High temperature and high pressure step-by-step packing and unpacking multi-stage fracturing tubular column and application method thereof

A fracturing string, high temperature and high pressure technology, applied in the direction of sealing/isolation, earthwork drilling, production fluid, etc., can solve the problems of reducing the service life of packers, tools are easy to be buried in sand, and the sealing performance of rubber cylinders is reduced. Achieve the effect of reducing time cost, reducing construction risk and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

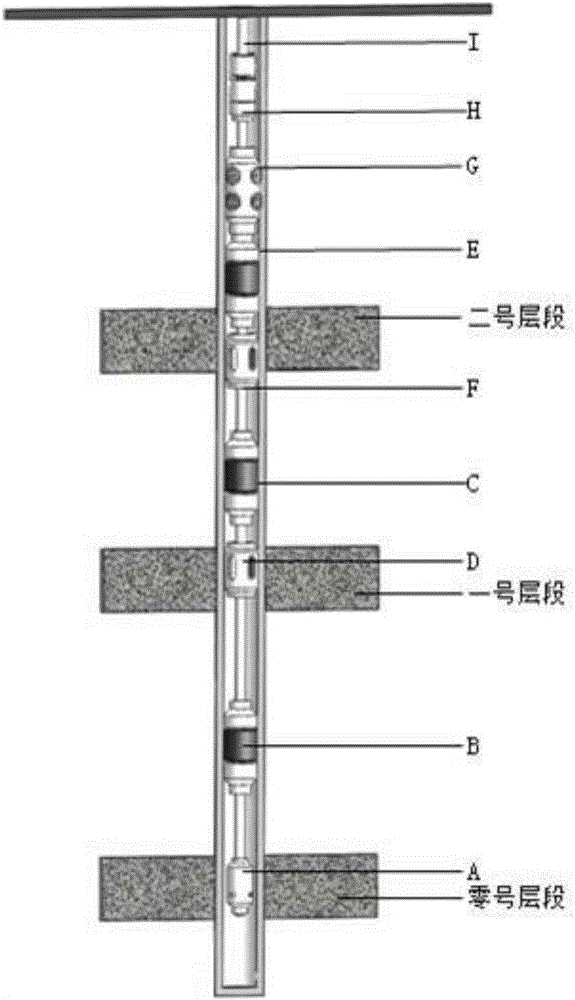

[0074] Such as Figure 1-9As shown, a high-temperature and high-pressure step-by-step setting and unsealing multi-stage fracturing string in this embodiment, the fracturing string includes several pairs of controllable packers and sand blasters that are set up and down and used in conjunction with each other. The fracturing string is connected in sequence from bottom to top with a bottom valve A, a packer B, a number of controllable packers and sandblasting devices used in conjunction with the above, a sand control hydraulic anchor G, and a hydraulic safety joint H. The tools are connected by oil pipe I;

[0075] The controllable packer is provided with an inner sliding sleeve assembly 4 that can slide down relative to the main body of the controllable packer, and the inner sliding sleeve assembly 4 is fixedly connected to the main body of the controllable packer by scissors 46, An openable liquid inlet is provided between the inner sliding sleeve assembly 4 and the main body...

Embodiment 2

[0087] Such as Figure 1-9 As shown, a high-temperature and high-pressure step-by-step setting and unsealing multi-stage fracturing string in this embodiment, the fracturing string includes several pairs of controllable packers and sand blasters that are set up and down and used in conjunction with each other. The fracturing string is connected in sequence from bottom to top with a bottom valve A, a packer B, a number of controllable packers and sandblasting devices used in conjunction with the above, a sand control hydraulic anchor G, and a hydraulic safety joint H. The tools are connected by oil pipe I;

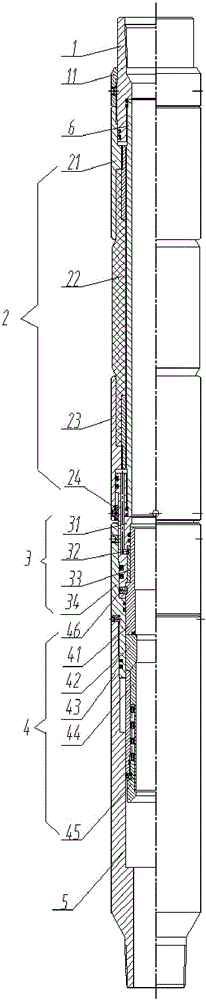

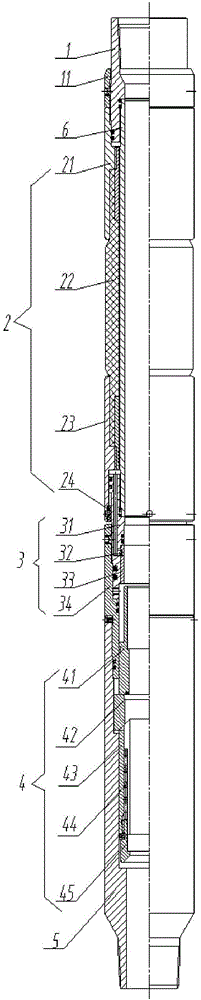

[0088] The controllable packer includes an upper joint 1, a rubber cartridge assembly 2, a contact control sleeve assembly 3, an inner sliding sleeve assembly 4 and a lower joint 5;

[0089] The upper joint 1 is sealed and fixed on the upper end of the central tube 6;

[0090] The rubber cartridge assembly 2 is sealed and sleeved on the periphery of the central pipe 6, an...

Embodiment 3

[0116] Such as Figure 1-9 As shown, a high-temperature and high-pressure step-by-step setting and unsealing multi-stage fracturing string in this embodiment, the fracturing string includes several pairs of controllable packers and sand blasters that are set up and down and used in conjunction with each other. The fracturing string is connected in sequence from bottom to top with a bottom valve A, a packer B, a number of controllable packers and sandblasting devices used in conjunction with the above, a sand control hydraulic anchor G, and a hydraulic safety joint H. The tools are connected by oil pipe I;

[0117] The controllable packer includes an upper joint 1, a rubber cartridge assembly 2, a contact control sleeve assembly 3, an inner sliding sleeve assembly 4 and a lower joint 5;

[0118] Wherein, the upper joint 1 is sealed and fixed on the upper end of the central tube 6;

[0119] Further, the upper joint 1 is also provided with an adjustment ring 11, the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com