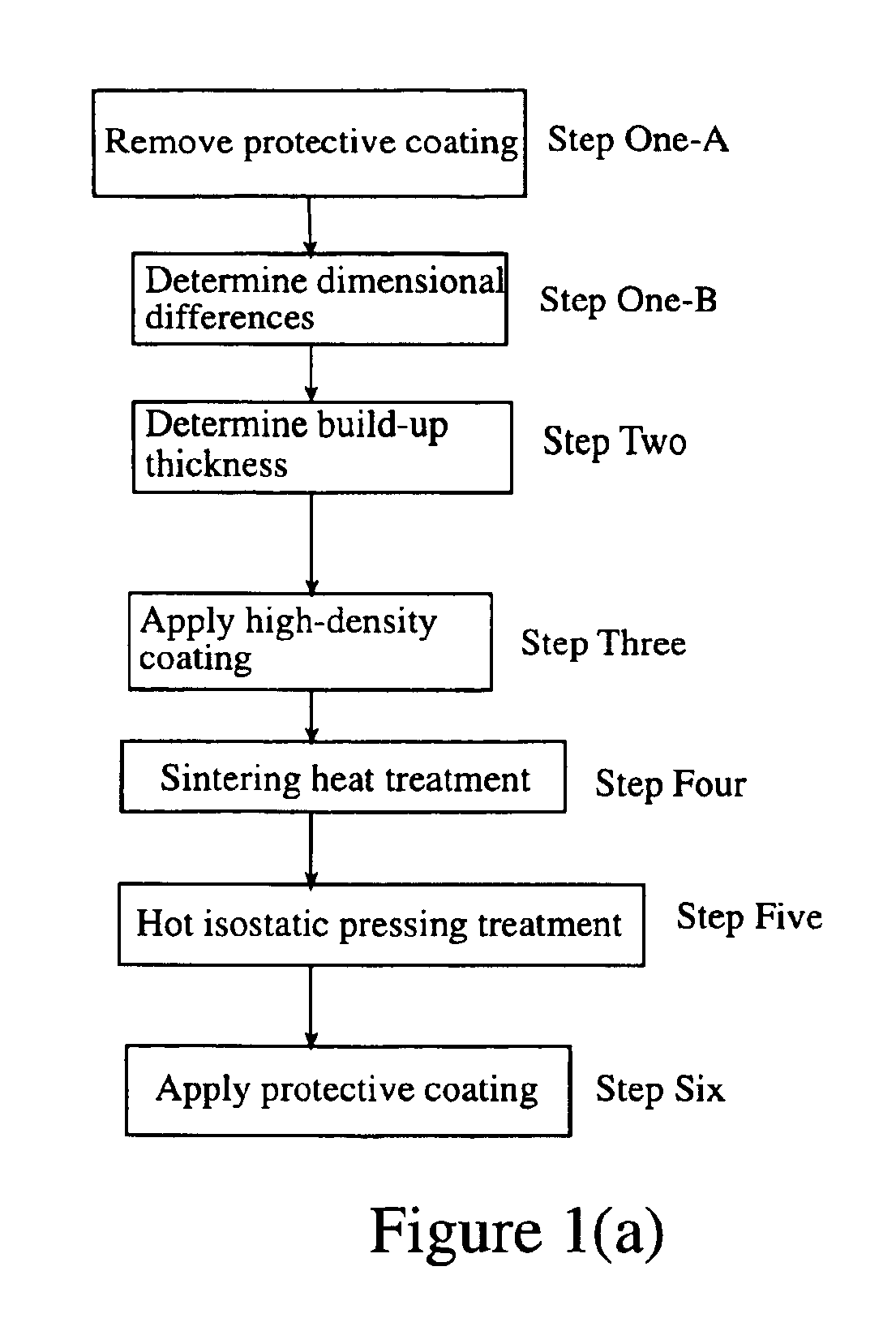

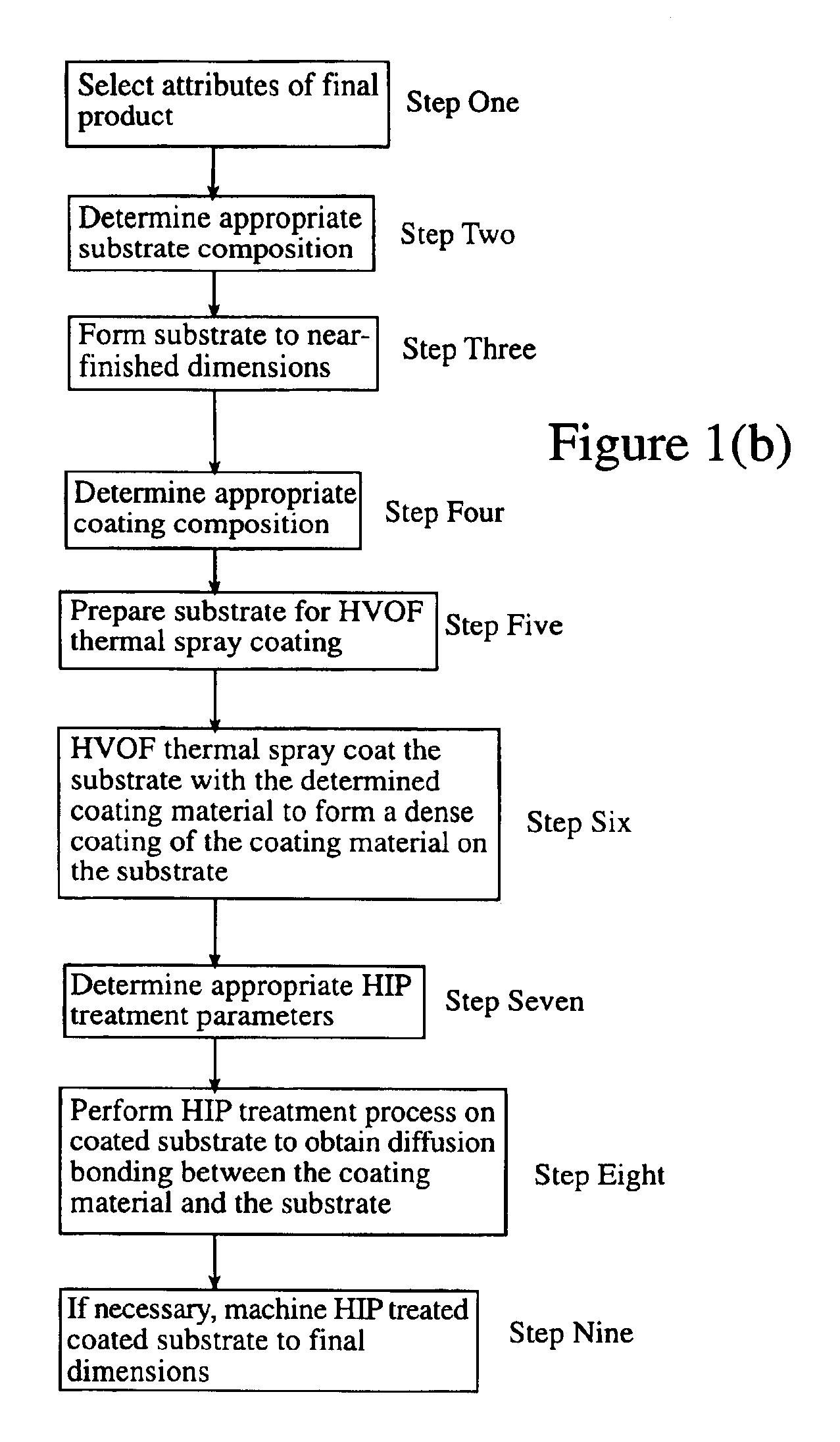

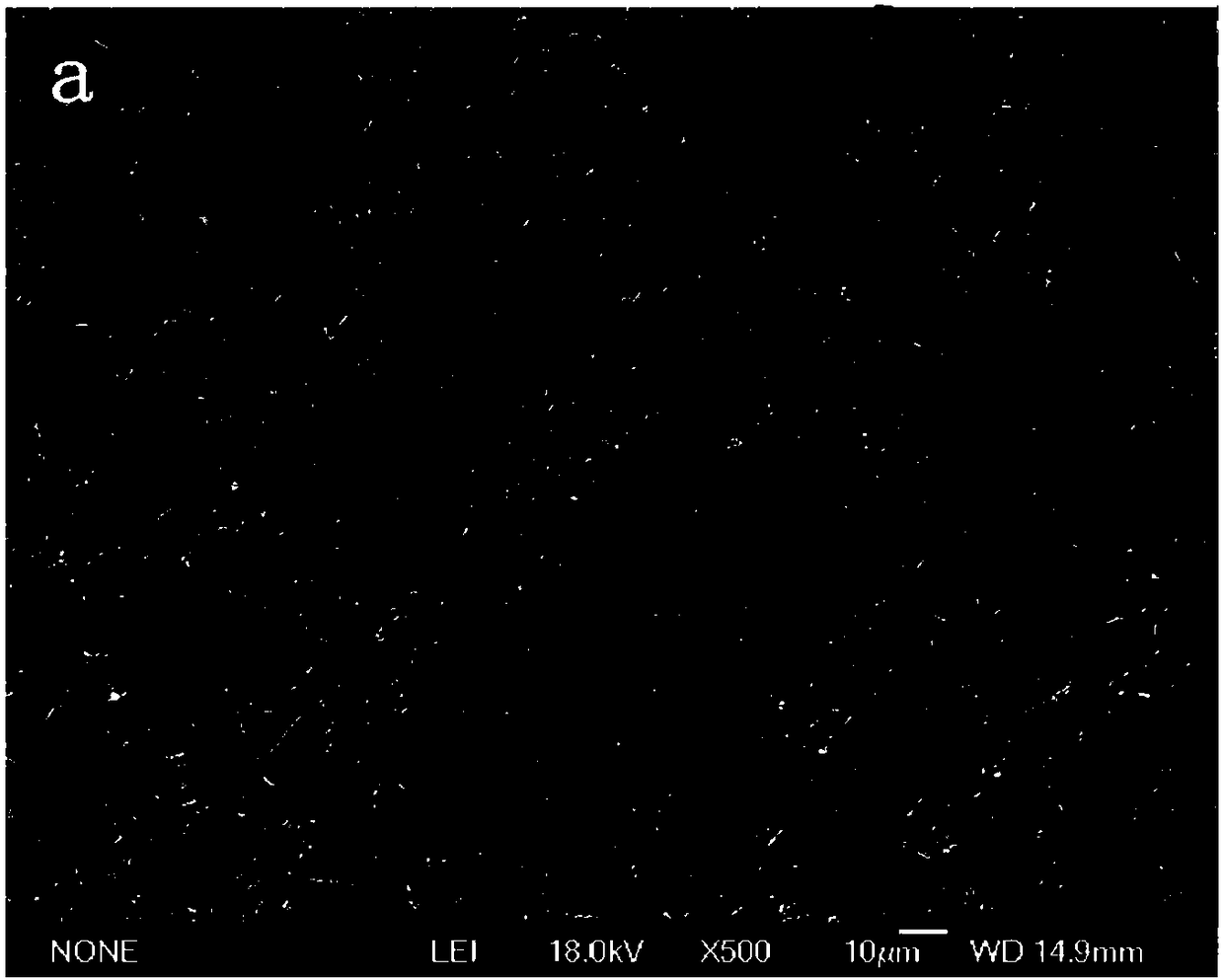

Methods for forming metal parts having superior surface characteristics

InactiveUS7043819B1Improve surface propertiesOvercomes drawbackMolten spray coatingMetal rolling stand detailsHigh densityMetal alloy

A method of forming a metal product. A metal alloy workpiece substrate is provided have pre-process dimensions. The dimensional differences are determined between the pre-process dimensions of the workpiece substrate and desired post-process dimensions of a post-process metal product formed from the workpiece substrate. A build-up thickness is determined of coating material required to obtain the desired post-process dimensions of the post-process metal product. A high-density coating process is performed to coat the workpiece substrate with a coating material to build-up a thickness of coating material effective to obtain desired finished dimensions after performing a sintering heat treatment process and / or a hot isostatic pressing treatment. The sintering heat treatment is performed on the coated workpiece substrate to densify the coating material. Then, the hot isostatic pressing treatment is performed to obtain the post-process metal product having the desired post-process dimensions and having diffusion bonding between the coating material and the workpiece substrate.

