Double-acting compression type setting mechanism

A compressive, double-acting technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve problems such as inability to effectively ensure reliable setting of packers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

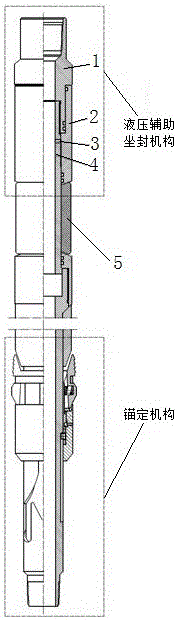

[0022] In order to overcome the problem that the existing compression packer relies on a single setting method and cannot effectively ensure the reliable setting of the packer, this embodiment provides a method such as figure 1 The shown double-acting compression setting mechanism includes a packer, and an anchoring mechanism is provided at the tail end of the packer. Hydraulic auxiliary setting mechanism.

[0023] The anchoring mechanism is located at the tail end of the packer and is supported by one-way slips, which can be seated by lifting, lowering, rotating, etc. The hydraulic auxiliary setting mechanism is located at the upper end of the rubber tube, and firstly provides one-way slip support through the anchoring mechanism And apply a certain pressure on bit to realize the compression of the rubber barrel, that is, the packer is set, the oil pipe is pumped, and the hydraulic auxiliary setting mechanism is activated to provide a certain compression force to the rubber ba...

Embodiment 2

[0026] The hydraulic auxiliary setting mechanism includes an upper joint 1, a hydraulic cylinder 2 and a central pipe 4. The upper section of the hydraulic cylinder 2 is placed outside the lower part of the upper joint 1, and the upper part of the central pipe 4 is connected to the upper joint 1 and the lower section of the hydraulic cylinder 2. Inside, the outside of the lower part of the central tube 4 is also covered with a rubber tube 5 .

[0027] Since the inner diameter of the lower section of the hydraulic cylinder 2 is smaller than the inner diameter of the upper section of the hydraulic cylinder 2, the liquid enters the closed cavity outside the central tube, and the pressure of the liquid pushes the hydraulic cylinder 2 to move down to realize the setting seal.

[0028] The upper joint 1 and the central pipe 4 are threadedly connected, and the liquid cylinder 2 cooperates with the upper joint 1 and the central pipe 4 to form a closed cavity. When pumping, the liquid ...

Embodiment 3

[0030] Further, when setting seal is not required, an outer edge is provided on the outer side of the lower part of the upper joint 1, the upper end of the liquid cylinder 2 rests on the outer edge, and the lower end of the upper joint 1 is placed on the upper and lower side walls of the liquid cylinder 2 The inner edge of the inner edge, the liquid cylinder 2 is stuck between the upper joint 1 and the rubber tube 5, and will not slip.

[0031] Further, a sealing ring is provided between the upper joint 1 and the liquid cylinder 2 , and a sealing ring is provided between the liquid cylinder 2 and the central pipe 4 . When the liquid enters the sealed cavity from the liquid inlet channel 3, the sealing ring can prevent liquid loss, ensure hydraulic pressure, push the hydraulic cylinder 2 downward, and compress the rubber cylinder 5, so that the packer always maintains a set state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com