Self-sealing setting ball seat

A technology for setting ball seats and sealing rings, used in sealing/isolation, wellbore/well components, earth-moving drilling, etc. to prevent well kick or blowout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

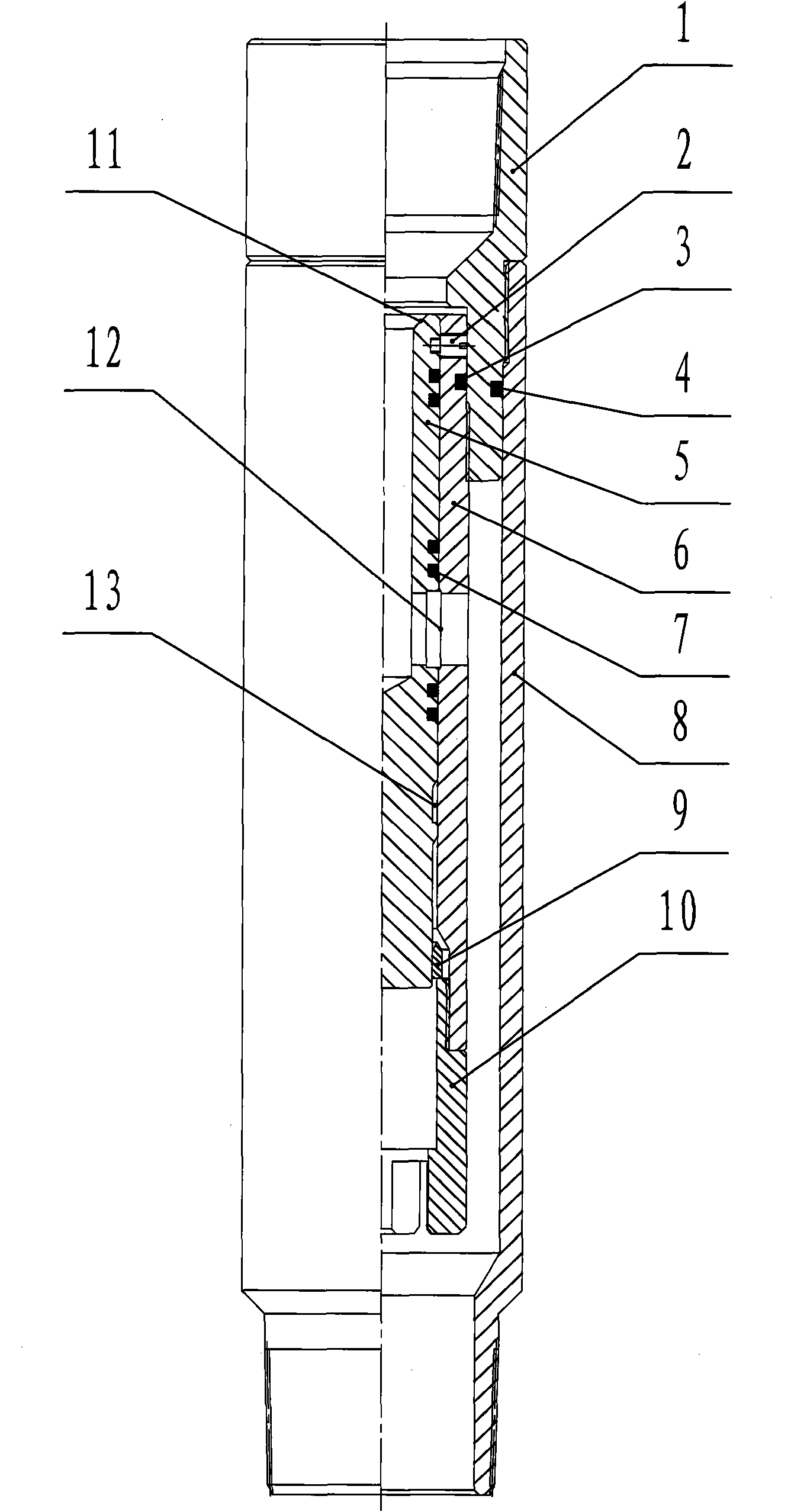

[0014] The present invention comprises self-sealing mechanism and shell mechanism, and self-sealing mechanism comprises self-sealing tube 5, self-sealing cover 6 and limit cover 10, and self-sealing tube 5 is arranged in self-sealing cover 6, and self-sealing tube 5 is fixed in self-sealing cover 6 by shear nail 2, for Channels are provided for the circulating replacement liquid, and four side holes 12 are evenly distributed at the corresponding positions of the self-sealing tube 5 and the self-sealing sleeve 6, an annular space is provided between the self-sealing sleeve 6 and the housing 8, and the bottom of the self-sealing tube 5 is provided with There is a lock ring groove 13, and a lock ring 9 is installed at the tail of the self-sealing pipe 5. The upper end surface of the lock ring groove 13 is a tapered surface, and the lower end surface is perpendicular to the axis. The upper end of the envelope 6 is connected with the internal thread of the joint 1 of the shell mecha...

Embodiment 2

[0016] The installation sequence of the present invention is: the upper end of the self-sealing sleeve 6 is installed inside the upper joint 1 through threads, the inner circle of the upper end of the housing 8 is connected with the outer circle of the upper joint 1 through threads, and the self-sealing sleeve 6 is installed inside the housing 8; 6 Install the self-sealing tube 5 inside, and the self-sealing tube 5 is fixed together with the self-sealing sleeve 6 through the shear nails 2. When installing the four side holes evenly distributed in the middle section of the self-sealing tube 5 and the self-sealing sleeve 6, the side holes must be aligned for installation. In order to achieve the purpose of the circulation channel; the self-sealing pipe 5 is provided with a lock ring groove 13, and the bottom is equipped with a lock ring 9, and then the lower end of the self-sealing sleeve 6 is threaded with the limit sleeve 10; for the purpose of sealing, the sealing ring 3, 4 , ...

Embodiment 3

[0018] During construction, the present invention, packer and other required tools are connected to the construction pipe string in the order of the design pipe string, and after going down to the design well depth, the completion fluid is pumped in from the wellhead pipe, and the well killing fluid in the pipe is pumped in from the self-sealing pipe. 5 enters through the upper inner hole, and then enters the annular space between the self-sealing sleeve 6 and the shell 8 through the four side holes 12 arranged at the corresponding positions of the self-sealing tube 5 and the self-sealing sleeve 6 to establish a self-sealing ball seat The circulation channel of the killing fluid from the upper pipe to the lower pipe; when the downhole packer needs to be set after replacing the killing fluid in the pipe, put the setting ball into it so that the sealing ball sits on the ball seat 11, and then continue to increase pressure, when the pressure rises to a certain value, the shear nai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com