Owner:RECAST AIRFOIL GROUP

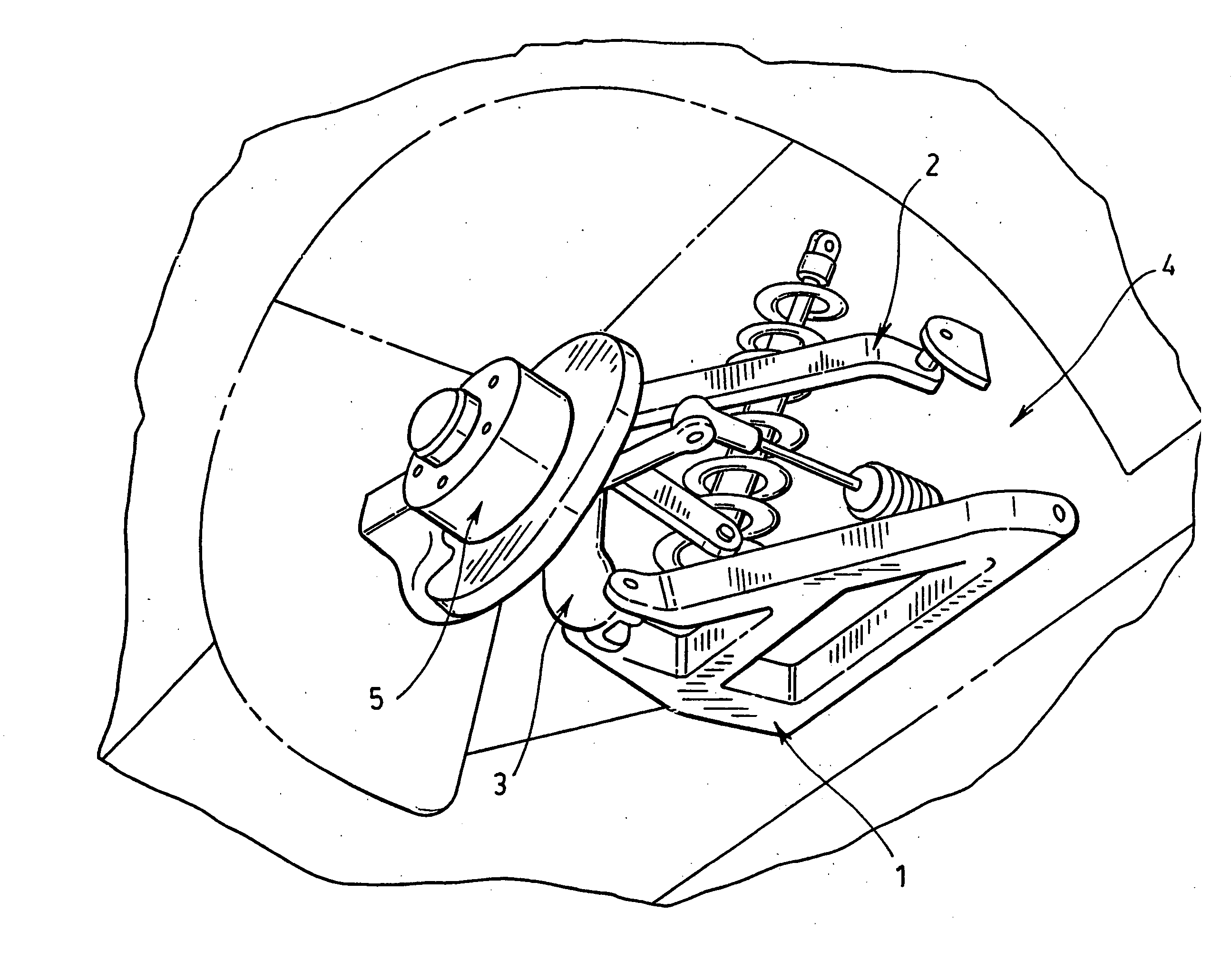

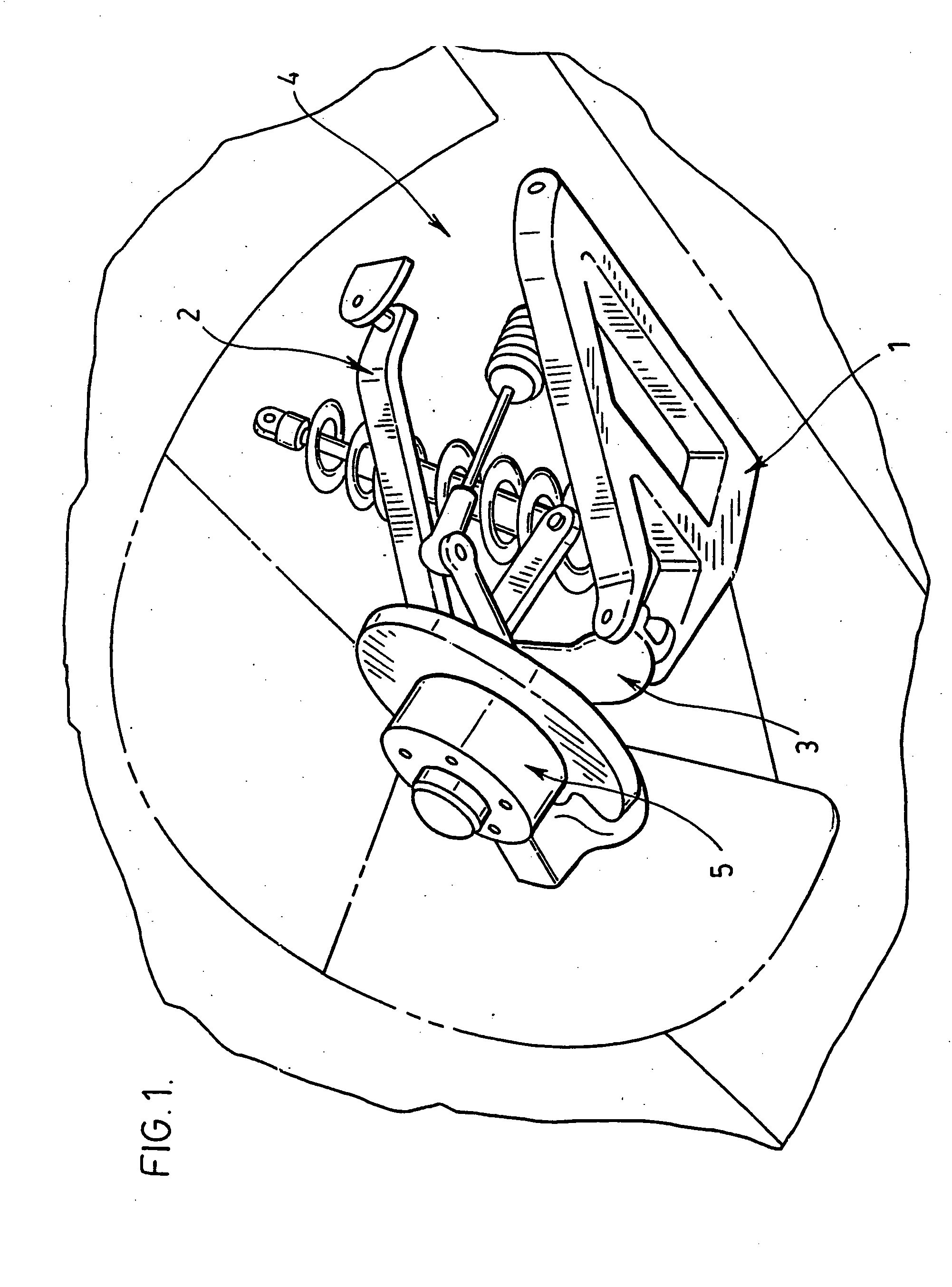

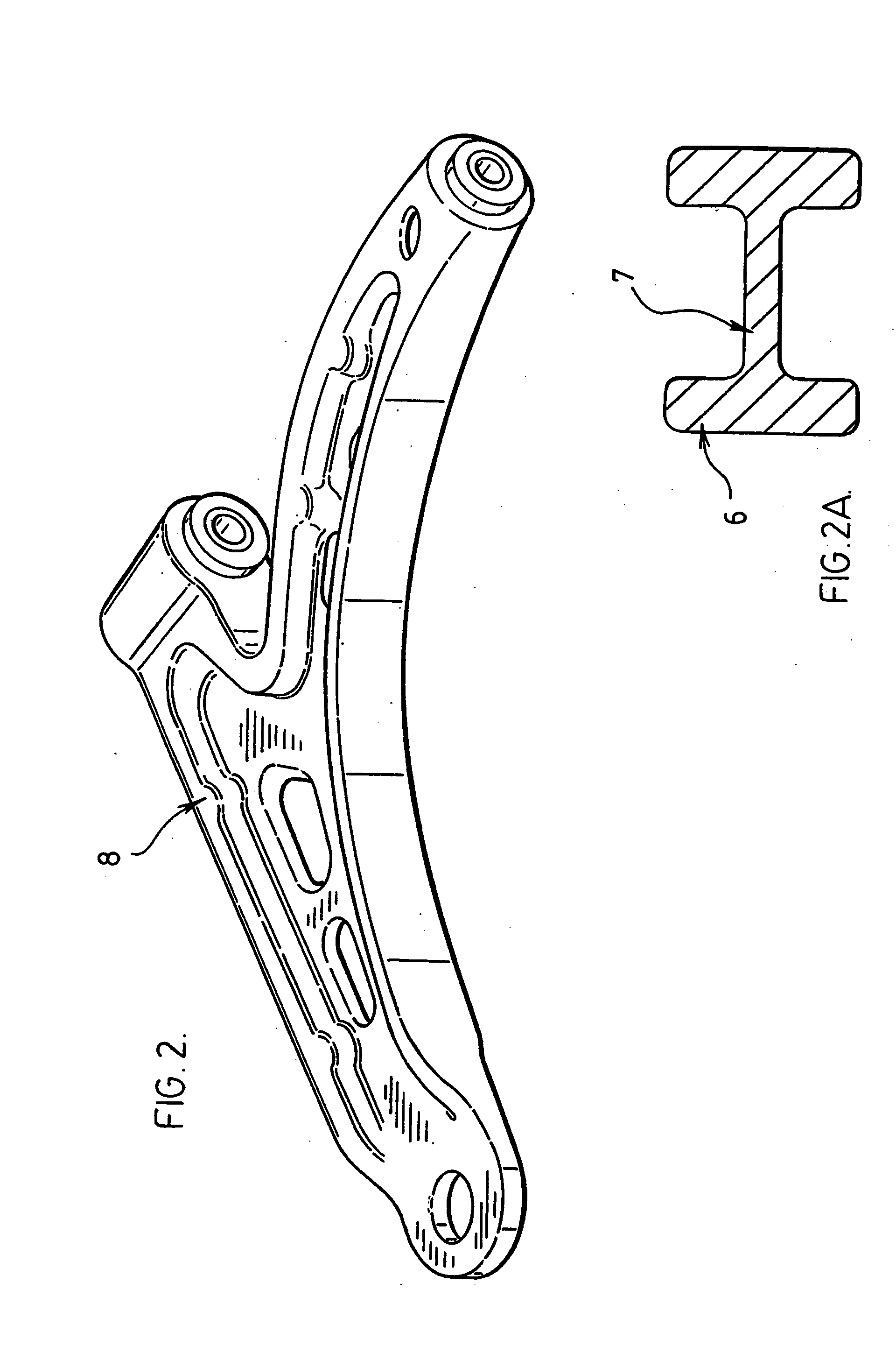

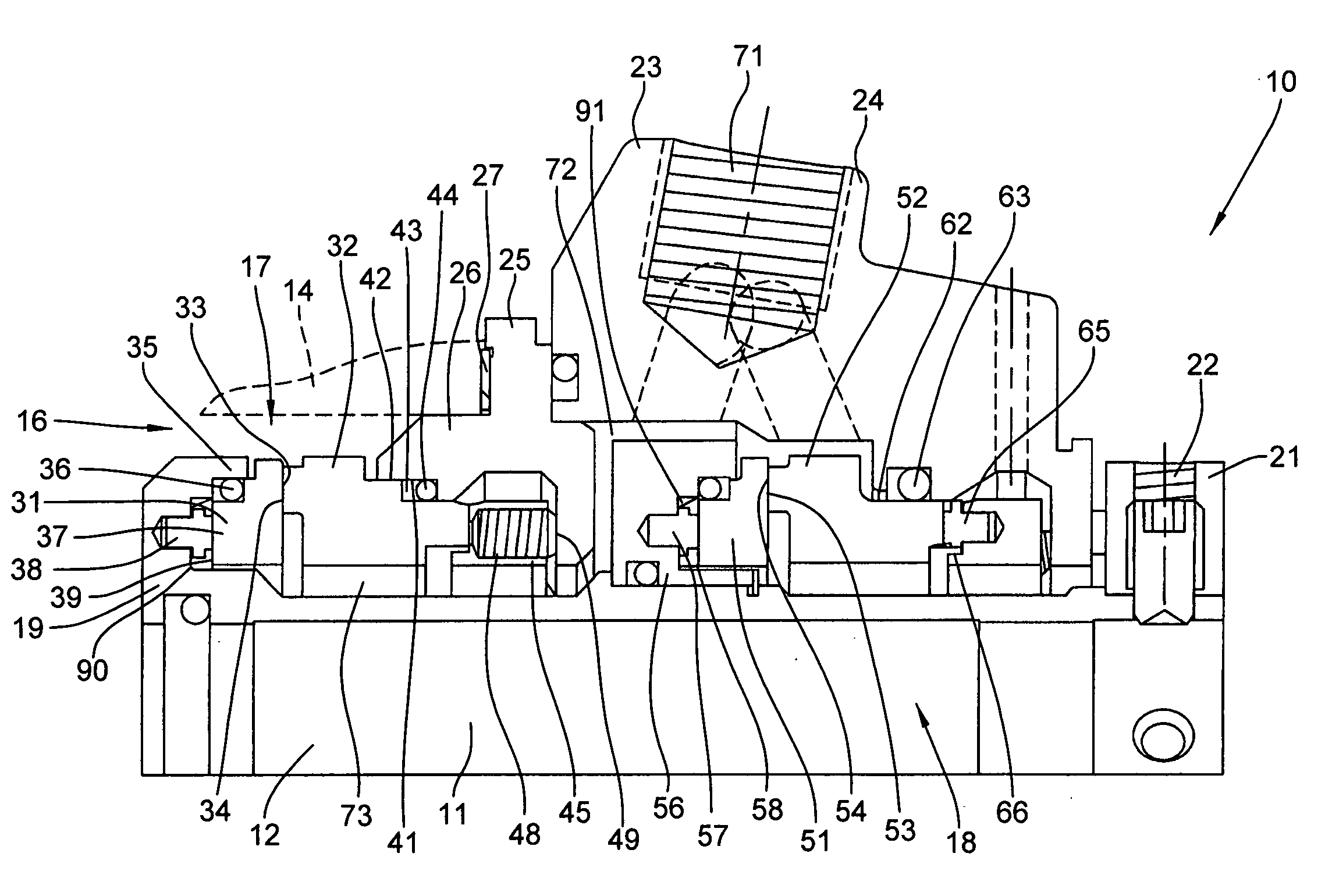

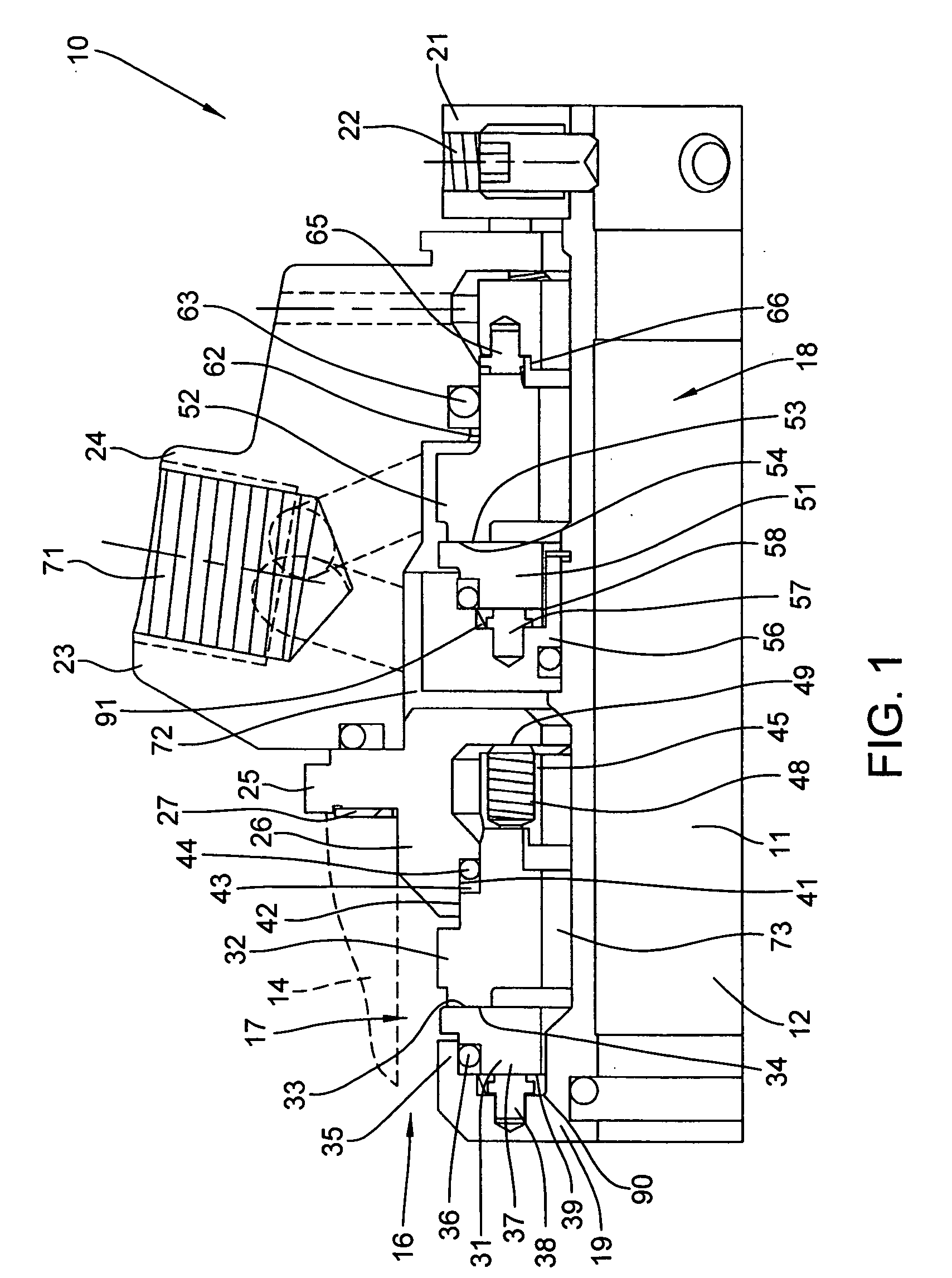

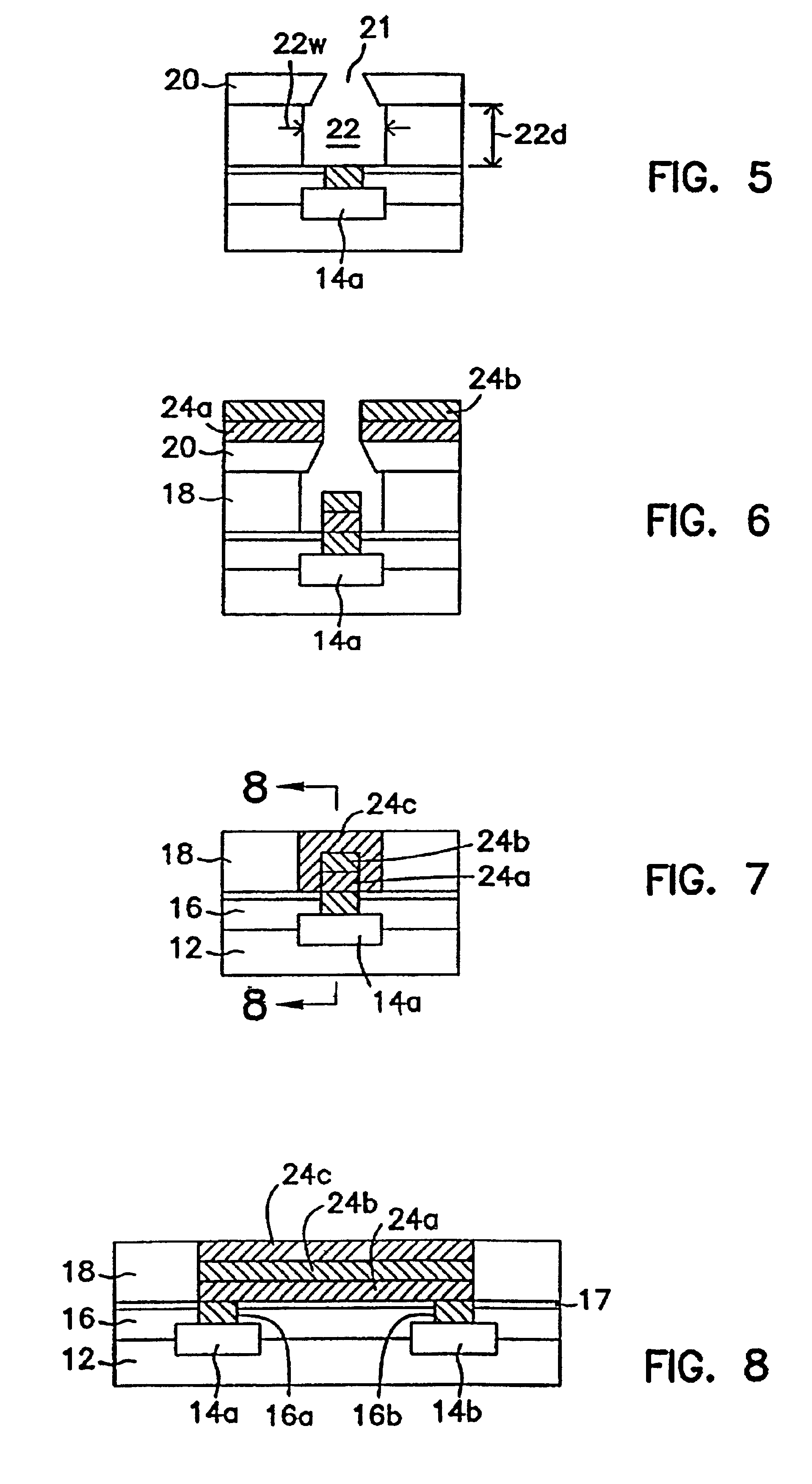

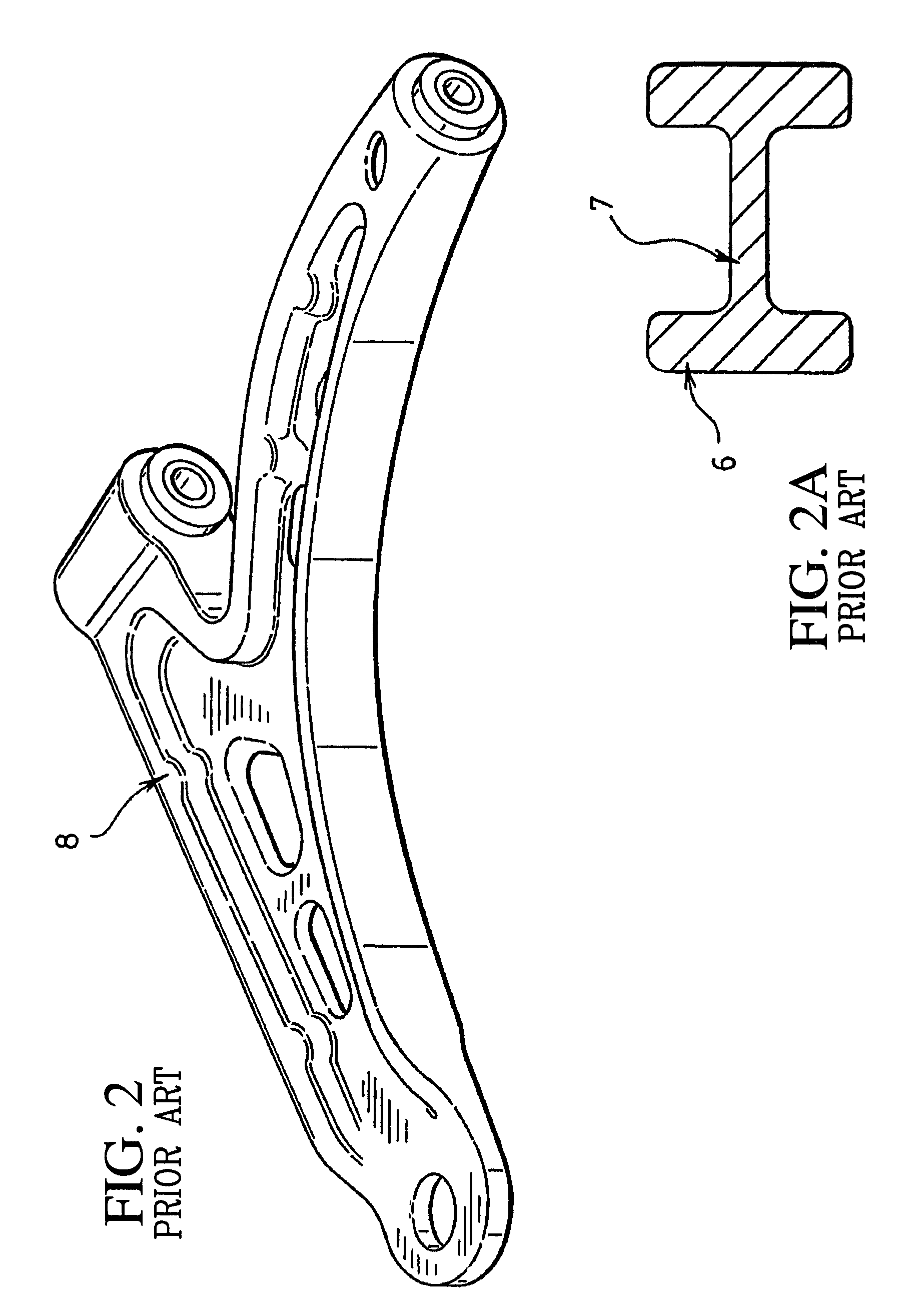

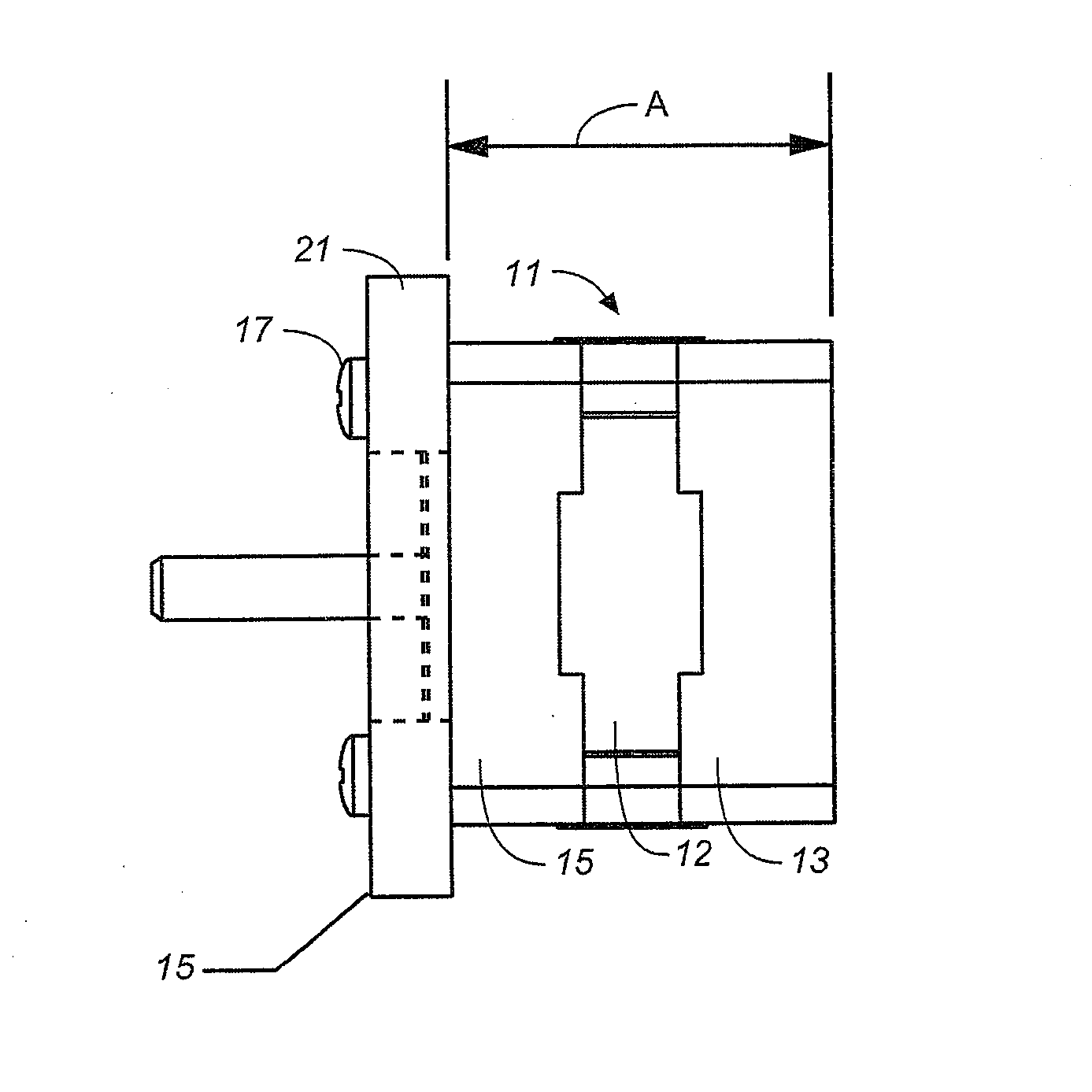

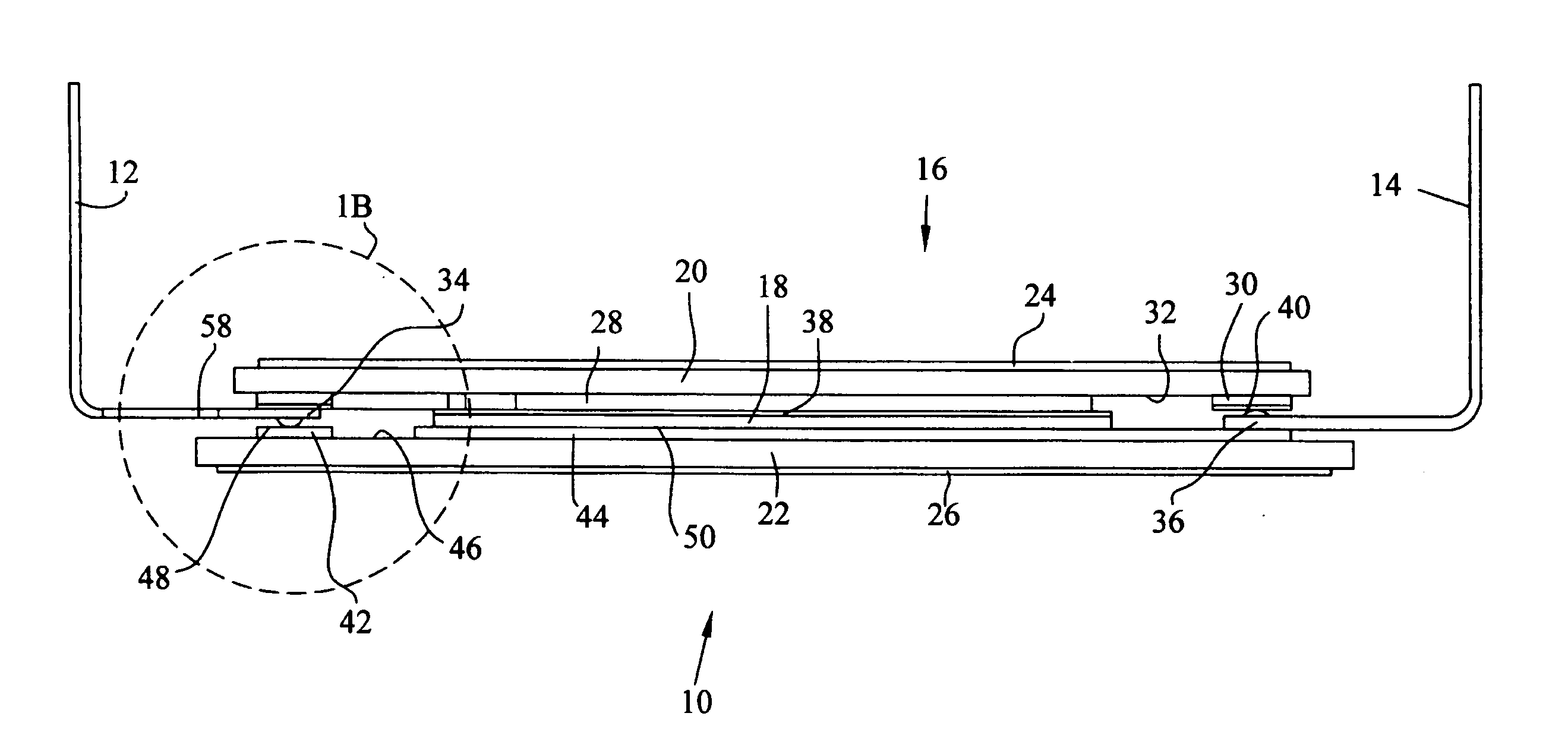

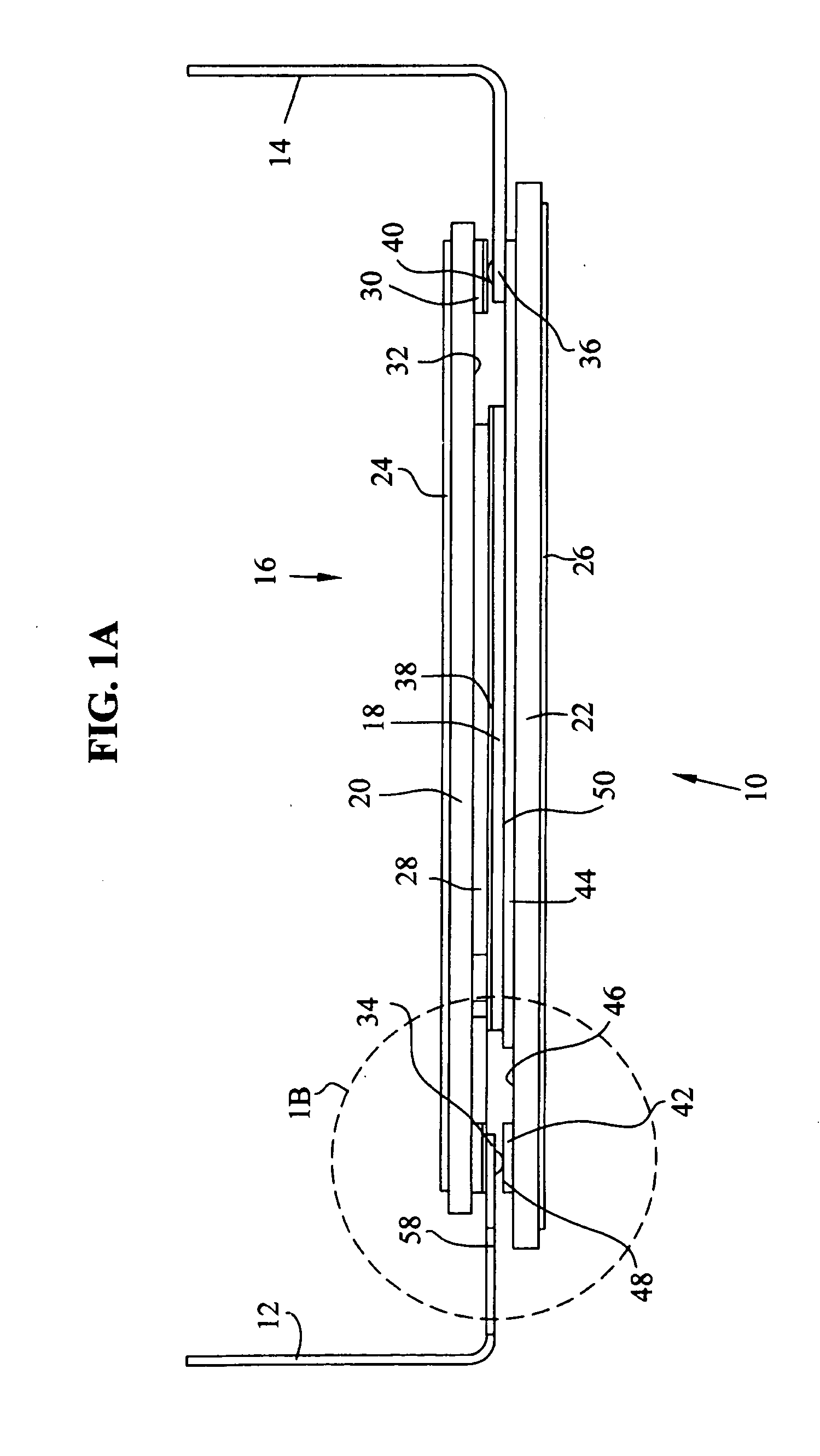

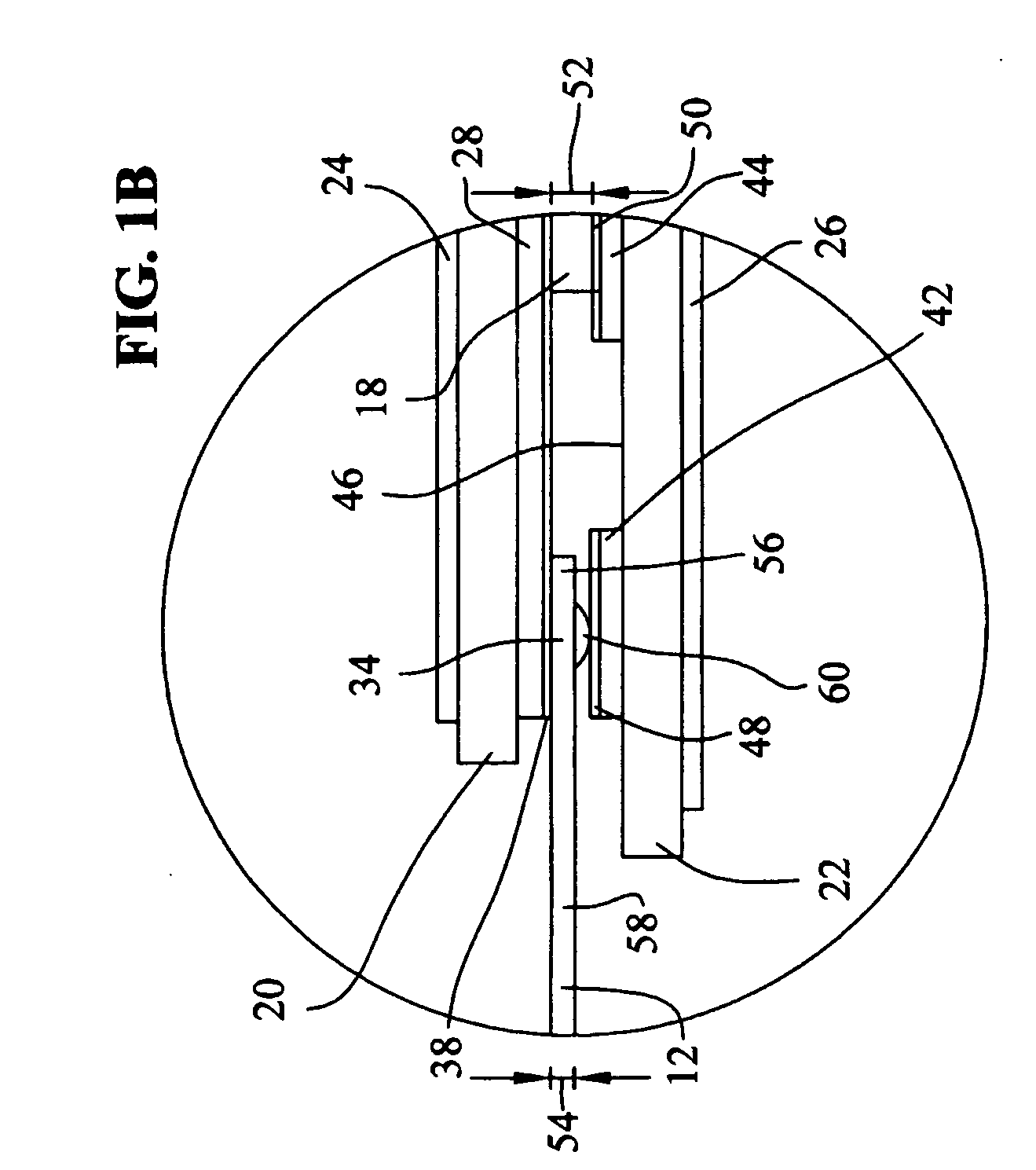

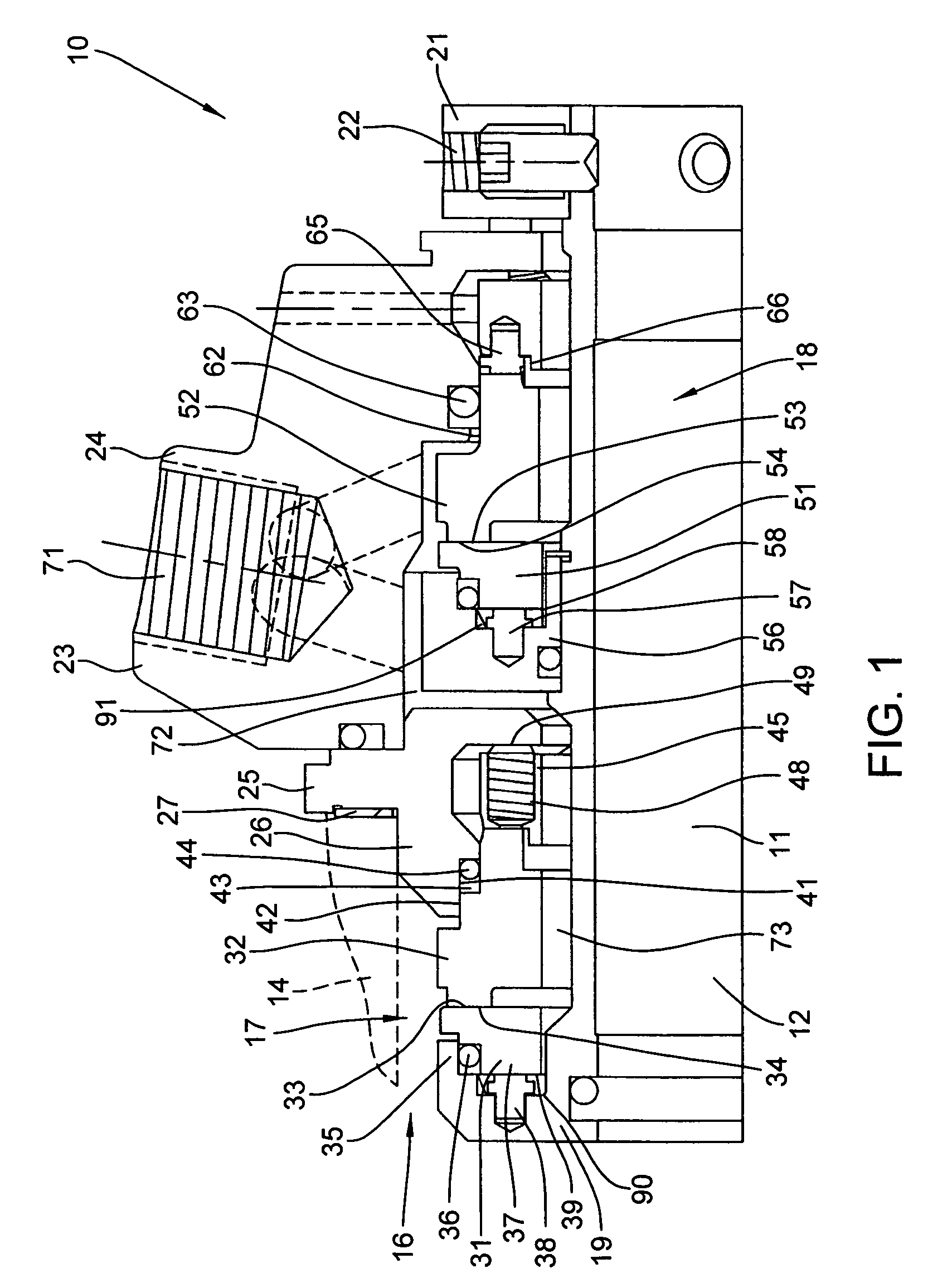

Structural i-beam automotive suspension arm

ActiveUS20050104315A1High inherent stiffnessHigh strengthMetal-working apparatusResilient suspensionsEngineeringFlange

A vehicular suspension arm (10) comprises an upper sheet metal stamped component (11) with a first outer face and a first inner face (19), and a first central web portion (17) with two opposites sides and first upstanding flange portions (13) at opposites sides of the first web portion, a lower sheet metal stamped component (12) with a second outer face and a second inner face (19), and a second central web portion (17) with two opposite sides and a second upstanding flange portions (13) at the opposite sides of the second web portion, the first and second inner faces (19) adapted to contact each other along a substantial portion of the first and second web portions (17), the upper and lower stamped components (11, 12) adapted to be rigidly attached to each other to create a structural I-beam section, wherein the thickness of each upstanding flange portion (13) is at least equal to the combined thickness of the first and second web portions (17).

Owner:MULTIMATIC INC

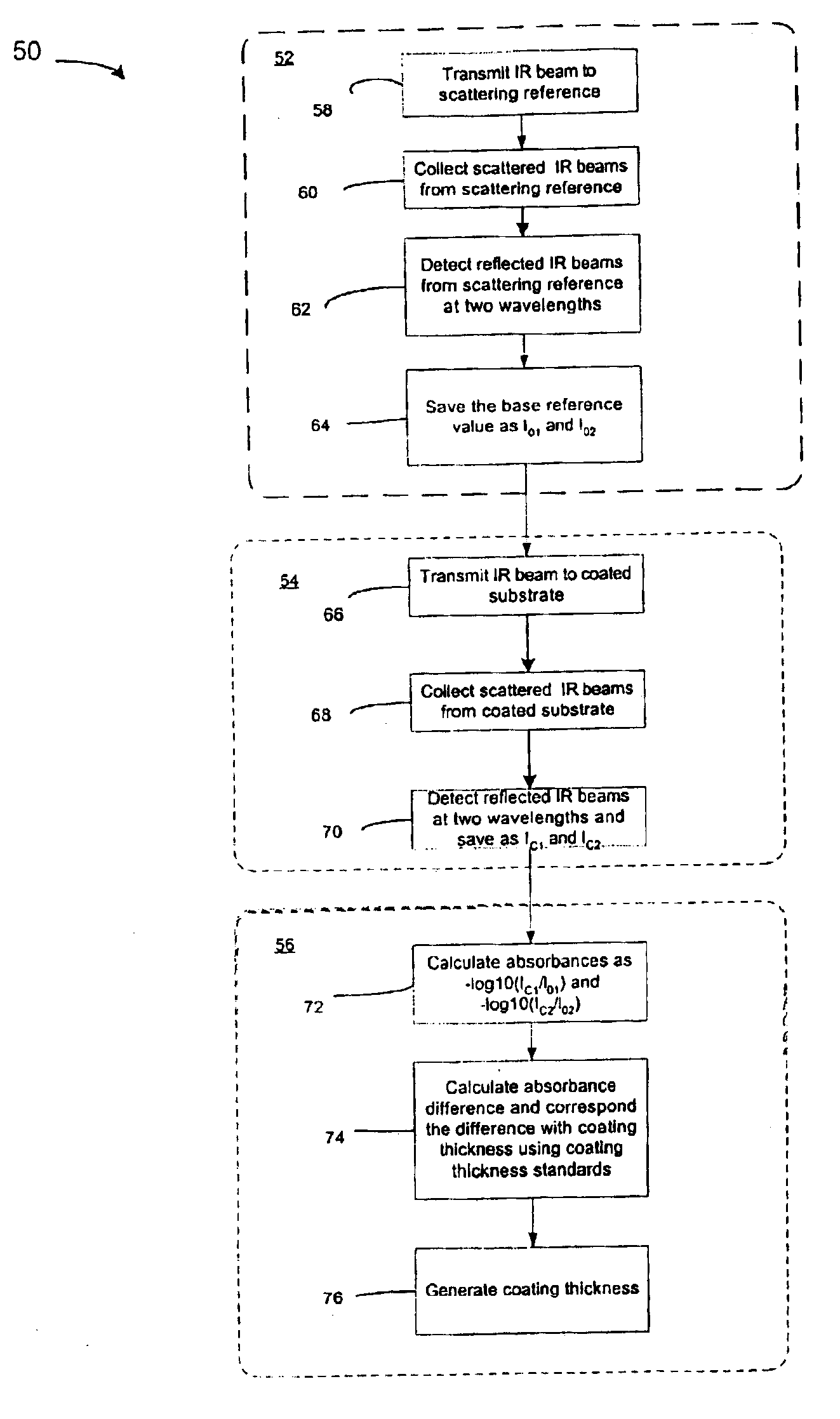

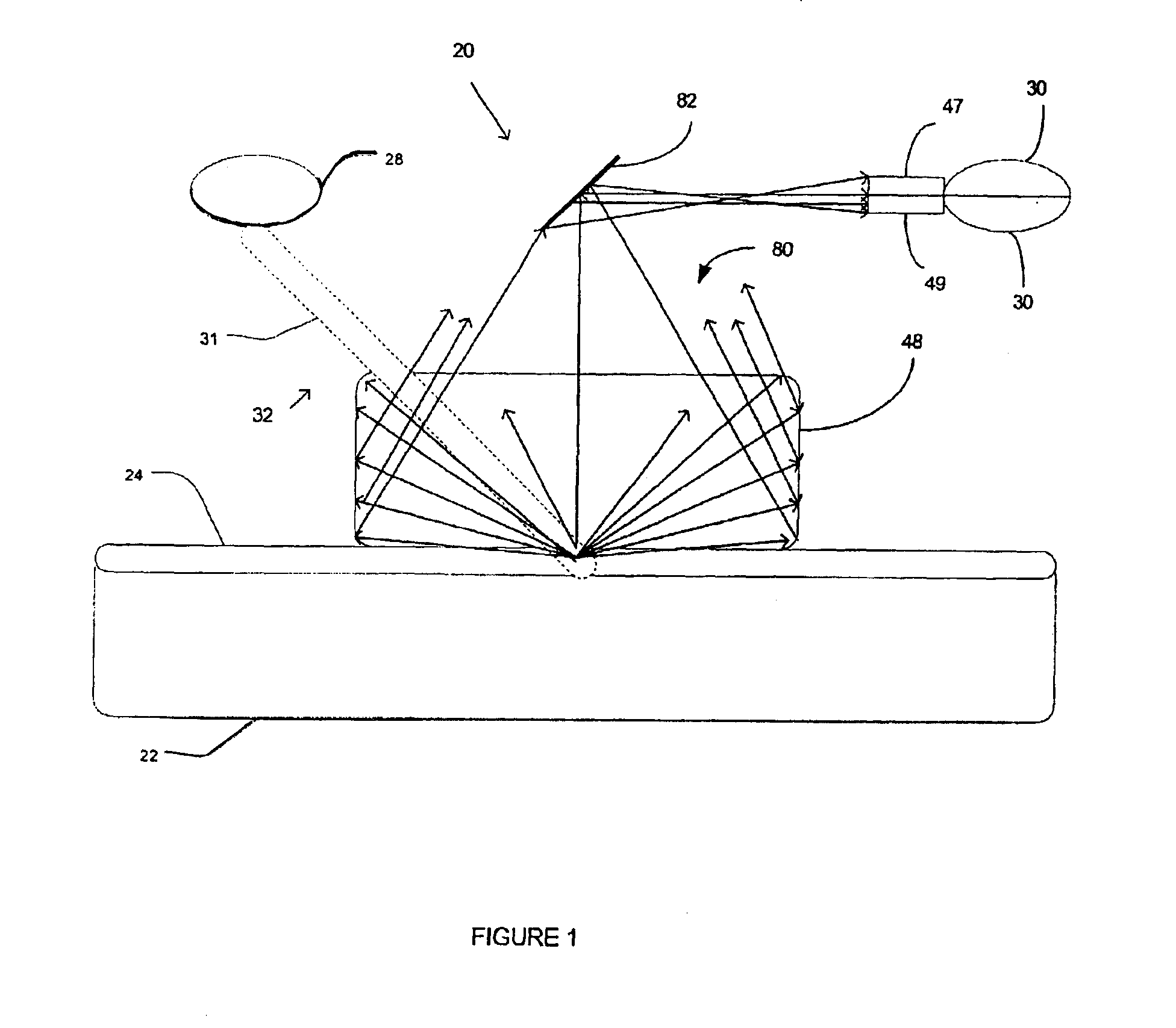

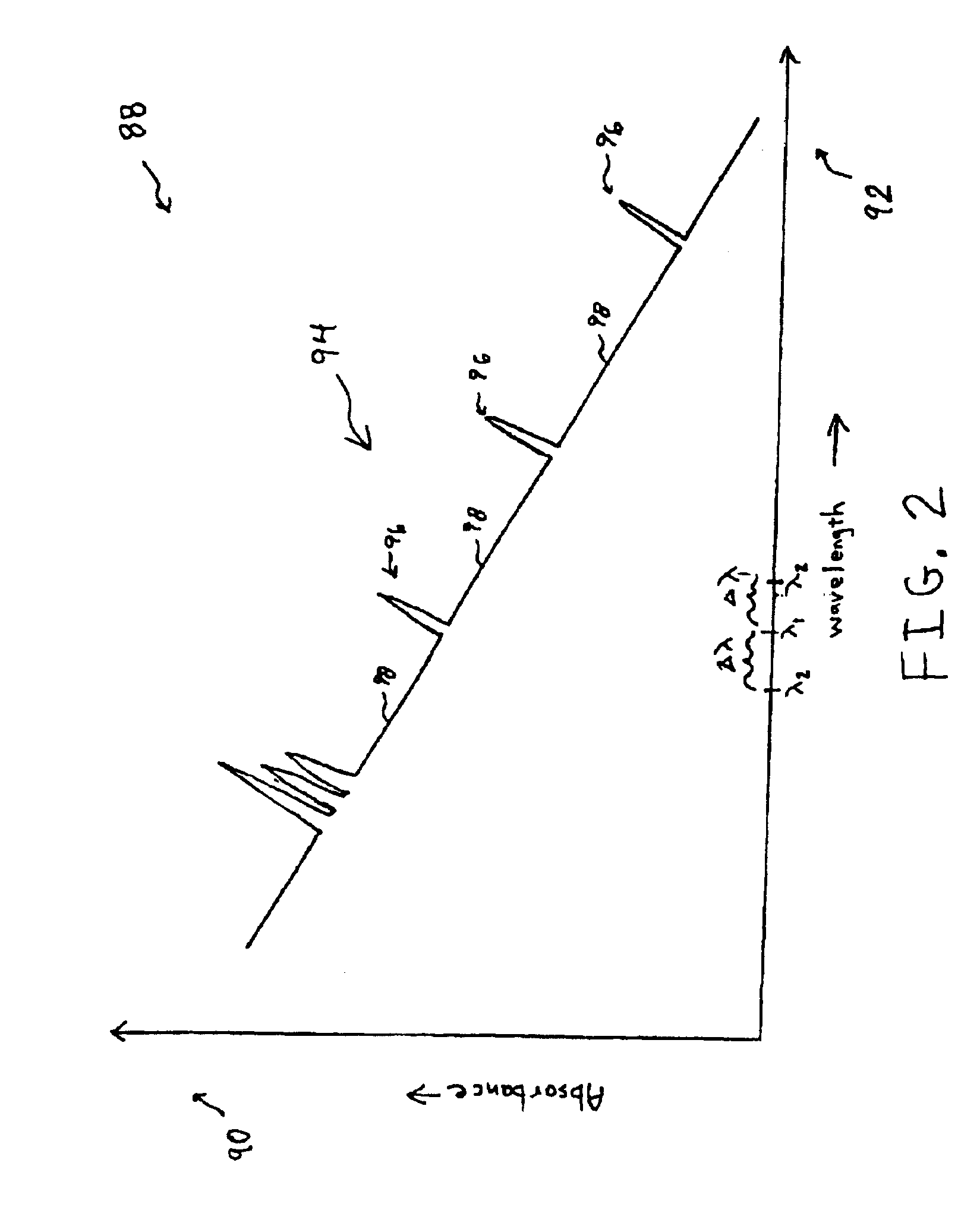

Method of measuring thickness of an opaque coating using infrared absorbance

InactiveUS6903339B2Simple and reliable nondestructiveEffective thicknessRadiation pyrometryScattering properties measurementsLight beamLength wave

Amount of opaque coating on a substrate is determined. An infrared beam is transmitted into the opaque coating on the substrate. Infrared beams scattered by the opaque coating are collected and detected at a first wavelength and a second wavelength. Infrared energy Ic1 and Ic2 of the collected infrared beams at the first and second wavelengths, respectively, are compared with predetermined values of infrared energy Io1 and Io2 of collected infrared beams at the first and second wavelengths, respectively, that are scattered by a reference substrate without the opaque coating to determine absorbance values A1 and A2 for the opaque coating at the first and second wavelengths, respectively. Absorbance values A1 and A2 at the first and second wavelengths are given by equations A1=−log10(Ic1 / Io1) and A2=−log10(Ic2 / Io2). A difference A1−A2 is correlated to an opaque coating amount.

