Thin Film of Solar Battery Structure, Thin Film of Solar Array and Manufacturing Method Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

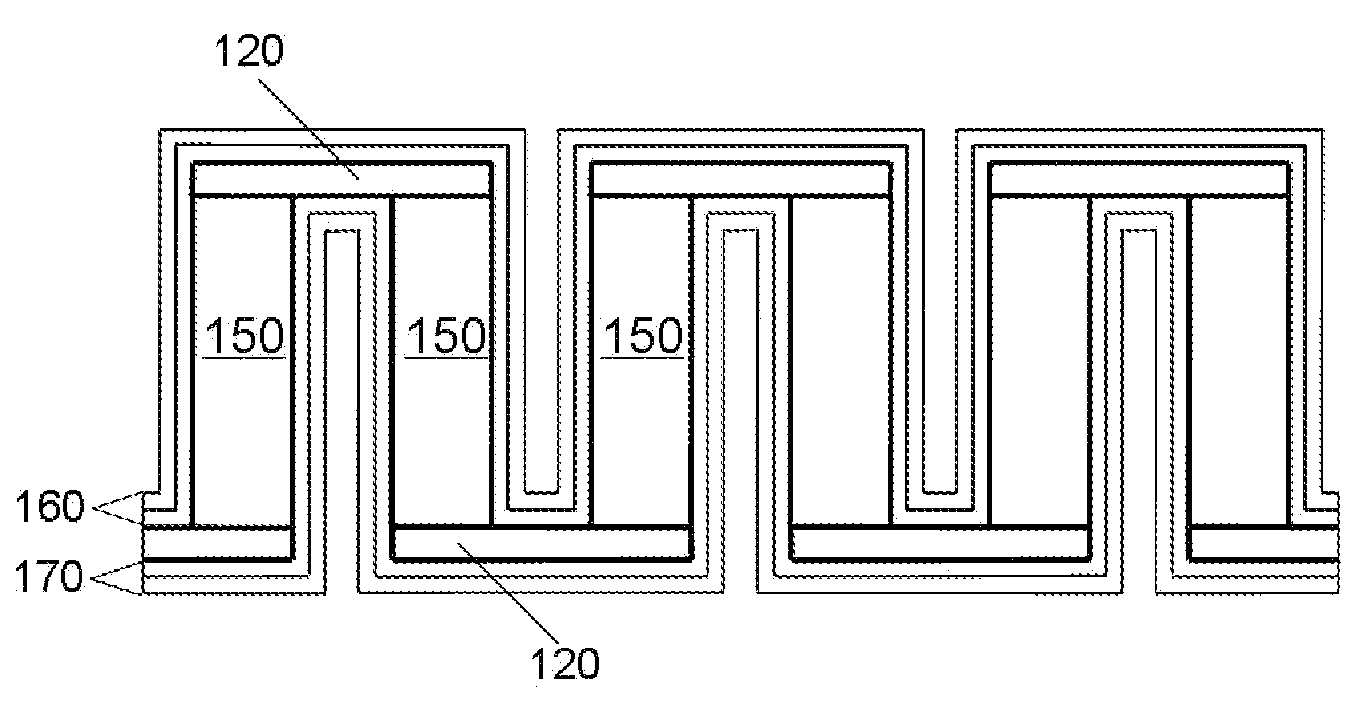

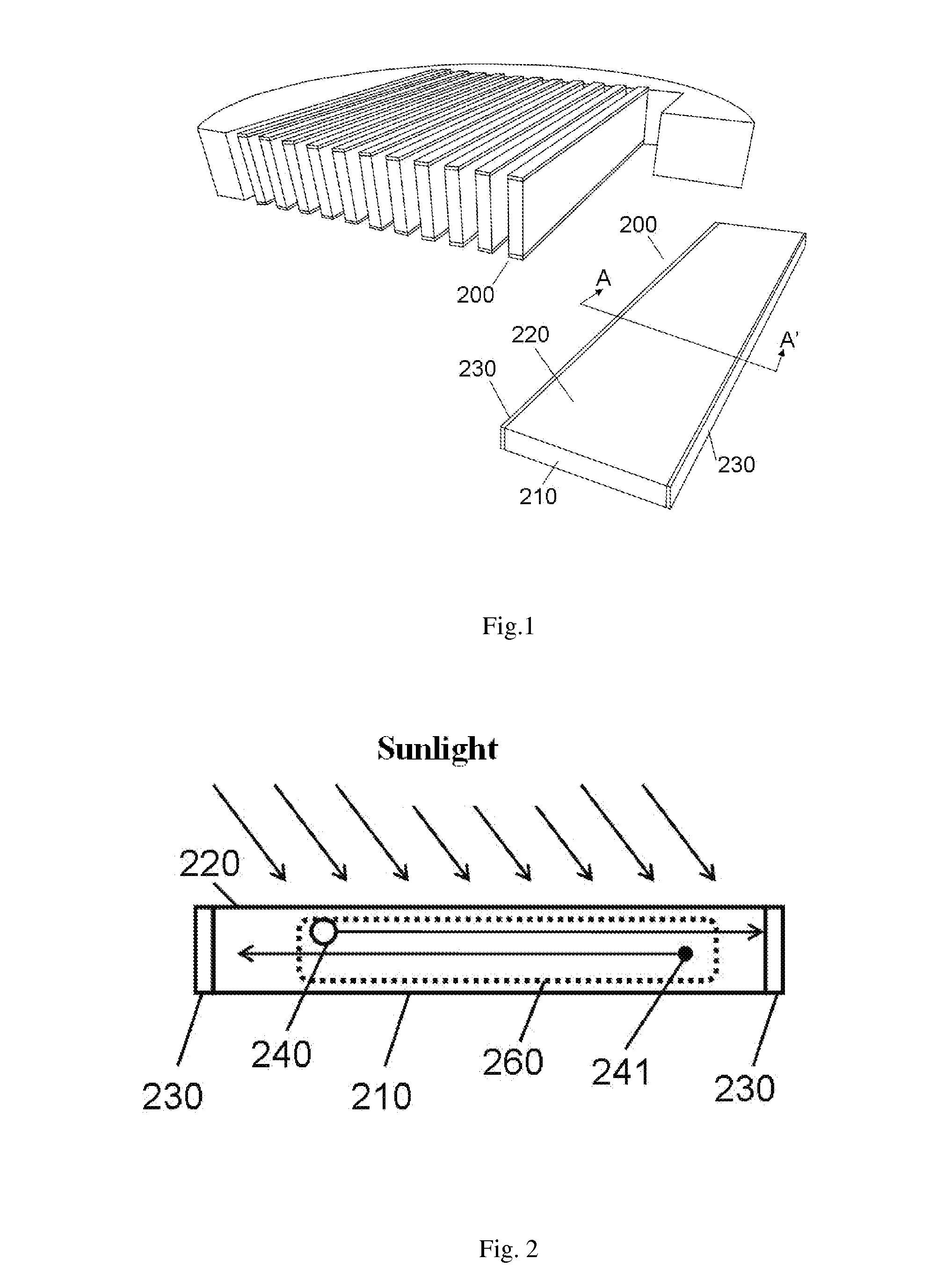

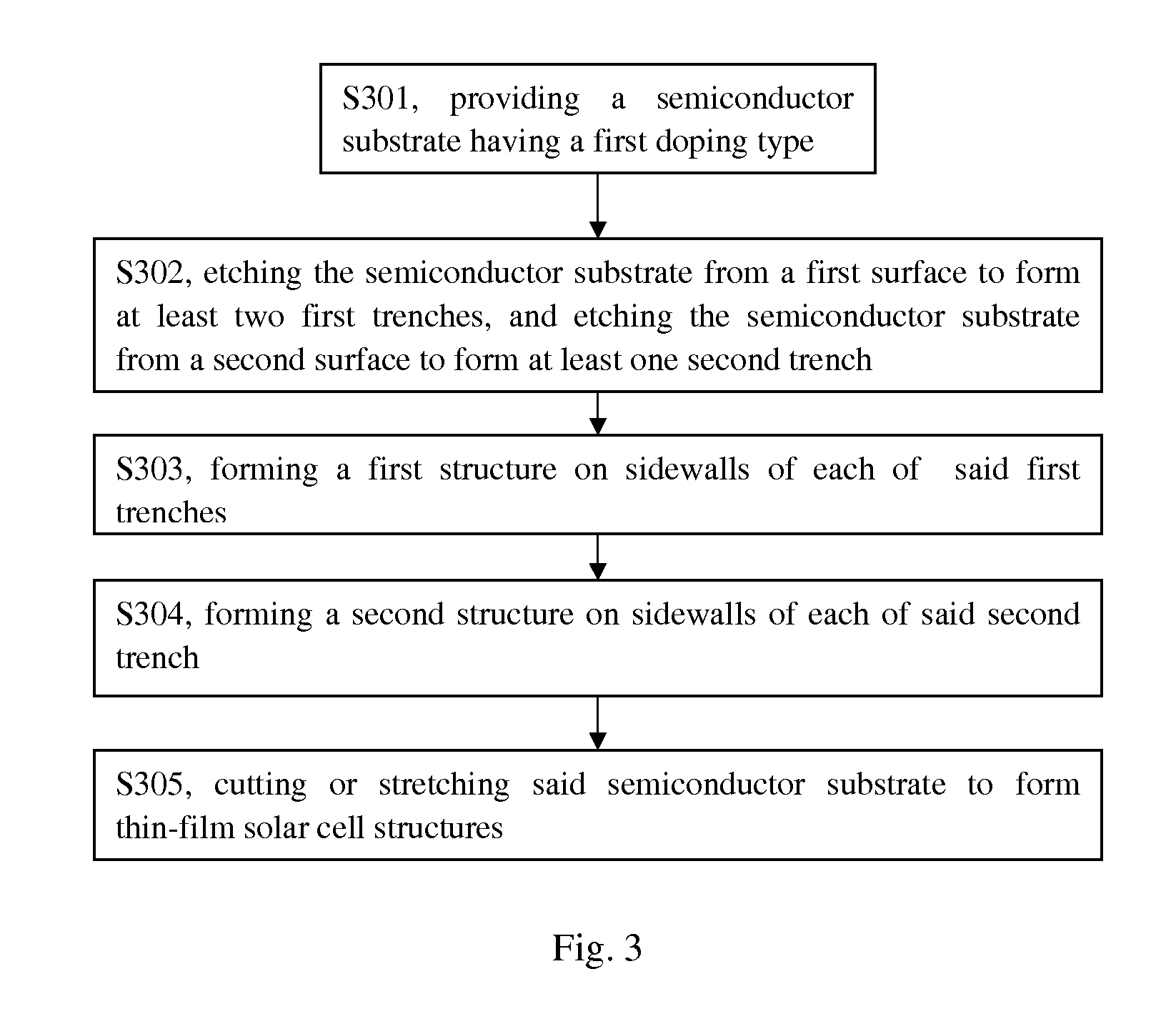

[0018]Various embodiments of the present invention are described in more details below with reference to the accompanying drawings, wherein like reference numerals used throughout the description represent like components or components having like functions. The embodiments described in conjunction with the drawings below are merely illustrative and used to explain the present invention alone, and cannot be construed as limiting the present invention.

[0019]One aspect of the present invention relates to forming electrodes on planes in the thickness direction of a substrate and positioning electrodes and light entry surface of a solar cell on the same surface so as to reduce recombination distance, shorten distance between electrodes, reduce bulk recombination current and improve power generation efficiency. Furthermore, in the structures according to embodiments of the present invention, insulation layers are provided on both sides of a cell strip plate, which can further reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com