Tank synchronizer and tapered roller bearing adjuster

A technology of tapered roller bearings and synchronizers, which is applied to instruments, measuring devices, etc., and can solve problems such as backward adjustment methods and means, large errors, and adjustment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

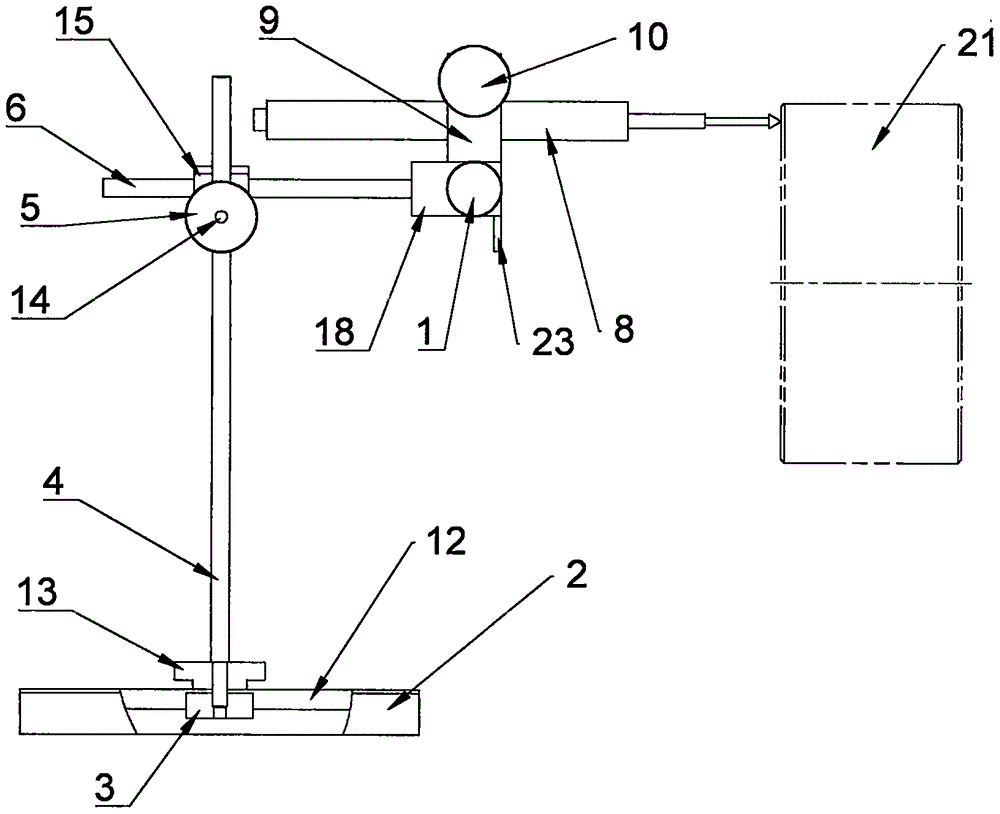

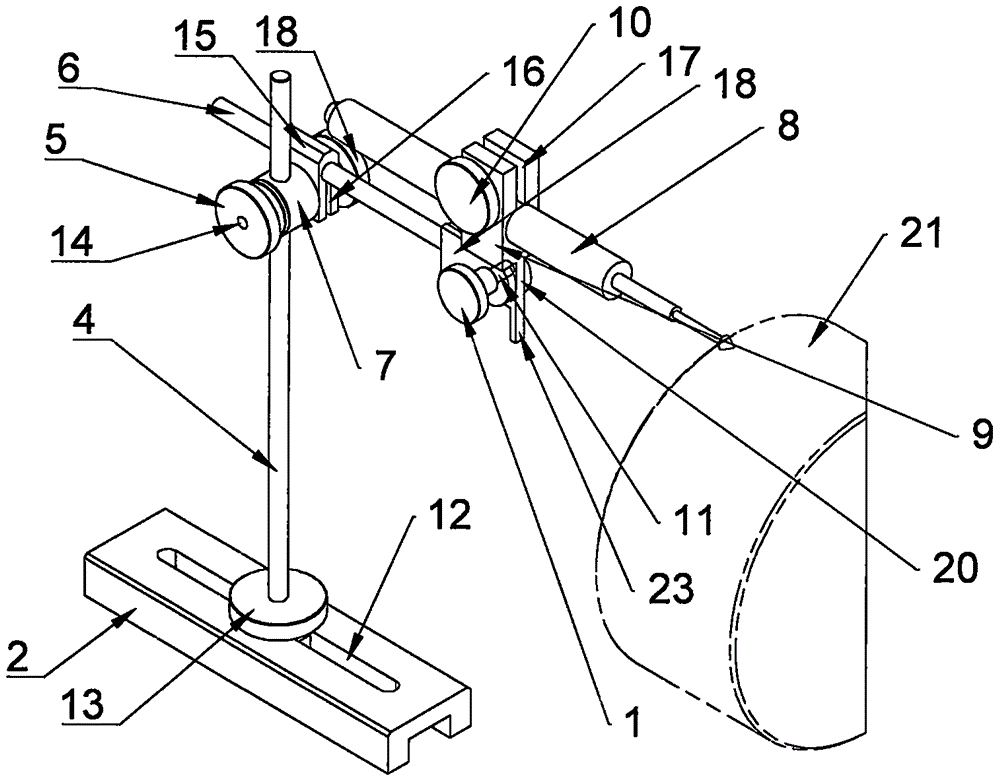

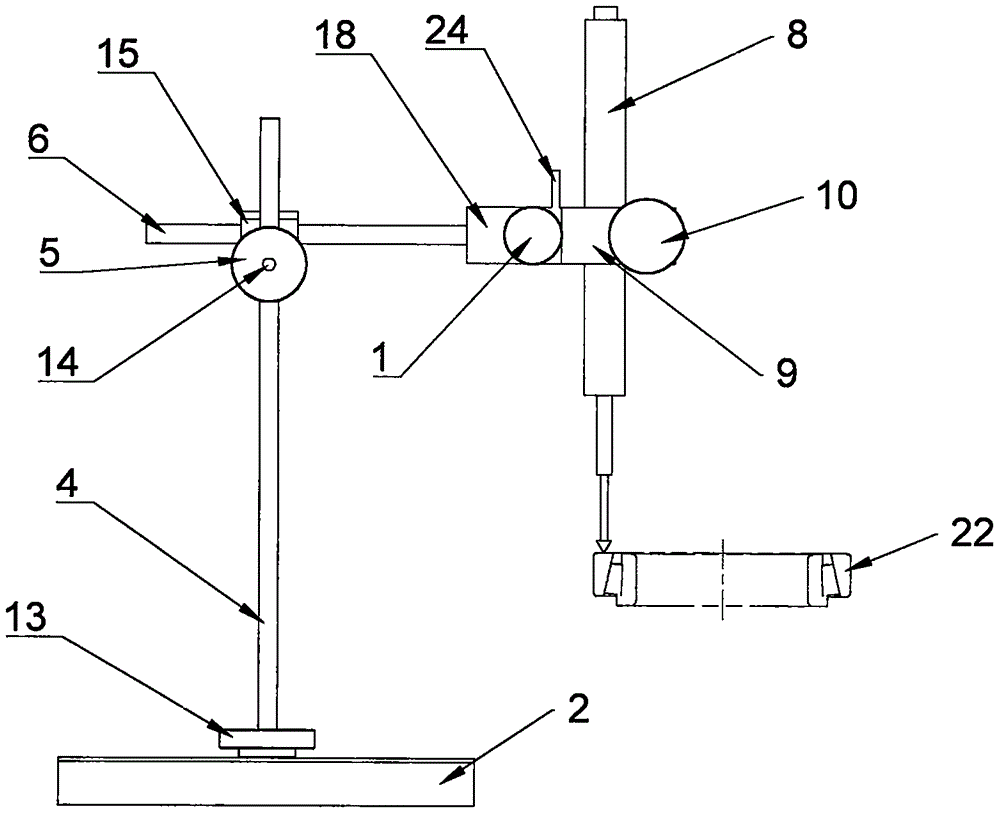

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the tank synchronizer and the tapered roller bearing adjuster of the present invention include a fixed seat 2, the bottom end surface and the top end surface of the fixed seat 2 are respectively horizontal planes, and the fixed seat 2 is provided with a fixed arm 4 along the vertical direction. The cross-section of the fixed arm 4 is circular, and the middle part of the fixed seat 2 is provided with a strip-shaped fixed arm mounting groove 12 along the left and right horizontal directions. Cooperate through the fixed arm installation groove 12, and the fixed arm 4 is clamped on the fixed seat 2 by using the lock nut 13 located on the upper surface of the fixed seat 2 and the nut 3 located at the lower part of the fixed seat 2;

[0021] The fixed arm 4 adopts a clearance fit sleeve to be equipped with a slide block 7, and the middle part of the front end of the slide block 7 is screwed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com