Owner:THE BOEING CO

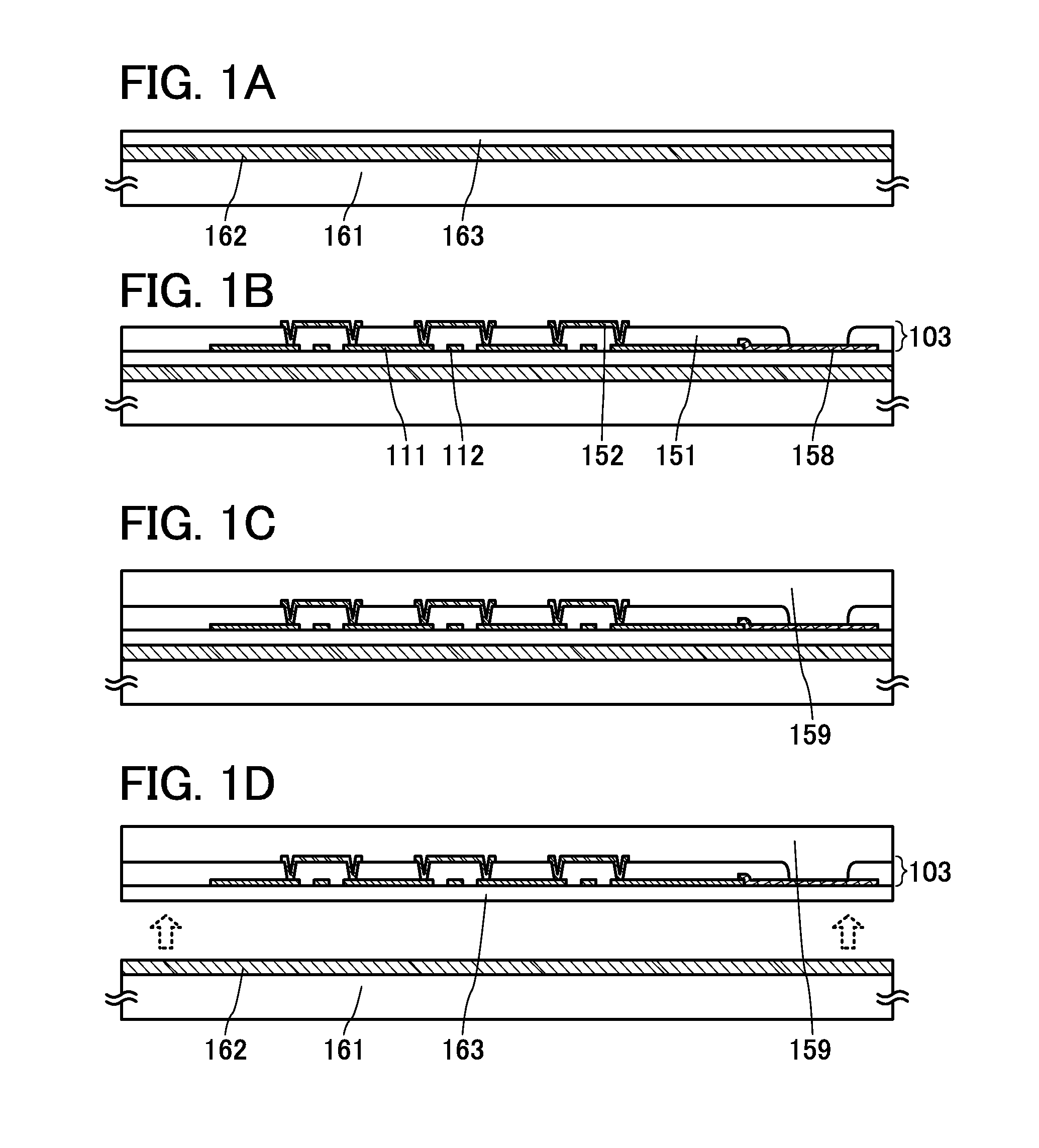

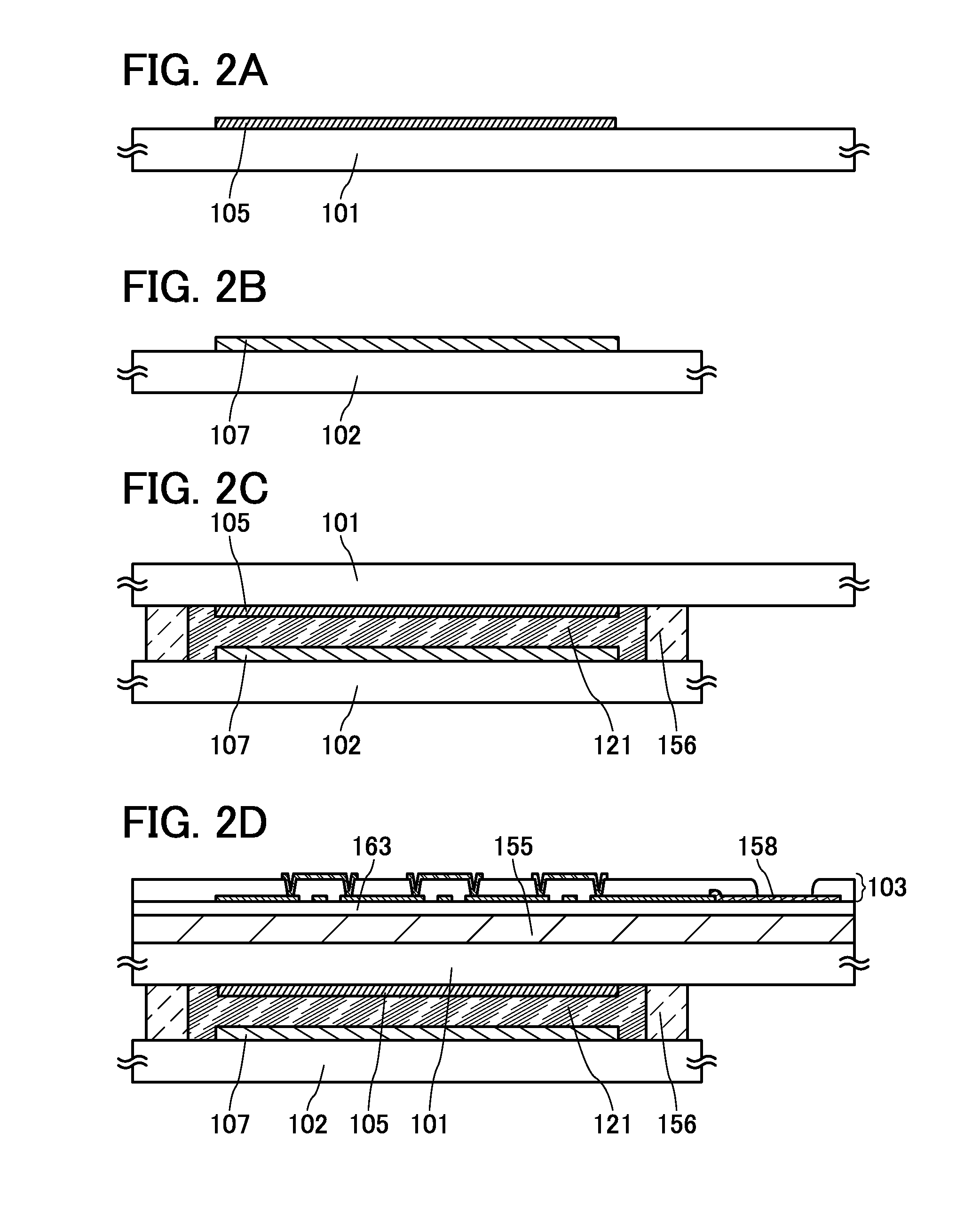

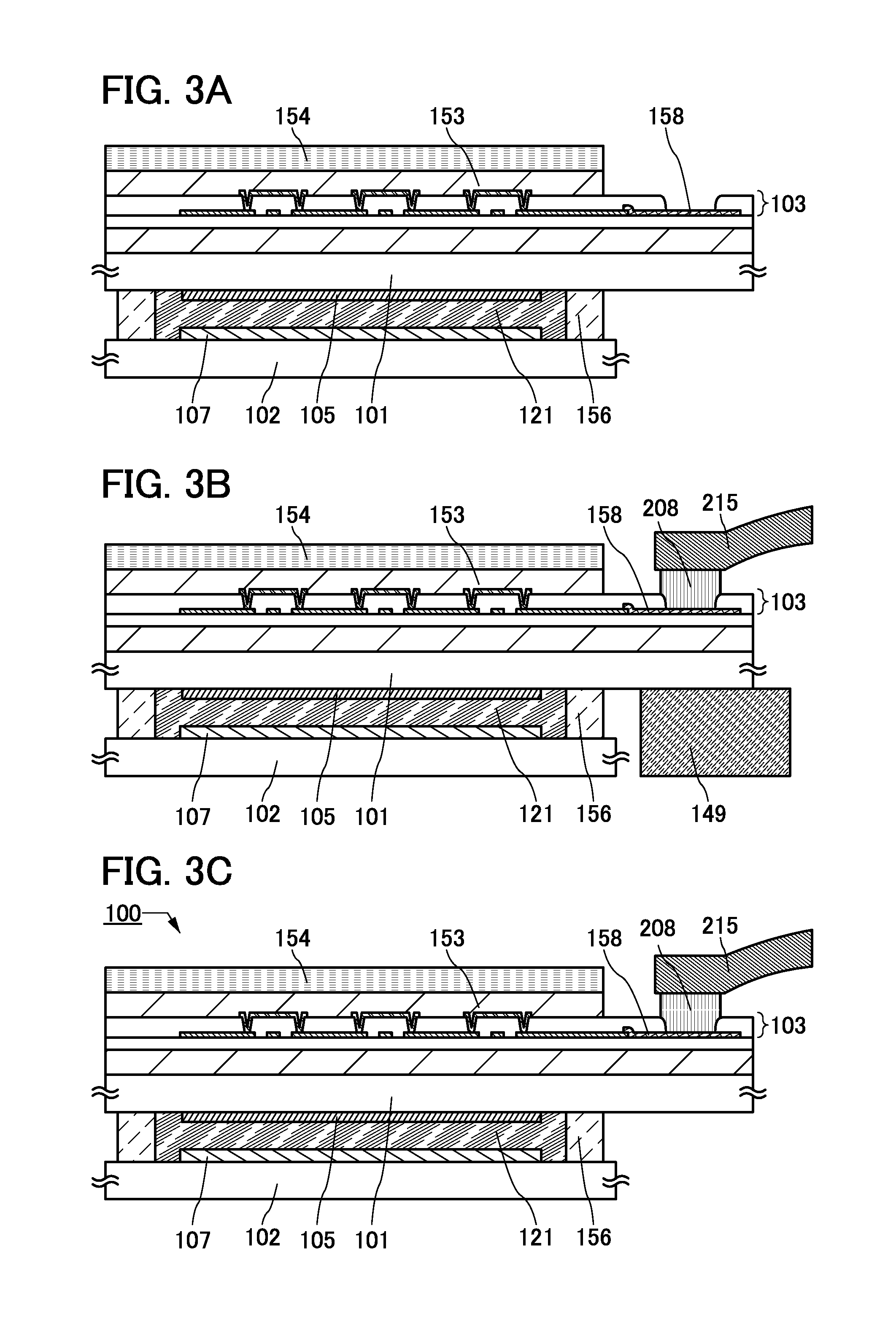

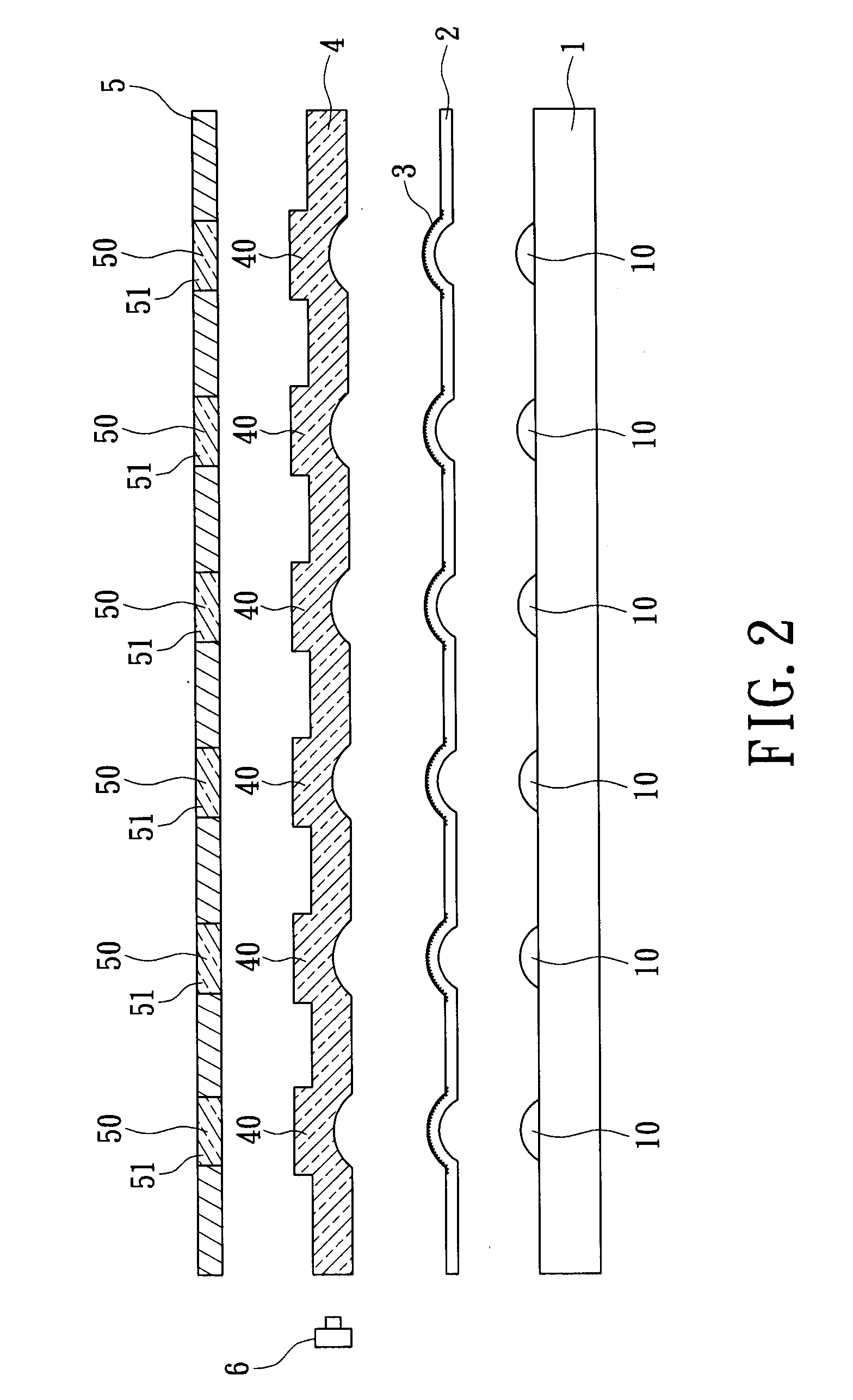

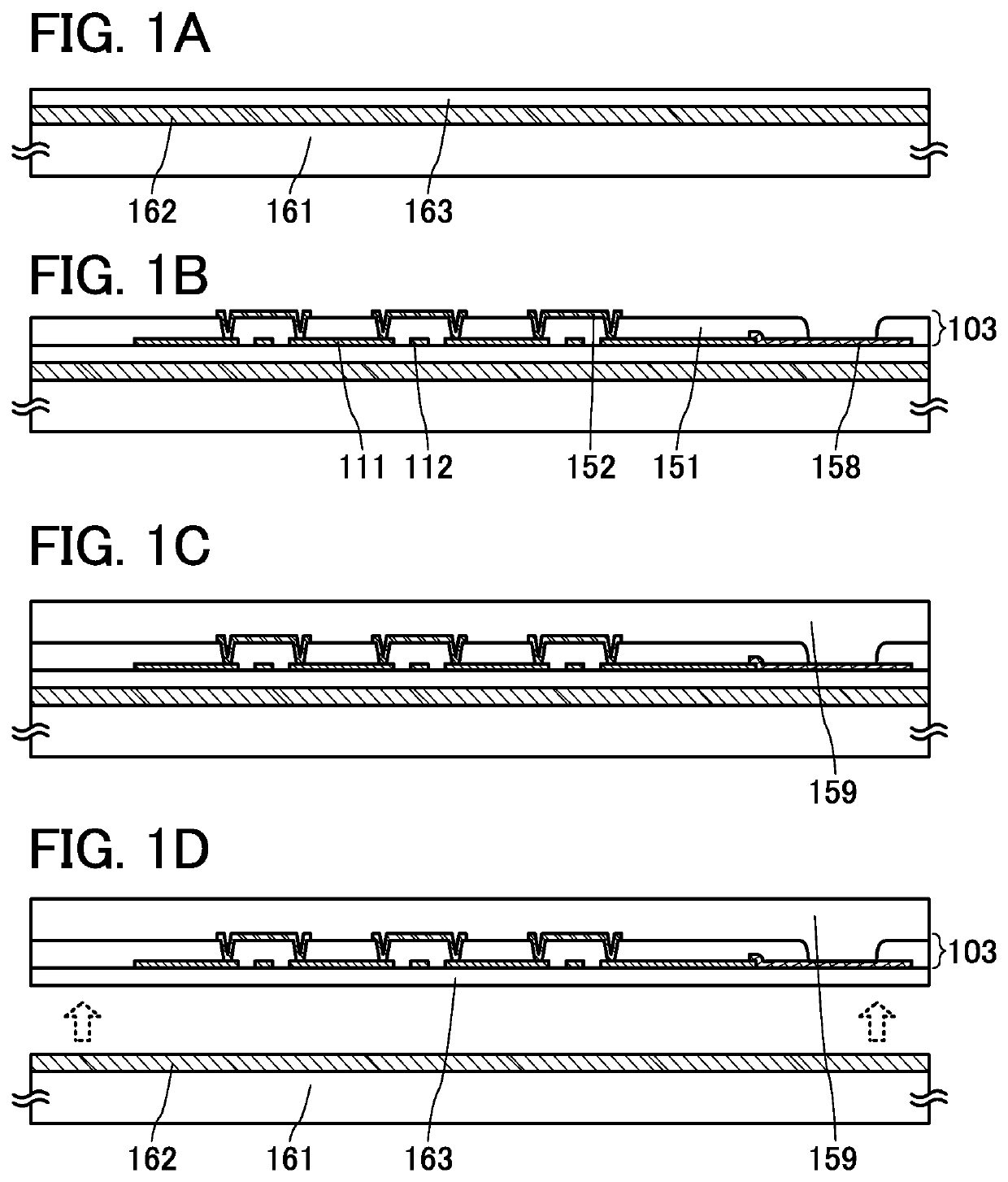

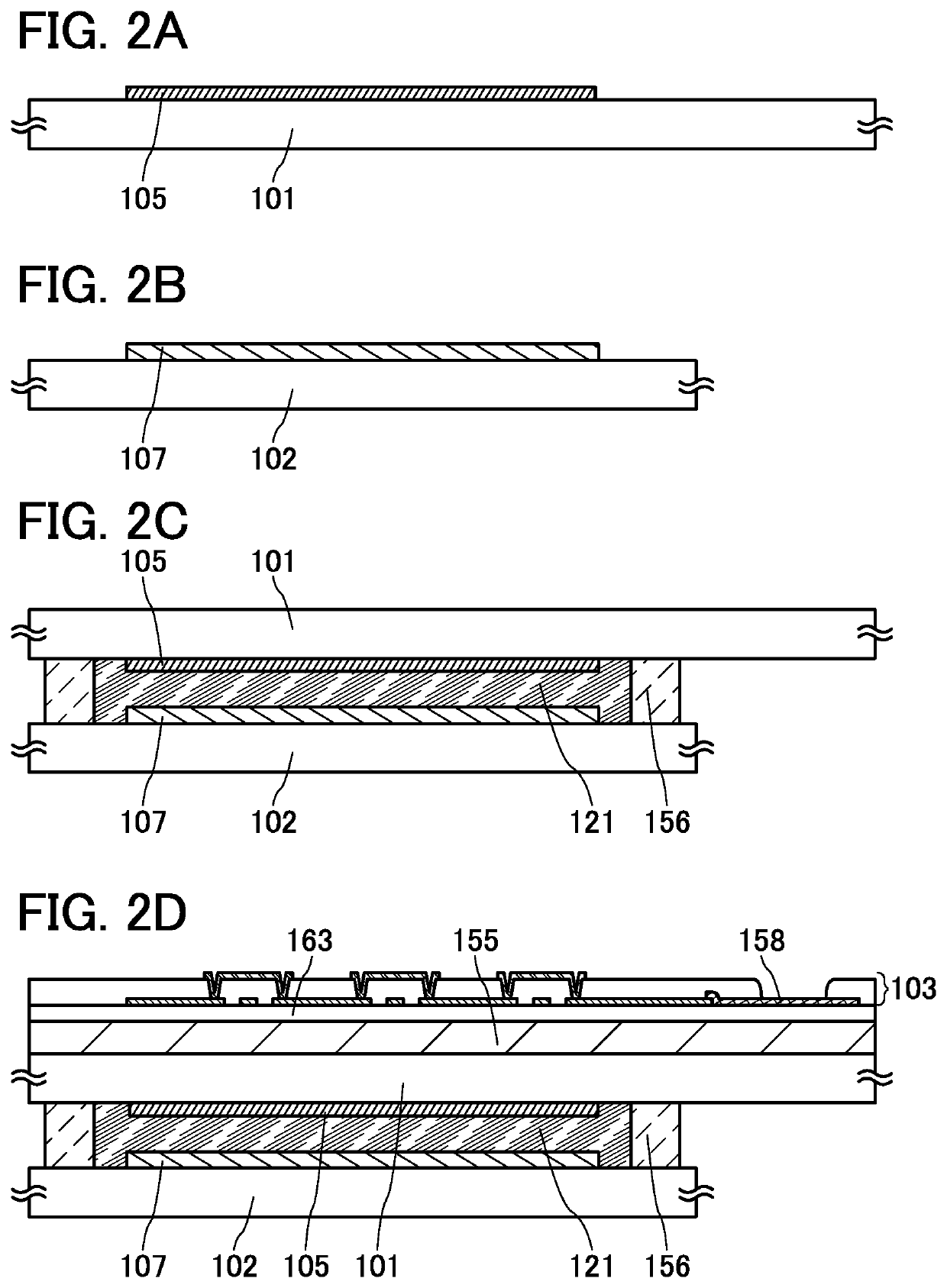

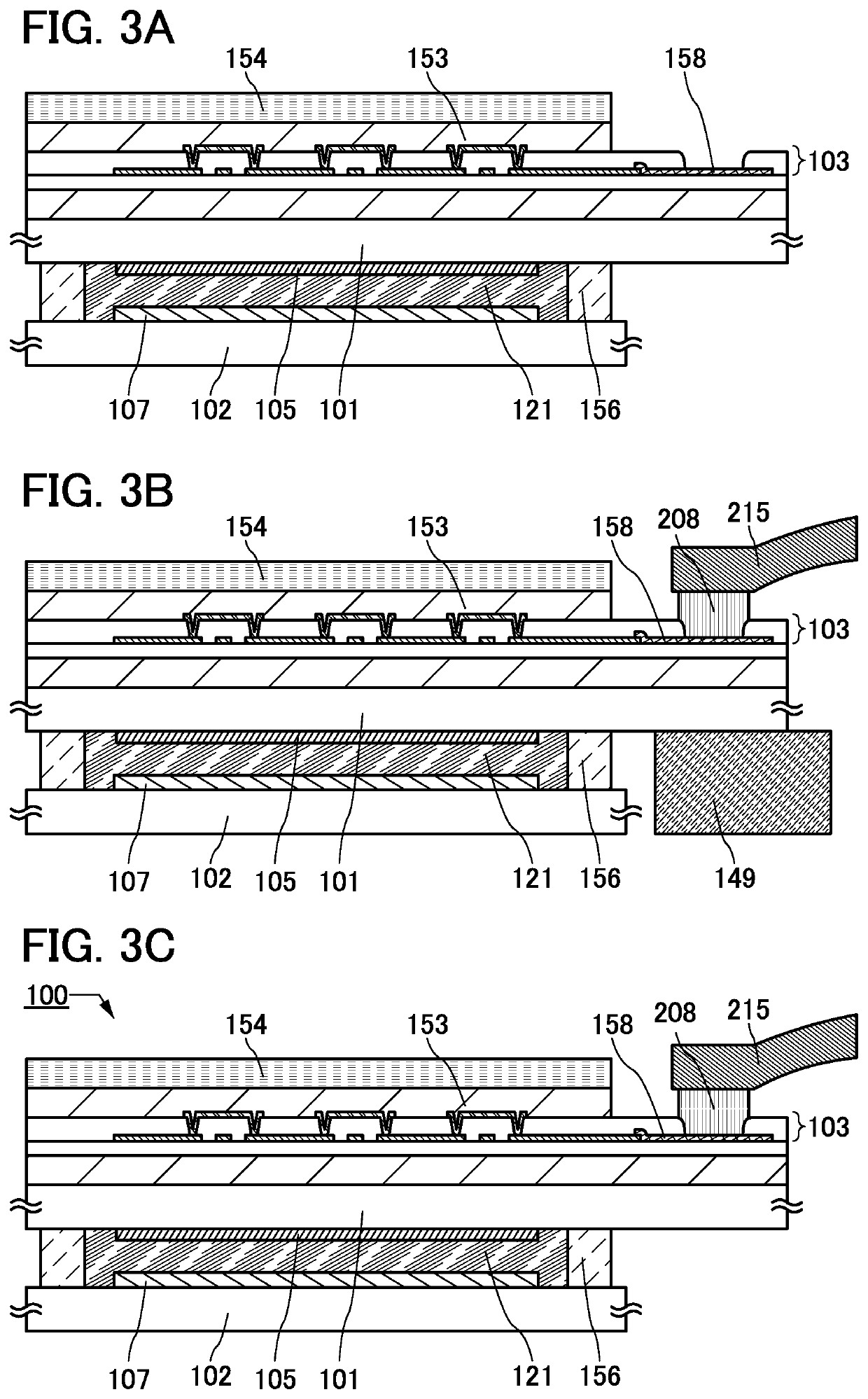

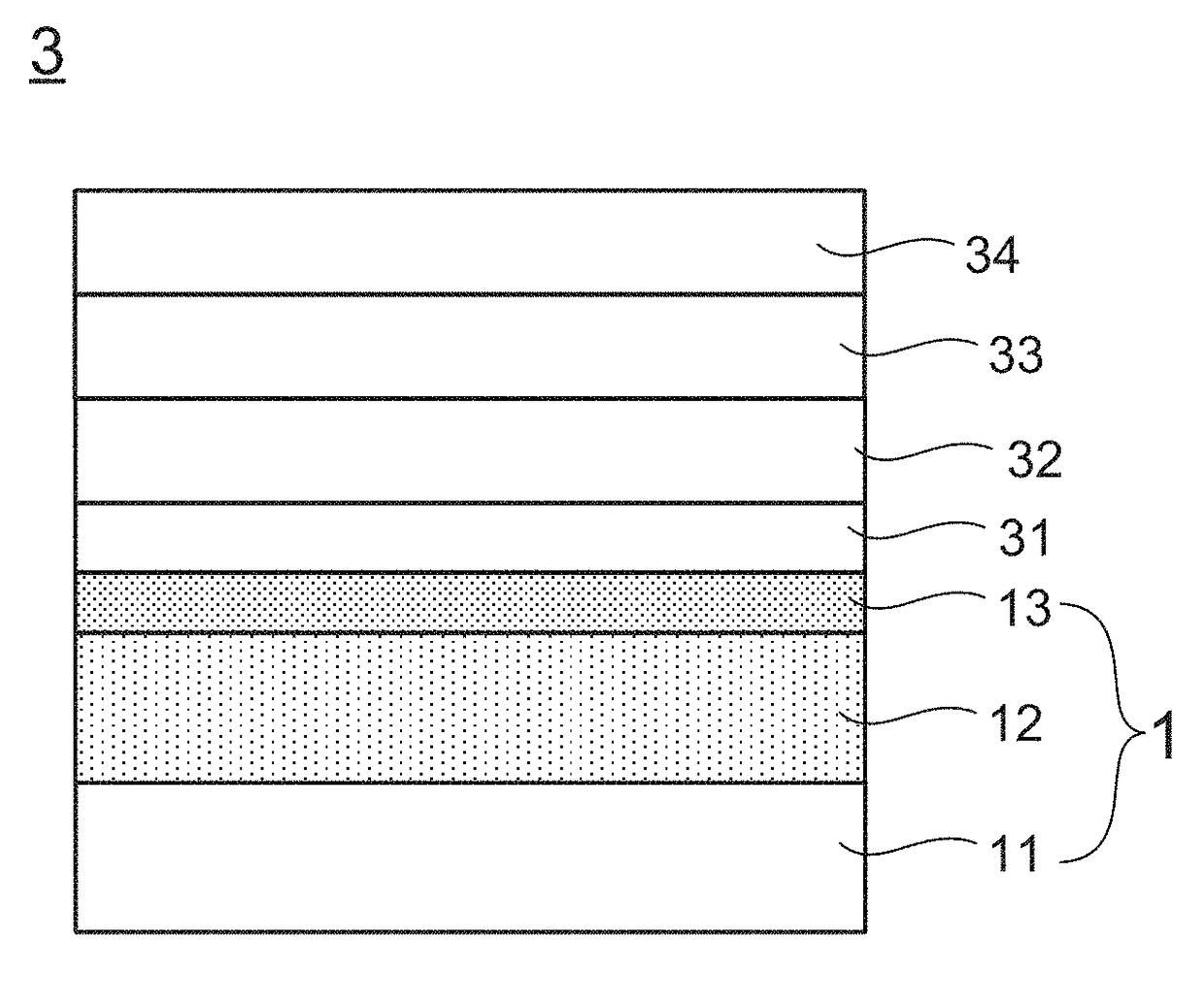

Display device and method for manufacturing the same

ActiveUS20140063364A1Reliable display deviceReduce thicknessDigital data processing detailsVessels or leading-in conductors manufactureDisplay deviceBiomedical engineering

To provide a thinned display device with a touch sensor and to provide a highly reliable display device. A sensor layer including an electrode of a touch sensor is formed in advance over a support substrate which is different from a substrate which forms a display device so that the sensor layer can be separated, the sensor layer is separated from the support substrate, and the separated sensor layer is attached to one surface of a substrate the other surface of which is provided with a component such as a color filter, with a bonding layer interposed therebetween.

