A Closed-loop Feedback Optimal Control Allocation Method for Assembled Spacecraft

A technology of optimal control and distribution method, which is applied in the direction of attitude control, non-electric variable control, control/regulation system, etc., and can solve the problems of control precision reduction and installation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

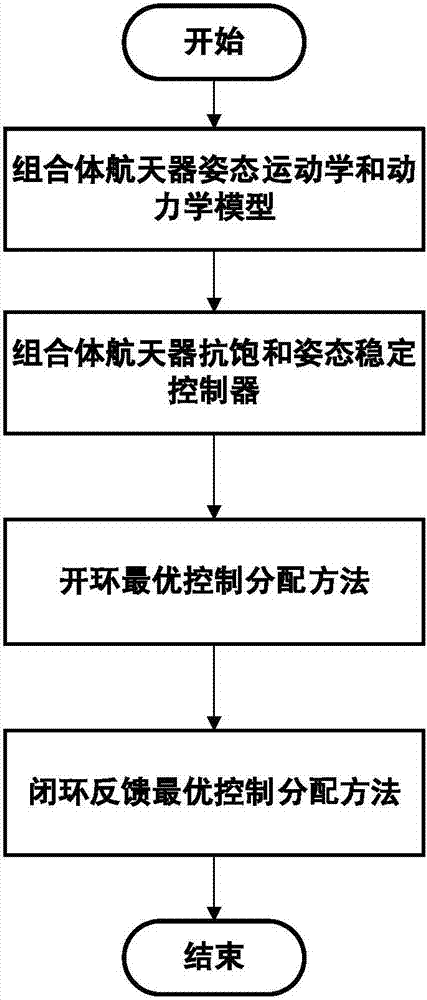

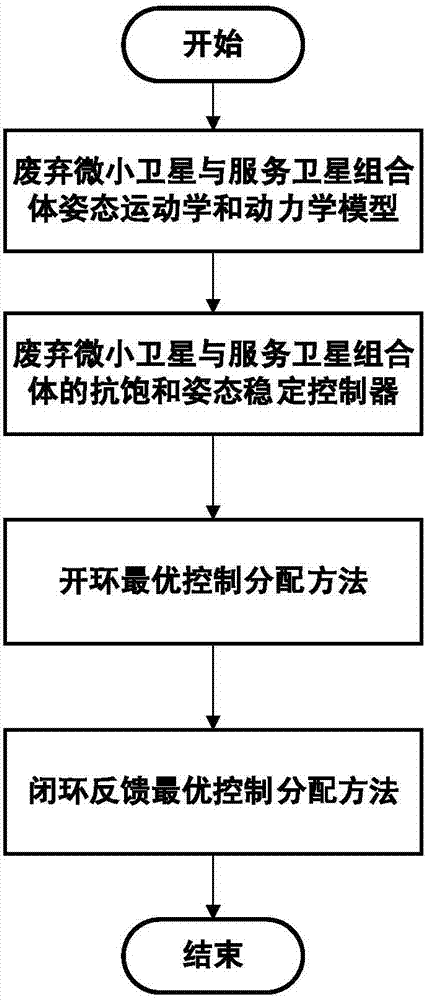

[0040] like figure 2 As shown, the specific implementation steps of the present invention are as follows (the following is an example to illustrate the specific implementation of the method by taking the composite spacecraft formed by the abandoned micro-satellite and service satellite in space):

[0041] The first step is to establish the attitude kinematics and dynamics models of the abandoned micro-satellites and service satellites:

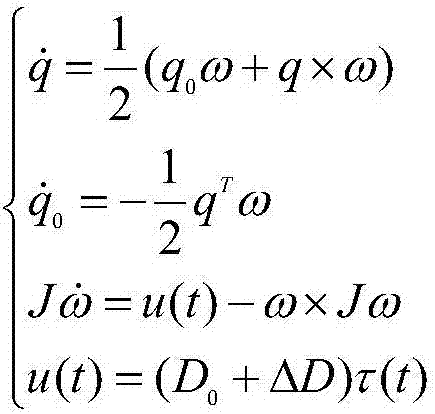

[0042]

[0043] Among them, q and q 0 are the attitude four-element vector and scalar of the abandoned microsatellite and service satellite assembly respectively, and the initial value is q=[0.4,-0.4,0.2] T ,q 0 =0.8, is the moment of inertia of the abandoned microsatellite and service satellite assembly, ω is the attitude angular velocity of the abandoned microsatellite and service satellite assembly, the initial value is ω=[1,-1,0.5]rad / s, u(t) is the virtual control command, τ(t) is the output of the actuator, is the nominal actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com