Three-dimensional deep composite sand control method for oil and gas wells

A three-dimensional technology for oil and gas wells, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of reducing the effective period of sand control, erosion of sand control pipes, serious reservoir damage, etc., and overcome the problem of drilling plugs in the wellbore , extend the service life, expand the effect of the affected volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

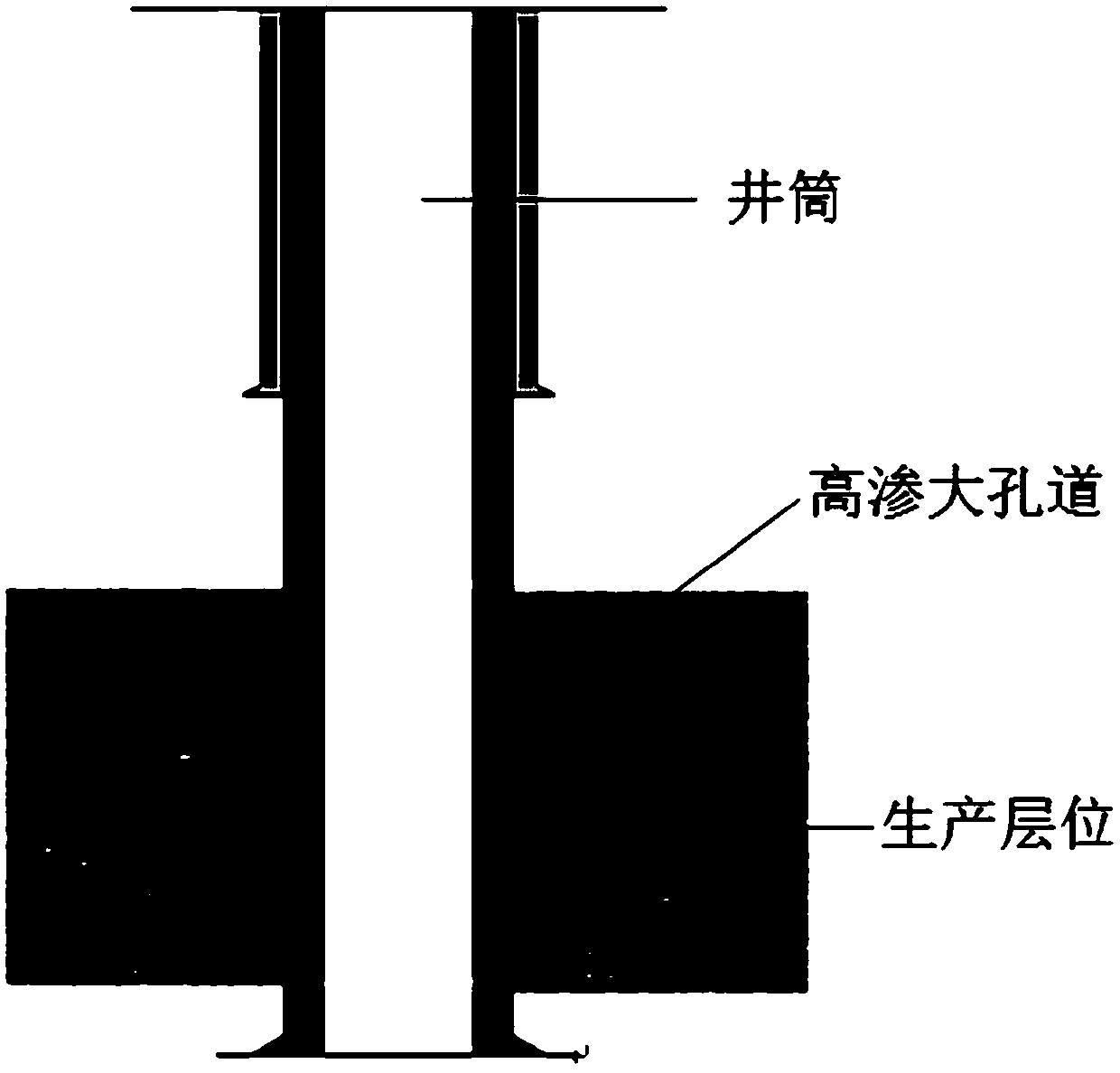

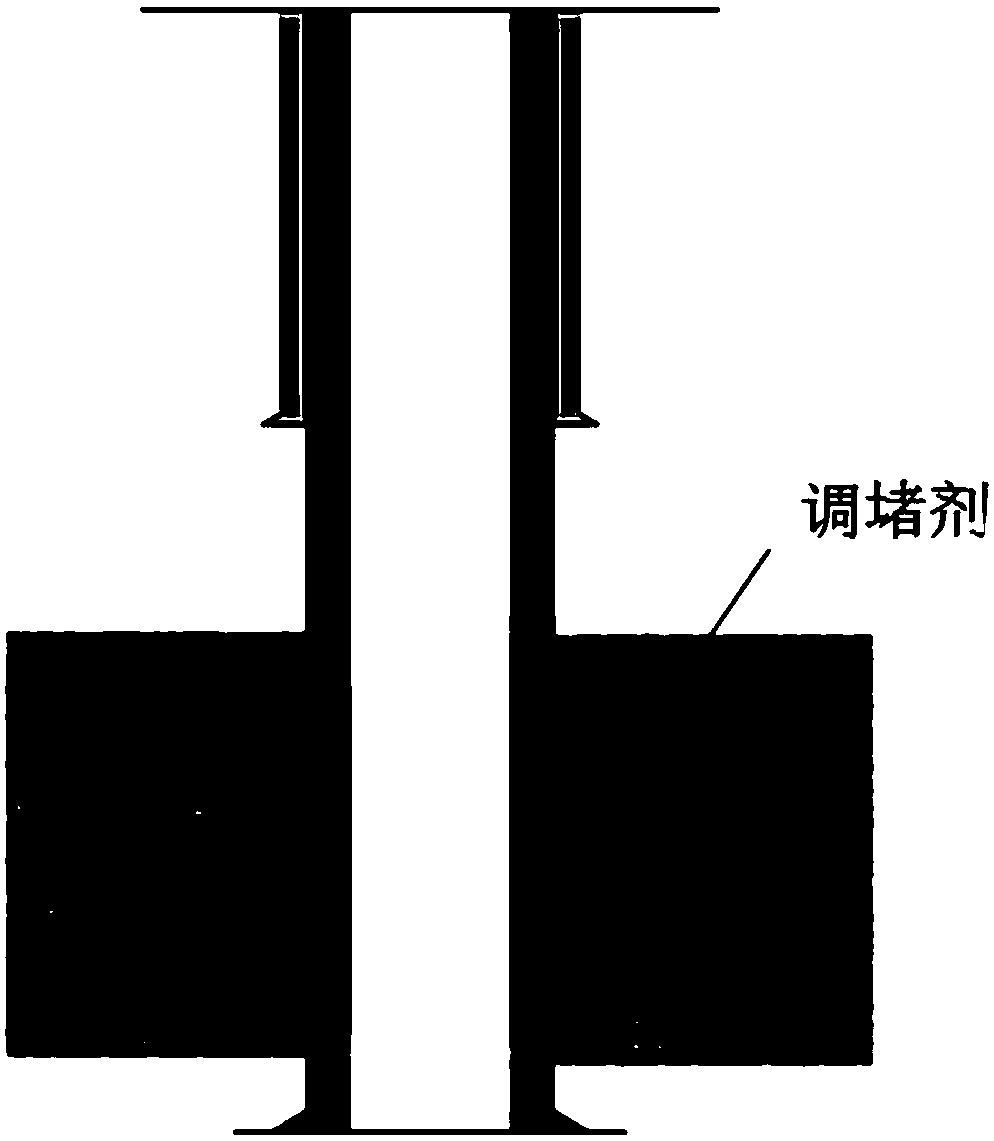