Owner:SEMICON ENERGY LAB CO LTD

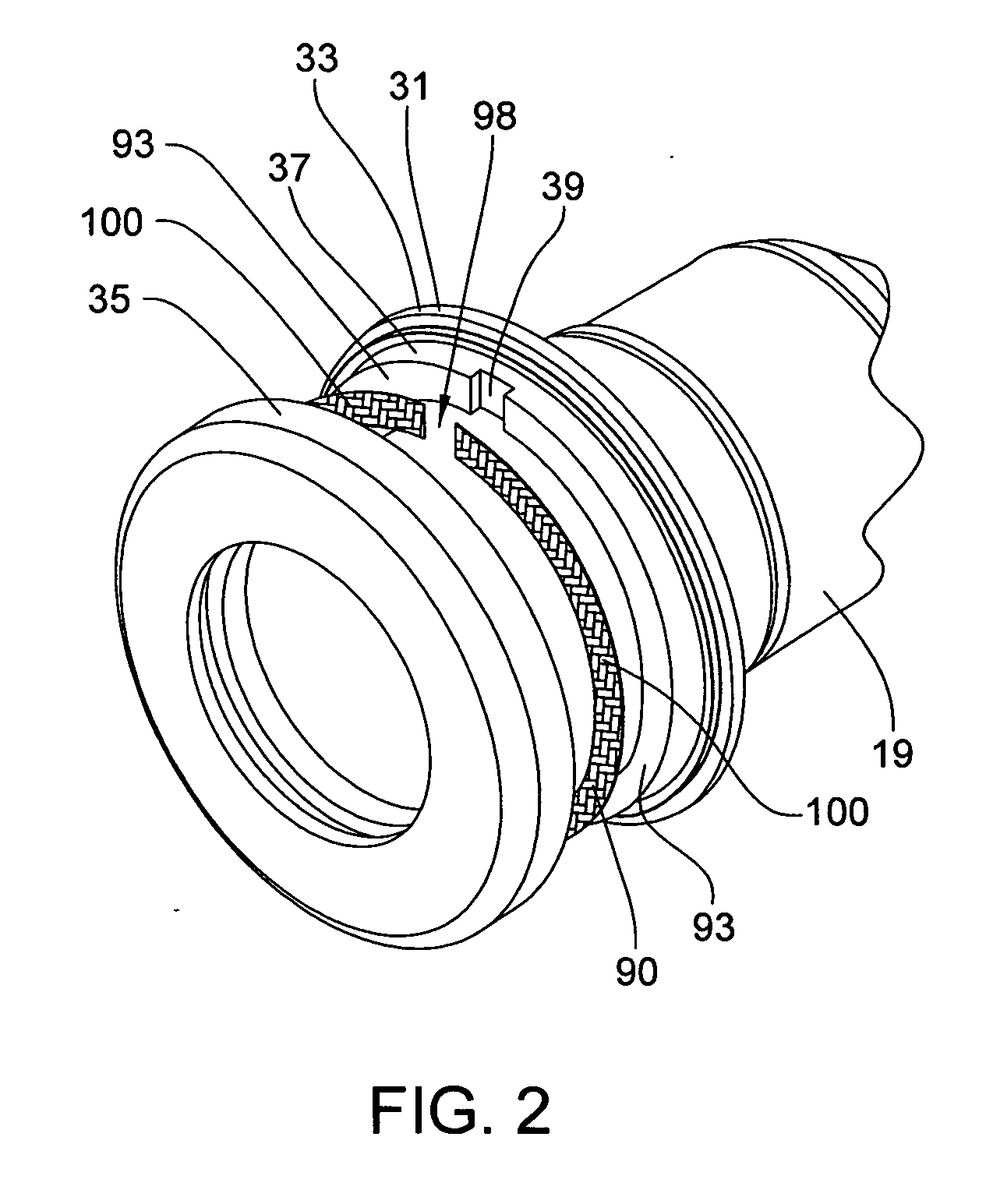

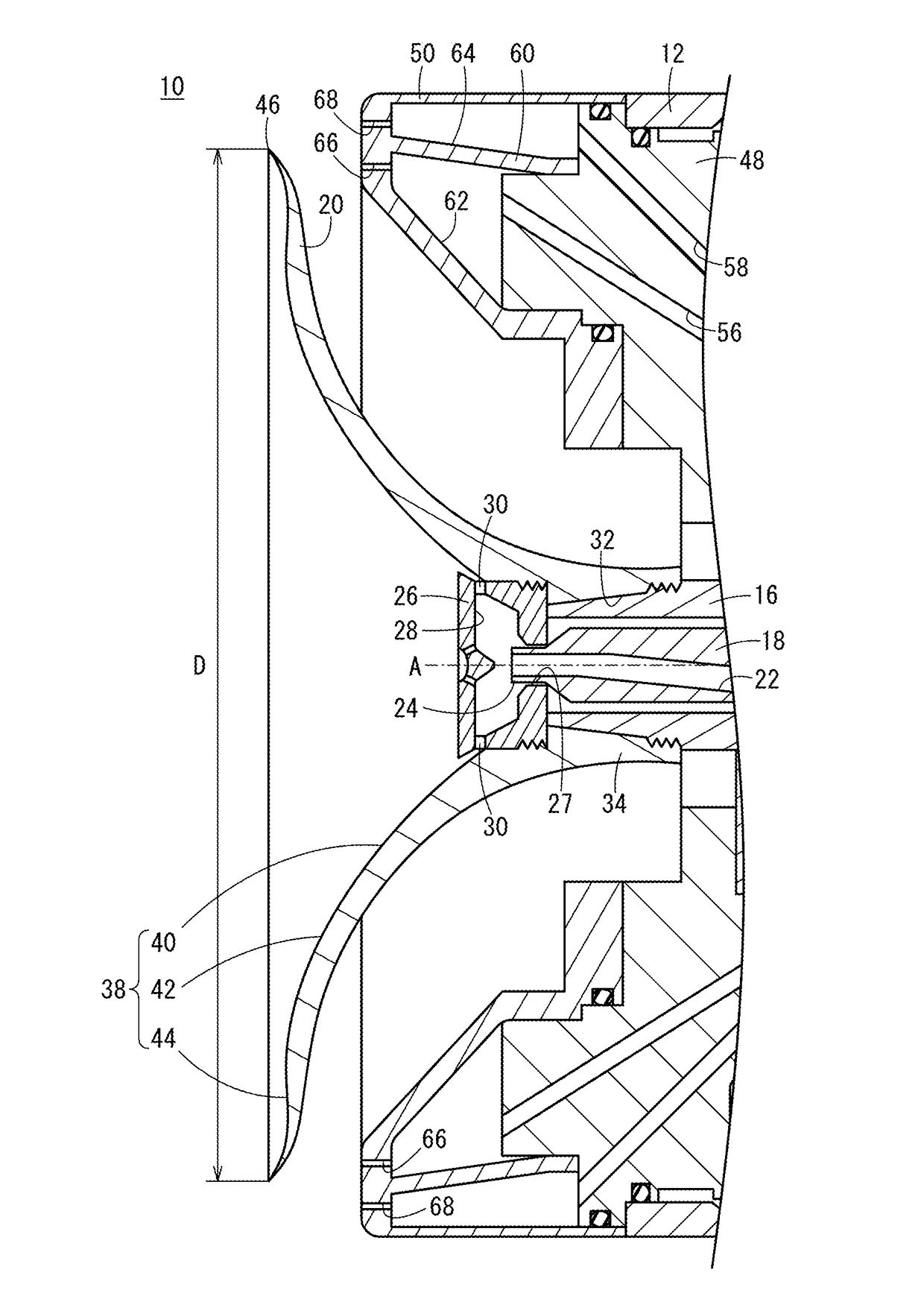

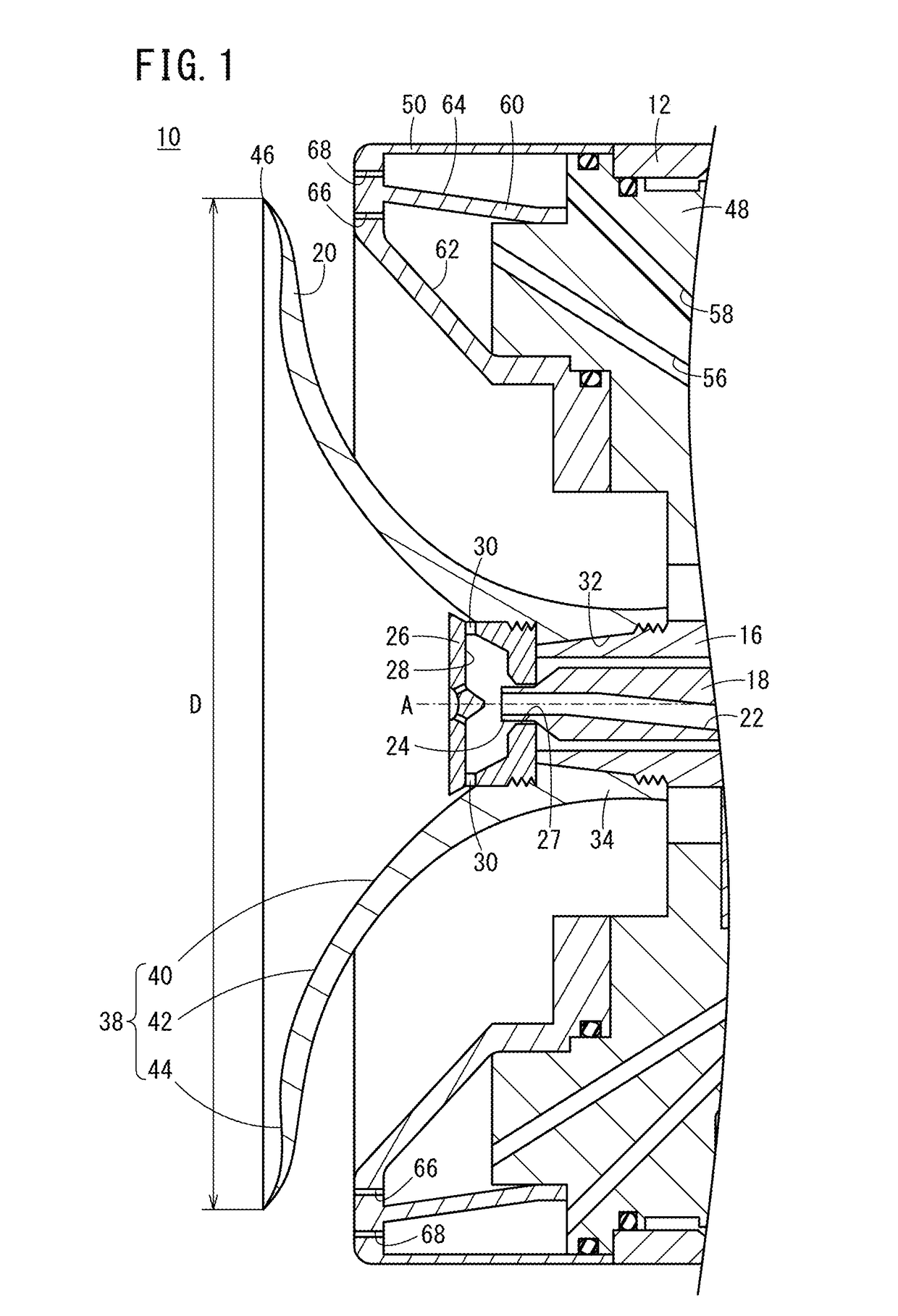

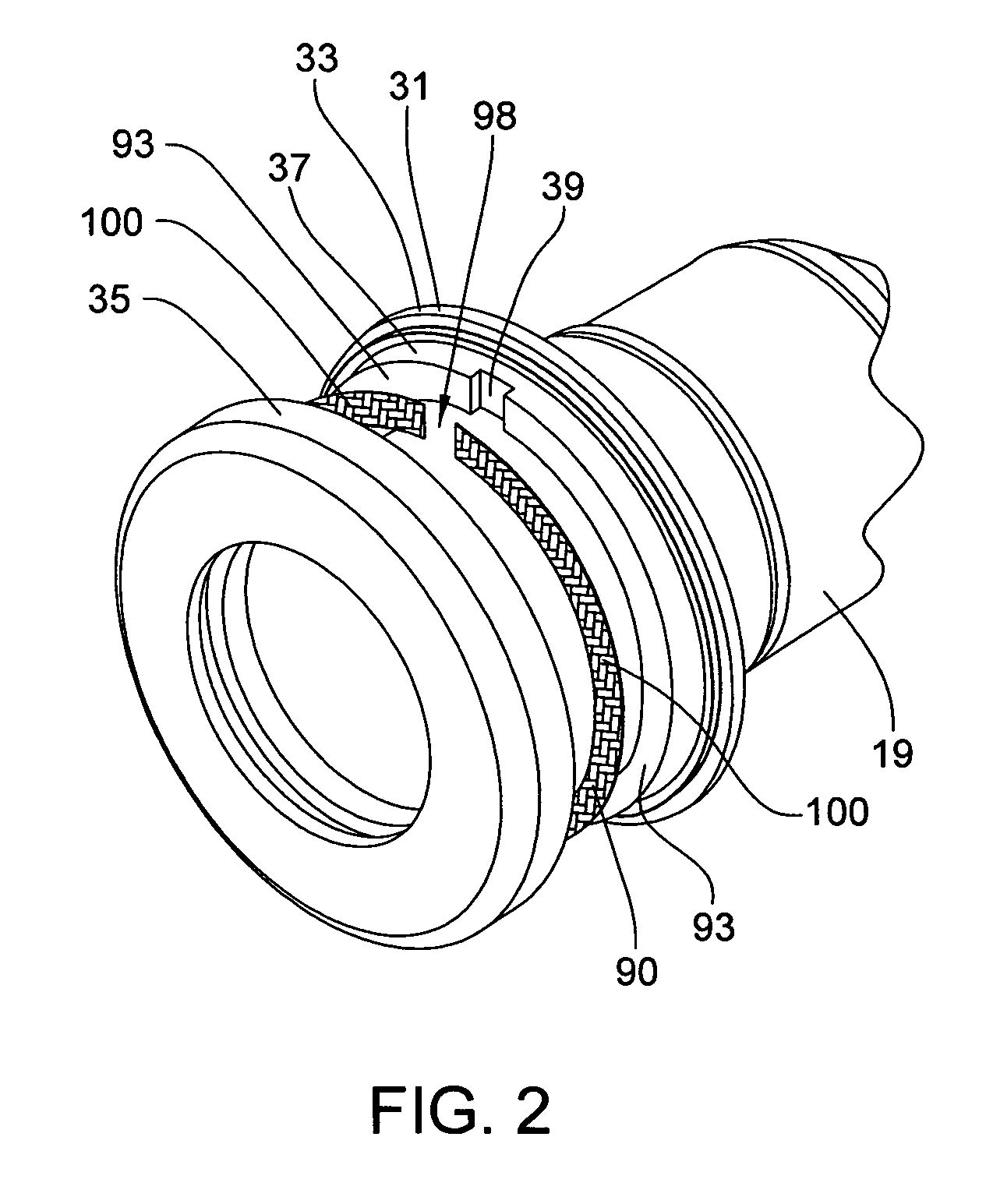

Upset resistant mechanical seal

ActiveUS20090127793A1Smooth connectionFacilitate conductionEngine sealsSpring forceMetallic materials

A mechanical seal face has a significant increase in the ability of the seal to tolerate poor lubrication conditions such as dry running. The mechanical seal employs a thin, non-corrugated flat sheet of flexible thermally conductive graphite material placed between one of the mechanical seal faces and a metal surface such as a metal surface defined by a shaft sleeve or gland serving as a seal ring holder. The graphite sheet is located axially between a back face of the more thermally conductive mechanical seal ring and the metal face holder part. The conductive seal face material preferably is a ceramic or cermet material such as silicon carbide, tungsten carbide, silicon nitride, aluminum oxide, or a metallic material such as stainless steel. Fluid pressure and spring forces are used to create a compressive load between the seal face, graphite sheet, and metal part to maximize continuous contact between the opposed faces of these parts and the opposite sides of the graphite sheet, and heat buildup at contacting seal faces flows away therefrom to the metal part through the thermally conductive sheet.

Owner:FLOWSERVE MANAGEMENT CO

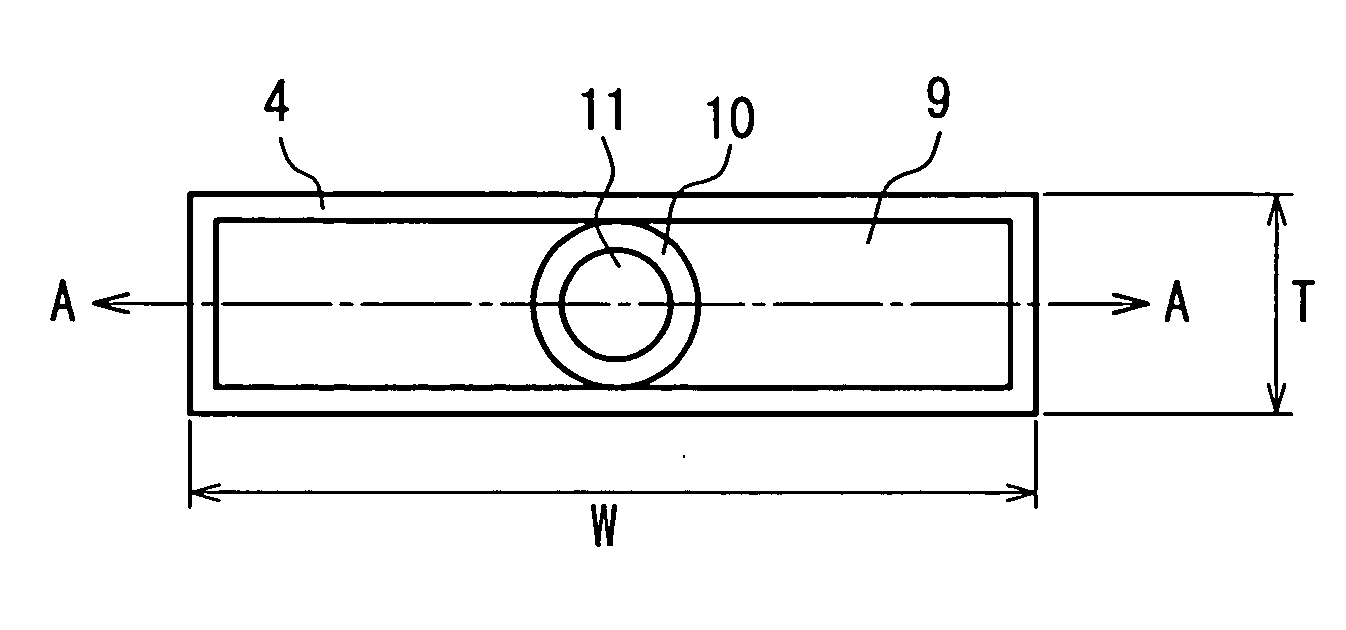

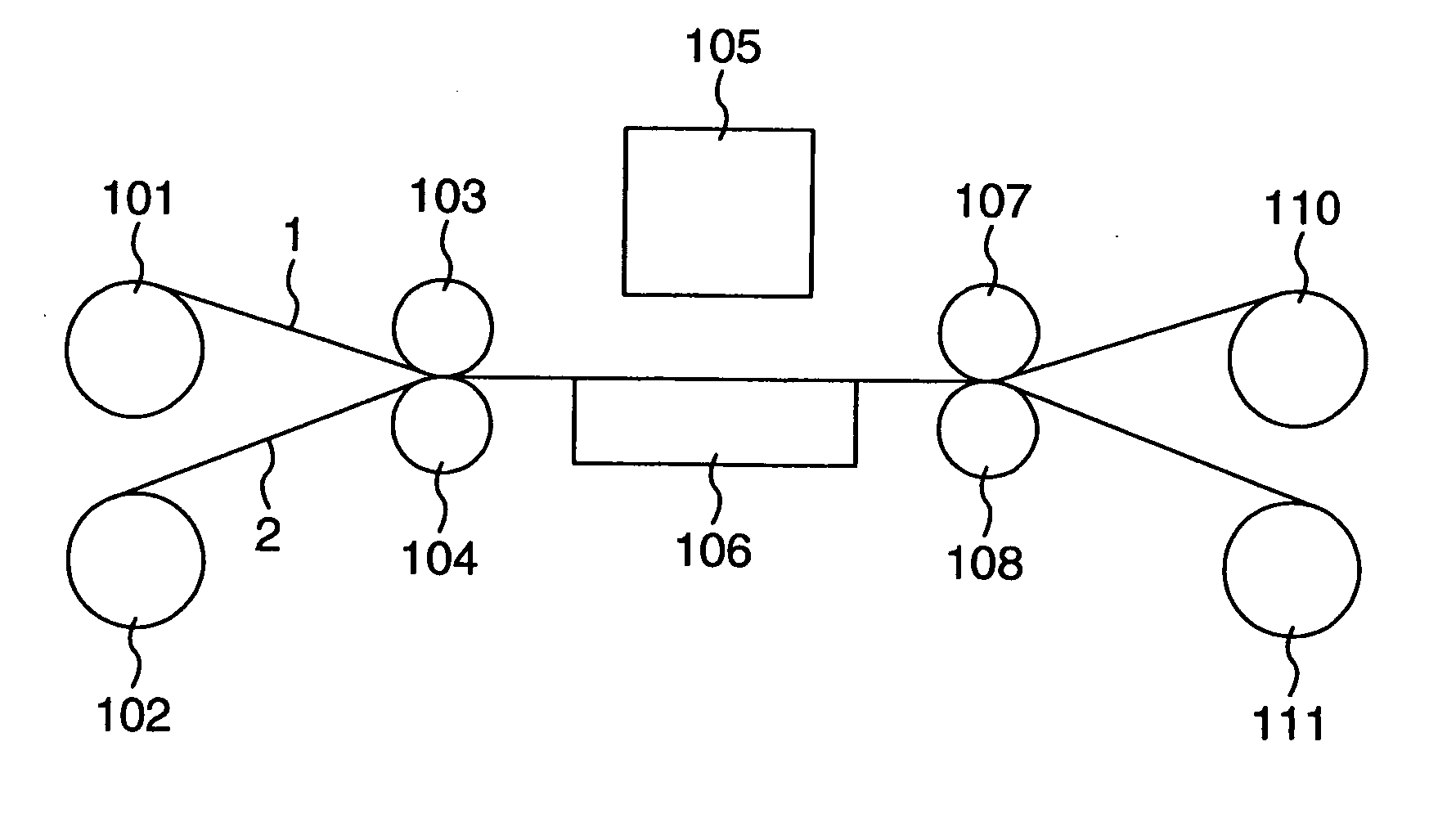

Nonaqueous secondary cell and electronic device incorporating same

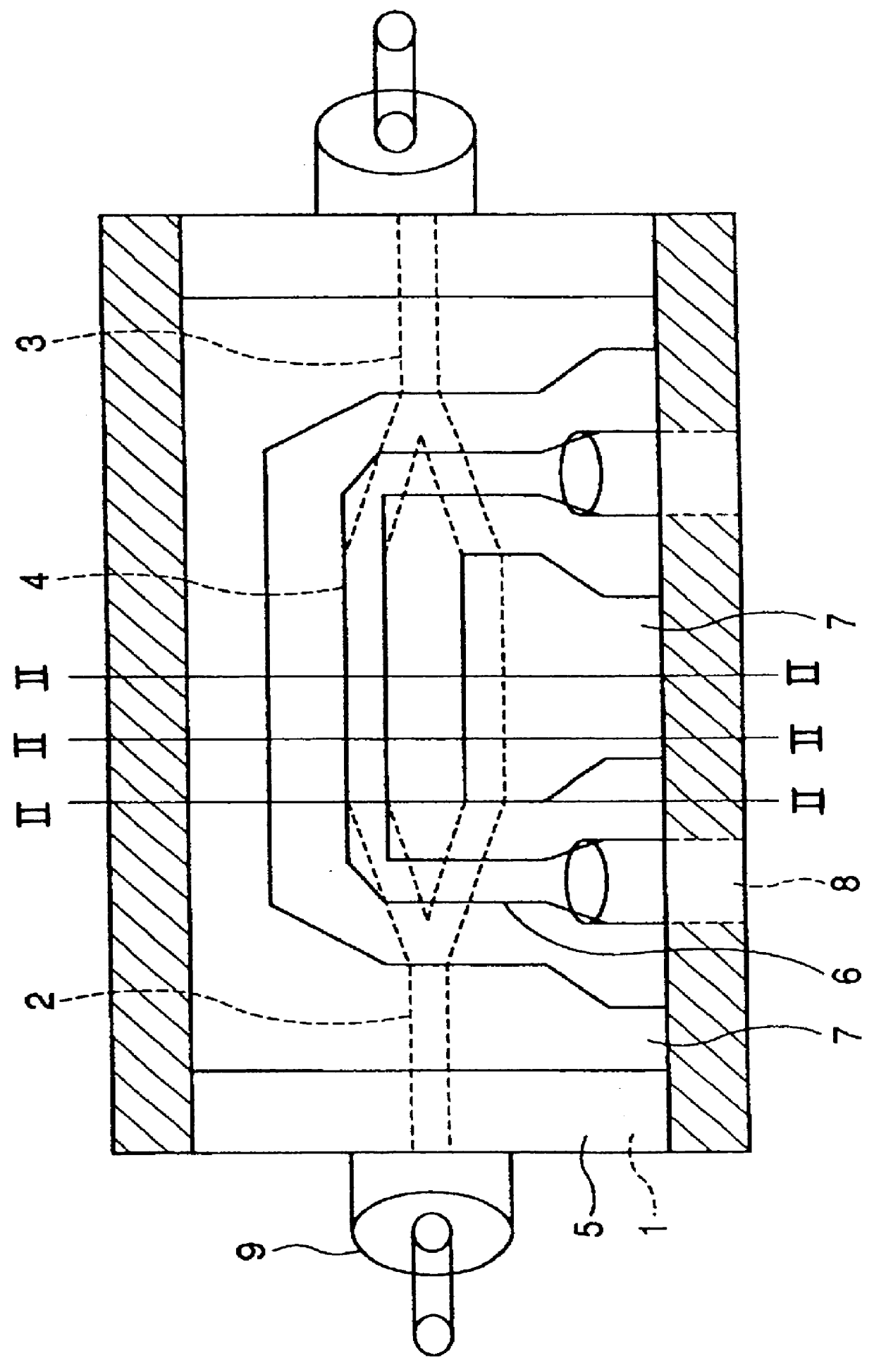

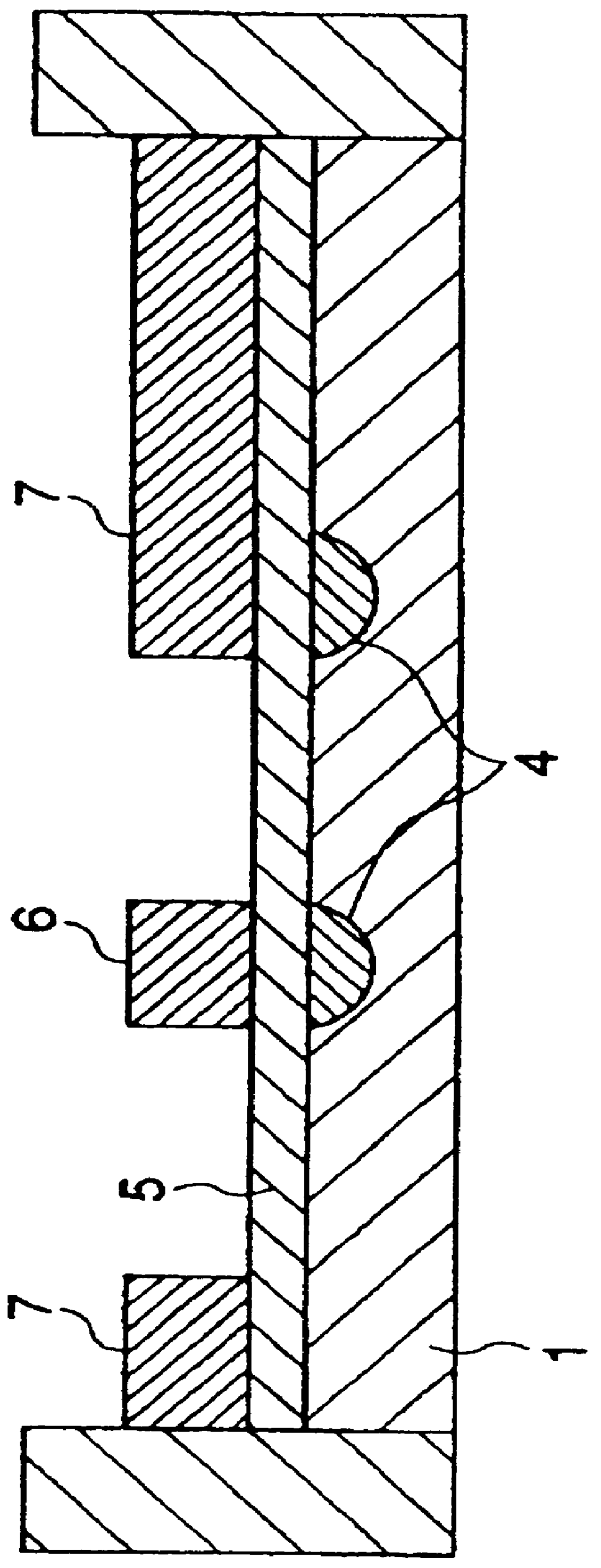

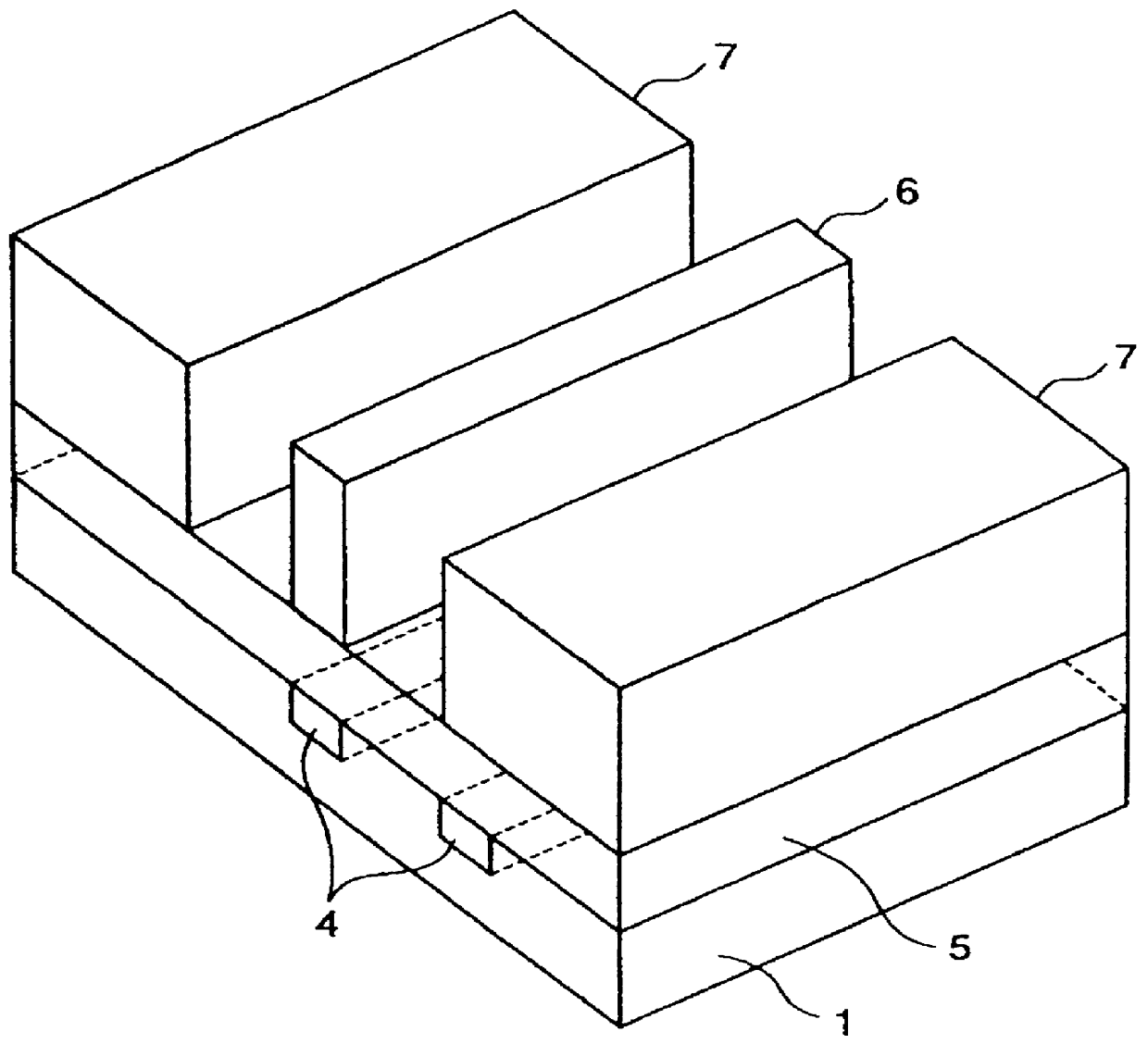

InactiveUS20040142245A1Exhibit some effectImprove securityCell seperators/membranes/diaphragms/spacersOrganic electrolyte cellsHigh ratePhysical chemistry

A non-aqueous secondary battery includes a positive electrode 1, a negative electrode 2, a separator 3, and a non-aqueous electrolyte solution, wherein the non-aqueous electrolyte solution contains an aromatic compound in an amount of 2 to 15% by mass with respect to a total mass of the electrolyte solution, the separator 3 has a MD direction and a TD direction, a heat shrinkage at 150° C. in the TD direction of 30% or less, a thickness of 5 to 20 mum, and an air permeability of 500 seconds / 100 ml or less. Because of this, a non-aqueous secondary battery can be obtained, which is excellent in safety and high rate characteristics and is operated stably even at a high temperature. Furthermore, by allowing the non-aqueous secondary battery of the present invention to be contained in electronic equipment, the reliability of the electronic equipment can be enhanced. Furthermore, a prismatic or laminate-shaped non-aqueous secondary battery is pressed in its direction to be contained in electronic equipment, whereby the safety of the electronic equipment can be enhanced.

Owner:HITACHT MAXELL LTD

Forming submicron integrated-circuit wiring from gold, silver, copper, and other metals

InactiveUS6849927B2Reduced responsePreserves insulativeSemiconductor/solid-state device detailsSolid-state devicesCapacitanceElectrical resistance and conductance

A typical integrated circuit interconnects millions of microscopic transistors and resistors with aluminum wires buried in silicon-dioxide insulation. Yet, aluminum wires and silicon-dioxide insulation are a less attractive combination than gold, silver, or copper wires combined with polymer-based insulation, which promise both lower electrical resistance and capacitance and thus faster, more efficient circuits. Unfortunately, conventional etch-based techniques are ineffective with gold, silver, or copper, and conventional polymer formation promote reactions with metals that undermine the insulative properties of polymer-based insulations. Accordingly, the inventor devised methods which use a liftoff procedure to avoid etching problems and a non-acid-polymeric precursor and non-oxidizing cure procedure to preserve the insulative properties of the polymeric insulator. The resulting interconnective structures facilitate integrated circuits with better speed and efficiency.

Owner:ROUND ROCK RES LLC

Structural I-beam automotive suspension arm

ActiveUS7575244B2High inherent stiffness and strengthReduce quality problemsMetal-working apparatusResilient suspensionsEngineeringFlange

A vehicular suspension arm, comprises an upper sheet metal stamped component with a first outer face and a first inner face, and a first central web portion with two opposites sides and first upstanding flange portions at opposites sides of the first web portion; a lower sheet metal stamped component with a second outer face and a second inner face, and a second central web portion with two opposite sides and second upstanding flange portions at the opposite sides of the second web portion. The first and second inner faces are adapted to contact each other along a substantial portion of the first and second web portions. The upper and lower stamped components adapted to be rigidly attached to each other to create a structural I-beam section. The thickness of each upstanding flange portion is at least equal to the combined thickness of the first and second web portions.

Owner:MULTIMATIC INC

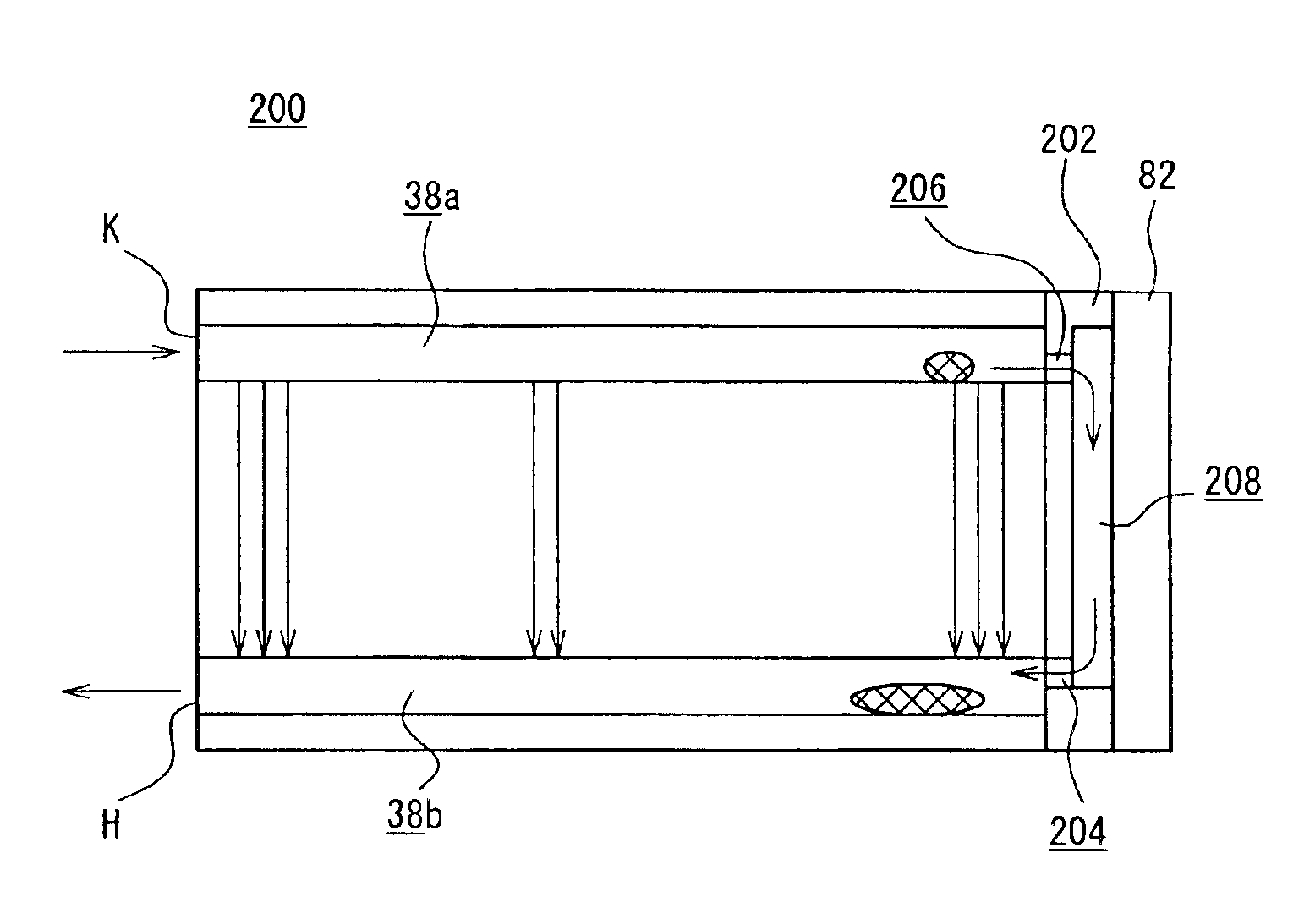

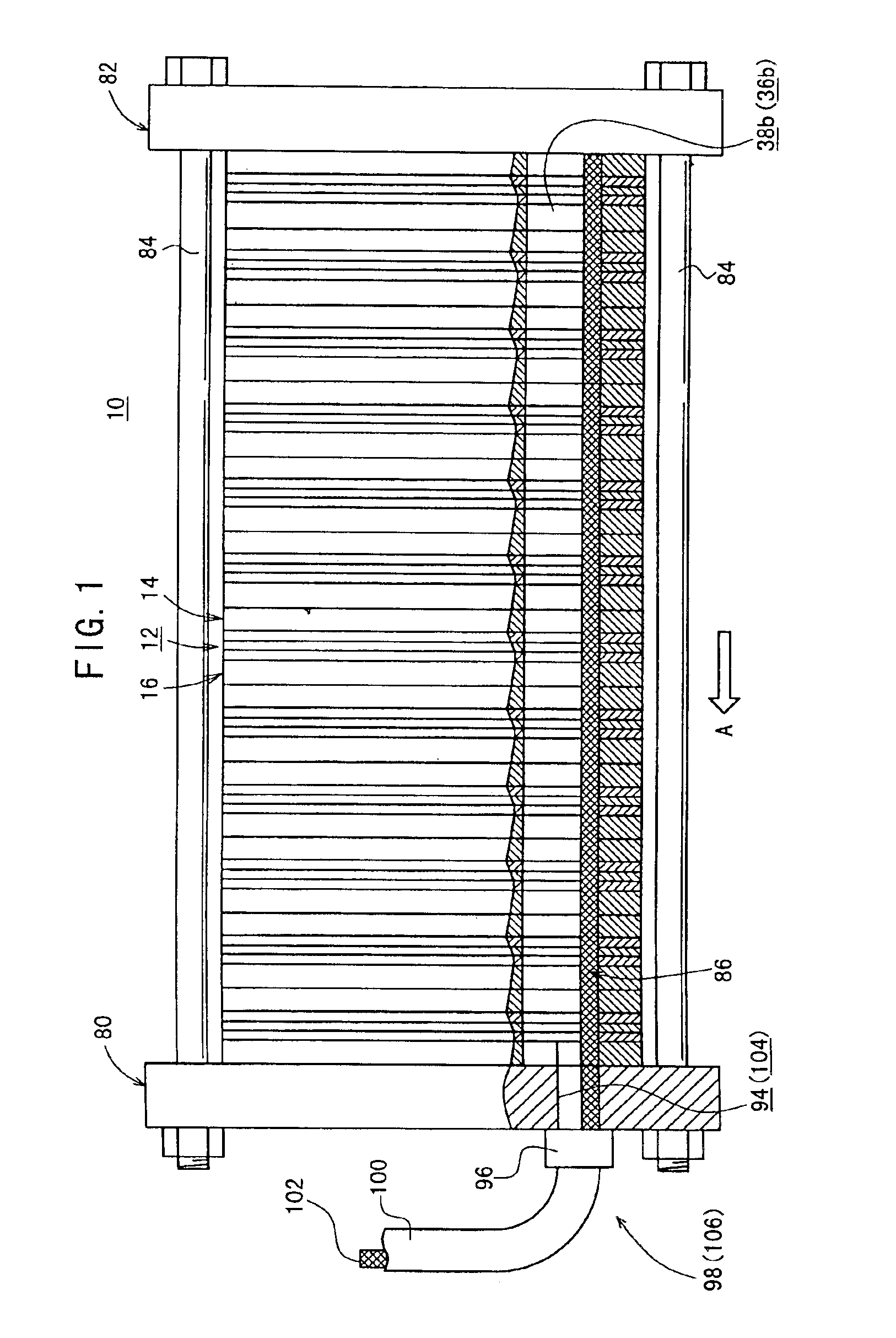

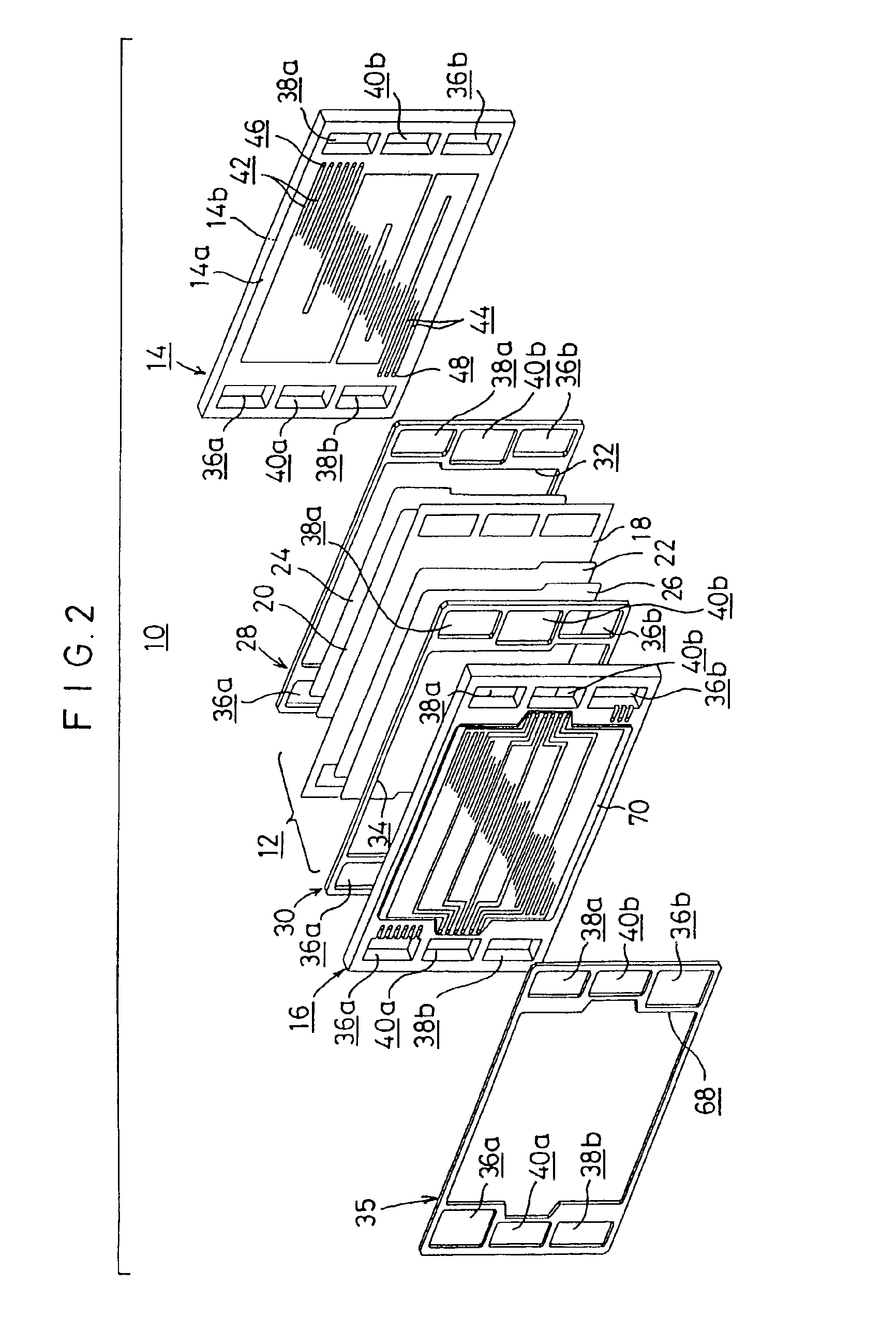

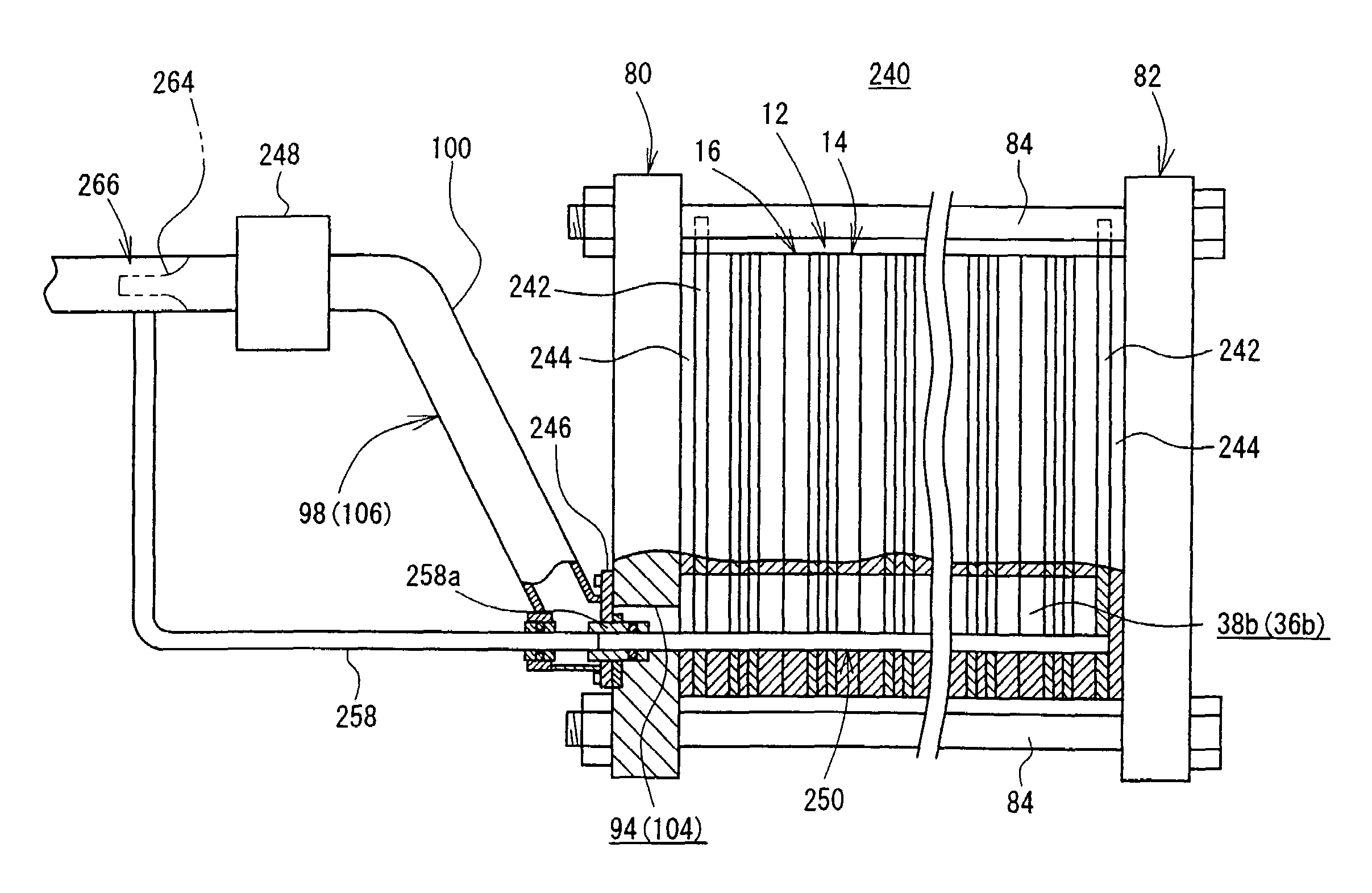

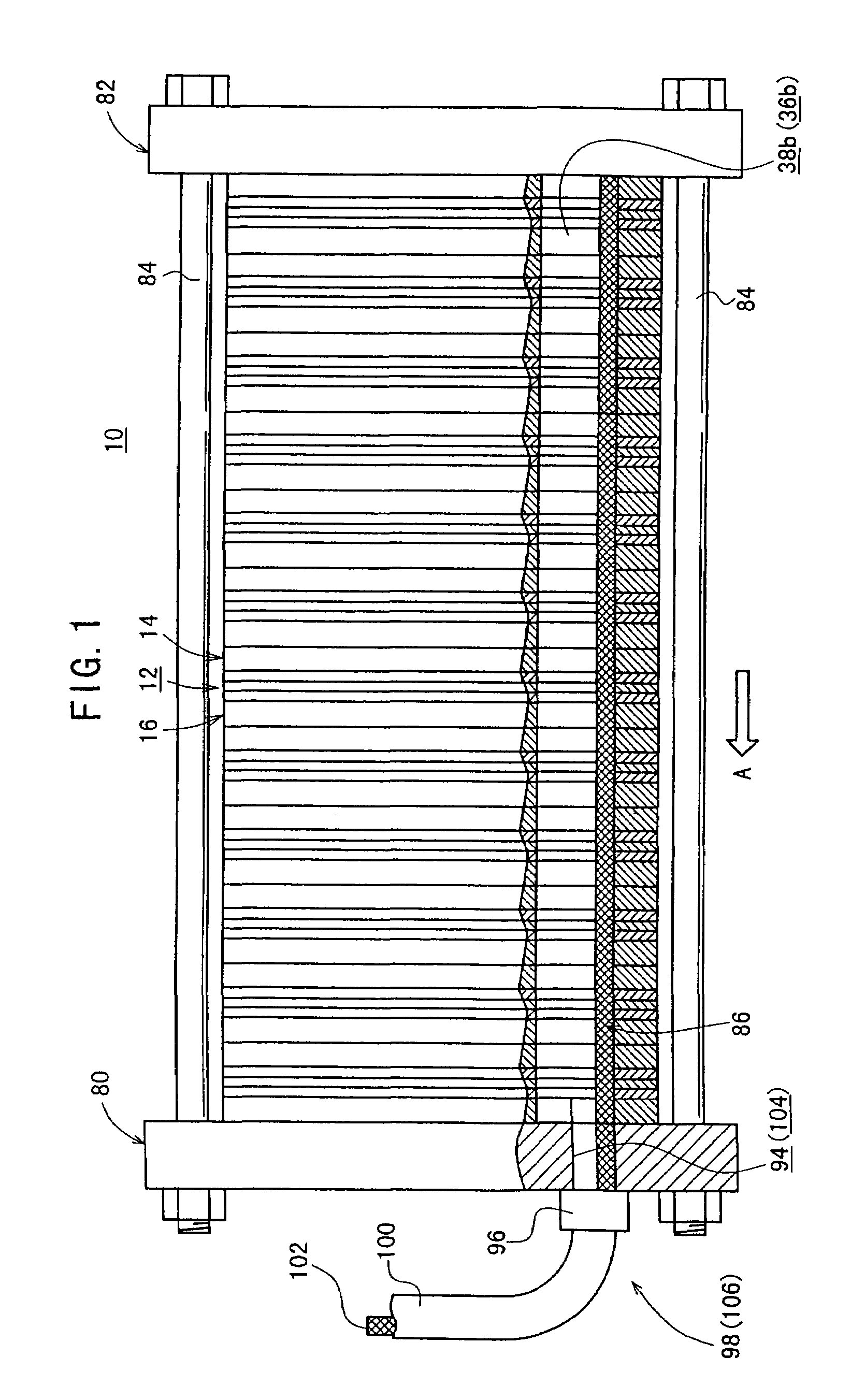

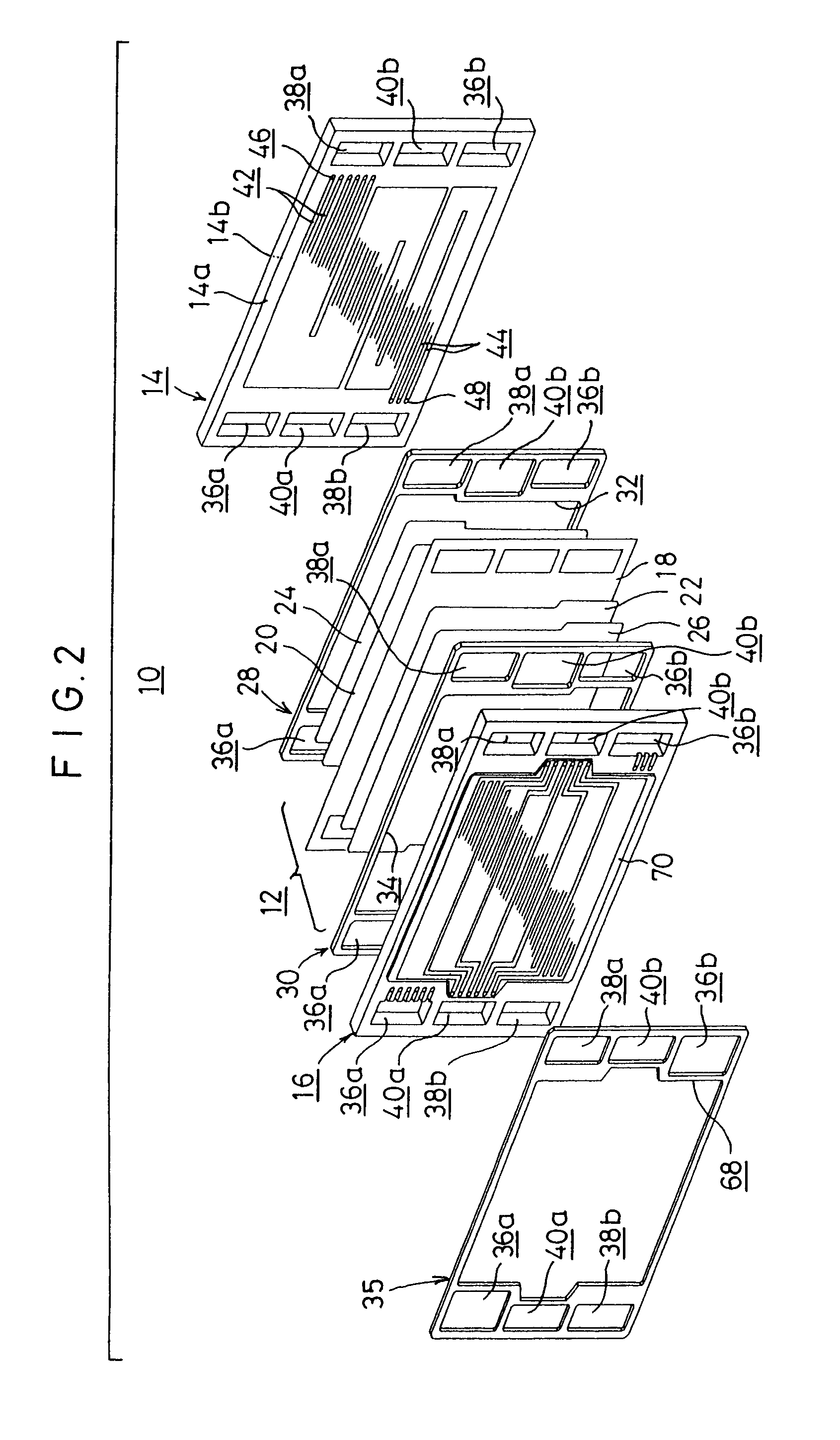

Fuel cell stack

InactiveUS6936369B1Smoothly and reliably discharge waterSmall sizeFuel cells groupingWater management in fuel cellsEngineeringFuel cells

A fuel cell stack is provided with an outlet side oxygen-containing gas communication hole. First and second oxygen-containing gas flow passage grooves are provided in the direction of the gravity while meandering in the horizontal direction on a surface of a first separator. The second oxygen-containing gas flow passage grooves communicate with the outlet side oxygen-containing gas communication hole via second oxygen-containing gas connecting flow passages. A porous water-absorbing tube, which is used to discharge water to the outside of the fuel cell stack in accordance with the capillary phenomenon and the difference in pressure of air, is provided for the is outlet side oxygen-containing gas communication hole.

Owner:HONDA MOTOR CO LTD

Wide band and low driving voltage optical modulator with an improved dielectric buffer layer

InactiveUS6021232ADrive voltage to dropHigh bandwidthCoupling light guidesOptical waveguide light guideElectric fieldRefractive index profile

An optical modulator has a dielectric buffer layer extending over an optical waveguide and extending under an electrode which applies an electric field through the dielectric buffer layer to the optical waveguide for causing the optical waveguide to vary in refractive index profile in linear-proportion to an intensity of the electric field thereby causing a phase shift of a light which is on propagation in the optical waveguide, wherein the dielectric buffer layer varies in thickness whereby an overlap integral of a profile of the electric field and an optical mode field profile at a thinner portion of the dielectric buffer layer is larger than that at a thicker portion of the dielectric buffer layer, and whereby a difference of an effective microwave refractive index from an optical refractive index at the thicker portion is smaller than that at the thinner portion.