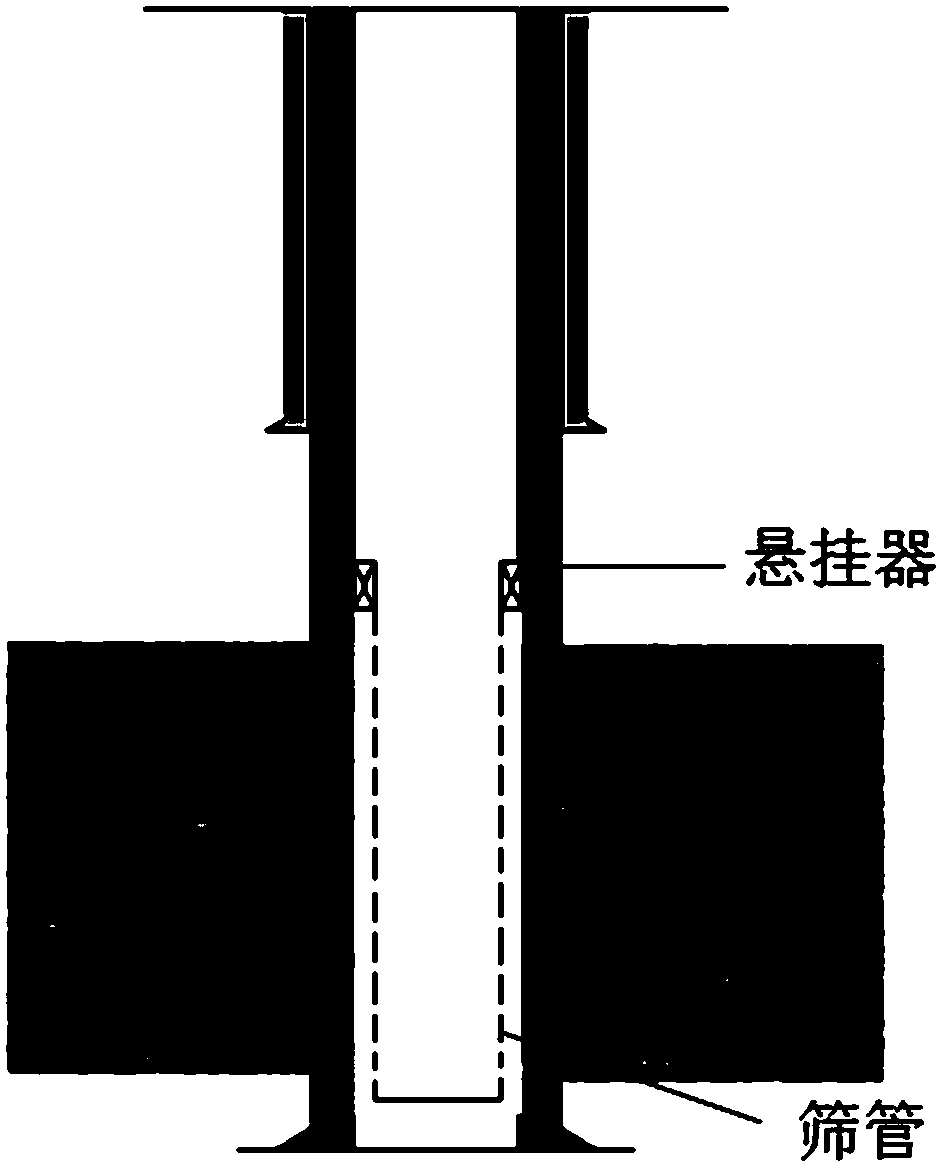

[0020] The three-dimensional deep composite sand control method for oil and gas wells comprises the following steps,

[0021] Step 1: Before construction, take on-site water samples for formula optimization and screening to determine the best formula of plugging agent; determine the treatment radius according to the sand and water output conditions, and calculate the dosage of plugging agent;

[0022] Step 2: Test the water absorption index of the target well to understand the suction capacity of the well, determine the construction pressure range and displacement according to the pressure stability, and improve the efficiency of the plugging agent entering the plugging zone;

[0023] Step 3: Determine the squeeze injection method of the plugging agent, and the squeeze injection pressure shall not exceed 80% of the fracture pressure of the formation; Drilling, retrievable bridge plugs or sand filling are used to protect non-operating formations; for thin formations or conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com