Owner:NEC CORP

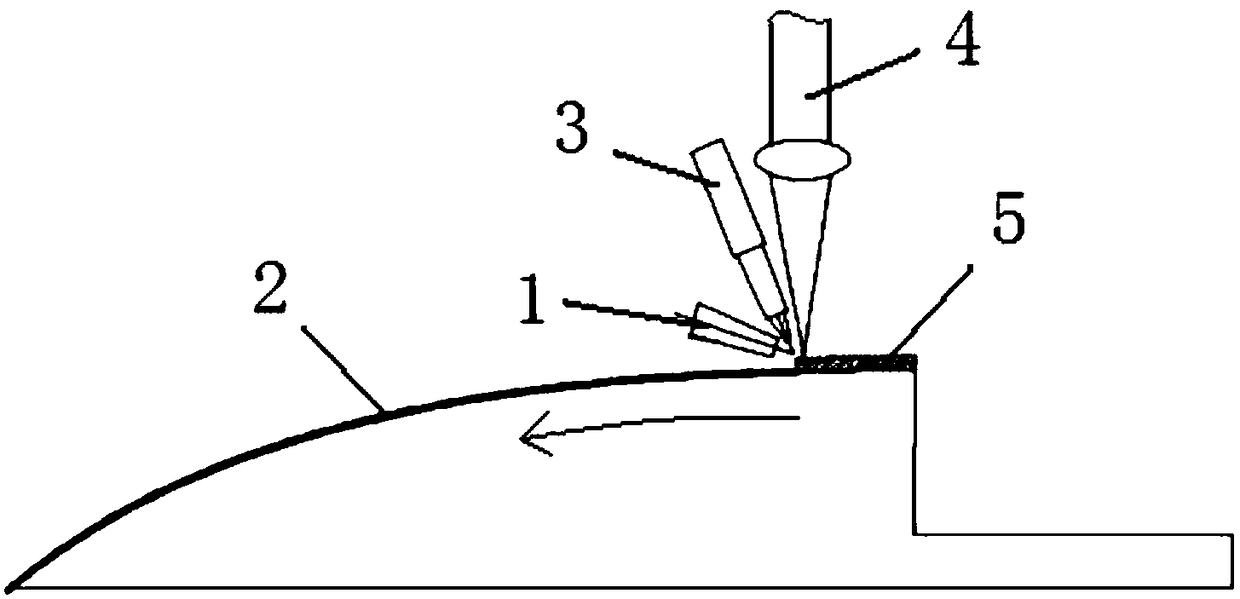

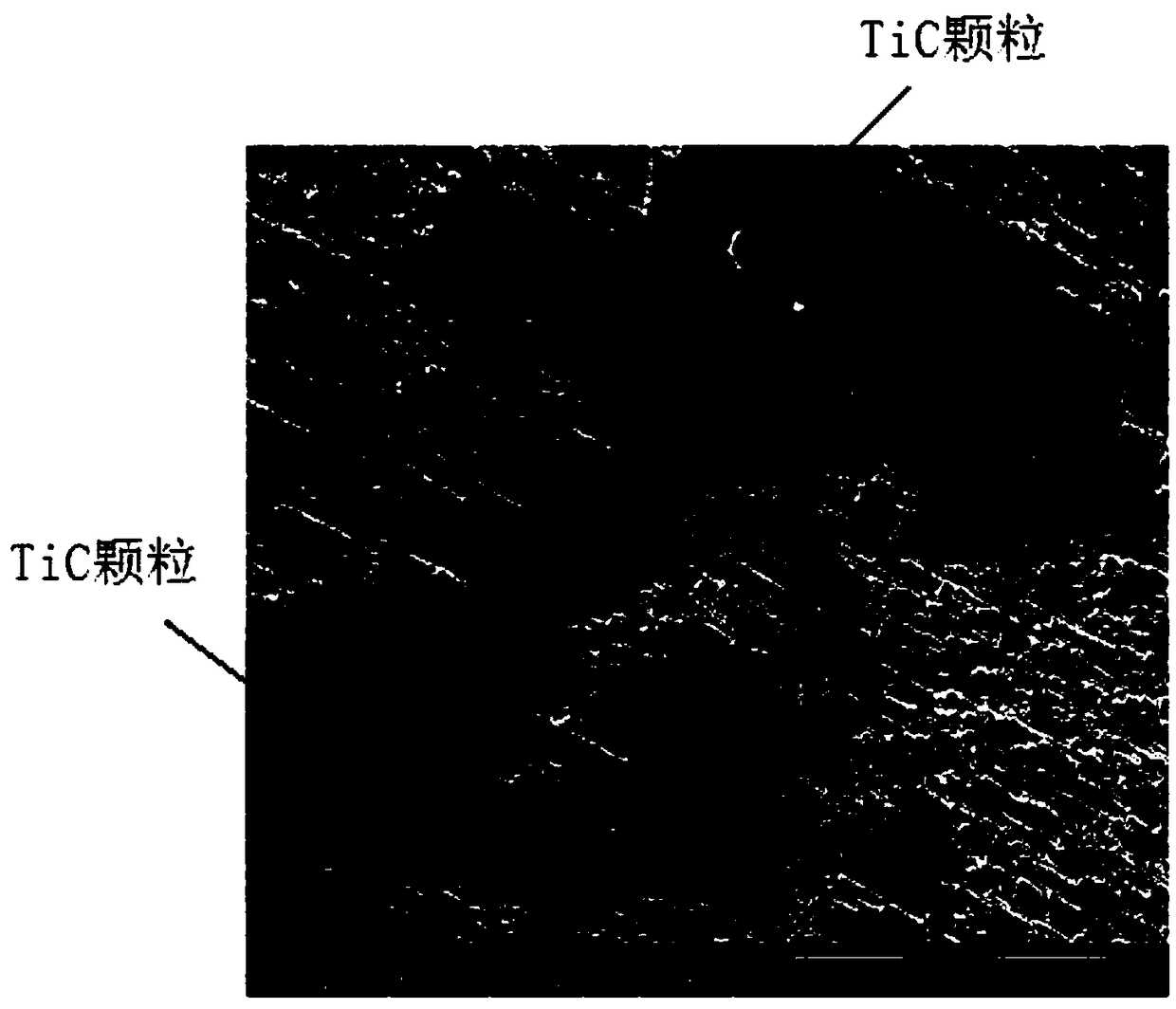

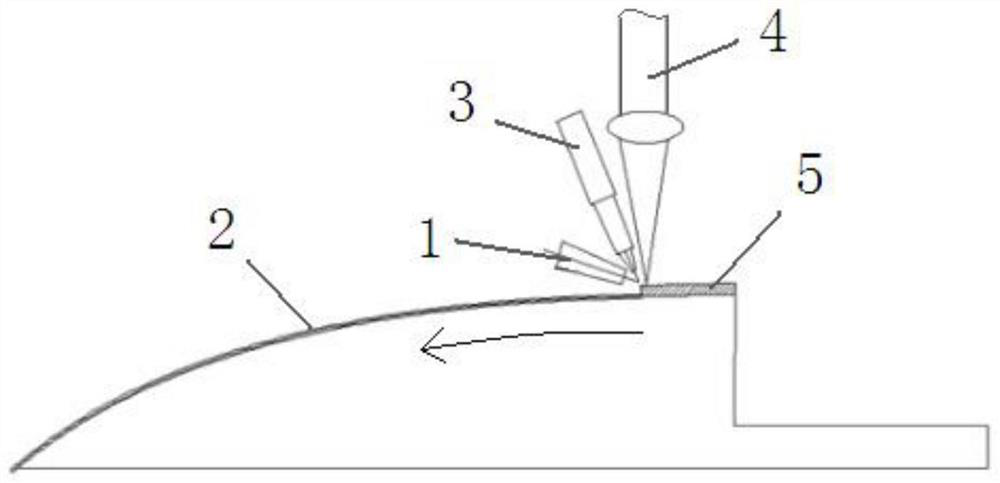

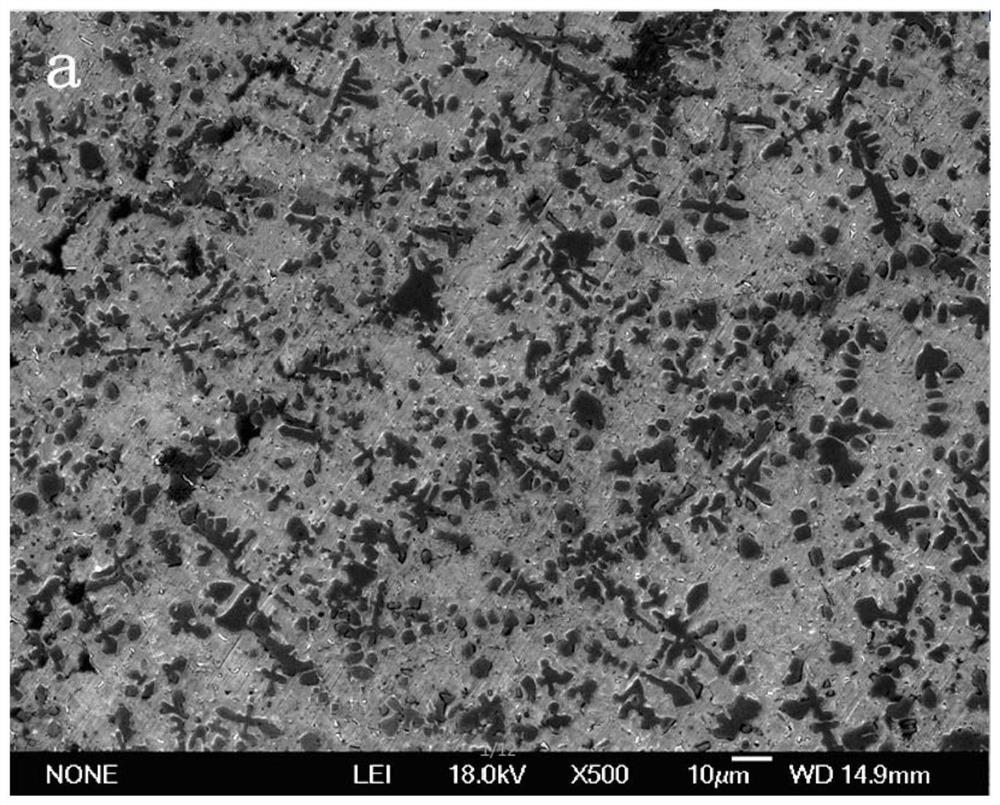

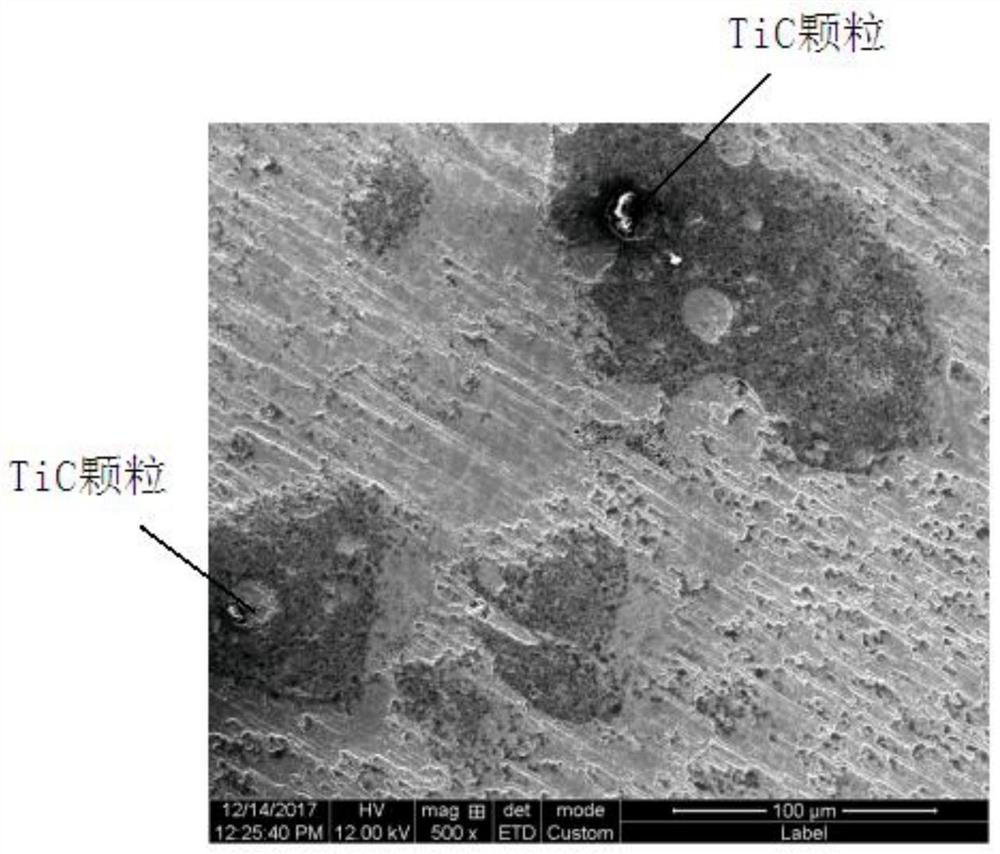

Cutting edge treatment method

ActiveCN108453345AImprove performanceReduce manufacturing costArc welding apparatusMetallic material coating processesManufacturing technologyEngineering

The invention belongs to the technical field of cutter manufacturing, and particularly relates to a cutting edge treatment method. In order to solve the problem that when imported high-quality steel is adopted to manufacture a cutter so as to improve the cutting edge performance of the cutter at present, the manufacturing cost of the cutter is high, the invention discloses the cutting edge treatment method. The cutting edge treatment method specifically comprises the following steps that S1, manufacturing preparation of a cutter is carried out, and the cutting edge part is cleaned; S2, a welding and laser cladding combined mode is adopted for machining a cutting edge strengthened layer; and S3, the cutting edge strengthened layer is coped, and final cutting edges are obtained. When the cutting edge treatment method is adopted for cutting edge treatment, not only can the performance of the cutting edges be greatly improved, the use effect of the cutter is guaranteed, but also the requirements for cutter body materials can be reduced, and the cost of the cutter is reduced.

Owner:YANGJIANG DONGHUA LASER INTELLIGENT TECH CO LTD +1

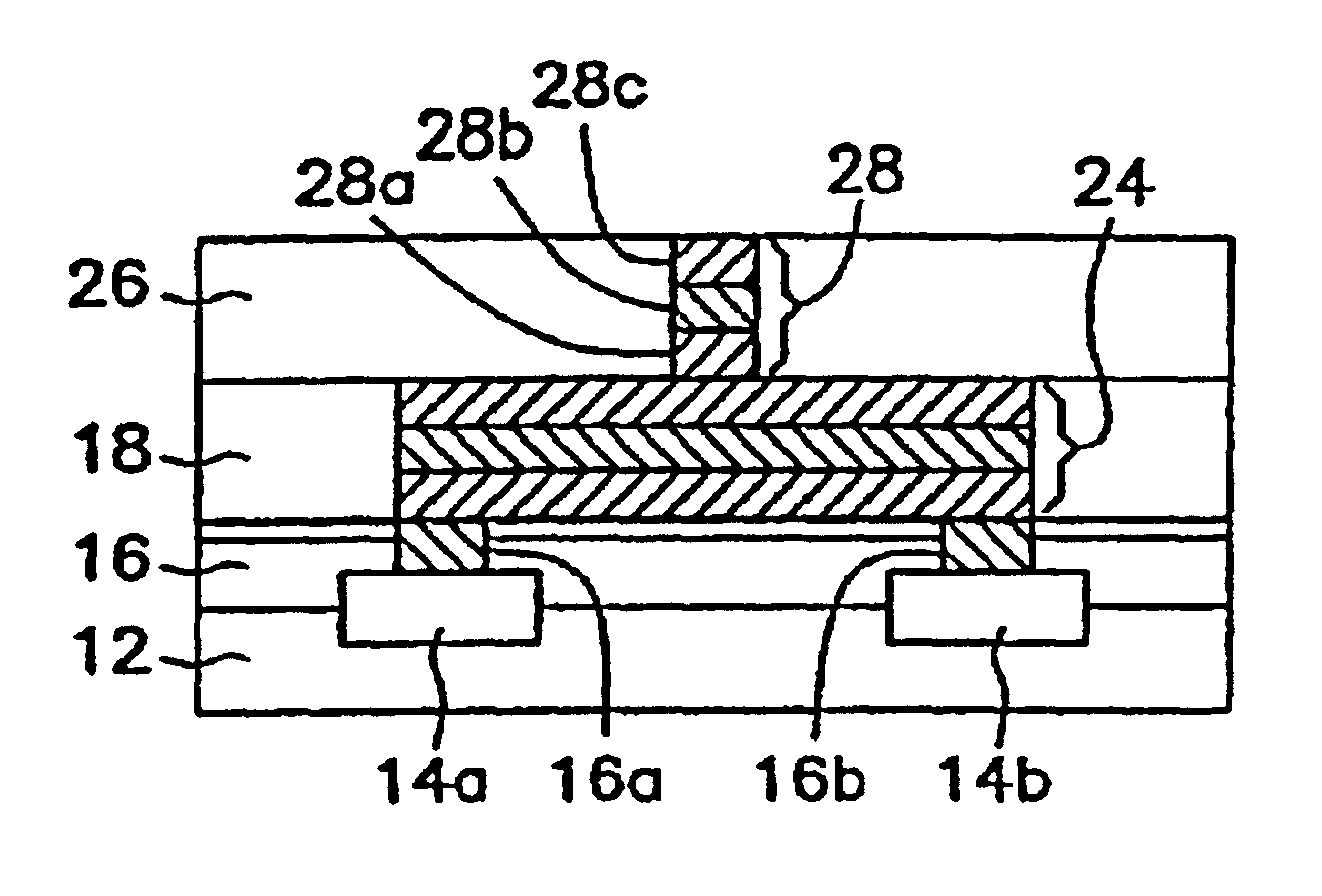

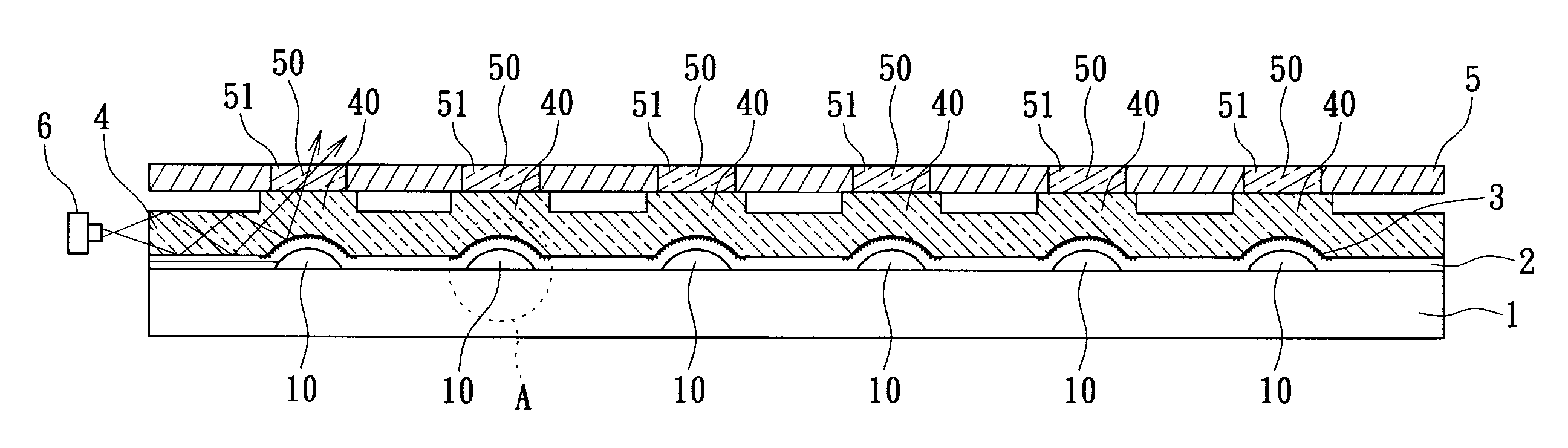

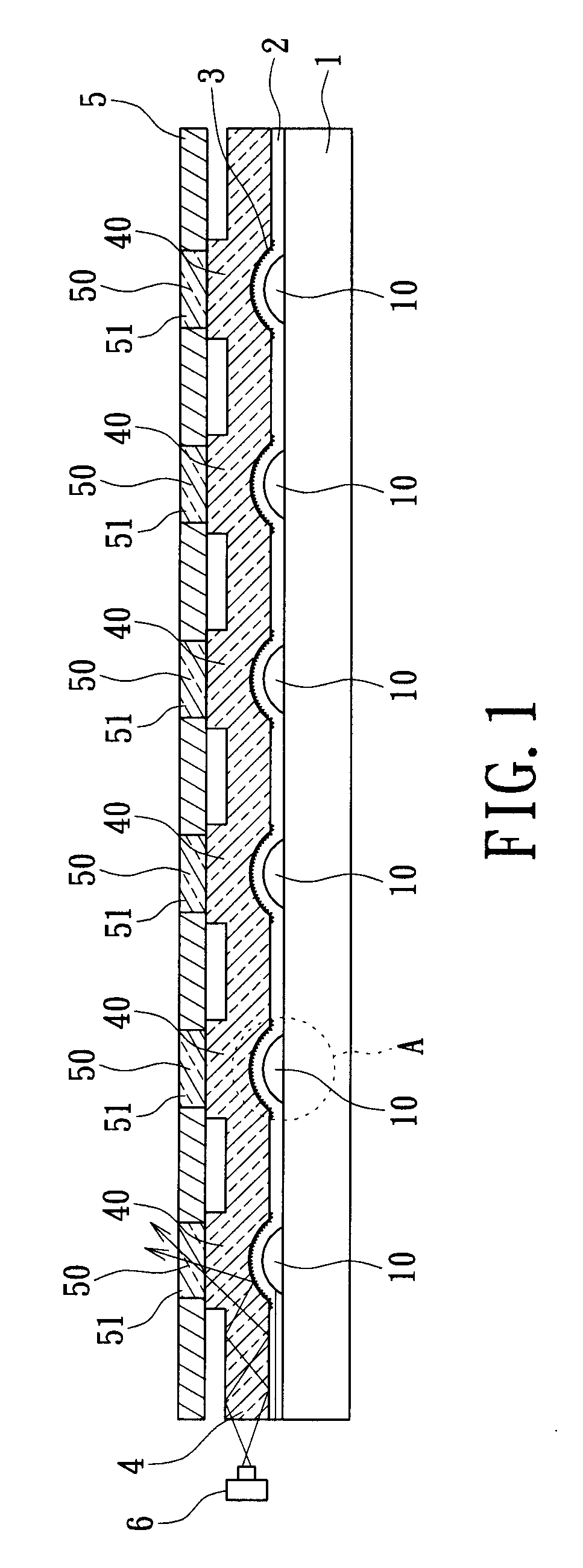

Thin keymat module with a reflection structure

InactiveUS20090173607A1Improve light reflection effectIncrease lighting brightnessEmergency actuatorsLegendsMirror reflectionEngineering

A thin keymat module with a reflection structure includes a circuit board with a plurality of elastic conductive elements, a mirror reflection sheet, a transparent elastic layer, a keymat layer and a light-emitting unit. The mirror reflection sheet is disposed on the circuit board, evenly corresponding to the elastic conductive elements. The mirror reflection sheet has a reflection microstructure corresponding to the elastic conductive elements. The transparent elastic layer is disposed on the mirror reflection sheet and has elastic portions corresponding to the elastic conductive elements. The keymat layer is disposed on the transparent elastic layer and has transparent portions corresponding to the elastic portions. The light-emitting unit is located on one side of the transparent elastic layer. When the light-emitting unit projects light onto the mirror reflection sheet and the reflection microstructure, each elastic portion and each transparent portion have a light displaying effect.

Owner:SILITECH TECH CORP

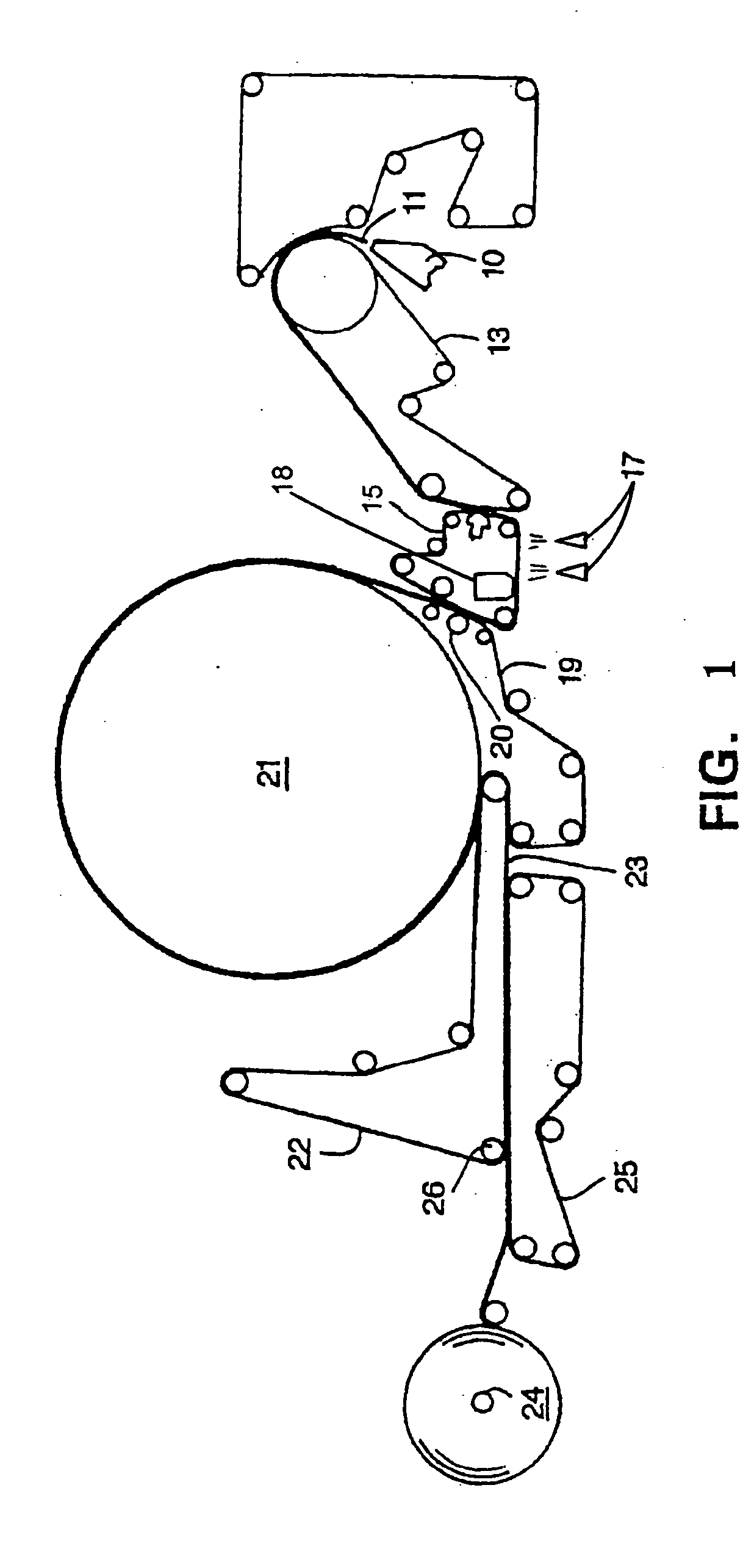

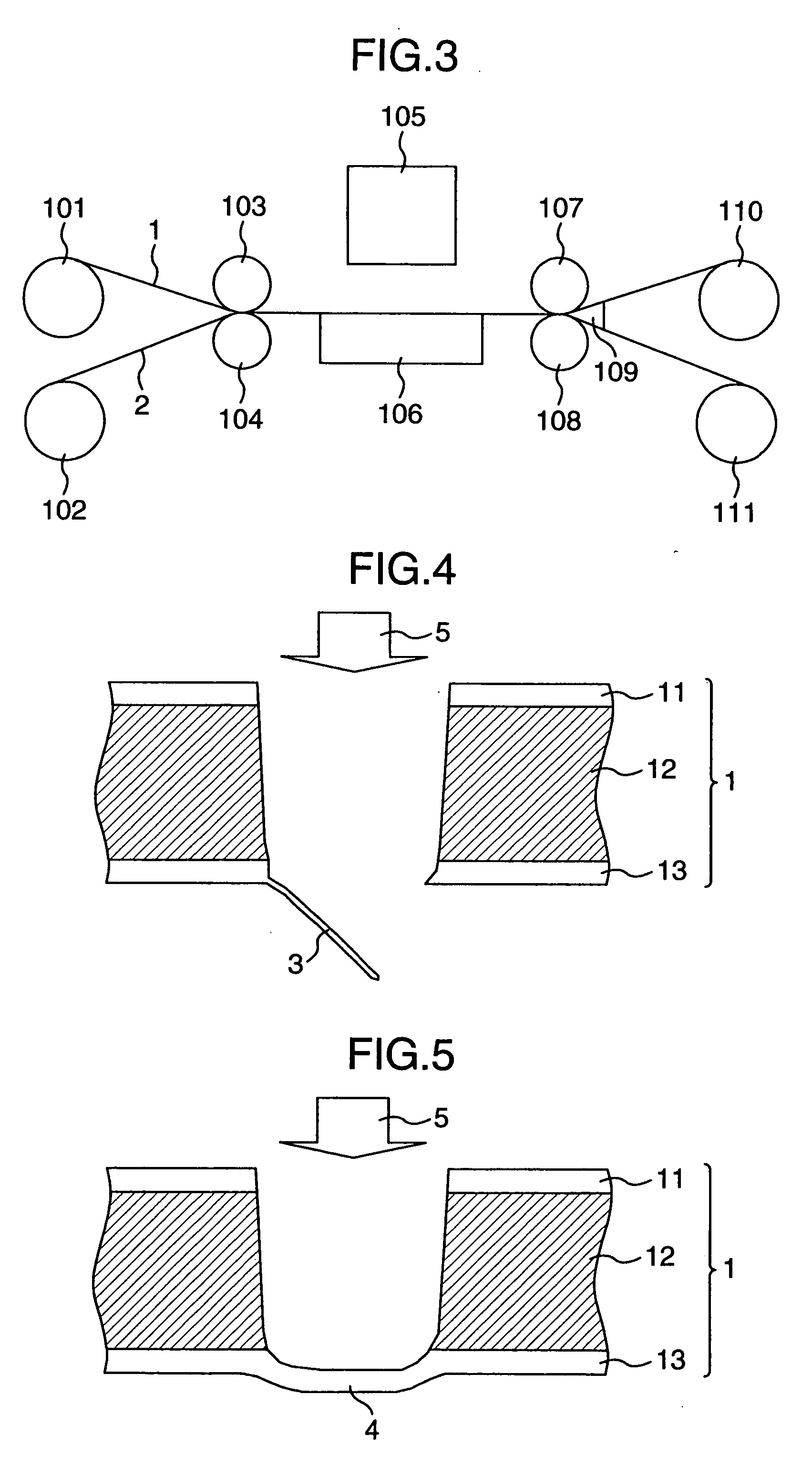

Method to debond paper on a paper machine

InactiveUS20050241791A1Effective thicknessNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberPaper machine

Disclosed is a method of making a soft, strong cellulosic tissue sheet comprising the steps of forming a web of cellulosic fibers on a forming wire, thereafter treating the exposed surface of the web with a treatment composition comprising a chemical debonding agent, subjecting the opposing surface of the web to vacuum suction whereby the chemical debonding agent is distributed substantially through the entire thickness of the web, and through-air drying the web. The method allows grade changes to be made much more rapidly and with less waste than when adding debonder at the wet end of the paper making process.

Owner:KIMBERLY-CLARK WORLDWIDE INC

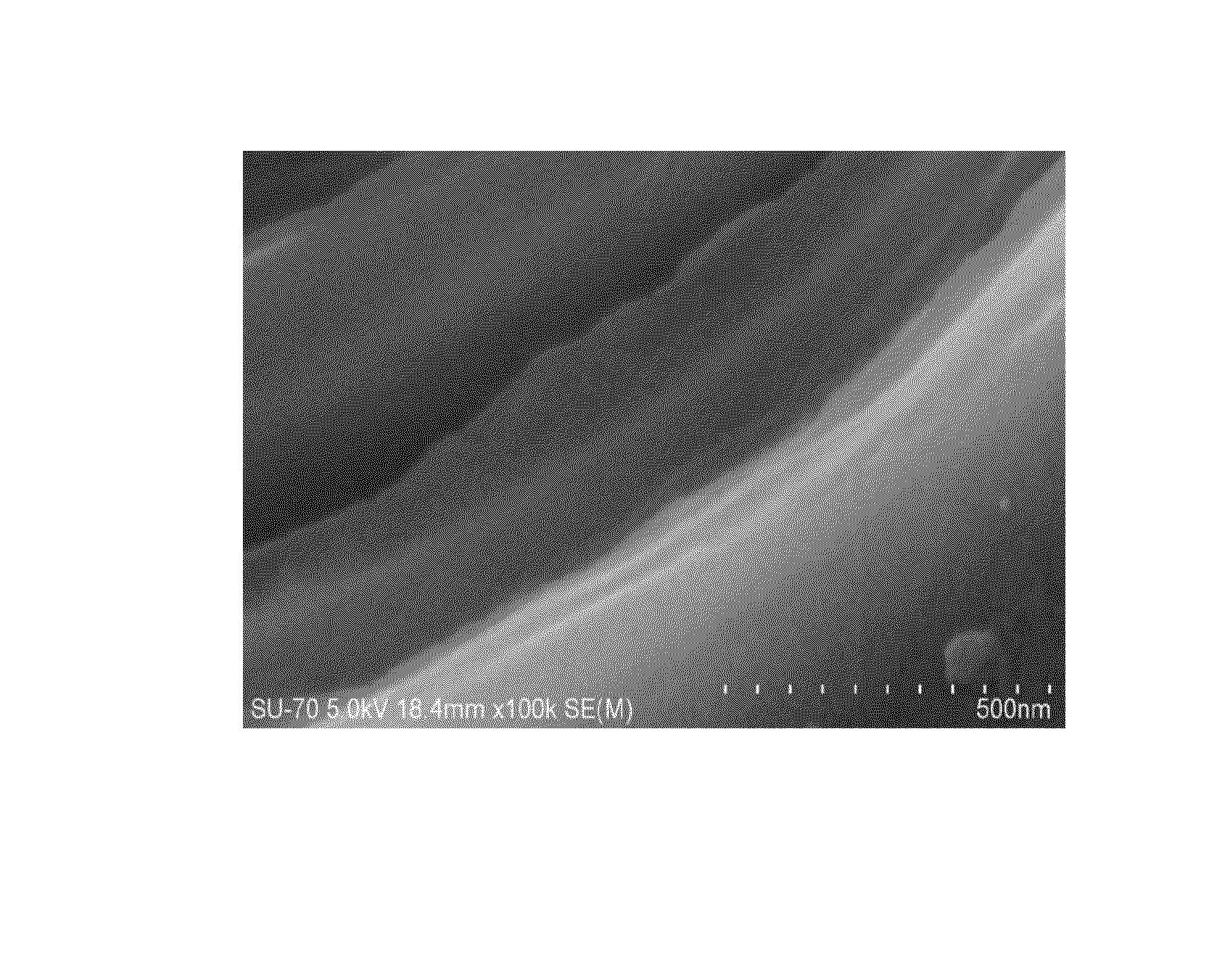

Graphene film, preparation method and application thereof

InactiveUS20150125758A1Reduce weightIncrease energy densityElectrolytic capacitorsSynthetic resin layered productsCvd grapheneSubstrate surface

Disclosed is a preparation method of graphene film. The method comprises the following steps: providing a clean substrate, followed by positively charged processing of the substrate surface; preparing suspension of graphene with negative charges on surface and the suspension of graphene with positive charges on surface respectively; immersing the surface-treated substrate into the suspension of graphene with negative charges on surface for 5-20 minutes, then taking the substrate out, washing, drying, and then immersing it into the suspension of graphene with positive charges on surface for 5-20 minutes, then taking the substrate out, washing, drying, so alternately repeated 10 to 50 times to obtain a graphene film precursor, and finally reducing the graphene film precursor at 500-1000° C. to obtain the grapheme film.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

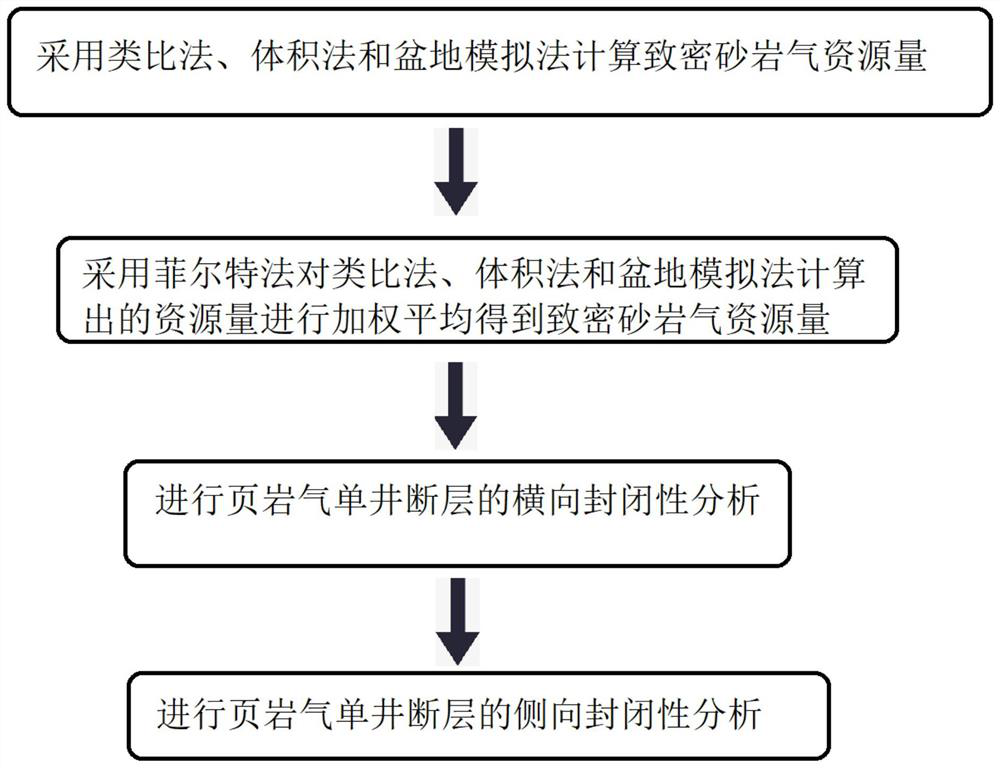

Shale gas single well geology comprehensive evaluation method

PendingCN111897012AEffective areaEffective thicknessSeismic signal processingSeismology for water-loggingThermodynamicsShale gas

The invention provides a shale gas single well geology comprehensive evaluation method. The method comprises the steps that 1 the tight sandstone gas resource amount is calculated through an analogy method, a volume method and a basin simulation method; 2 weighted average is carried out on the resource quantity calculated by the analogy method, the volume method and the basin simulation method byadopting a fiert method to obtain a tight sandstone gas resource quantity; 3 transverse sealing performance analysis of the shale gas single well fault is conducted; and 4 lateral sealing performanceanalysis of the shale gas single well fault is carried out.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

Display device and method for manufacturing the same

ActiveUS11074025B2Reduce thicknessEffective thicknessDigital data processing detailsNon-linear opticsDisplay deviceMaterials science

To provide a thinned display device with a touch sensor and to provide a highly reliable display device. A sensor layer including an electrode of a touch sensor is formed in advance over a support substrate which is different from a substrate which forms a display device so that the sensor layer can be separated, the sensor layer is separated from the support substrate, and the separated sensor layer is attached to one surface of a substrate the other surface of which is provided with a component such as a color filter, with a bonding layer interposed therebetween.

Owner:SEMICON ENERGY LAB CO LTD

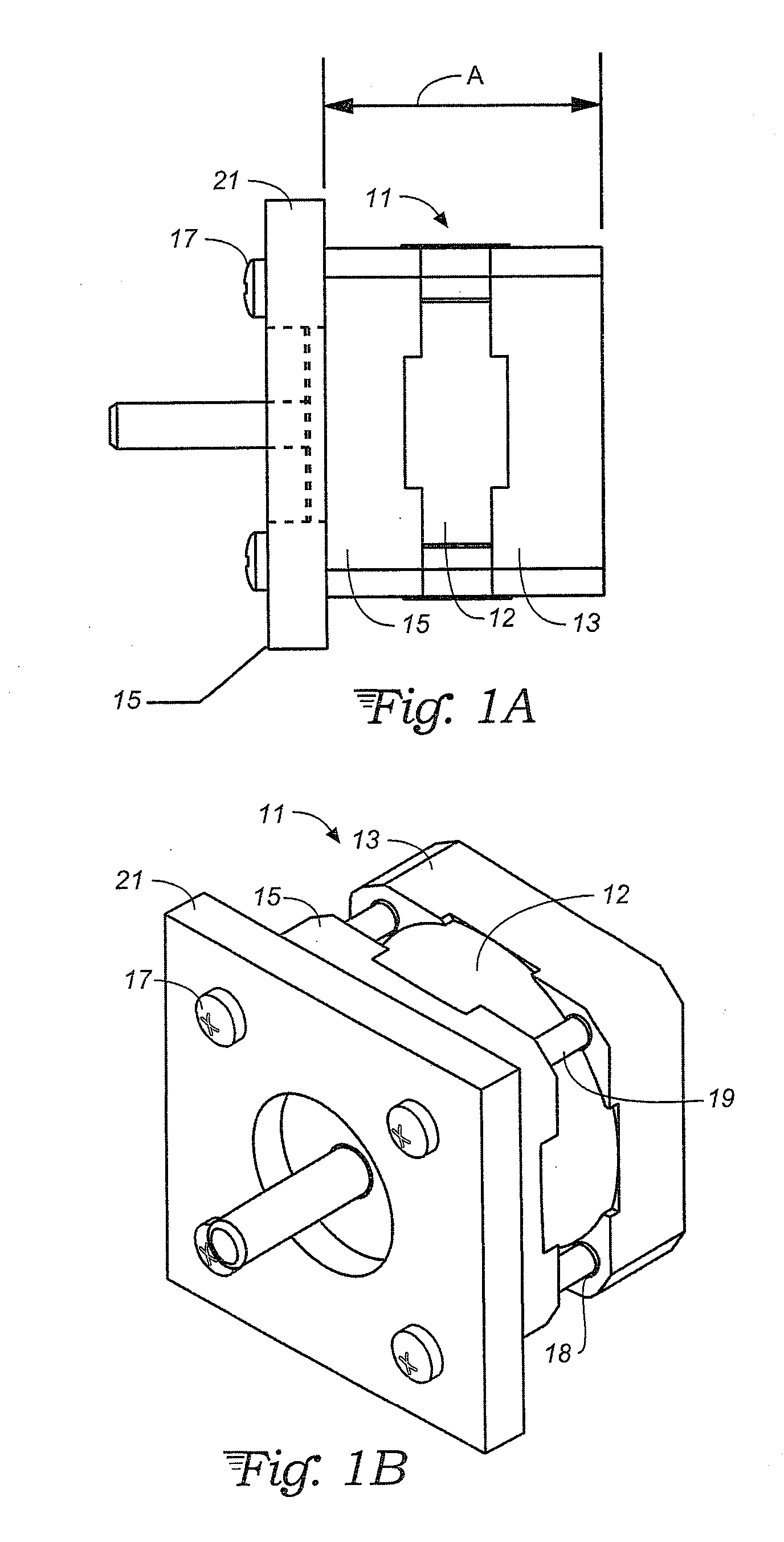

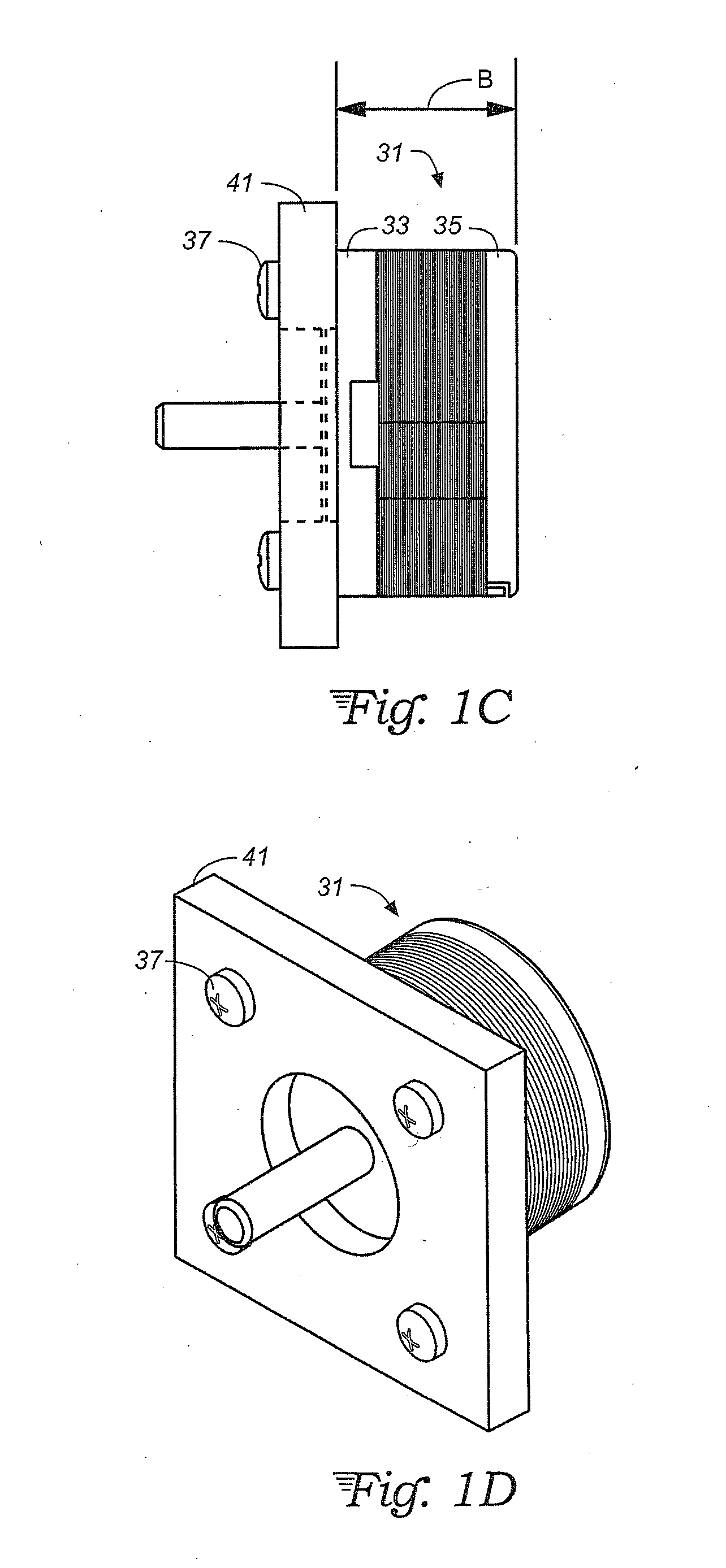

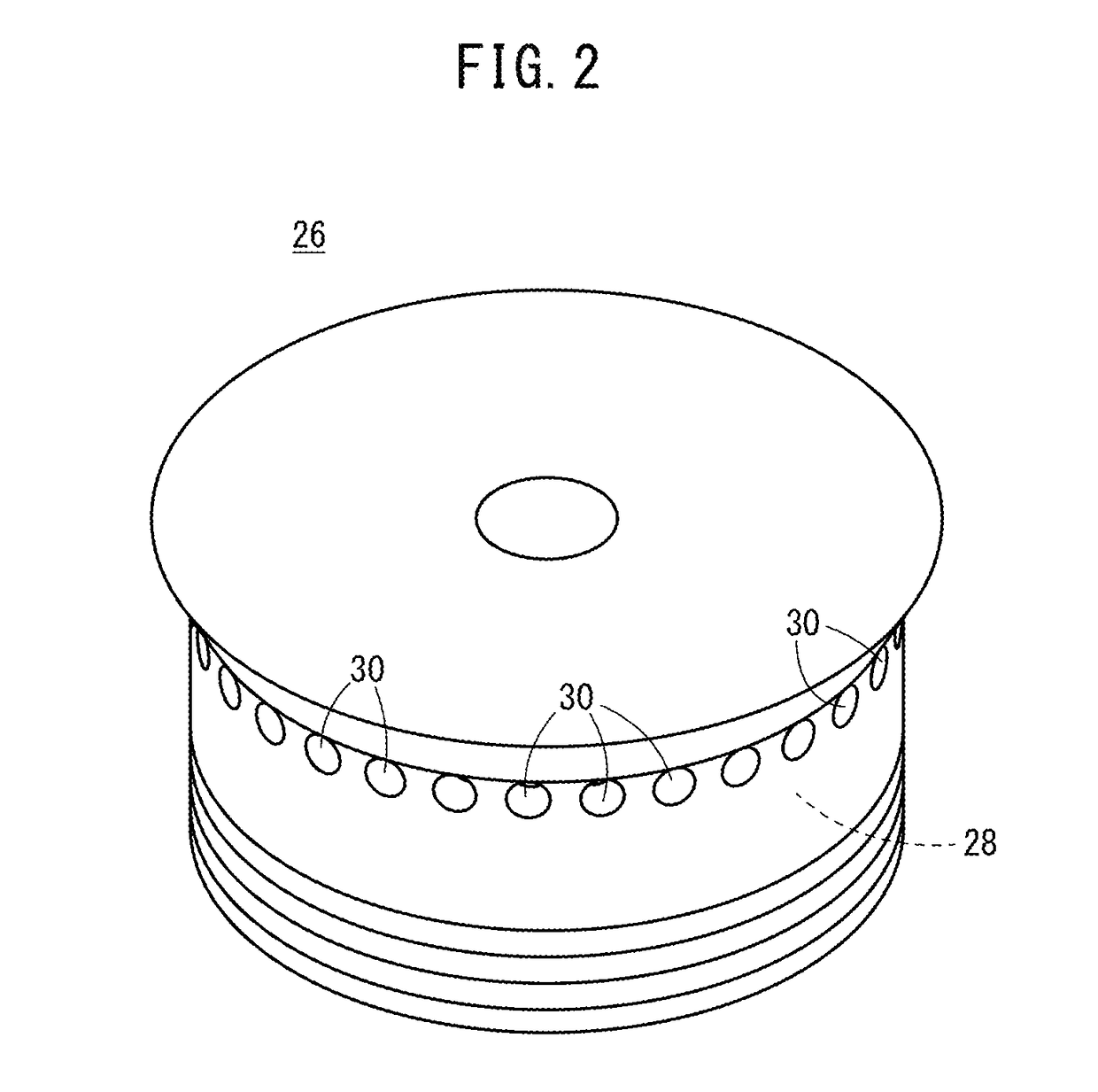

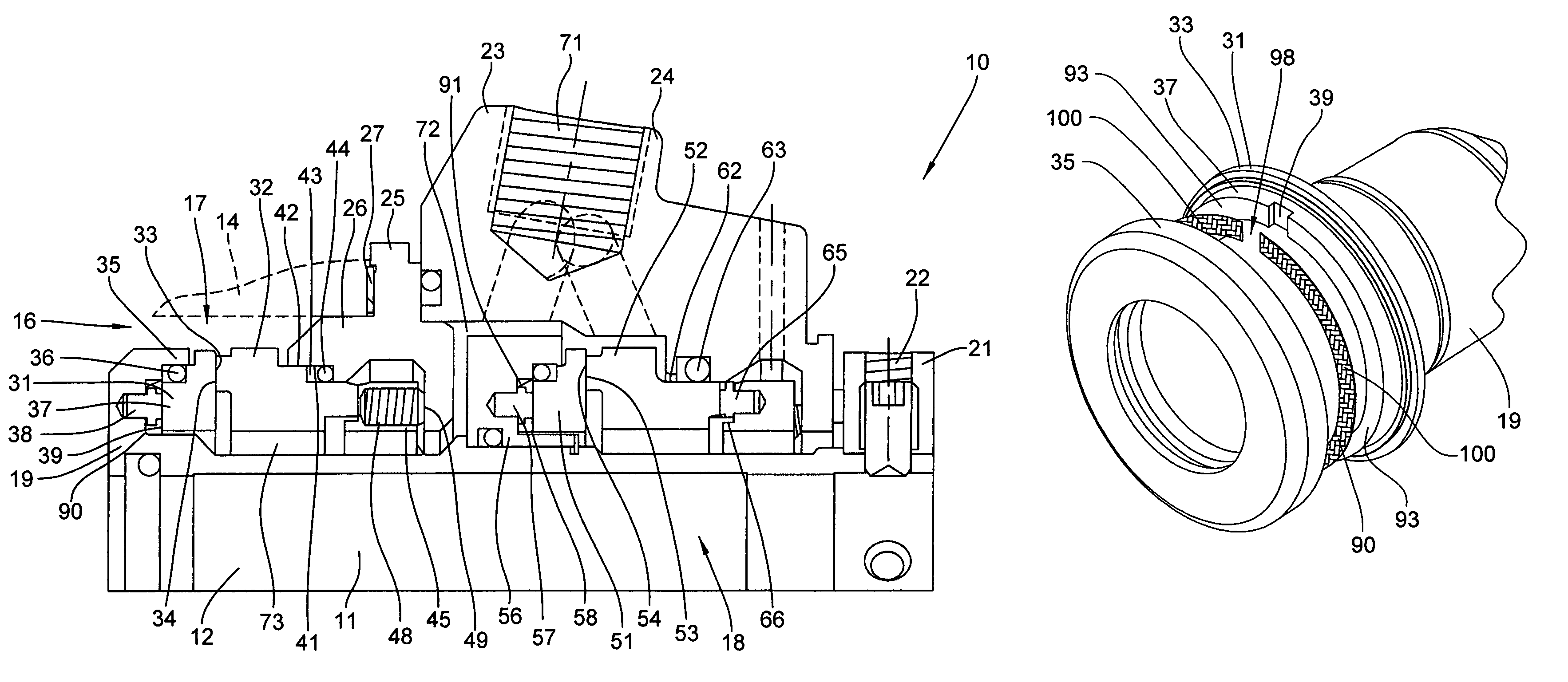

Motor having stator assembly with integrated mounting and heat sink features

ActiveUS20160049843A1Effective thicknessImprove cooling effectMagnetic circuit stationary partsMaster clocksDrive shaftHeat spreader

A step motor integrates its mounting face and heat sink into the stator design. In particular, mounting holes (typically, four in number) are provided through the stator stack in outer perimeter areas. The stator stack itself becomes the mounting surface, allowing the heat generated from the stator to conduct directly to the mounting plate. The front end cap for holding the rotor in alignment is situated inside of the stator's mounting surface and takes no part in mounting the motor to the mounting surface. The end caps only hold the rotor in proper relation within the stator and contain the bearing assembly for the rotor's axial drive shaft. The perimeter of the stator assembly between the mounting screw holes may have saw-tooth cutouts that define heat-dissipation fins.

Owner:LIN ENG INC

Method and apparatus for laser drilling

InactiveUS20060076323A1Prevention of expansionNo damagePrinted circuit aspectsPrinted circuit manufactureCopper foilLaser drilling

There is provided a laser drilling method that prevents hanging, expansion, or crinkles of copper foil caused when an ultraviolet laser beam that requires no surface roughening is used for a thin double-sided copper-clad film. The drilling method of the copper-clad film comprises the steps of: using an ultraviolet laser as a laser beam; drilling after bonding a resin film to the backside of the film which is the opposite side to the laser-beam-incidence; and delaminating the resin film on the backside after drilling. The resin film bonded to the backside prevents the copper foil from hanging, thus allowing the laser beam to be efficiently applied to the copper foil, and allowing the copper foil to be completely removed by ablation. In the case of a blind hole, the resin film bonded to the backside prevents expansion of the copper foil. Crinkles can be also prevented.

Owner:HITACHI SEIKO LTD

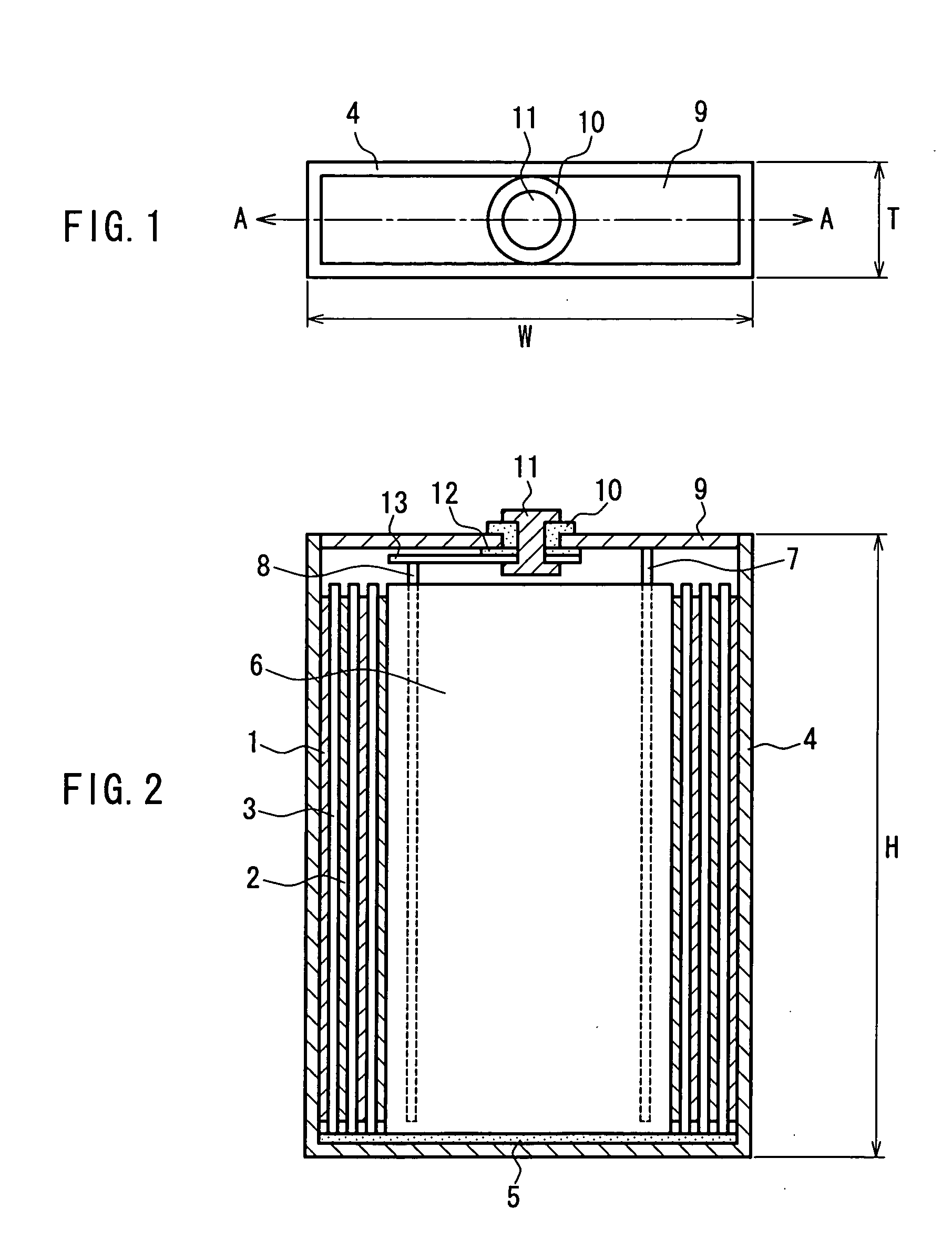

Dual-sided substrate integrated circuit package including a leadframe having leads with increased thickness

ActiveUS20050179123A1Less prone to defectsEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringIntegrated circuit

An integrated circuit package includes a first non-conductive substrate having a first inner surface and a second non-conductive substrate having a second inner surface. A die having a first thickness is disposed between the first and second inner surfaces. A leadframe includes a member having a proximal end and a distal end. The proximal end has a second thickness less than the first thickness. The distal end is disposed between the first and second inner surfaces. The distal end is undulated such that the distal end has an effective thickness greater than the second thickness.

Owner:DELPHI TECH IP LTD

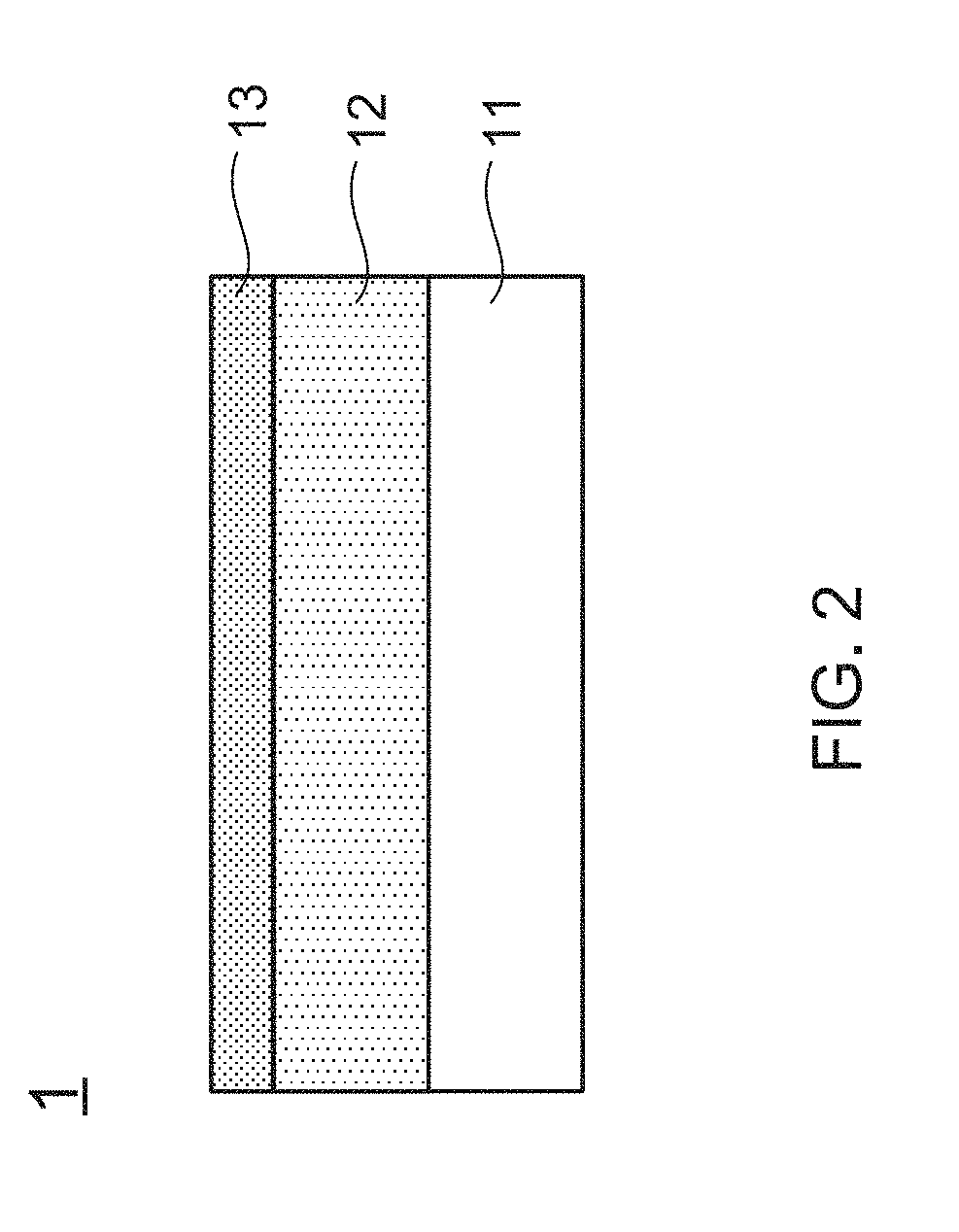

Transparent conductive film and electro-optical device having the same

ActiveUS9871217B1Reduce manufacturing costImprove sheet resistanceFinal product manufactureSolid-state devicesThin metalOrganic solar cell

Compared to traditional ITO transparent substrate showing drawbacks of high sheet resistance, poor flexibility and high manufacturing cost, the present invention mainly discloses a transparent conductive film fabricated by sequentially forming a wetting layer and an ultra-thin metal layer onto a transparent substrate, wherein the transparent conductive film includes advantages of low sheet resistance, high transmittance, great flexibility, and low manufacturing cost. Moreover, a variety of experiment data have proved that, this novel transparent conductive film can not only be applied in the fabrication of some electro-optical devices such as organic solar cell and OLED, but also helpful to the enhancement of the fundamental and essential characteristics of the electro-optical devices.

Owner:NATIONAL TSING HUA UNIVERSITY

Painting method and device for same

InactiveUS20180185859A1Reduce speedEasy to getLiquid surface applicatorsMovable spraying apparatusMechanical engineering

The present invention relates to a painting method and a rotating atomization type painting device. On an inner surface of a bell cup constituting the rotating atomization type painting device are formed a first paint diffusion unit positioned on the inside in the radial direction and a second paint diffusion unit positioned between the first paint diffusion unit and a peripheral edge part. The first paint diffusion unit has a convex shaped curved surface extending toward the center of rotation of the bell cup, whereas the second paint diffusion unit has a concave shaped curved surface extending away from the center of rotation. The diameter of the bell cup is set at 75-150 mm, and the speed of rotation of the bell cup is set at 8000-30000 rpm.

Owner:HONDA MOTOR CO LTD

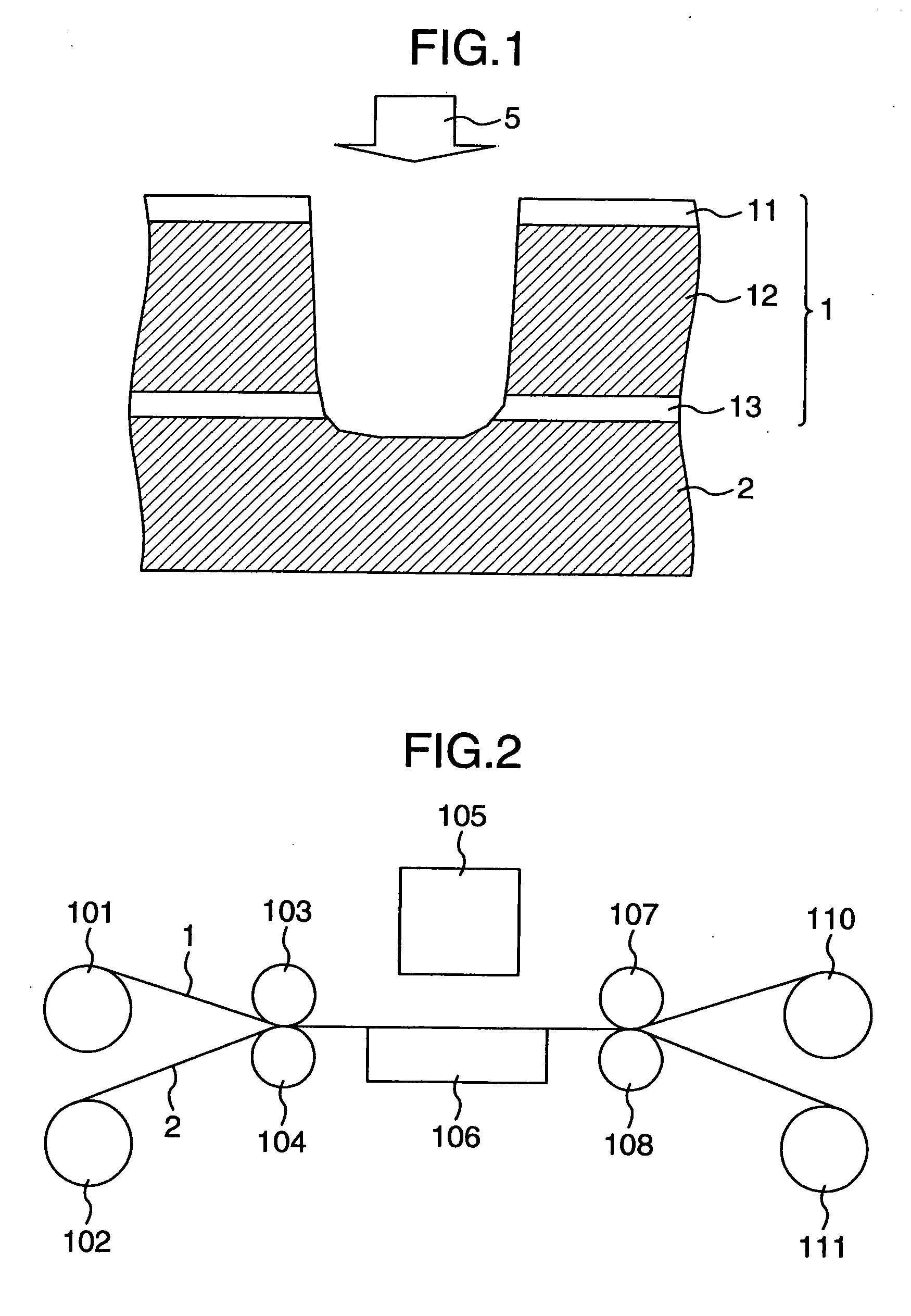

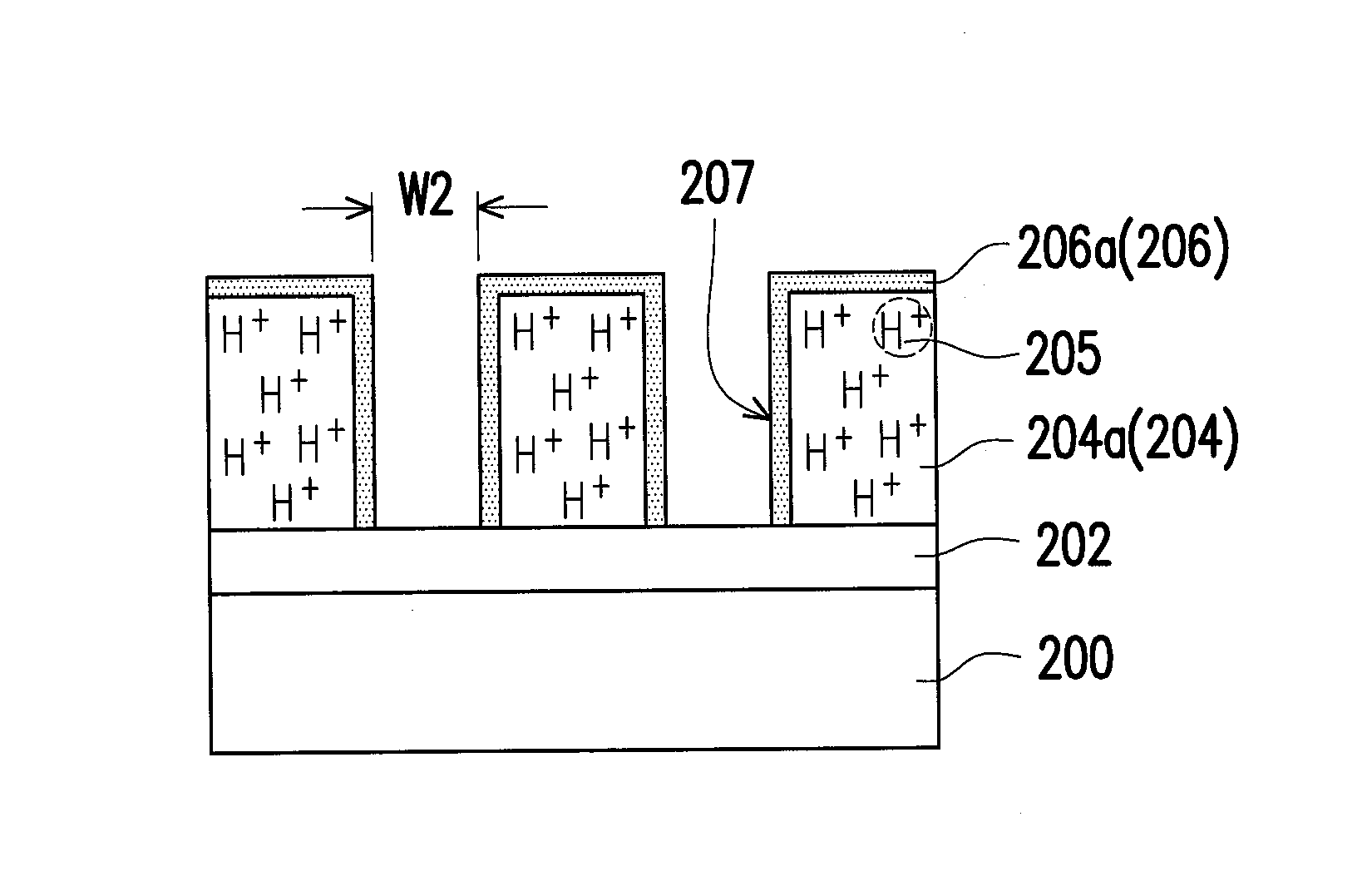

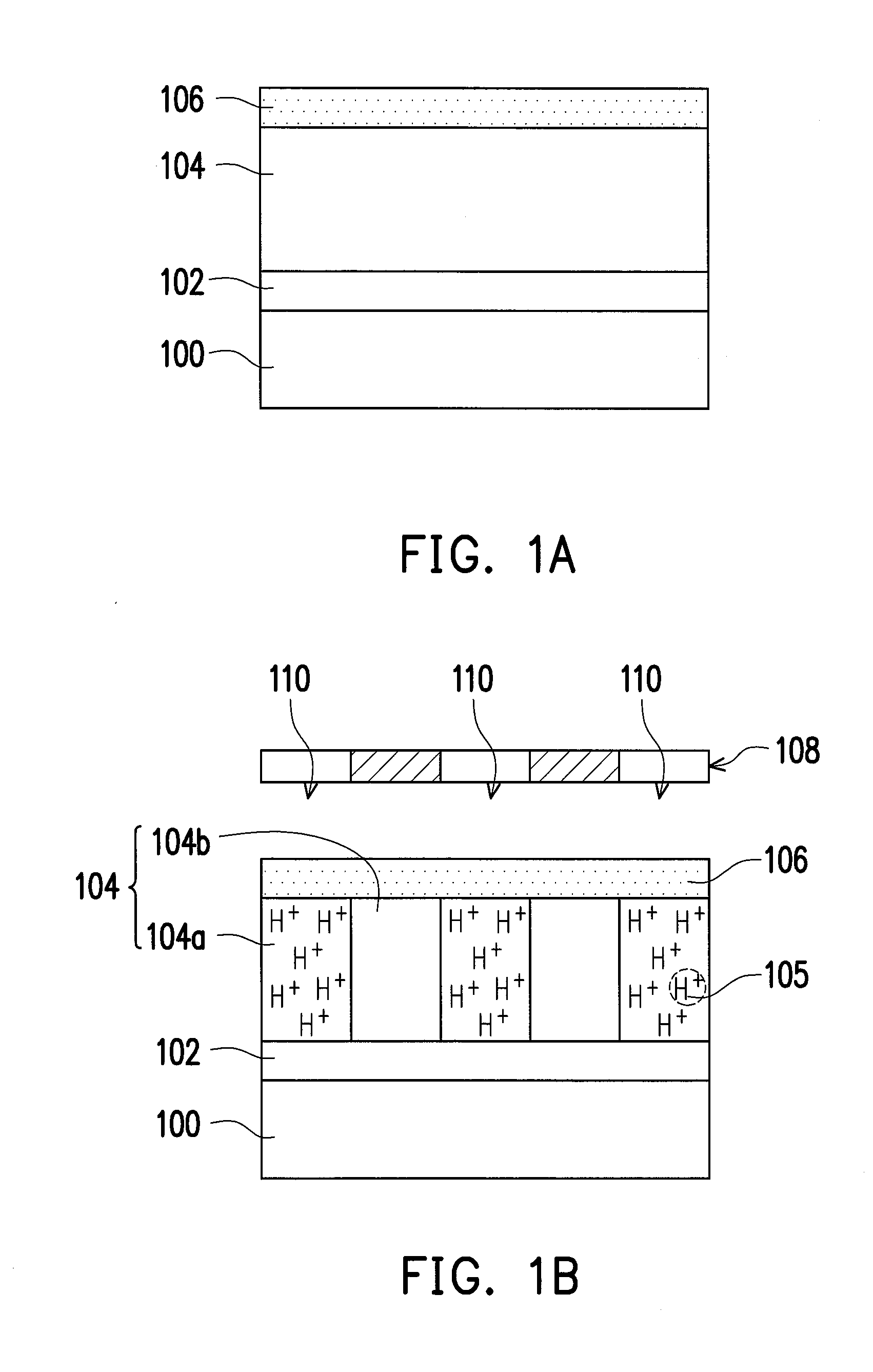

LDMOS transistor having elevated field oxide bumps and method of making same

ActiveUS9330979B2Effective thicknessTransistorSemiconductor/solid-state device manufacturingLDMOSPower flow

A low Rdson LDMOS transistor having a shallow field oxide region that separates a gate electrode of the transistor from a drain diffusion region of the transistor. The shallow field oxide region is formed separate from the field isolation regions (e.g., STI regions) used to isolate circuit elements on the substrate. Fabrication of the shallow field oxide region is controlled such that this region extends below the upper surface of the semiconductor substrate to a depth that is much shallower than the depth of field isolation regions. For example, the shallow field oxide region may extend below the upper surface of the substrate by only Angstroms or less. As a result, the current path through the resulting LDMOS transistor is substantially unimpeded by the shallow field oxide region, resulting in a low on-resistance.

Owner:TOWER SEMICONDUCTOR

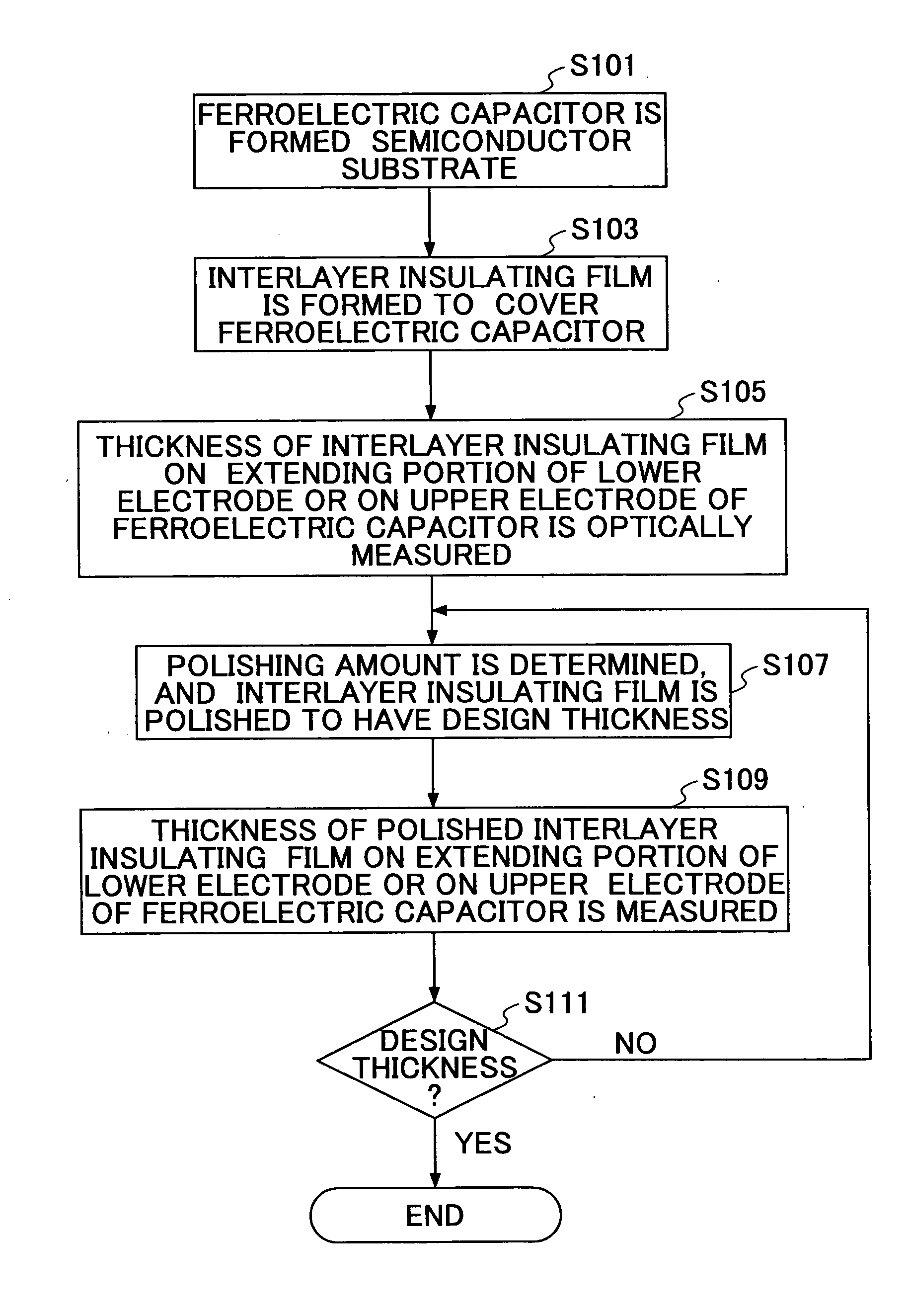

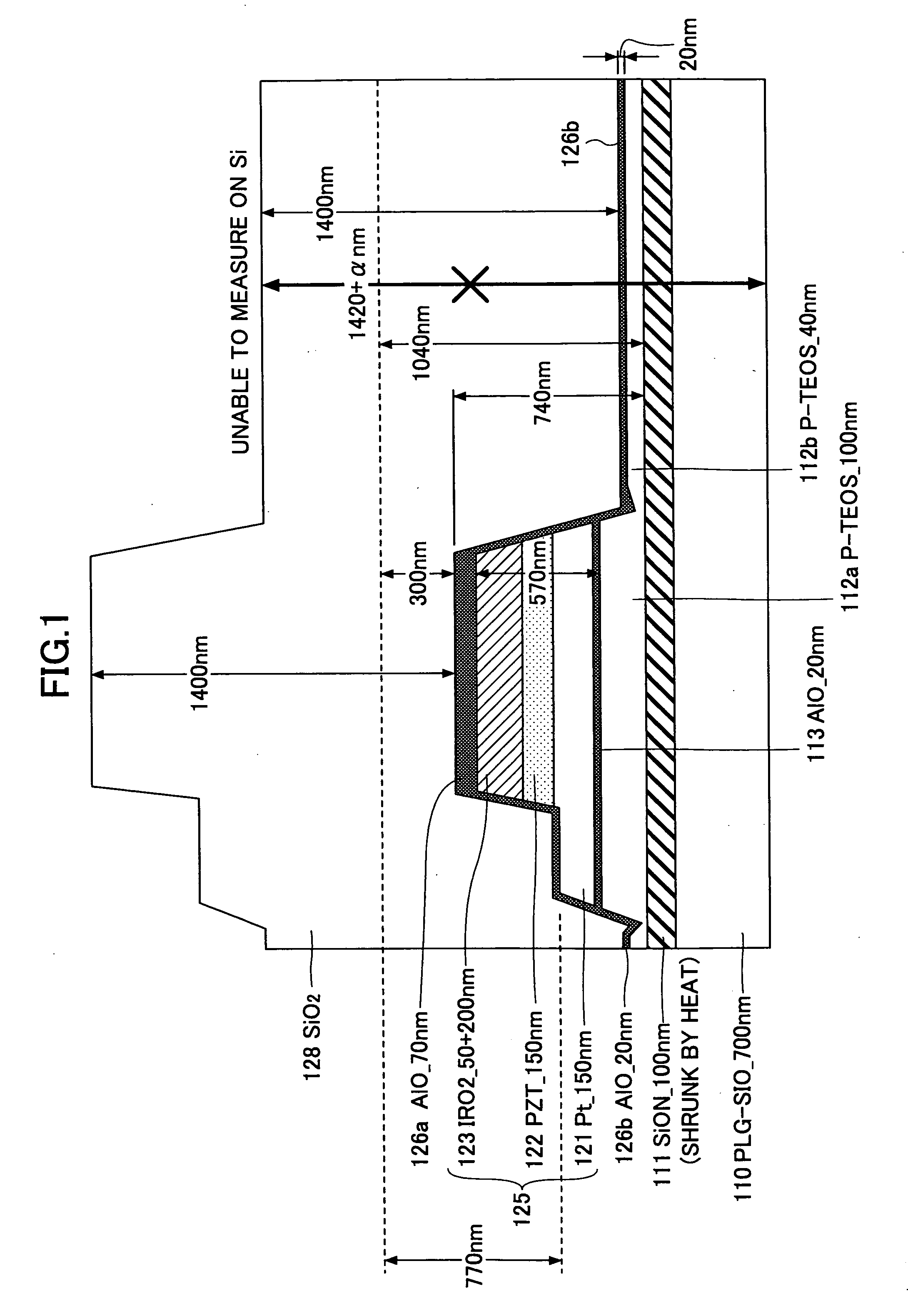

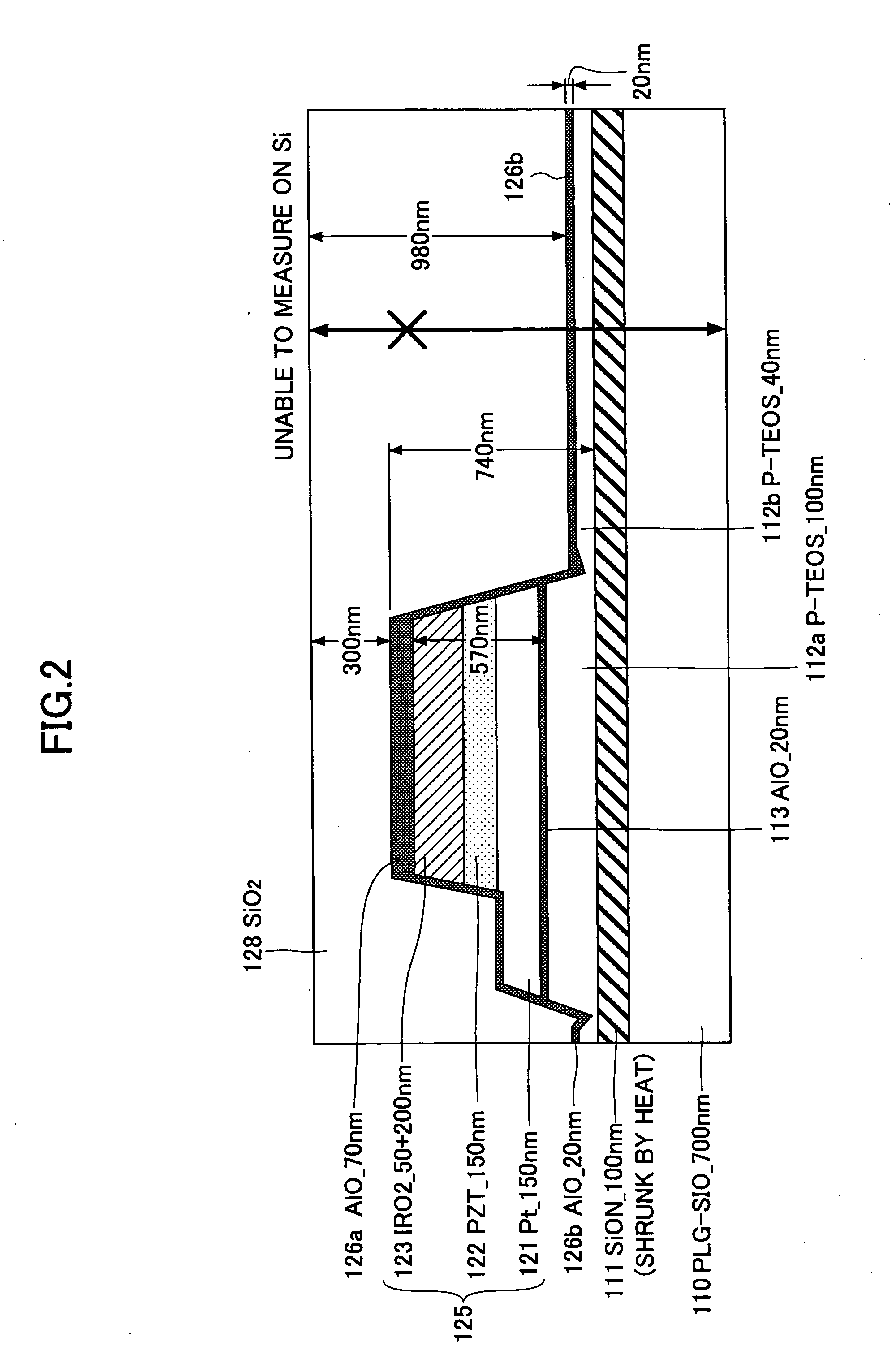

Method of measuring film thickness and method of manufacturing semiconductor device

InactiveUS20070148791A1Increase productivityHigh yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method of measuring a film thickness is disclosed. The method includes a step of forming a ferroelectric capacitor on a substrate, a step of forming an insulating film to cover the ferroelectric capacitor, and a step of optically measuring the thickness of the insulating film on an electrode of the ferroelectric capacitor.

Owner:FUJITSU SEMICON LTD

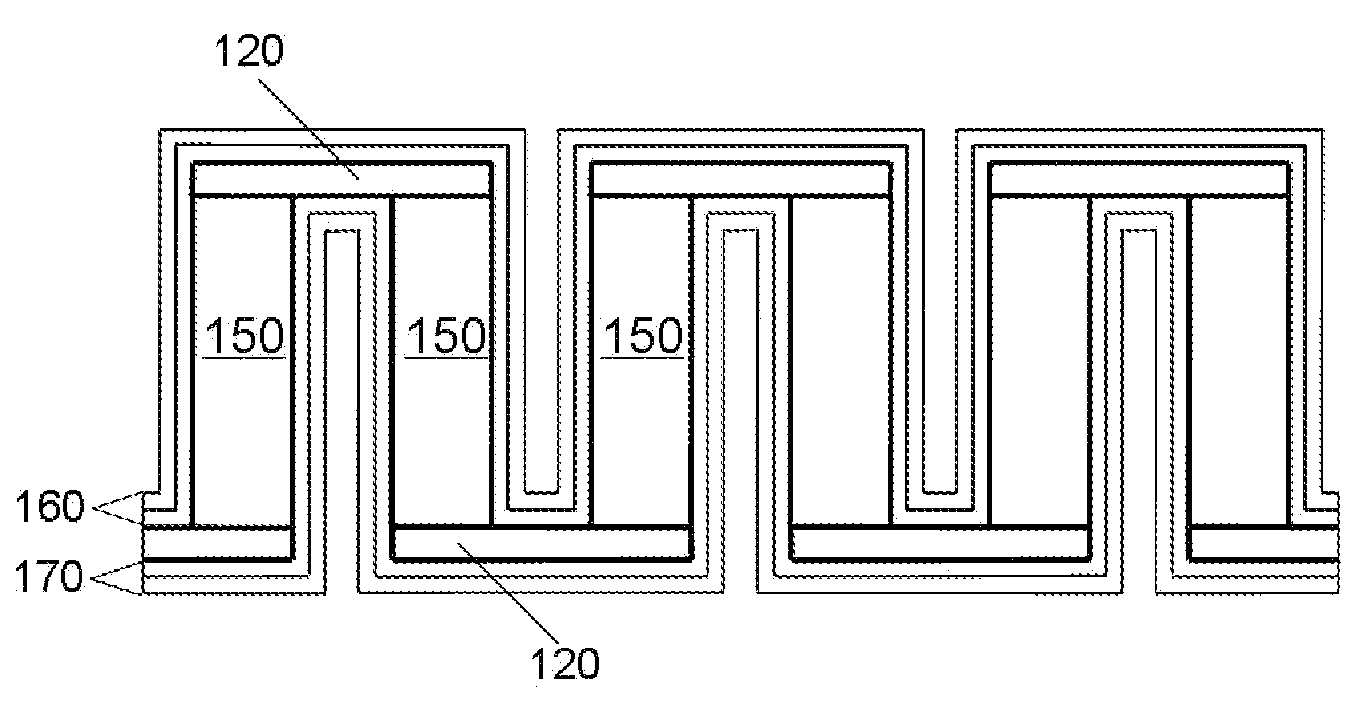

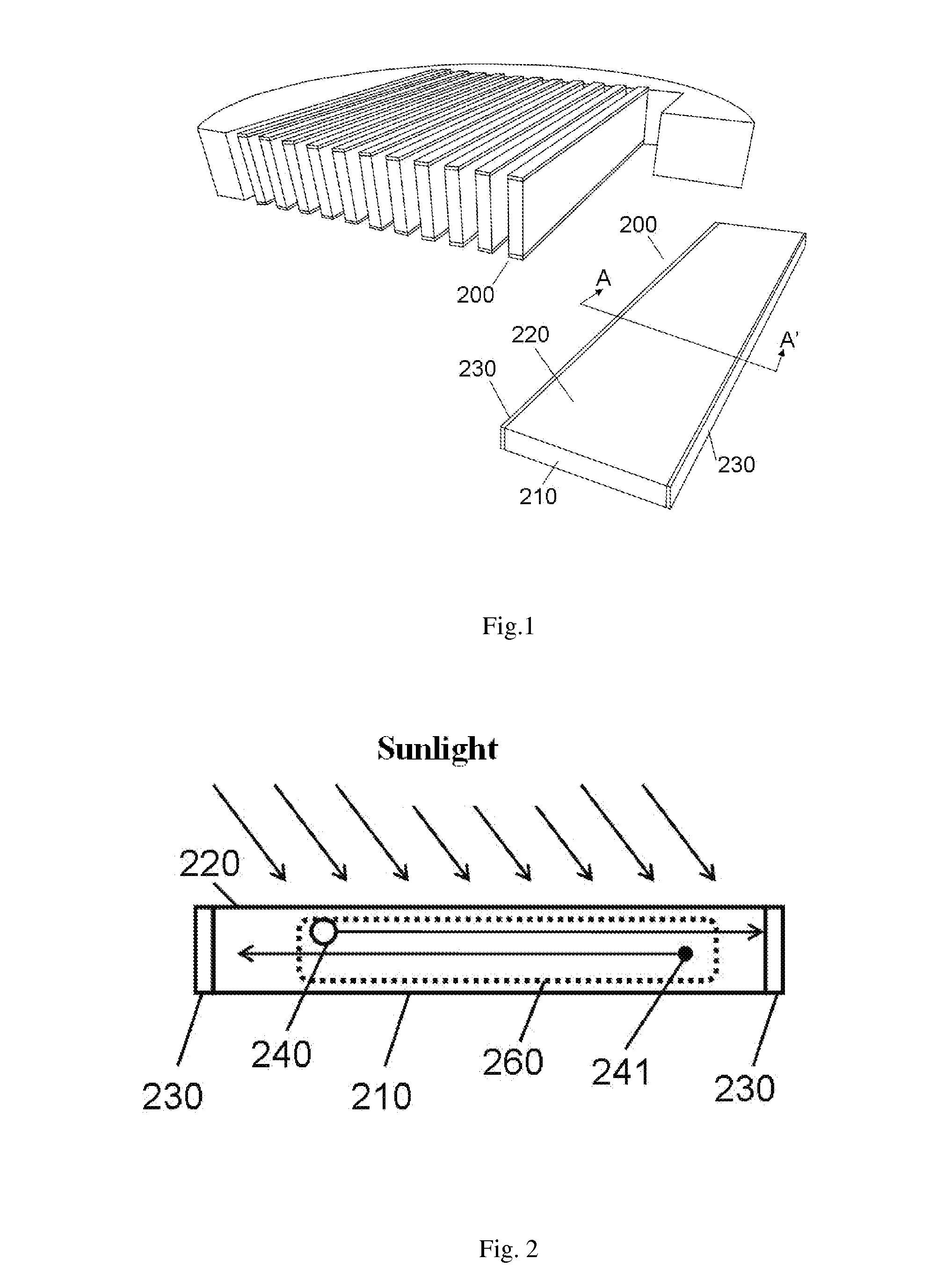

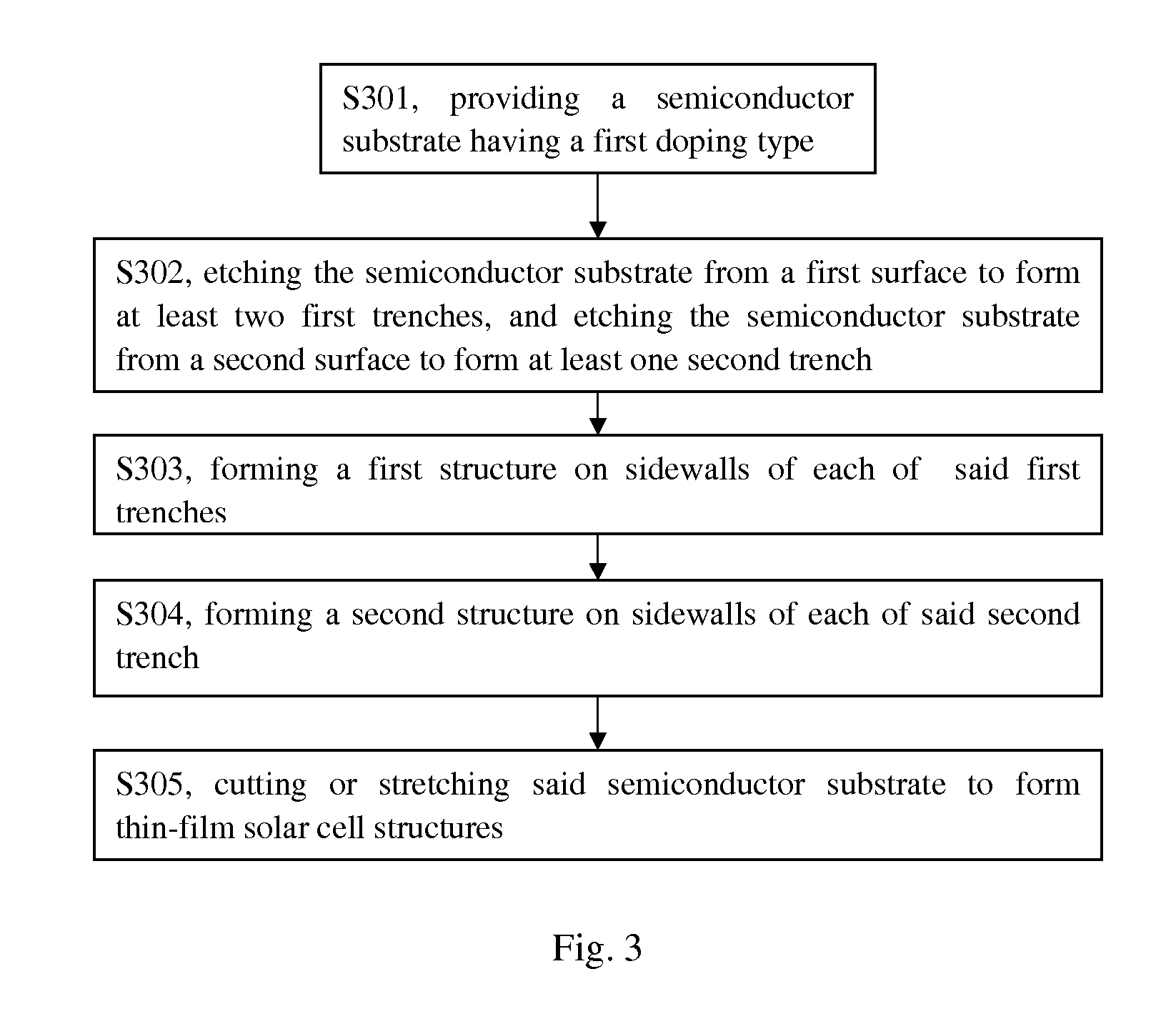

Thin Film of Solar Battery Structure, Thin Film of Solar Array and Manufacturing Method Thereof

InactiveUS20120037211A1Reduce power generation efficiencyReduce distancePV power plantsSemiconductor/solid-state device manufacturingRecombination currentSemiconductor materials

The present invention proposes a thin-film solar cell structure, a method for manufacturing the same and a thin-film solar cell array. The method for manufacturing thin-film solar cell structures comprises: forming at least two first trenches through a first surface into said semiconductor substrate, forming at least one second trench through a second surface into said semiconductor substrate, said second trench located between two neighboring said first trenches; forming a first structure on sidewalls of each of said first trenches; to forming a second structure on sidewalls of each of said second trench; and cutting or stretching said semiconductor substrate to form thin-film solar cell structures. The distance between the electrodes can be effectively shortened through the present invention such that the recombination rate between the electrons and the holes can be reduced and the bulk recombination current and the surface recombination current can be reduced to achieve the objective of improving power generation efficiency. The thin-film solar cell structure and the method for manufacturing the same proposed in the present invention can also save semiconductor material and reduce production cost.

Owner:SUNOVEL SUZHOU TECH

Upset resistant mechanical seal

ActiveUS8011667B2Fast heat conductionReduce the temperatureEngine sealsMetallic materialsSpring force

A mechanical seal face has a significant increase in the ability of the seal to tolerate poor lubrication conditions such as dry running. The mechanical seal employs a thin, non-corrugated flat sheet of flexible thermally conductive graphite material placed between one of the mechanical seal faces and a metal surface such as a metal surface defined by a shaft sleeve or gland serving as a seal ring holder. The graphite sheet is located axially between a back face of the more thermally conductive mechanical seal ring and the metal face holder part. The conductive seal face material preferably is a ceramic or cermet material such as silicon carbide, tungsten carbide, silicon nitride, aluminum oxide, or a metallic material such as stainless steel. Fluid pressure and spring forces are used to create a compressive load between the seal face, graphite sheet, and metal part to maximize continuous contact between the opposed faces of these parts and the opposite sides of the graphite sheet, and heat buildup at contacting seal faces flows away therefrom to the metal part through the thermally conductive sheet.

Owner:FLOWSERVE MANAGEMENT CO

Full cell stack

InactiveUS7358000B2Smoothly and reliably discharge waterSmall sizeFuel cells groupingWater management in fuel cellsFuel cellsEngineering

A fuel cell stack is provided with an outlet side oxygen-containing gas communication hole. First and second oxygen-containing gas flow passage grooves are provided in the direction of the gravity while meandering in the horizontal direction on a surface of a first separator. The second oxygen-containing gas flow passage grooves communicate with the outlet side oxygen-containing gas communication hole via second oxygen-containing gas connecting flow passages. A porous water-absorbing tube, which is used to discharge water to the outside of the fuel cell stack in accordance with the capillary phenomenon and the difference in pressure of air, is provided for the outlet side oxygen-containing gas communication hole.

Owner:HONDA MOTOR CO LTD

A kind of blade treatment method

ActiveCN108453345BImprove performanceReduce manufacturing costArc welding apparatusMetallic material coating processesIndustrial engineeringWelding

The invention belongs to the technical field of cutter manufacturing, and particularly relates to a cutting edge treatment method. In order to solve the problem that when imported high-quality steel is adopted to manufacture a cutter so as to improve the cutting edge performance of the cutter at present, the manufacturing cost of the cutter is high, the invention discloses the cutting edge treatment method. The cutting edge treatment method specifically comprises the following steps that S1, manufacturing preparation of a cutter is carried out, and the cutting edge part is cleaned; S2, a welding and laser cladding combined mode is adopted for machining a cutting edge strengthened layer; and S3, the cutting edge strengthened layer is coped, and final cutting edges are obtained. When the cutting edge treatment method is adopted for cutting edge treatment, not only can the performance of the cutting edges be greatly improved, the use effect of the cutter is guaranteed, but also the requirements for cutter body materials can be reduced, and the cost of the cutter is reduced.

Owner:YANGJIANG DONGHUA LASER INTELLIGENT TECH CO LTD +1

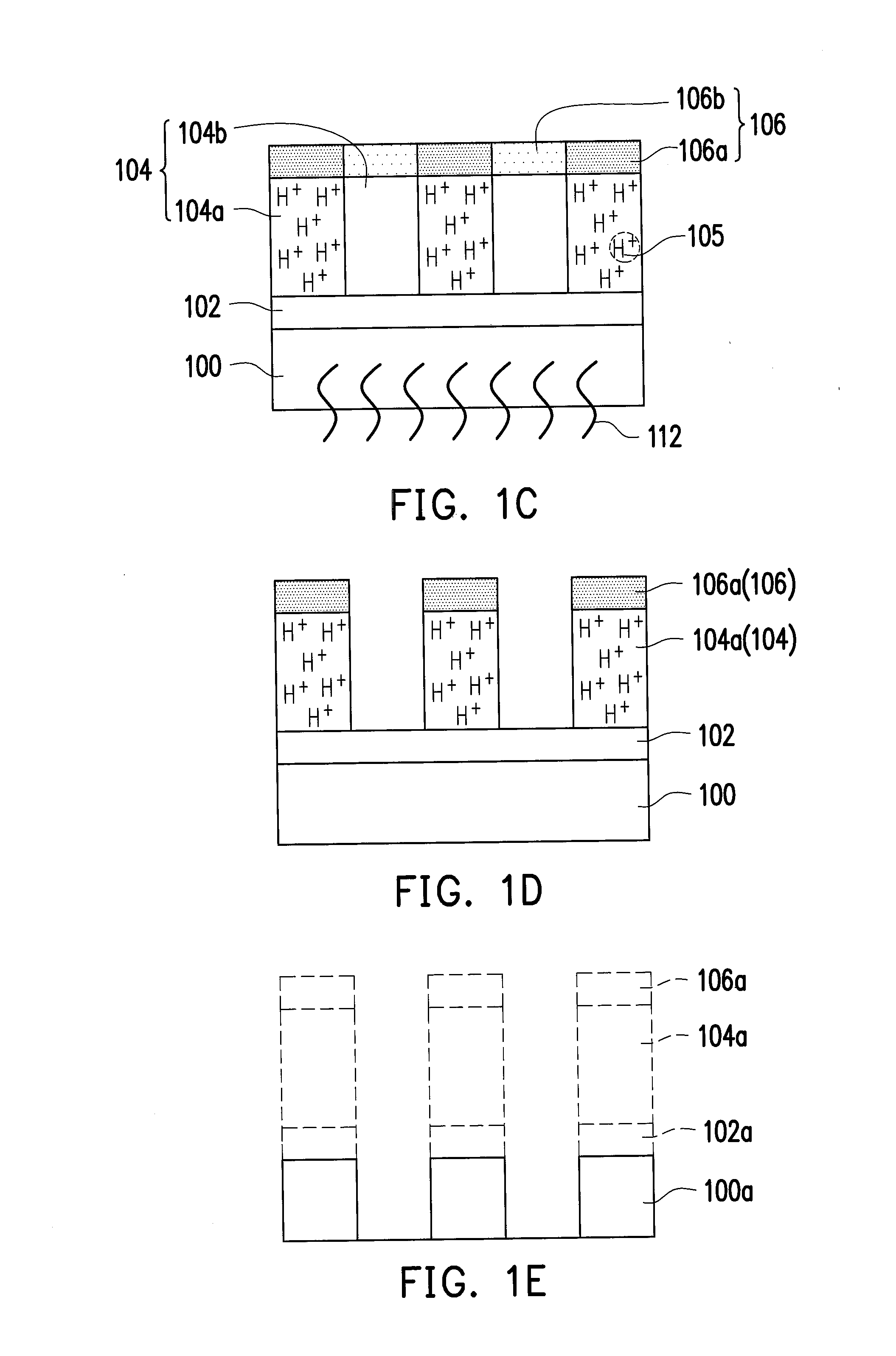

Patterning method

InactiveUS20160196968A1Effective thicknessReduced dimensionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptoelectronicsPhotoresist

A patterning method is provided. A photoresist layer is formed on a target layer. An etching resistance layer is formed on the photoresist layer. The photoresist layer is exposed to light and therefore a photo acid is generated in first regions of the photoresist layer. The photoresist layer is developed to remove second regions of the photoresist layer. It is noted that the etching resistance layer is non-photosensitive but reactive to the generated photo acid.

Owner:MACRONIX INT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com